Press release

Wood Veneer Manufacturing Plant Setup 2025: Raw Materials, Costs and Requirements

Setting up a wood veneer manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Wood Veneer Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a wood veneer manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Wood veneer refers to very thin slices of real wood, typically less than 1/40th of an inch thick, which are glued onto a core substrate like plywood, particle board, or MDF. This allows for the natural beauty and unique grain patterns of more expensive or rare wood species to be utilized efficiently and cost-effectively. Veneers are highly valued in furniture manufacturing, cabinetry, wall paneling, and interior decoration for their aesthetic appeal, stability, and versatility, offering the look of solid wood with reduced material consumption while maintaining a premium finish.

The wood veneer industry is undergoing significant transformation. A primary driver is the escalating demand for sustainable and eco-friendly building materials. As environmental consciousness grows, both consumers and industries seek products that minimize resource depletion. Wood veneers perfectly align with this trend, as they maximize the usable surface area from a single log compared to solid wood, leading to more efficient timber utilization. This is further supported by the increasing popularity of green building certifications. Moreover, the booming construction and real estate sectors, particularly in rapidly urbanizing regions like India, are fueling a strong demand for interior finishing materials. Wood veneer offers a premium, natural aesthetic that appeals to rising disposable incomes and the modern interior design trend favoring warm, refined finishes. Technological advancements in manufacturing and finishing are also enhancing product durability and expanding design possibilities, contributing to the industry's growth despite challenges like raw material supply volatility and competition from substitutes.

Request for a Sample Report: https://www.imarcgroup.com/wood-veneer-manufacturing-plant-project-report/requestsample

Key Steps Required to Set Up a Wood Veneer Plant.

1. Market Analysis

The report provides insights into the landscape of the wood veneer industry at the global level. The report also provides a segment-wise and region-wise breakup of the global wood veneer industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of wood veneer, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the wood veneer manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Speak to Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=19419&flag=C

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for wood veneer manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for wood veneer production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a wood veneer manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Wood Veneer Manufacturing Plant Setup 2025: Raw Materials, Costs and Requirements here

News-ID: 4133629 • Views: …

More Releases from IMARC Group

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

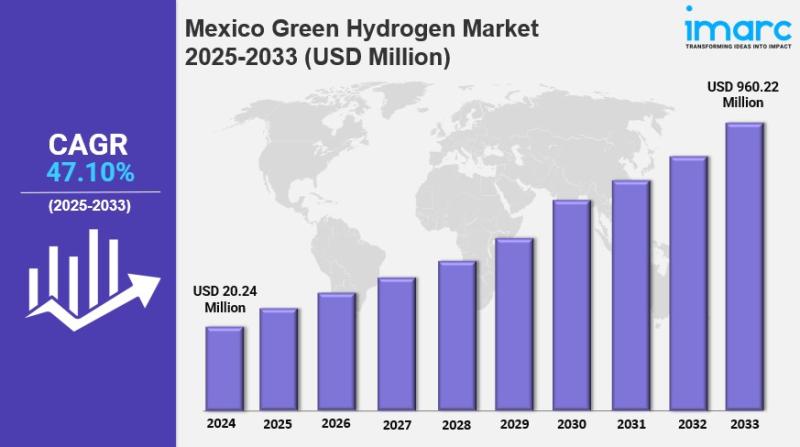

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

U.S. Pet Insurance Market Growth, Outlook & Key Players Analysis 2033

IMARC Group's Latest Research Reveals a CAGR of 10.8% from 2025-2033, with Customized Coverage Plans and Digital Platforms Accelerating Market Expansion

NEW YORK, USA - The U.S. pet insurance industry is witnessing rapid and sustained growth. According to a new market intelligence report by IMARC Group, the U.S. Pet Insurance Market, valued at USD 2.0 Billion in 2024, is projected to reach USD 5.1 Billion by 2033, registering a compound annual…

United States Home Healthcare Market Set to Reach USD 186.5 Billion by 2034, Dri …

PRESS RELEASE

FOR IMMEDIATE RELEASE

Date: February 24, 2026

Contact: sales@imarcgroup.com | +1-201-971-6302 | www.imarcgroup.com

IMARC-Style Industry Analysis Reveals a CAGR of 6.70% During 2026-2034, Supported by Expansion of Telehealth and Remote Patient Monitoring

The United States Home Healthcare Market reached a value of USD 103.7 Billion in 2025 and is projected to grow to USD 186.5 Billion by 2034, exhibiting a steady CAGR of 6.70% during 2026-2034.

Market growth is primarily driven by the rapidly…

More Releases for Wood

Key Influencer in the Wood Preservatives Market 2025: Rising Global Wood Demand …

"What market dynamics are playing a key role in accelerating the growth of the wood preservatives market?

The market growth of wood preservatives is expected to be fueled by the rising demand for wood in multiple applications over the forecast period. With the global population and industrialization on the rise, the need for wood products is progressively growing. Wood, being a substantial source of energy, housing, firewood, timber, and fodder, has…

Thermally Modified Wood Market Analysis By Top Key Players - Kebony, Stora Enso, …

The "Thermally Modified Wood Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Thermally Modified Wood Market, 2024-2031

Verified Market Research's most recent report, "Thermally Modified Wood Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2023-2030,"…

Palmetto Wood Shop: Personalized Wood Gifts for Every Occasion

Palmetto Wood Shop, a family-owned business renowned for its passion for woodworking, specializes in crafting high-quality, engraved gifts for every occasion. Since 2014, Palmetto Wood Shop's mission has been to provide customers across the U.S. and the world with personalized products that reflect the artistry and care that goes into each piece.

Palmetto Wood Shop's collection includes a wide array of products ranging from engraved pocketknives and hammers to personalized cutting…

Thermally Modified Wood Market 2023 Key Players - Stora Enso, Kebony, Thermory, …

Global Thermally Modified Wood Market 2023 introduced by a leading market research firm Fior Markets comes out as a highly reliable source of information and data on the global market. The report is a versatile and future-ready analytical survey that contains trend assessment, an in-depth assessment of market valuation, and revenue-generating trends. The report covers sharp insights into the present and forthcoming trends & developments in the global Thermally Modified…

Pressure-treated Wood Market | Navigating New Horizons: Analyzing Innovative Bus …

In the past few years, the Pressure-treated Wood market experienced a huge change under the influence of COVID-19 and Russia-Ukraine War, the global market size of Pressure-treated Wood reached the predicted milestone in 2022 with the rising CAGR from 2017-2022. Facing the complicated international situation, the future of the Pressure-treated Wood market is full of uncertain. Report predicts that the global Pressure-treated Wood market size will expected to achieve a…

Global Wood Processing Market | Global Wood Processing Industry: Ken Research

The wood processing market involves of sales of processed wood by several entities (organizations, sole traders and partnerships) that saw measurement lumber, boards, beams, timbers, poles, ties, shingles, shakes, siding, and wood chips from the logs or bolts. This industry also embraces establishments that treat planed, sawed and shaped wood with creosote or other preservers such as alkaline copper quat, copper azole, and sodium borates, to safeguard decay and to…