Press release

Discover the Superiority of Silicon Carbide Bricks for Business Industrial Needs

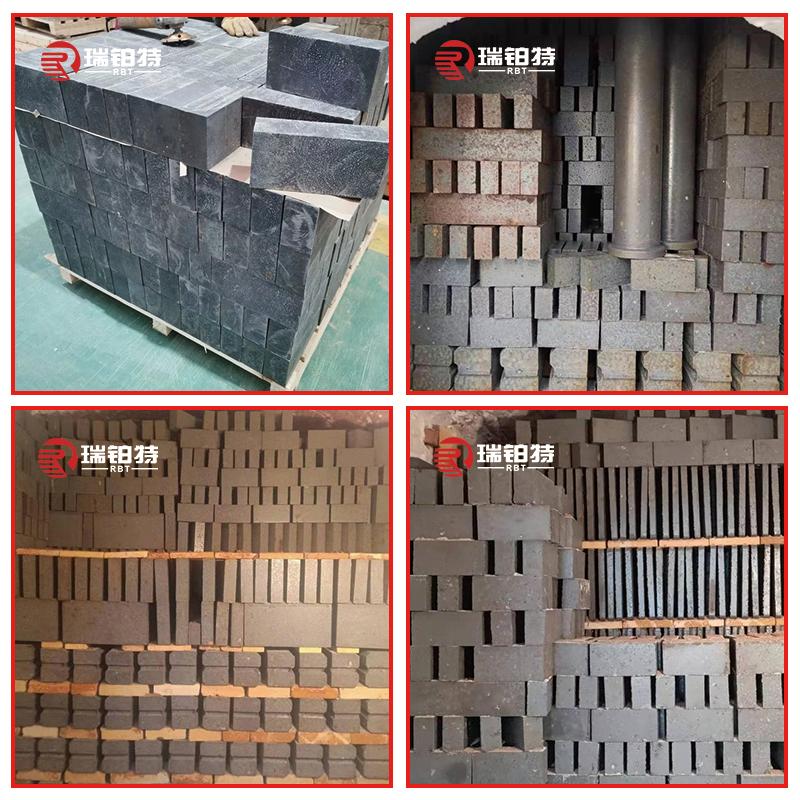

Image: https://www.sdrobert.com/uploads/55_014.jpgIn the realm of modern industry, where high - temperature operations are the norm, the choice of refractory materials can significantly impact the efficiency, durability, and cost - effectiveness of production processes. Silicon carbide bricks have emerged as a leading solution, offering a unique combination of properties that make them indispensable in a wide range of applications.

Exceptional Physical and Chemical Properties

High Hardness and Abrasion Resistance

Silicon carbide bricks boast a remarkable Mohs hardness of 9, which is close to that of a diamond. This high hardness enables them to withstand severe abrasion from high - velocity particles, molten materials, and mechanical scrubbing. In industries such as mining, metallurgy, and cement production, where equipment is constantly exposed to abrasive substances, the use of silicon carbide bricks can greatly extend the service life of furnace linings, ducts, and other critical components. For example, in cement kilns, the abrasive nature of the raw materials and the high - temperature environment can cause rapid wear of traditional refractory materials. Silicon carbide bricks, with their outstanding abrasion resistance, can endure these harsh conditions, reducing the frequency of maintenance and replacement, and ultimately lowering production costs.

Outstanding Thermal Conductivity

One of the key features of silicon carbide bricks is their high thermal conductivity. This property allows for efficient heat transfer within industrial furnaces and reactors. In applications where rapid heating and cooling cycles are required, such as in the semiconductor manufacturing process for annealing and sintering, silicon carbide bricks can quickly transfer heat to the workpiece, ensuring uniform temperature distribution. As a result, the production process becomes more efficient, and the quality of the final product is improved. In addition, the high thermal conductivity of silicon carbide bricks also helps to reduce energy consumption. By enabling faster heat transfer, less energy is wasted in the form of heat loss, leading to significant savings in energy costs over time.

Excellent Thermal Stability

Silicon carbide bricks can maintain their structural integrity and mechanical properties at extremely high temperatures, up to 1800 degrees C (3272 degrees F) in some cases. This exceptional thermal stability makes them suitable for use in high - temperature furnaces, such as those used in the production of steel, non - ferrous metals, and glass. In a steel - making furnace, for instance, the lining needs to withstand the intense heat of molten steel and the continuous thermal cycling during the production process. Silicon carbide bricks can endure these conditions without significant deformation or degradation, providing reliable protection for the furnace shell and ensuring smooth production operations.

Superior Chemical Resistance

These bricks exhibit excellent resistance to both acidic and alkaline substances. In chemical industries, where corrosive chemicals are used in large quantities, silicon carbide bricks can be used to line reactors, storage tanks, and pipelines. They can effectively resist the corrosion of various acids, alkalis, and salts, preventing leaks and ensuring the safe operation of the equipment. For example, in the production of fertilizers, where strong acids and alkalis are involved in the manufacturing process, silicon carbide bricks offer long - lasting protection against chemical corrosion, reducing the risk of equipment failure and environmental pollution.

Diverse Applications Across Multiple Industries

1. Metallurgical Industry

Steelmaking: In the steel - making process, silicon carbide bricks are used in electric arc furnaces, ladles, and tundishes. Their high thermal conductivity helps in quickly heating and melting the steel, while their excellent resistance to molten steel and slag erosion ensures the longevity of the furnace lining. This not only improves the efficiency of steel production but also reduces the need for frequent relining, which is a time - consuming and costly process.

Non - ferrous Metal Smelting: For the smelting of metals such as aluminum, copper, and zinc, silicon carbide bricks are also widely applied. In aluminum smelting, for example, the bricks are used in electrolytic cells and holding furnaces. Their resistance to the corrosive effects of molten aluminum and its associated salts, along with their high thermal stability, makes them an ideal choice for maintaining the integrity of the smelting equipment and ensuring a consistent production process.

2. Ceramic and Glass Industry

Ceramic Manufacturing: In ceramic kilns, silicon carbide bricks are used as kiln furniture, including shelves, supports, and saggers. Their high strength at elevated temperatures allows them to bear the weight of ceramic products during firing, while their good thermal conductivity ensures uniform heating of the ceramics. This results in high - quality ceramic products with consistent color and texture. Moreover, the long service life of silicon carbide kiln furniture reduces the cost of replacement and downtime in ceramic production.

Glass Production: In glass furnaces, silicon carbide bricks are used in the areas where high - temperature and corrosive environments are present, such as the combustion chamber and the glass - melting zone. They can withstand the high - temperature molten glass and the corrosive action of glass - forming chemicals, providing reliable insulation and protection for the furnace structure. This helps to improve the efficiency of glass melting and the quality of the glass produced.Power Generation and Waste Incineration.

Power Plants: In coal - fired power plants, silicon carbide bricks are used in boilers and ash - handling systems. They can resist the abrasion of fly ash and the high - temperature combustion environment, enhancing the reliability and efficiency of power generation equipment. In addition, in biomass - fired power plants, where the combustion of biomass produces corrosive gases and ash, silicon carbide bricks offer excellent resistance to these harsh conditions, ensuring the stable operation of the power plant.

Waste Incineration Plants: Waste incineration involves high - temperature combustion of various waste materials, which can produce highly corrosive gases and ash. Silicon carbide bricks are used in the lining of incinerators to withstand these extreme conditions. Their chemical resistance protects the incinerator walls from corrosion, while their high - temperature stability ensures the safe and efficient operation of the waste incineration process.

Image: https://www.sdrobert.com/uploads/%E7%94%A8%E9%80%94_012.jpg

Choosing the Right Silicon Carbide Bricks for Your Needs

When selecting silicon carbide bricks for your industrial application, several factors need to be considered:

Purity and Composition

The purity of silicon carbide in the bricks affects their performance. Higher - purity silicon carbide bricks generally offer better thermal conductivity, chemical resistance, and mechanical strength. For applications where extreme conditions are present, such as in high - temperature, highly corrosive environments, high - purity silicon carbide bricks are recommended. Additionally, the type of binder used in the brick manufacturing process can also impact its properties. Different binders, such as clay, nitride, or sialon, provide different levels of strength, thermal shock resistance, and chemical resistance.

Manufacturing Process and Quality Control

Choose bricks that are manufactured using advanced and reliable processes. A well - controlled manufacturing process ensures consistent quality in terms of brick dimensions, density, and mechanical properties. Look for manufacturers who adhere to international quality standards, such as ISO 9001. Quality control measures, including strict inspection of raw materials, in - process monitoring, and final product testing, are essential to ensure that the silicon carbide bricks meet the required specifications.

Customization Options

Depending on your specific application, you may require silicon carbide bricks in non-standard shapes or sizes. As a manufacturer, Robert can offer customization services to meet your unique needs. Custom-made bricks can be designed to fit precisely into your equipment, optimizing their performance and ensuring a perfect fit in your industrial setup. In conclusion, silicon carbide bricks are a versatile and high - performance refractory material that can significantly enhance the efficiency and durability of industrial operations. Whether you are in the metallurgical, ceramic, glass, power generation, or waste incineration industry, considering silicon carbide bricks for your high - temperature applications can lead to substantial savings in terms of maintenance, energy consumption, and production downtime. Explore the possibilities of silicon carbide bricks today and take your industrial processes to the next level of excellence.

Image: https://www.sdrobert.com/uploads/44_012.jpg

Media Contact

Company Name: Shandong Robert New Material Co., Ltd.

Email:Send Email [https://www.abnewswire.com/email_contact_us.php?pr=discover-the-superiority-of-silicon-carbide-bricks-for-your-industrial-needs]

Phone: +86 15666531308

Address:10/F, Building A, Zibo New Material Trading Center, Zhangdian, Zibo, Shandong

Country: China

Website: https://www.sdrobert.com/

Legal Disclaimer: Information contained on this page is provided by an independent third-party content provider. ABNewswire makes no warranties or responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you are affiliated with this article or have any complaints or copyright issues related to this article and would like it to be removed, please contact retract@swscontact.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Discover the Superiority of Silicon Carbide Bricks for Business Industrial Needs here

News-ID: 4117111 • Views: …

More Releases from ABNewswire

Post-Construction Cleaning Demand Rises Among Miami Renovators as The Prime Clea …

Miami homeowners and contractors are driving increased demand for professional post-construction cleaning services, with The Prime Cleaner reporting significant growth in this specialty category across South Florida.

MIAMI, FL - Demand for professional post-construction cleaning services is rising across Miami as homeowners complete renovations and contractors seek reliable cleaning partners for new builds. The Prime Cleaner has expanded its post-construction cleaning services [https://www.theprimecleaner.com/service/post-construction-cleaning] to meet the growing need.

Miami's construction and renovation…

Extending the Invisible Cord: Why Bluetooth Repeaters Are Essential for Seamless …

We live in a wireless world. Our headphones, keyboards, speakers, and even our lightbulbs connect via Bluetooth, freeing us from the tangle of cables. Yet, despite its convenience, Bluetooth has a wellknown limitation: range. The connection between a device and its source-whether it's a phone streaming music or a sensor reporting data-can stretch only so far before it stutters and drops. For homes, offices, and industrial facilities, these dead zones…

Beyond GPS: How Bluetooth Beacons Are Bridging the Gap Between Digital and Physi …

In an era dominated by GPS, it is easy to assume we have solved the problem of location tracking. We can navigate bustling cities, track lost phones, and find the nearest coffee shop with pinpoint accuracy-provided we are outside. But the moment we step indoors, the satellite signals fade, leaving a blind spot in our connected experiences.

This is where a small, unassuming piece of technology is making a massive impact:…

ECI Jewelers Introduces Streamlined Selling Experience with Same-Day Offers and …

ECI Jewelers has enhanced its luxury watch and jewelry buying service with same-day market-based offers and instant payment options for sellers nationwide. The concierge-style approach includes free valuations, full insurance coverage during transit, and expert assessment from the company's New York City Diamond District location, simplifying the selling process for owners of premium timepieces from brands like Rolex, Patek Philippe, and Audemars Piguet.

Elegant Creations Inc, operating as ECI Jewelers, has…

More Releases for Silicon

Silicon Carbide Ceramics and Silicon Nitride Ceramics

Overview of Silicon Carbide Ceramics [https://www.rbsic-sisic.com/wear-resistant-silicon-carbide-ceramic-tiles-3.html]

Silicon carbide ceramics are a new type of ceramic material made mainly from silicon carbide powder through high-temperature sintering. Silicon carbide ceramics have high hardness, wear resistance, corrosion resistance, and excellent high temperature resistance, with excellent mechanical, thermal, and electrical properties. Silicon carbide ceramics can be divided into compacted sintered silicon carbide ceramics and reaction sintered silicon carbide ceramics due to different firing processes.

Overview of…

High Purity Silicon Metal Market Growth Forecast: Latest Research Unveils Opport …

Global High Purity Silicon Metal Market Overview:

Global High Purity Silicon Metal Market Report 2022 comes with the extensive industry analysis by Introspective Market Research with development components, patterns, flows and sizes. The report also calculates present and past market values to forecast potential market management through the forecast period between 2022-2028.

This research study of High Purity Silicon Metal involved the extensive usage of both primary and secondary data sources. This…

Future Prospects of Silicon Rings and Silicon Electrodes for Etching Market by …

The Silicon Rings and Silicon Electrodes for Etching Market research report provides all the information related to the industry. It gives the outlook of the market by giving authentic data to its client which helps to make essential decisions. It gives an overview of the market which includes its definition, applications and developments and manufacturing technology. This Silicon Rings and Silicon Electrodes for Etching market research report tracks all the…

Silicon Metal Market Global Outlook 2021-2026: Ferroglobe, Mississippi Silicon, …

The Global Silicon Metal Market Research Report 2021-2026 is a valuable source of insightful data for business strategists. It provides the industry overview with growth analysis and historical & futuristic cost, revenue, demand, and supply data (as applicable). The research analysts provide an elaborate description of the value chain and its distributor analysis. This Market study provides comprehensive data which enhances the understanding, scope, and application of this report.

The market…

Global Solar Grade Multi-Crystal Silicon Market Leading Major Players – GCL-Po …

Researchmoz added Most up-to-date research on "Global (United States, European Union and China) Solar Grade Multi-Crystal Silicon Market Research Report 2019-2025" to its huge collection of research reports.

The Solar Grade Multi-Crystal Silicon market report [6 Year Forecast 2019-2025] focuses on Major Leading Industry Players, providing info like company profiles, product type, application and regions, production capacity, ex-factory price, gross margin, revenue, market share and speak to info. Upstream raw materials…

Silicon Metal Market 2018: Top Key Players H.C. Starck, Elkem, Zhejiang Kaihua Y …

Silicon Metal Market Status and Forecast 2025

This Write up presents in detail analysis of Silicon Metal Market especially market drivers, challenges, vital trends, standardization, deployment models, opportunities, future roadmap, manufacturer’s case studies, value chain, organization profiles, Sales Price and Sales Revenue, Sales Market Comparison and strategies.

The Silicon Metal market Report provides a detailed analysis of the Silicon Metal industry. It provides an analysis of the past 5 years and a future forecast till the year…