Press release

Solar Cell Manufacturing Plant Cost 2025: Setup Details, Capital Investments, and Business Plan

A solar cell, also known as a photovoltaic (PV) cell, is a semiconductor device that converts sunlight directly into electricity through the photovoltaic effect. Made primarily from silicon, solar cells generate electric current when exposed to sunlight, offering a clean, renewable, and sustainable energy solution. These cells are the fundamental building blocks of solar panels and are widely used in residential, commercial, and industrial applications to reduce dependence on fossil fuels and lower carbon emissions.Setting up a solar cell production plant involves acquiring precision equipment for wafer cutting, doping, layering, and assembling, along with cleanroom facilities. A medium-scale setup requires investment in land, machinery, skilled labor, utilities, and quality control systems, all tailored to output capacity and technology type (e.g., monocrystalline or thin-film).

IMARC Group's report, titled "Solar Cell Manufacturing Plant Setup Cost 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a Solar Cell manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Solar Cell Industry Outlook 2025:

The solar cell industry in 2025 is on a strong growth path, driven by increasing global demand for clean energy, government incentives, and continuous advancements in technology. Crystalline silicon solar cells remain the industry standard due to their proven efficiency and widespread use, while next-generation technologies like perovskite, tandem, and thin-film cells are gaining attention for their potential to boost performance and lower costs. Automation and AI integration in manufacturing are improving production efficiency and quality, helping manufacturers scale up sustainably. Globally, countries are investing in domestic solar manufacturing to reduce dependence on imports and strengthen energy security. Despite challenges such as trade barriers, supply chain issues, and raw material constraints, the industry's long-term outlook remains positive, with utility-scale projects, innovation, and policy support driving continued expansion and investment.

Request for Sample Report: https://www.imarcgroup.com/solar-cell-manufacturing-plant-project-report/requestsample

Key Insights for Solar Cell Manufacturing Plant Setup:

Detailed Process Flow:

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements, and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Buy Now: https://www.imarcgroup.com/checkout?id=23630&method=1911

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components of Setting Up a Solar Cell Plant:

• Machinery and Equipment: High-precision equipment for wafer slicing, doping, diffusion, deposition, metallization, and testing-core to the production of solar cells.

• Land and Infrastructure: Cost of acquiring land and constructing cleanrooms, manufacturing halls, R&D labs, warehousing, and administrative offices.

• Raw Materials: Includes silicon wafers, conductive metals (like silver and aluminum paste), gases, chemicals, and glass-key inputs for cell fabrication.

• Utilities and Power Supply: Solar cell production is energy- and water-intensive, requiring stable electricity, deionized water, vacuum systems, and HVAC units.

• Skilled Labor and Staffing: Technicians, engineers, operators, quality control staff, and R&D personnel are needed for specialized processes and automation systems.

• Automation and Control Systems: Investment in robotics, AI-driven quality inspection, real-time monitoring, and data logging for process optimization.

• Licensing and Environmental Compliance: Costs related to permits, pollution control, safety standards, and waste management systems.

• Maintenance and Spare Parts: Regular servicing of sensitive equipment, procurement of critical spares, and upkeep of cleanroom standards.

• Packaging and Storage: Proper handling and packaging systems for delicate solar cells, along with safe storage facilities to prevent damage.

• Technology Licensing or R&D: For newer technologies like perovskite or tandem cells, licensing fees or R&D investments may be required.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=23630&flag=C

Economic Trends Influencing Solar Cell Plant Setup Costs 2025:

• Raw Material Price Volatility: Fluctuating costs for polysilicon, silver paste, solar glass, and aluminum frames directly impact capital and operational budgets.

• Oversupply and Industry Consolidation: Chinese producers plan to cut polysilicon capacity by roughly one-third, which is already pushing prices up-adding uncertainty to cost projections.

• Tariffs & Trade Policies: New anti-dumping duties and customs duties on solar imports (cells, modules, glass, inverters) raise equipment lead times and capital costs, while policy uncertainty affects investment timing.

• Government Incentives & Domestic Targets: Subsidies, tax credits (e.g. US IRA, India's PLI and ALMM mandates), and localization policies partially offset capex but introduce compliance-related cost premiums.

• Inflation & Energy Costs: Rising inflation raises labor, material, and utility costs; high energy consumption in silicon processing amplifies cost sensitivity.

• Automation & Tech Innovation: Adoption of AI, robotics, high-efficiency materials (e.g. perovskite, TOPCon, HJT cells) boosts upfront investment but may lower long term unit costs.

• Supply Chain Complexity & Delays: Extended lead times-from 35 to over 50 weeks for module delivery-mean higher working capital needs and price variability.

• Regional Labor & Installation Costs: Labor costs vary by region and are rising in mature markets, increasing overall project setup costs and operational expense ratios.

Challenges and Considerations for Investors in Solar Cell Plant Projects:

• High Capital Investment: Setting up a solar cell manufacturing plant requires substantial upfront investment in specialized equipment, cleanroom infrastructure, and technology.

• Technology Obsolescence: Rapid advancements in solar cell technology (e.g., shift from PERC to TOPCon or perovskite) demand constant upgrades to remain competitive.

• Raw Material Volatility: Prices for key inputs like polysilicon, silver paste, and glass can fluctuate significantly, impacting production costs and margins.

• Supply Chain Risks: Dependence on imported machinery or materials exposes projects to delays, tariffs, and geopolitical disruptions.

• Regulatory and Trade Barriers: Import duties, changing government policies, and international trade restrictions can impact cost structures and access to markets.

• Energy and Utility Costs: Solar cell production is energy-intensive, making consistent and affordable power supply crucial for cost efficiency.

• Environmental Compliance: Meeting pollution control norms, managing chemical waste, and acquiring necessary clearances require dedicated systems and investments.

• Skilled Workforce Requirement: Operating and maintaining advanced manufacturing equipment requires technically trained personnel, which may be limited in certain regions.

• Market Competition: Intense global competition, particularly from low-cost producers, can pressure pricing and profit margins.

• Policy Dependency: Investor returns are often influenced by government incentives, subsidies, and mandates, making long-term planning susceptible to policy changes.

Conclusion:

The solar cell industry represents a vital pillar in the global shift toward clean energy, offering sustainable solutions through innovative and efficient photovoltaic technologies. Setting up a solar cell manufacturing plant requires careful planning, significant investment, and technological precision, but presents substantial opportunities for long-term returns. With rising global demand, supportive government policies, and advancements in automation and cell efficiency, the industry outlook for 2025 remains optimistic. However, investors must navigate challenges such as raw material volatility, regulatory shifts, and intense global competition. Strategic planning, adaptability, and a focus on innovation will be key to success in this fast-evolving sector.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Solar Cell Manufacturing Plant Cost 2025: Setup Details, Capital Investments, and Business Plan here

News-ID: 4133743 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

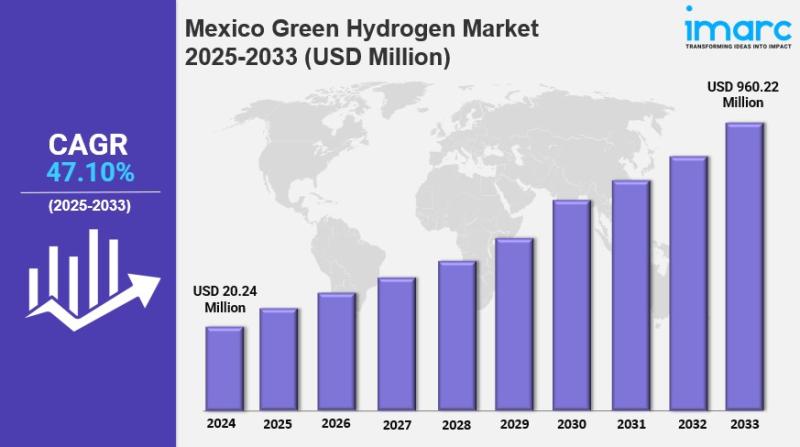

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…