Press release

Methyl Formate Production Cost Analysis Report 2025: Plant Setup, Capital Investments and Business Plan

Methyl formate, also known as methyl methanoate, is an organic compound with the formula HCOOCH3. It is a colorless, volatile liquid with a pleasant, ether-like odor and is primarily used as an intermediate in the production of formic acid and formamide. Methyl formate also finds applications as a blowing agent in foam manufacturing, a solvent in paints and adhesives, and a precursor in various chemical syntheses. Due to its relatively low toxicity and high solubility, it is considered an environmentally safer alternative in industrial uses.Setting up a methyl formate production plant involves securing feedstock like methanol and carbon monoxide, installing synthesis and distillation units, and ensuring compliance with environmental and safety regulations. Efficient catalyst systems and process control automation are essential for optimizing yields and minimizing emissions.

IMARC Group's report, titled "Methyl Formate Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a methyl formate production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/methyl-formate-manufacturing-plant-project-report/requestsample

Methyl Formate Industry Outlook 2025

The global methyl formate market is expected to experience steady growth in 2025, with annual demand rising in sectors such as pharmaceuticals, agrochemicals, paints, coatings, and specialty chemicals. Emerging markets in Asia-Pacific, Latin America, and parts of Africa are fueling this demand surge, as industries increasingly adopt methyl formate for its low toxicity, biodegradability, and compliance with stricter environmental regulations such as low‐VOC mandates. Technological improvements in production-such as more efficient catalysts and process innovations-are likely to enhance yield and reduce costs, helping stabilize prices even amid feedstock volatility. Regulatory momentum toward greener solvents, alongside expansion in electronic materials and foam insulation applications, should further support market expansion and innovation throughout 2025.

Key Insights for setting up a Methyl Formate Production Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Buy now: https://www.imarcgroup.com/checkout?id=9256&method=1911

Key Cost Components

• Raw Materials:

• Methanol and carbon monoxide are the primary feedstocks. These account for a significant portion of operational expenses.

• Costs can fluctuate with oil and gas market trends.

• Catalysts and Chemicals:

• Specialized catalysts (e.g., alkali metal alkoxides) are needed for efficient synthesis.

• Additional chemicals for purification may be required.

• Plant Machinery and Equipment:

• Reactors, heat exchangers, distillation columns, storage tanks, and pressure systems.

• Automation and control systems for reaction monitoring and safety.

• Utilities:

• High consumption of electricity, steam, and cooling water.

• Fuel for heating processes and maintaining pressure in reactors.

• Labor and Staffing:

• Skilled chemical engineers, plant operators, maintenance staff, and safety personnel.

• Costs vary by location and plant size.

• Construction and Civil Work:

• Costs for land development, building structures, safety systems, and utility pipelines.

• Environmental and Safety Compliance:

• Installation of emission control units, effluent treatment systems, and fire safety mechanisms.

• Permits, audits, and certifications.

• Maintenance and Spare Parts:

• Routine upkeep of equipment and replacement of worn-out components.

• Packaging and Storage:

• Tanks, drums, or bulk containers depending on distribution methods.

• Facilities for safe, long-term storage of both raw materials and final product.

• Logistics and Distribution:

• Transportation infrastructure for feedstock supply and product delivery.

• Overheads and Administrative Costs:

• Insurance, licenses, management expenses, and operational support systems.

Economic Trends Influencing Methyl Formate Plant Setup Costs 2025

• Feedstock Price Volatility

Methanol and carbon monoxide prices are closely tied to crude oil and natural gas markets. Fluctuating feedstock costs directly impact both capital investment (e.g. storage capacity sizing) and operating budgets. Sharp price swings can force contingency provisions and buffer inventories at higher cost.

• Energy and Utility Inflation

Rising electricity, steam, and cooling costs significantly affect OPEX. In many regions, industrial energy tariffs have increased, driving up fuel and utility infrastructure investments-like cogeneration systems or heat-recovery units-to manage long term expenses.

• Catalyst and Specialty Chemical Market Dynamics

Global demand and limited suppliers of high-performance synthesis catalysts can inflate prices. Supply chain constraints or trade restrictions may also boost upfront inventory requirements and safety stock for catalysts and purification agents.

• Regulatory and Environmental Compliance Costs

Stringent emissions restrictions, waste water treatment mandates, and VOC abatement regulations push plant integrators to invest in advanced environmental control technology. Permit fees, ongoing audits, and green technology certification add to both CAPEX and recurring costs.

• Labor Market Pressures and Skilled Workforce Scarcity

In regions where experienced chemical engineering labor is scarce, wages and training costs climb. A tight market drives up HR expense and may compel companies to invest in automation and remote operation to mitigate reliance on costly human operators.

• Inflation and Local Currency Exchange Rates

In countries with high inflation or weak local currency relative to the dollar, imported equipment and feedstock become more expensive. Project budgeting must include contingencies for exchange rate fluctuations and inflation-linked cost escalation.

• Logistics and Supply Chain Disruptions

Global transportation disruptions, port congestion, or regional geopolitical instability can increase shipping, insurance, and storage costs. This also compels flexibility in logistics planning-dual suppliers, local sourcing, and buffer storage-all raising early stage CAPEX and OPEX.

• Technological Innovation and Economies of Scale

Advances in reactor design, catalyst reusability, and process automation can reduce per unit production cost-if deployed at scale. However, early adoption often requires higher upfront investment in R&D and integration, which must be balanced against expected long-term savings.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=9256&flag=C

Challenges and Considerations for Investors

• Raw Material Dependency

• Methyl formate production depends on the availability and pricing of methanol and carbon monoxide. Fluctuations in global energy markets or disruptions in supply chains can impact production costs and margins.

• Environmental and Safety Regulations

• Being a flammable and volatile compound, methyl formate is subject to strict environmental and safety standards. Compliance requires investment in emissions control, waste management, and safety systems, increasing both capital and operational costs.

• High Initial Investment

• The setup of a methyl formate plant involves significant capital expenditure for reactors, distillation units, safety infrastructure, and automation. This can lead to a long payback period and demands careful financial planning.

• Market Demand Fluctuations

• Methyl formate demand is influenced by industries like agrochemicals, pharmaceuticals, and foam manufacturing. Any decline or disruption in these sectors can affect sales volume and profitability.

• Skilled Labor Shortage

• Chemical manufacturing requires technically trained staff for plant operation, quality control, and maintenance. Finding and retaining skilled personnel can be a challenge in certain regions.

• Competitive Pressure

• The market faces competition from alternative solvents and chemical intermediates. To stay competitive, investors must focus on quality, pricing, and building long-term customer relationships.

• Technological Considerations

• Investors must choose efficient and scalable production technologies. Outdated or inefficient methods may lead to higher operating costs, lower yields, and greater environmental impact.

Conclusion

The methyl formate industry is poised for steady growth in 2025, supported by its expanding role in environmentally friendly applications across pharmaceuticals, agrochemicals, and specialty chemicals. Setting up a methyl formate production plant offers promising investment potential, but it requires careful attention to feedstock sourcing, regulatory compliance, technology selection, and capital planning. With rising environmental awareness and industrial demand, investors who proactively address key challenges such as raw material volatility, high initial costs, and labor availability can position themselves for long-term profitability in this evolving sector.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Methyl Formate Production Cost Analysis Report 2025: Plant Setup, Capital Investments and Business Plan here

News-ID: 4134931 • Views: …

More Releases from IMARC Group

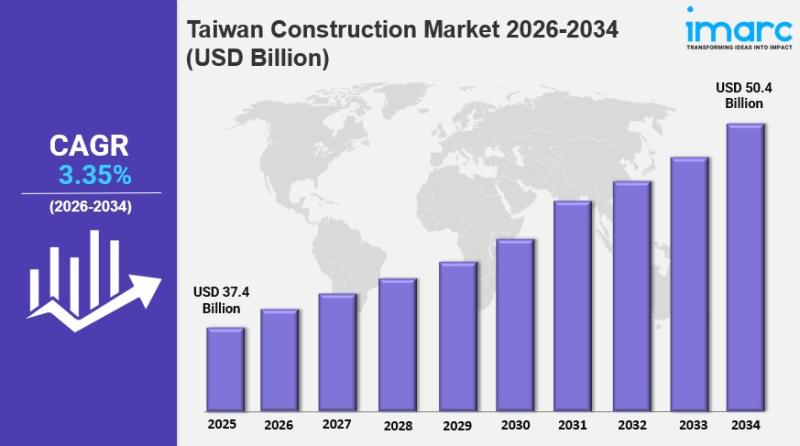

Taiwan Construction Market Size, Share, In-Depth Insights, Trends and Forecast 2 …

IMARC Group has recently released a new research study titled "Taiwan Construction Market Report by Sector (Residential, Commercial, Industrial, Infrastructure (Transportation), Energy and Utilities Construction), and Region 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Taiwan construction market size reached USD 37.4 Billion in 2025 and is projected to grow to USD 50.4…

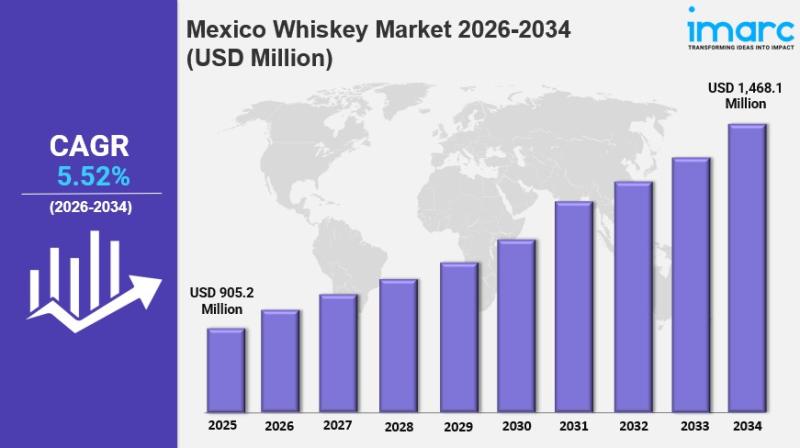

Mexico Whiskey Market Size to Hit USD 1,468.1 Million by 2034: Trends & Forecast

IMARC Group has recently released a new research study titled "Mexico Whiskey Market Size, Share, Trends and Forecast by Product Type, Quality, Distribution Channel, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico whiskey market size reached USD 905.2 Million in 2025. It is projected to grow to USD 1,468.1 Million…

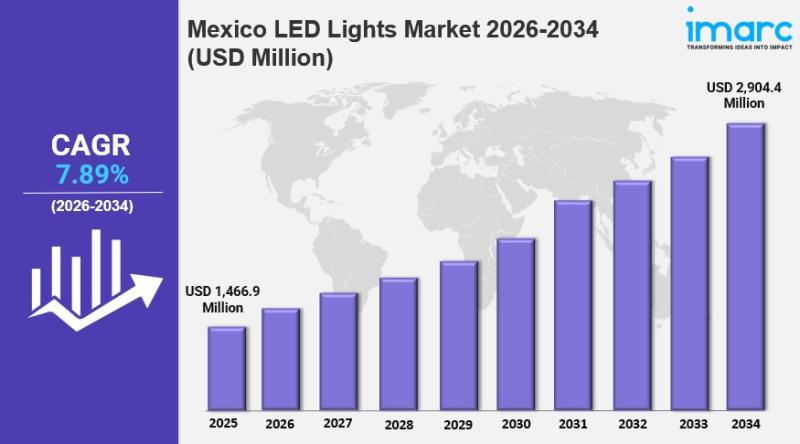

Mexico LED Lights Market 2026 : Industry Size to Reach USD 2,904.4 Million by 20 …

IMARC Group has recently released a new research study titled "Mexico LED Lights Market Size, Share, Trends and Forecast by Product Type, Application, Import and Domestic Manufacturing, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico LED lights market was valued at USD 1,466.9 million in 2025 and is projected to…

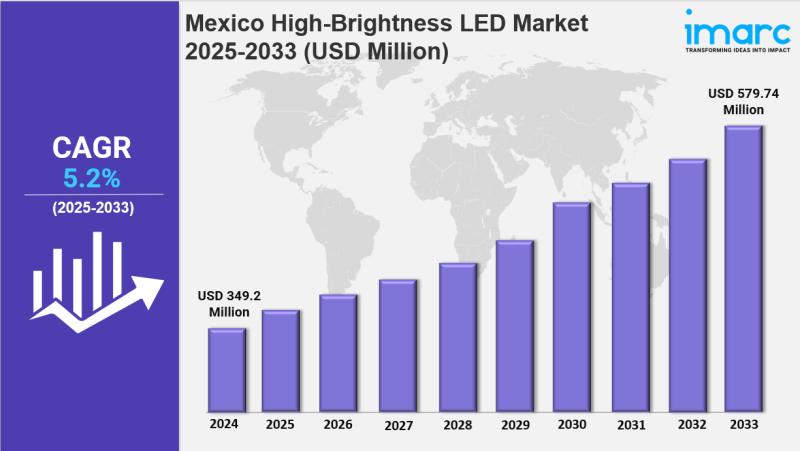

Mexico High-Brightness LED Market Size, Share, Latest Insights and Forecast 2025 …

IMARC Group has recently released a new research study titled "Mexico High-Brightness LED Market Size, Share, Trends and Forecast by Application, Distribution Channel, Indoor and Outdoor Application, End-Use Sector, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico high-brightness LED market size reached USD 349.2 Million in 2024 and is…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…