Press release

Ion Exchange Resins Market Key Players Evoqua Water Technologies, Ion Exchange (India) Ltd., Pure Resin Co., Ajinomoto Fine-Techno Co., Novasep Holding, Hebi Higer Chemical, Samyang Corporation

The global ion exchange resins market-often synonymously referred to as the water softening resins market or industrial purification resin systems sector-has gained prominence due to its widespread application in water treatment, pharmaceuticals, food processing, and chemical separation. While typical discourse in this market revolves around municipal water treatment and boiler feed applications, a quieter but critically important segment is emerging: nuclear-grade ion exchange resins.These highly specialized resins, used in nuclear power plants and radioactive waste management, are facing a demand surge driven by the global shift toward low-carbon energy and small modular reactors (SMRs). As the world re-embraces nuclear energy amid net-zero goals, the reliability and supply of nuclear resins have become a key strategic concern. This evolving pressure is reshaping supply chains, investment priorities, and even geopolitical alignments in the ion exchange resins market.

Unlock Comprehensive Market Insights - Explore the Full Report Now: https://www.futuremarketinsights.com/reports/ion-exchange-resins-market

The Unique Role of Nuclear-Grade Resins

Nuclear ion exchange resins are engineered to operate in high-radiation, high-temperature environments, often dealing with complex radioactive isotopes such as cesium-137, cobalt-60, and strontium-90. These resins are typically sulfonated polystyrene-divinylbenzene copolymers, designed with strict purity levels, controlled particle size distribution, and radiation-resistant backbones.

Unlike resins used in conventional water softening or demineralization, nuclear-grade resins are critical for decontaminating reactor coolant loops, purifying spent fuel pools, and treating liquid radioactive waste. Their failure could lead to operational delays or safety concerns in nuclear facilities-making their performance and reliability non-negotiable.

A real-world case underscores this importance: during the Fukushima disaster, improvised ion exchange systems using nuclear resins were deployed within days to remove cesium and reduce radiation in cooling waters. This demonstrated how strategic these materials can be in both planned and emergency nuclear operations.

Rising Demand Amid Nuclear Renaissance

Global interest in nuclear energy is undergoing a revival. Countries like China, India, France, and the United Kingdom are investing billions into next-generation reactors, while the United States and Canada are pushing forward with SMRs that are safer and faster to deploy. This nuclear resurgence is directly translating into higher demand for advanced nuclear resins.

According to Future Market Insights, the Ion Exchange Resins Market is projected to grow from USD 1,617.6 million in 2025 to USD 2,609.9 million by 2035, reflecting a CAGR of 4.9% over the forecast period.

This rising demand is not only stretching production capacities but also creating a strategic bottleneck-since only a handful of global suppliers, including Purolite (now part of Ecolab), Thermax, and LANXESS, are qualified to produce resins suitable for nuclear applications under ISO 9001 and NRC/IAEA standards.

Supply Chain Complexity and Geopolitical Risk

The production of nuclear-grade resins is highly specialized, requiring pharmaceutical-grade facilities, rigorous testing, and long approval cycles. The supply chain involves sourcing high-purity monomers, precision polymerization, and stringent quality assurance-all within a framework of regulatory scrutiny and intellectual property restrictions.

Geopolitical tensions and trade restrictions are further complicating access to key raw materials like styrene and divinylbenzene, which are often sourced from specific regions. In 2023, a trade dispute between the EU and China disrupted the flow of polymer precursors, causing temporary shortages of high-grade resins in Europe.

Adding to the complexity is the fact that resin manufacturers must be certified by nuclear regulatory authorities, making rapid capacity expansions challenging. Even large industrial resin suppliers may be unable to enter the nuclear segment without years of investment and regulatory alignment.

Make Informed Decisions - Access Your Sample Report Instantly! https://www.futuremarketinsights.com/reports/sample/rep-gb-1001

Innovation and Localization Trends

To mitigate supply risks and reduce foreign dependence, several countries are investing in domestic resin production and innovation. India's Department of Atomic Energy has partnered with local resin manufacturers to develop indigenous nuclear-grade resins, with successful trials reported at the Tarapur Atomic Power Station.

In the U.S., the Department of Energy is funding research into novel composite resins that incorporate inorganic nanoparticle additives for enhanced radiation stability and ion selectivity. These resins aim to be both safer and longer-lasting, reducing the frequency of replacement and radioactive waste generation.

Meanwhile, additive manufacturing and continuous polymerization techniques are being explored to reduce production time and cost without compromising quality-signaling a potential disruption in how nuclear resins are manufactured in the next decade.

Market and Regulatory Outlook

The rising strategic importance of nuclear-grade ion exchange resins is prompting new frameworks for procurement and regulation. International alliances like the Nuclear Energy Agency (NEA) are exploring joint procurement programs to ensure stable supply among member nations, similar to how critical medical isotopes are jointly sourced.

From a commercial perspective, buyers in the nuclear sector are increasingly demanding long-term fixed contracts with resin suppliers, favoring vertically integrated companies that offer turnkey purification systems and post-use disposal support. This shift in procurement behavior is gradually driving a realignment of revenue streams in the ion exchange resins market-from product sales to long-term service contracts.

Moreover, nuclear regulators are now encouraging power plants to factor resin lifecycle management into their license applications, linking resin performance directly to reactor safety and operational approvals.

Related Reports:

Pour Point Depressants Market: https://www.futuremarketinsights.com/reports/pour-point-depressants-market

Terephthalic Aldehyde Market: https://www.futuremarketinsights.com/reports/terephthalic-aldehyde-market

Epoxy Curing Agent Market: https://www.futuremarketinsights.com/reports/epoxy-curing-agents-market

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 5000 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ion Exchange Resins Market Key Players Evoqua Water Technologies, Ion Exchange (India) Ltd., Pure Resin Co., Ajinomoto Fine-Techno Co., Novasep Holding, Hebi Higer Chemical, Samyang Corporation here

News-ID: 4130265 • Views: …

More Releases from Future Market Insights

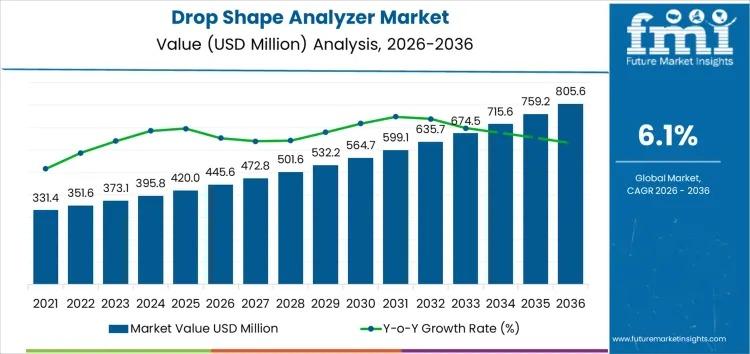

Global Drop Shape Analyzer Market Set to Reach USD 805.6 Million by 2036, Driven …

The Drop Shape Analyzer Market is witnessing robust growth, projected to expand from USD 445.6 million in 2026 to USD 805.6 million by 2036 at a CAGR of 6.1%. Driven by rising demand across coatings, electronics, medical devices, and academic research, the market is increasingly essential for industries that rely on precise surface and interfacial property measurements. Contact angle measurement leads the market with a 40% share, reflecting its significance…

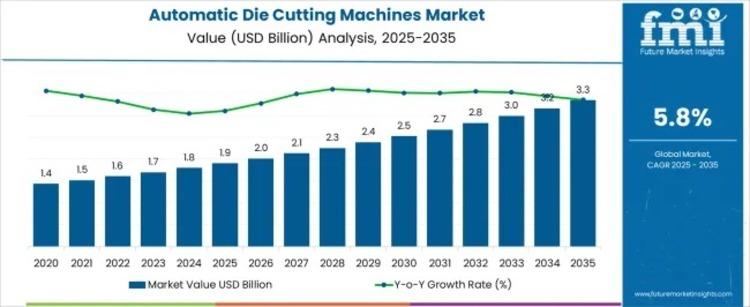

Global Automatic Die Cutting Machines Market 2025-2035: Automation & Efficiency …

Market Overview

The Automatic Die Cutting Machines Market is experiencing steady growth as industries seek automation, precision, and efficiency in production processes. Valued at USD 1.9 billion in 2025, the market is expected to reach USD 3.3 billion by 2035, growing at a CAGR of 5.8%. Key drivers include the demand for high-speed, error-free cutting, especially in automotive, packaging, and paper industries where quality and turnaround time are critical.

Automation continues to…

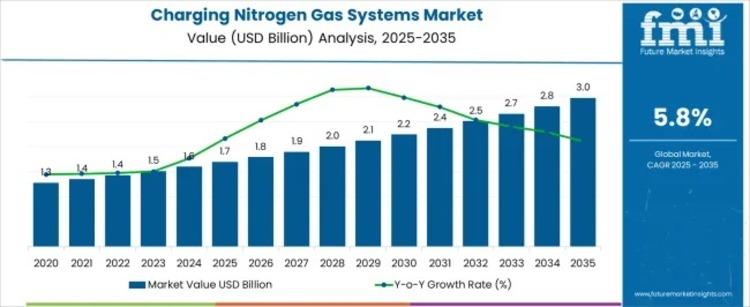

Global Charging Nitrogen Gas Systems Market 2025-2035: Growth Driven by Aerospac …

Global Charging Nitrogen Gas Systems Market Set for Steady Growth Through 2035

The Charging Nitrogen Gas Systems Market is expected to grow from USD 1.7 billion in 2025 to USD 3.0 billion by 2035, registering a CAGR of 5.8%. Increasing reliance on nitrogen charging systems across aerospace, defense, industrial machinery, and energy sectors is driving demand, as these systems ensure operational safety, hydraulic efficiency, and reduced downtime.

Request For Sample Report |…

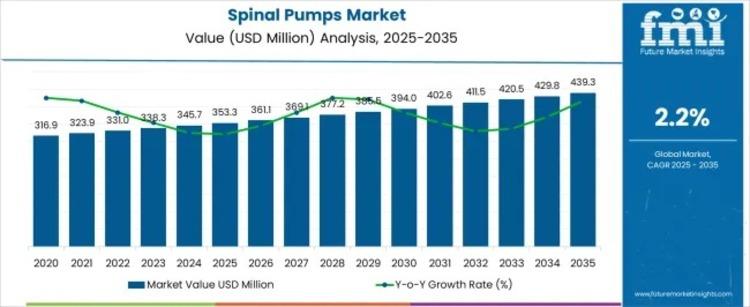

Global Spinal Pumps Market Outlook 2025-2035: Growth Driven by Advanced Pain Man …

The Spinal Pumps Market is projected to grow from USD 353.3 million in 2025 to USD 439.3 million by 2035, at a CAGR of 2.2%. Rising prevalence of chronic pain, neurological disorders, and spasticity is driving demand for precise intrathecal therapy over systemic drug delivery. Spinal pumps offer precise medication delivery directly into the spinal fluid, reducing side effects and improving patient quality of life.

Request For Sample Report | Customize…

More Releases for Resins

Polyester Resins Market to Garner 3.12 billion at 7.4% CAGR by 2031 | NCS Resins …

The global market for Polyester Resins was estimated to be worth US$ 1.91 billion in 2024 and is forecast to a readjusted size of US$ 3.12 billion by 2031 with a CAGR of 7.4% during the forecast period 2025-2031.

According to QYResearch New Study Report 'Polyester Resins Market 2025' provides a comprehensive analysis of the industry with market insights will definitely facilitate to increase the knowledge and decision-making skills of the…

2025 Analysis on Polyester Resins Market Report Forecast By key players BASF, Th …

Up Market Research offers a latest published report on “Global Polyester Resins Market Research Report 2019” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 97 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Request Sample Copy Of this Report @ https://www.upmarketresearch.com/home/requested_sample/62882

Polyester Resins Market research report delivers a close watch on…

2025 Analysis on Polyester Resins Market Report Forecast By key players BASF, Th …

Up Market Research offers a latest published report on “Global Polyester Resins Market Research Report 2019” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 97 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Request Sample Copy Of this Report @ https://www.upmarketresearch.com/home/requested_sample/62882

Polyester Resins Market research report delivers a close watch on…

Global Specialty Resins Market

Global Specialty Resins Market – Industry Analysis and Forecast (2018-2026) – by Resin Type, End User, and Region.

Global Specialty Resins Market was valued at US$ 7.45 Bn in 2017 and is expected to reach US$ 11.34 Bn by 2026, at a CAGR of 5.4 % during the forecast period.

The objective of the report is to present a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, industry-validated…

Polyester Resins Market Research Report Global Forecast 2018-25 Estimated with T …

UpMarketResearch published an exclusive report on “Polyester Resins market” delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 117 pages which highly exhibits on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability. This report focuses on the Polyester Resins market, especially in North America, Europe and Asia-Pacific, South America, Middle East and Africa. This report…

Phenolic Resins Market Players Prefere Resins, Kolon Industries, Inc., Momentive …

Introduction:

Phenolic resins or phenol-formaldehyde resins are the synthetic polymers obtained by the polymerization of phenol and formaldehyde. Phenolic resins possess good physical and chemical properties such as high mechanical strength, low toxicity, good heat resistance, low smoke formation and high thermal stability. Due to such high properties, phenolic resins find their applications in myriad industrial products. From molded products such as billiard balls to coatings and adhesives, phenolic resins…