Press release

Industrial Magnetic Fluid Sealing Systems Market to Hit USD 1.24 Billion by 2031 at 14.3% CAGR, Led by Ferrotec and Leybold

The global market for Industrial Magnetic Fluid Sealing Systems is projected to expand from USD 485 million in 2024 to USD 1,236 million by 2031, representing a compound annual growth rate (CAGR) of 14.3%, according to the 2025 QYResearch Report. This growth is fueled by robust demand from the semiconductor manufacturing, aerospace, and precision instrumentation industries, and further influenced by global tariff policy adjustments and supply chain reconfigurations.Get Full PDF Sample Copy of Report: (Including Full TOC, List of Tables & Figures, Chart)

https://www.qyresearch.com/sample/4806260

Key Companies in Focus

Leading companies in the global market include:

• Ferrotec Corporation

• Leybold GmbH

• Ulvac Technologies

• Rigaku Corporation

• MKS Instruments

• Meggitt PLC

• Dekker Vacuum Technologies

• Edwards Vacuum

• Pfeiffer Vacuum

• Oxford Instruments

• Nikkiso Co Ltd

• Sumitomo Heavy Industries

• Kurt J. Lesker Company

• Shimadzu Corporation

Selected Product Profiles - Industrial Magnetic Fluid Sealing Systems

1. Ferrotec SS 375 SLBE (Feedthrough Model)

• Manufacturer: Ferrotec Corporation

• Type: Vacuum rotary feedthrough with hydrocarbon-based ferrofluid

• Operating temperature (uncooled): approx. -6 °C to +80 °C; bakeable to ~150 °C

• Pressure capability: vacuum down to ~10−9 Torr

• Leak rate (helium standard): ~10−11 scc/s

• Shaft configuration: solid shaft with nut-mounted threaded body (Model SS 375 SLBE)

• Typical use: rotary motion feedthroughs in vacuum environments, such as semiconductor sputtering and CVD tools

2. Pfeiffer Vacuum Magnetic Coupled Rotary Feedthrough

• Manufacturer: Pfeiffer Vacuum

• Type: Magnetic coupling eliminates conventional shaft seal

• Leak tightness: tested to ~1×10−9 mbar·l/s via helium leak test

• Application focus: backing pumps for turbomolecular vacuum systems, hermetically sealed pumps to minimize contamination

• Temperature & performance note: rotor should not exceed ~120 °C; magnetic shielding recommended above ~7 mT fields

3. MKS Instruments Ferrofluidic Seal Modules

• Manufacturer: MKS Instruments, Inc.

• Type: Vacuum process seal modules integrated into wafer fabrication tools

• Key application: semiconductor manufacturing, display and vacuum process tools in cleanroom environments

• Notable attributes: engineered for high-speed rotation, tight vacuum sealing, and minimal lubricant contamination

4. Rigaku Magnetic Fluid Vacuum Feedthrough

• Manufacturer: Rigaku Corporation (Rigaku Mechatronics)

• Type: Magnetic fluid sealing feedthroughs integrated into irradiation and vacuum metrology equipment

• Industry use: Semiconductor metrology and analytical systems using high-vacuum environments

5. Edwards Vacuum Ferrofluidic Flange Seal

• Manufacturer: Edwards Vacuum

• Type: Flange-mounted magnetic fluid seal for vacuum deposition systems

• Use cases: semiconductor sputtering, photovoltaic and display deposition tools

• Performance: supports ultra-high vacuum processing; low-wear, maintenance-reduced sealing

Applications Driving Growth

The sealing systems are increasingly deployed in the following sectors:

• Semiconductor Manufacturing Equipment

• High Vacuum Laboratory Equipment

• Optical and Precision Instruments

• Aerospace and Defense

• Others

Product Categories

Products in this market are segmented into:

• Shaft Magnetic Fluid Sealing Systems

• Flange Magnetic Fluid Sealing Systems

• Vacuum Magnetic Fluid Sealing Systems

• High-speed Rotating Magnetic Fluid Sealing Systems

• Others

Key Trends in 2025

In 2025, the industrial magnetic fluid sealing systems market is undergoing a significant transformation driven by two related themes: the adoption of smart seals with built in sensors, and a push for eco friendly ferrofluids with reduced VOC levels and improved biocompatibility.

1. Smart Seals & Real Time Monitoring

The industry is increasingly integrating sensors and IoT connectivity into magnetic fluid seals. These smart seals enable real time monitoring of parameters like temperature, rotational speed, and leakage, supporting predictive maintenance strategies. As automation and digitalization continue across semiconductor fabs and cleanroom environments, smart seal adoption is expected to rise rapidly.

Although firm market data is limited, industry forecasts suggest the broader ferrofluidic seal market reached around USD 200 million in 2024, trending toward USD 400 million by 2033 at roughly 8-9% CAGR.

Several manufacturers and research groups are developing self diagnostic ferrofluid seals that can report wear, viscosity changes, or seal gap anomalies-minimizing unexpected downtime in semiconductor processing and vacuum instrument applications.

2. Biocompatible, Low VOC Ferrofluids

Environmental regulations in regions like Europe and Asia are increasingly restrictive regarding volatile organic compounds (VOCs) and chemical toxicity in industrial fluids. In response, major suppliers are formulating ferrofluids that are biodegradable, less volatile, and compatible with strict cleanroom and medical standards.

These eco friendly variants typically use ester based or water based carrier fluids, reducing vapor pressure and potential emissions while maintaining sealing performance. Compared to traditional hydrocarbon or fluorocarbon ferrofluids, they offer lower odor, improved human and environmental safety, and better chemical stability.

Early adoption is occurring in European semiconductor fabs, medical research instruments, and bio pharmaceutical equipment, where sustainability credentials and contamination control are priorities.

3. Underlying Drivers Beyond CAGR

Beyond raw growth rates, these trends reflect deeper shifts in industry dynamics:

• Industry 4.0 integration: connected sealing systems support automated diagnostics and maintenance in smart factories.

• Precision and miniaturization: smaller fabs and optical systems demand seals with tighter tolerances and more stable performance under variable operating conditions.

• Regulatory pressure: semiconductor and biotech industries increasingly require materials free from micro contaminants or toxic residuals, reinforcing demand for cleaner ferrofluids.

• Cost and reliability: sensor enabled seals are reducing mean time between failures (MTBF) by enabling early detection of degradation, which helps control maintenance costs even when the initial seal unit cost is higher.

4. Market Outlook - Emerging Focus Areas

Looking forward through 2025 and beyond, we expect:

• Smart-seal-enabled maintenance contracts: OEMs offering maintenance-as-a-service based on sensor feedback.

• Standardization initiatives: industry groups defining protocols for sensor data, ferrofluid chemistries, and environmental safety levels.

• Cross-sector technology transfer: innovations in medical/sensor-safe ferrofluids spreading to aerospace, robotics, and semiconductor sectors.

Recent Company Highlights

Ferrotec Corporation, the global leader in ferrofluidic sealing systems, expanded its high-tech manufacturing presence by breaking ground on a second production facility in Malaysia in early 2025. The move is set to increase capacity for high-temperature sealing solutions used in advanced GaN semiconductor fabrication.

Edwards Vacuum and Pfeiffer Vacuum have also announced innovations in flange-mounted magnetic seals, optimizing performance in ultra-high-vacuum deposition systems for photovoltaic and display applications.

Verified Downstream Customers (End Users) of Industrial Magnetic Fluid Sealing Systems

The following companies are confirmed end users deploying ferrofluidic / magnetic fluid sealing systems in their equipment or operations:

• Applied Materials

• Ferrotec Corporation

• Eagle Industry Co., Ltd.

• Rigaku Corporation

• Edwards Vacuum

• Pfeiffer Vacuum

• MKS Instruments

• Oxford Instruments

• Shimadzu Corporation

• Beijing Yanshan Petrochemical

• Trivac Vacuum Technology

• Kurt J. Lesker Company

• Sumitomo Heavy Industries

• Ulvac Technologies

• Photonics and Optical Coating Fabs

Request for Pre-Order Enquiry On This Report https://www.qyresearch.com/customize/4806260

Regional Insights

The Asia-Pacific region is expected to remain the dominant market through 2031, followed by Europe and North America. China, Japan, and South Korea will drive the majority of new installations, particularly in semiconductor fabs and precision optics production lines.

Market Outlook

With continued technological innovation and increased application in high-precision industries, Industrial Magnetic Fluid Sealing Systems are poised for significant expansion through 2031. The combination of performance reliability, environmental compliance, and the emergence of sensor-enabled solutions presents new opportunities for both established players and emerging suppliers.

Contact Information:

Tel: +1 626 2952 442 ; +351 914374211(Tel & Whatsapp); +86-1082945717

Email: qinyue@qyresearch.com; global@qyresearch.com

Website: www.qyresearch.com

About QY Research

QY Research has established close partnerships with over 71,000 global leading players. With more than 20,000 industry experts worldwide, we maintain a strong global network to efficiently gather insights and raw data.

Our 36-step verification system ensures the reliability and quality of our data. With over 2 million reports, we have become the world's largest market report vendor. Our global database spans more than 2,000 sources and covers data from most countries, including import and export details.

We have partners in over 160 countries, providing comprehensive coverage of both sales and research networks. A 90% client return rate and long-term cooperation with key partners demonstrate the high level of service and quality QY Research delivers.

More than 30 IPOs and over 5,000 global media outlets and major corporations have used our data, solidifying QY Research as a global leader in data supply. We are committed to delivering services that exceed both client and societal expectations.

Chapter Outline:

Chapter 1: Introduces the report scope of the report, executive summary of different market segments (by region, product type, application, etc), including the market size of each market segment, future development potential, and so on. It offers a high-level view of the current state of the market and its likely evolution in the short to mid-term, and long term.

Chapter 2: key insights, key emerging trends, etc.

Chapter 3: Manufacturers competitive analysis, detailed analysis of the product manufacturers competitive landscape, price, sales and revenue market share, latest development plan, merger, and acquisition information, etc.

Chapter 4: Provides profiles of key players, introducing the basic situation of the main companies in the market in detail, including product sales, revenue, price, gross margin, product introduction, recent development, etc.

Chapter 5 & 6: Sales, revenue of the product in regional level and country level. It provides a quantitative analysis of the market size and development potential of each region and its main countries and introduces the market development, future development prospects, market space, and market size of each country in the world.

Chapter 7: Provides the analysis of various market segments by Type, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different market segments.

Chapter 8: Provides the analysis of various market segments by Application, covering the market size and development potential of each market segment, to help readers find the blue ocean market in different downstream markets.

Chapter 9: Analysis of industrial chain, including the upstream and downstream of the industry.

Chapter 10: The main points and conclusions of the report.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial Magnetic Fluid Sealing Systems Market to Hit USD 1.24 Billion by 2031 at 14.3% CAGR, Led by Ferrotec and Leybold here

News-ID: 4127223 • Views: …

More Releases from QYResearch Europe

Global Aerospace Grade Smart Assembly Lines Market 2024 USD 4251 Million to 2031 …

According to recent report from QYResearch, the global market for aerospace-grade smart assembly lines stood at US$4,251 million in 2024 and is projected to reach US$8,712 million by 2031 at a 10.2% CAGR (2025-2031). In 2024, approximately 670 lines were produced globally at an average selling price (ASP) of about US$6.343 million per line. These highly automated systems integrate AI, industrial robotics, advanced sensing, and digital control to deliver repeatable,…

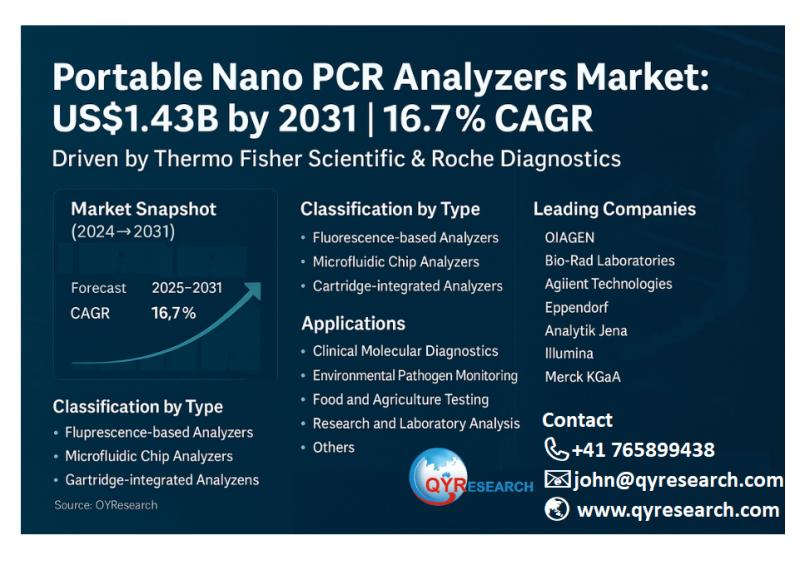

Portable Nano PCR Analyzers Market Growth to US$1.43 Billion by 2031 with 16.7% …

According to the latest QYResearch Report, the global market for Portable Nano PCR Analyzers was valued at US$484 million in 2024 and is expected to reach US$1,427 million by 2031, growing at a CAGR of 16.7% during the forecast period of 2025-2031. Global production in 2024 reached around 96,800 units, with an average price of about US$5,000 per unit. These portable devices utilize nanotechnology-enhanced PCR processes for rapid on-site genetic…

Global Multiphase Flow Conveying Equipment Market to Reach USD 10.88 Billion by …

The global market for Multiphase Flow Conveying Equipment is transitioning from a specialized engineering niche to a core enabler of industrial efficiency across upstream energy, chemicals, mining, and wastewater sectors. According to QYResearch 2025 edition of Multiphase Flow Conveying Equipment - Global Market Share and Ranking, Overall Sales and Demand Forecast 2025-2031, the market was valued at US$7,380 million in 2024 and is projected to reach US$10,879 million by 2031,…

Global Smart Eye-Tracking Medical Devices Market Size Reaches US$3.0 Billion by …

The global Smart Eye-Tracking Medical Devices market has entered a stage of accelerated clinical adoption and product diversification. According to QYResearch 2025 Global Smart Eye-Tracking Medical Devices Market Research Report, the market was valued at US$973 million in 2024 and is projected to reach US$3,009 million by 2031, growing at a CAGR of 17.5% from 2025 to 2031. Global output in 2024 reached approximately 64,900 units, with an average price…

More Releases for Vacuum

Semiconductor Screw Vacuum Pump Market Industry Trends - Atlas Copco (Edwards Va …

MarketQuest.biz proclaims the addition of another new report titled Global Semiconductor Screw Vacuum Pump Market which is a well-synchronized synopsis of the market. The report offers broad insights extracted by thoroughly analyzing historical and current developments in the market. The report outlines the distinguishable players in the global Semiconductor Screw Vacuum Pump market with a clear-cut end goal to give an intelligent standpoint of the forces of the market, while…

Roots Vacuum Pumps Market SWOT Analysis by Key Players: Pfeiffer, Leybold, ANLET …

Roots vacuum pumps, or vacuum boosters, are dry vacuum pumps that are used together with backing pumps in a wide range of applications where large pumping speeds are required. Vacuum boosters operate completely contact-free and without sealing fluids such as oil or water in the working chamber, although with most models the two gearwheels of the synchromesh gearing and the bearings for the impeller shafts are lubricated with oil. Some…

Vacuum Coating Machines Market 2018 Global Key Country Analysis: Denton Vacuum, …

Vendor Landscape

Tetra Technologies, Inc., (U.S.), BP P.L.C. (U.K.), Statoil ASA (Norway), DNV GL (Norway), TechnipFMC PLC (U.K.), AF Gruppen ASA (Norway), Ramboll Group A/S (Denmark), and Aker Solutions ASA (Norway) are some of the key companies operating in the market. Amec Foster Wheeler (U.K.), John Wood Group Plc. (Scotland), Claxton Engineering Services (U.K.), Allseas group SA (Switzerland), and DeepOcean Group (Netherlands) among others.

Market Research Future’s (MRFR) latest study reveals that…

Global Rotary Vane Vacuum Pumps Market- Pfeiffer Vacuum, Tuthill, Osaka Vacuum, …

Global Rotary Vane Vacuum Pumps Market report 2017 is an in-depth research on the current situation of the Rotary Vane Vacuum Pumps industry.

The Scope of the Rotary Vane Vacuum Pumps research report:

The Global Rotary Vane Vacuum Pumps Market primarily includes a basic overview of the Rotary Vane Vacuum Pumps industry. It also includes Rotary Vane Vacuum Pumps definitions, classifications and applications. It segments the market by applications, types, regions, competitive…

Metallurgical High Vacuum Announces High Vacuum Newsletter

Fennville, MI---Metallurgical High Vacuum has created a new “High Vacuum News” to provide heat treat industry professionals with tips and hints to keep their vacuum pumps running strong.

As Geoff Humberstone, MHV President, comments: “This year marks 30 years for us as Metallurgical High Vacuum. Back in 1981, I saw the need for vacuum design and consulting and started the company. Within four years we added pump remanufacturing because we…

Metallurgical High Vacuum Ships Vacuum Chambers (Corrected)

Special Designs are Built to Customer Specifications

Fennville, MI--- Metallurgical High Vacuum recently shipped two chambers for customer-specific applications. One vacuum chamber is over 72” high and will be used in P E. Chemical Vapor Deposition. The other chamber is a 12-inch square design that will be used to weld silicon sticks, complete with a two-stage booster vacuum pumping system. Both chambers are built of type 304 stainless steel for…