Press release

Carbide Tools Market Insights (2025-2035): High‐Precision Tool Evolution and Global Expansion Led by Sandvik, Kennametal & Mitsubishi

Market OverviewThe global carbide tools market is poised for substantial growth, driven by rising industrial automation, increased demand for high-speed machining, and the expansion of manufacturing capabilities in critical industries like aerospace, automotive, and precision engineering. Valued at USD 8.7 billion in 2025, the market is projected to achieve USD 16.9 billion by 2035, reflecting a steady CAGR of 6.9%.

Carbide tools, known for their superior hardness, wear resistance, and longevity, are being increasingly utilized for complex machining operations that demand high accuracy, speed, and durability. The continued push toward electric vehicles (EVs), lightweight components, and sustainability is reshaping tool usage across global industries.

Browse Full Report Here: https://www.futuremarketinsights.com/reports/carbide-tools-market

Growth Drivers and Technology Trends

Advanced material technologies and nanostructured coatings are among the key contributors fueling growth in the carbide tools market. Hybrid carbide composites and AI-enabled smart machining tools are enhancing operational efficiency while minimizing tool wear and cycle times. As industries transition to high-speed, precision-based workflows, the demand for carbide tools that offer consistent surface finish and extended tool life continues to rise.

Additionally, the proliferation of sensor-integrated tooling for real-time wear tracking and predictive maintenance is transforming how manufacturers manage productivity and quality assurance. These smart machining solutions are expected to play a pivotal role in shaping the future of the carbide tools landscape.

Regional Market Landscape

North America remains a major hub, supported by strong automotive and aerospace sectors in the U.S. and Canada. With increased EV production and aircraft manufacturing, demand for high-precision carbide tools continues to escalate.

Europe follows closely, with countries like Germany, France, and Italy leading the adoption of advanced machining techniques. The transition to sustainable manufacturing and stringent quality norms has driven OEMs in the region to embrace next-generation carbide solutions.

Asia-Pacific is projected to experience the fastest growth. Manufacturing powerhouses like China, India, Japan, and South Korea are investing heavily in smart factories, CNC machining, and industrial automation. This shift supports higher tool consumption, especially in the automotive and electronics sectors.

Challenges and Strategic Responses

Despite the growth outlook, the industry faces raw material cost volatility, particularly for tungsten carbide and cobalt. Geopolitical risks and supply chain disruptions have added pressure to sourcing and production timelines. As a countermeasure, leading manufacturers are prioritizing raw material recycling, adopting additive manufacturing, and leveraging alternative super-hard materials.

Moreover, firms are investing in self-optimizing tooling systems that reduce downtime and maximize tool efficiency through real-time analytics and AI algorithms, creating cost-saving opportunities amidst material constraints.

Competitive Analysis and Market Structure

The carbide tools market is highly competitive, with several global players leading innovation and market share. Sandvik AB holds the top spot with an estimated 15-20% share, offering AI-powered tooling and high-performance coatings. Kennametal Inc. and Iscar Ltd. follow closely, known for their solid carbide drills and precision tools used across automotive and aerospace manufacturing.

Other notable players include Mitsubishi Materials Corporation and Walter AG, both investing in heat-resistant applications and digital machining analytics. Meanwhile, regional players like Guhring KG, Kyocera, and Tungaloy are contributing through cost-effective tooling solutions and industry-specific advancements.

Future Outlook: 2025 to 2035

Looking ahead, the next decade will be marked by integration of AI, sustainable material sourcing, and digital twin technologies in carbide tool production. With industries demanding ultra-hard, high-speed machining solutions, carbide tools with nano-coatings and smart wear monitoring systems will set new benchmarks in manufacturing efficiency.

The rise of precision-intensive sectors such as EV, medical devices, and renewable energy will further accelerate demand, making carbide tooling an indispensable component in the evolution of modern manufacturing.

Request a Sample Report Here: https://www.futuremarketinsights.com/reports/sample/rep-gb-1775

Conclusion

The carbide tools market is undergoing a transformation powered by industrial automation, sustainability, and digital innovation. With a projected value of USD 16.9 billion by 2035 and a CAGR of 6.9%, the sector is set to become a critical enabler of high-performance machining. Companies that invest in next-gen tooling, AI-driven analytics, and circular material sourcing will be best positioned to lead in this competitive and rapidly evolving market landscape.

Related Reports:

Large Industrial Displays Market- https://www.futuremarketinsights.com/reports/large-industrial-displays-market

Passenger Boarding Bridge Market- https://www.futuremarketinsights.com/reports/passenger-boarding-bridge-market

Building Automation System Market- https://www.futuremarketinsights.com/reports/building-automation-systems-market

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Carbide Tools Market Insights (2025-2035): High‐Precision Tool Evolution and Global Expansion Led by Sandvik, Kennametal & Mitsubishi here

News-ID: 4130145 • Views: …

More Releases from Future Market Insights

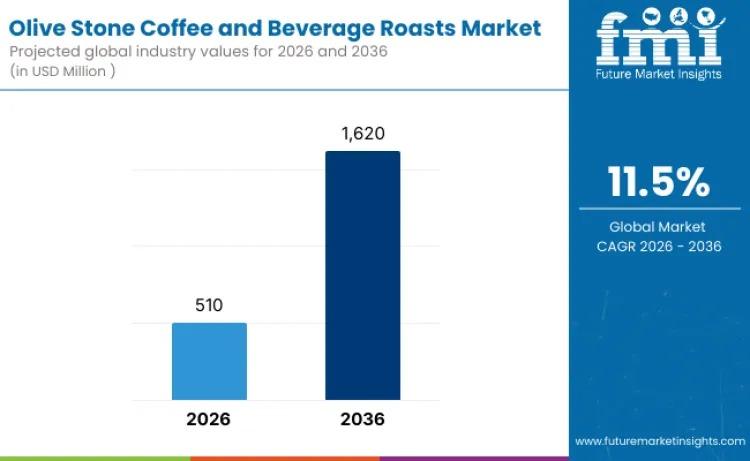

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

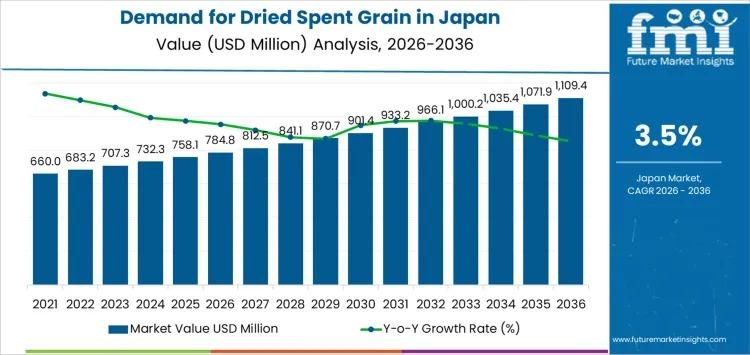

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

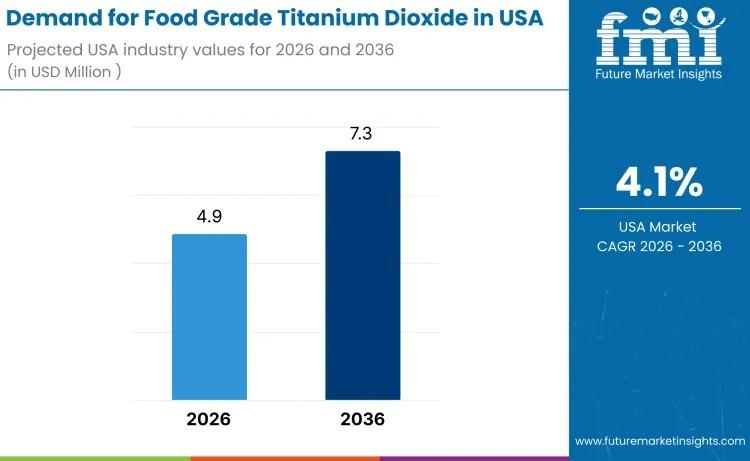

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

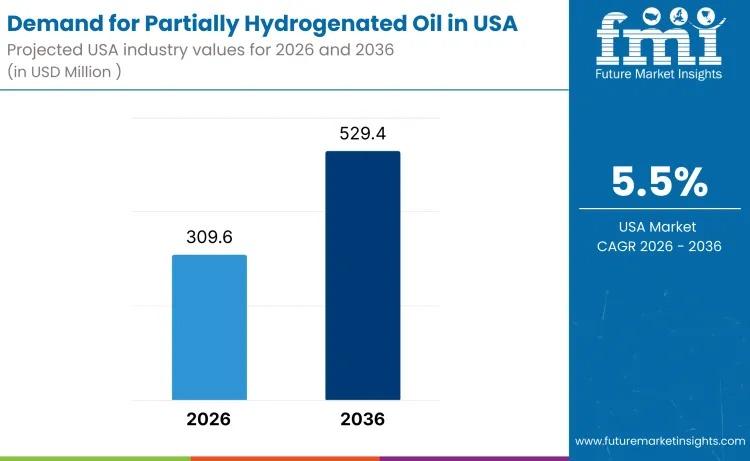

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for Carbide

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…