Press release

Aluminum Foam Market Soars to USD 73.4 Million by 2035, Driven by Lightweighting and Safety Innovations

The global aluminum foam market is set for robust expansion, projected to reach an impressive valuation of USD 73.4 million by 2035, up from USD 47.4 million in 2025, demonstrating a Compound Annual Growth Rate (CAGR) of 4.5%. This significant growth is primarily fueled by the accelerating demand for lightweight, high-performance materials across critical industries, particularly automotive and aerospace, where reducing carbon emissions and enhancing safety are paramount.Aluminum foam, a revolutionary material renowned for its exceptional strength-to-weight ratio and superior energy absorption capabilities, is increasingly being integrated into diverse applications. From bumpers and crash barriers in vehicles to advanced battery enclosures and sophisticated sound-dampening solutions, its unique properties are proving indispensable.

Dive Deeper into the Data-View the Full Report Here!

https://www.futuremarketinsights.com/reports/aluminum-foam-market

Market Dynamics: A Snapshot of Growth

The market's upward trajectory is further propelled by stringent global regulatory pressures emphasizing fuel efficiency and passenger safety. However, the high cost of production remains a notable hurdle, particularly in price-sensitive regions and for certain applications. Continuous efforts in material optimization and supply chain efficiency are underway to mitigate these cost constraints and unlock broader market penetration.

Looking ahead, the market stands to gain significantly from breakthroughs in production techniques such as powder metallurgy and 3D printing, which promise more efficient and customizable manufacturing processes. Moreover, aluminum foam's inherent recyclability aligns seamlessly with global sustainability objectives, making it a preferred choice for eco-friendly building constructions and the rapidly expanding electric vehicle sector.

Market Comparison: A Glimpse at Regional and Segment Performance

While the global aluminum foam market is growing steadily, a closer look reveals varied growth rates across different segments and regions. The overall CAGR from 2025 to 2035 stands at 4.5%.

A semi-annual market update indicates dynamic shifts. The first half of the decade from 2024 to 2034 is projected to see a CAGR of 4.3%, followed by a slightly higher 4.7% in the second half. For the 2025 to 2035 period, the CAGR is expected to be 3.6% in H1, followed by a more robust 5.4% in H2. This indicates a decrease of 70 basis points (BPS) in H1 and an increase of 70 BPS in H2 compared to the previous semi-annual period.

In terms of product type, open-cell foam is poised to dominate, capturing an impressive 46.3% market share by 2035. This is attributed to its superior sound absorption and structural support capabilities, making it highly sought after in automotive, construction, and packaging industries. Companies such as Alcoa, Henkel, and Exco Technologies are key players in this segment.

The energy absorption segment is projected to exhibit the highest CAGR of 5.6% from 2025 to 2035. This surge is fueled by the escalating demand for high-performance materials in automotive crash protection systems, aerospace, and military technologies, where effective energy dissipation is critical. Leading companies in this domain include ArcelorMittal, Aerospace Manufacturing, and Hawke Aerospace.

Competitive Landscape

The aluminum foam market is characterized by a moderately fragmented landscape, with Tier 1 companies like Cymat Technologies Ltd., American Elements Corporation, and ERG Aerospace Corp. leading the way with extensive R&D and broad product portfolios. Tier 2 players, including Composite Materials Ltd. and Hollomet GmbH, focus on regional presence and niche applications, while Tier 3 companies such as VIM Technology Ltd. and Nanoshel LLC cater to specialized or custom-grade foam demands.

Recent Industry Developments

Cymat's launch of "AluCell X" for enhanced energy absorption and ERG Aerospace's certification for sandwich panels in regional jets exemplify the ongoing commitment to innovation. Aluinvent's grants for pilot façade panels and Nanoshel's high-surface-area foam for thermal storage devices showcase the material's expanding utility. Furthermore, partnerships like American Elements with Composite Materials Ltd. to co-develop acoustic-grade foams demonstrate a concerted effort to meet evolving industry needs.

Aluminum Foam Market Segmentation

By Product Type:

The aluminum foam market is categorized into different product types, including open-cell foam, closed-cell foam, and others.

By Application Type:

In terms of application, aluminum foam is used in various sectors such as energy absorption, heat exchangers, damping structures, filtration, insulation, and other applications.

By End-Use Industry:

The market also sees demand from several end-use industries, including automotive & transportation, aerospace & defense, building & construction, chemical industries, and other industrial sectors.

By Region:

Key Countries of North America, Latin America, East Asia, South Asia & Pacific, Western Europe, Eastern Europe and Middle East & Africa are covered.

Explore Opportunities - Get Your Sample of Our Industry Overview Now!

https://www.futuremarketinsights.com/reports/sample/rep-gb-8402

Have a Look at Related Research Reports on the Packaging Domain:

MOPP Packaging Films Market - https://www.futuremarketinsights.com/reports/mopp-packaging-films-market

Plastic Corrugated Sheets Market - https://www.futuremarketinsights.com/reports/plastic-corrugated-sheets-market

Edible Oil Packaging Market - https://www.futuremarketinsights.com/reports/edible-oil-packaging-market

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Foam Market Soars to USD 73.4 Million by 2035, Driven by Lightweighting and Safety Innovations here

News-ID: 4117917 • Views: …

More Releases from Future Market Insights Inc

Procurement & Supply Assurance Models for PCR Material Market to Reach USD 5,620 …

The global procurement & supply assurance models for PCR material market is projected to expand significantly over the next decade, increasing from USD 1,540.0 million in 2026 to USD 5,620.0 million by 2036, registering a CAGR of 13.8%, according to the latest analysis by Future Market Insights (FMI). Growth is being driven by increasing complexity in recycled material sourcing, rising procurement risk exposure, and the growing need for structured assurance…

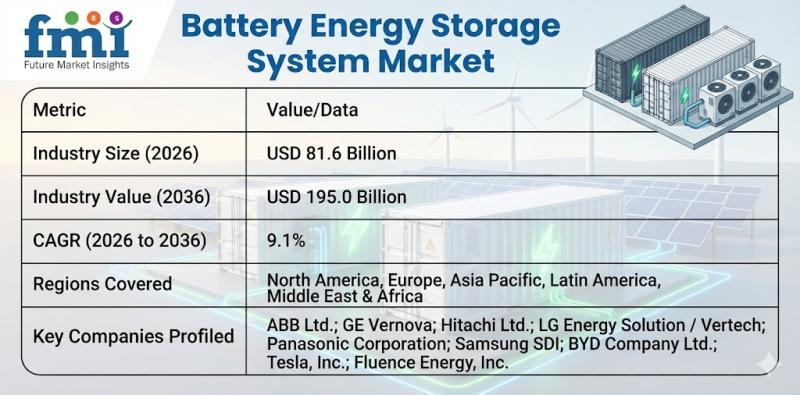

Global Battery Energy Storage System Market Forecast 2026-2036: Rapid Grid Moder …

The global battery energy storage system (BESS) market is projected to grow significantly over the next decade, expanding from USD 81.6 billion in 2026 to USD 195.0 billion by 2036, registering a CAGR of 9.1%, according to the latest analysis by Future Market Insights (FMI). Market expansion is being fueled by increasing renewable energy deployment, grid modernization programs, and growing demand for flexible power management solutions across utilities, commercial facilities,…

Gemstone Market Outlook 2026-2036: Industry to Reach USD 72.8 Billion by 2036 at …

The global gemstone market is projected to expand from USD 38.4 billion in 2026 to USD 72.8 billion by 2036, registering a CAGR of 6.6%, according to the latest analysis by Future Market Insights (FMI). Growth is increasingly driven by value concentration rather than pure volume expansion, as industry players prioritize provenance verification, ethical sourcing, and performance differentiation across natural and synthetic gemstone categories.

Demand momentum reflects a structural divergence between…

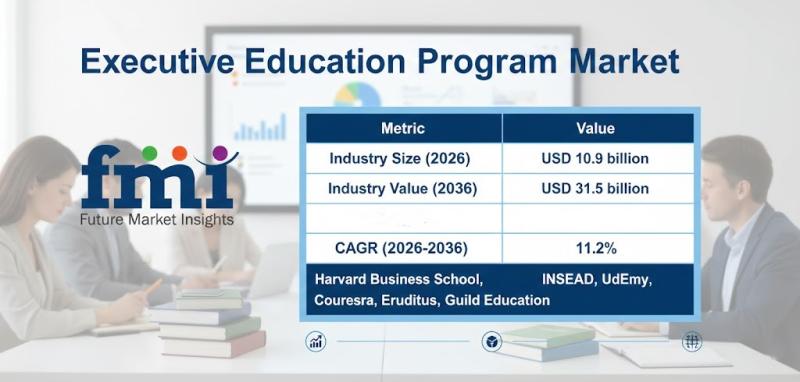

Global Executive Education Program Market Forecast 2026-2036: AI-Driven Learning …

The global executive education program market is projected to grow robustly over the next decade, expanding from USD 10.9 billion in 2026 to USD 31.5 billion by 2036, registering a CAGR of 11.2%. According to the latest analysis by Future Market Insights (FMI), growth is driven by the structural shift toward continuous workforce upskilling, enterprise-funded customized programs, and the integration of generative AI into learning delivery systems.

Traditional, campus-centric executive programs…

More Releases for Aluminum

New Aluminum Material-Aluminum Foam Application Summary

Aluminum Foam [https://www.beihaicomposite.com/aluminum-foam-tag/] Characteristics

Ultra-lightness

The density is 0.2~0.4g/cm3, which is about 1/10 of the density of aluminum, 1/20 of the density of titaNium, 1/30 of the density of steel, 1/30 of the density of steel, and 1/3 of the density of wood.

Sound Absorbability

Aluminum foam [https://www.beihaicomposite.com/about-us/] can be used to muffle and reduce noise by absorbing sound energy through the vibration of the pores' walls.

Heat resistance

It has high heat resistance; the general…

5083 medium-thick aluminum plate 5083 marine aluminum plate 5083 automotive alum …

5083 aluminum plate(https://www.mingtai-al.com/5083-Aluminum-Sheet.html) is a typical aluminum-magnesium alloy with light weight and high strength. With its excellent performance, it can be widely used in many industries such as automobile manufacturing, shipbuilding and rail transportation. With the vigorous development of lightweight, the demand for 5083 medium-thick aluminum plate in aluminum tank trucks and marine aluminum plates has increased.

5083 medium-thick aluminum plate-5083 marine aluminum plate-5083 automotive aluminum plate manufacturer introduction

In recent years,…

Yocon Aluminum Announces Availability of 3003 Aluminum Coil

Yocon Aluminum, a leading supplier of aluminum coil products in China, today announced the availability of 3003 aluminum coil. The company's new product is made from high-quality, mill-finished 3003 alloy and features excellent formability, weldability, and corrosion resistance. It is ideally suited for a wide range of applications in the transportation, construction, and industrial markets. With its outstanding properties, 3003 aluminum coil is quickly becoming a preferred choice for customers…

Yocon Aluminum china factory offers 3003 Aluminum Coil

Yocon Aluminum china factory is proud to offer 3003 aluminum coil. This high-quality product is perfect for a variety of applications, and we are confident that you will be satisfied with its performance. We are committed to providing our customers with the best products and services possible, and we look forward to helping you meet your needs. Contact us today to learn more about our 3003 aluminum coil!

In an effort…

Yocon Aluminum Supplies Aluminum Foil Coils for Major Appliances

Yocon Aluminum, a leading manufacturer and supplier of aluminum foil coils, has announced that they are now supplying major appliance manufacturers with their high-quality aluminum foil coils. With over forty years of experience in the industry, Yocon Aluminum is known for their dedication to quality and customer satisfaction. Their products are used in a variety of applications, including air conditioners, refrigerators, and freezers. When it comes to choosing a supplier…

Aluminum Frp Market Size, Status and Global Outlook 2021-Shandong Nanshan Alumin …

The MarketInsightsReports has published the obtainability of a new statistical data to its repository titled as, Aluminum Frp market. The comprehensive report provides useful insights into Market growth, revenue, and market trends, in order to enable readers to gauge market scope more proficiently. Furthermore, the report also sheds light on recent developments and platforms, in addition to distinctive tools, and methodologies that will help to propel the performance of industries.…