Press release

New UV-adhesive for Bonding Elastomeric Materials

Techsil presents a new solvent free UV-adhesive from German manufacturers Panacol. Vitralit® VBB-2N LV features low viscosity and is ideally suited for bonding elastomeric materials.Elastomeric materials and rubbers all differ in their polymer structure, polarity, and surface properties. This makes them very difficult to bond and there are drawbacks with using traditional adhesive systems. Cyanoacrylates offer an easy bonding solution, but have decisive drawbacks; they become brittle quickly and exhibit a very low impact strength. Solvents and solvent evaporation can be hazardous in the workplace making solvent based adhesives an undesirable method to use.

Techsil’s UV curing acrylates are specially formulated for bonding rubbers. They are solvent-free, simple to dispense, and are easily integrated into existing production processes. They cure within seconds under UV or visible light and are therefore the perfect choice for high volume production in manual or automated production lines. Bond lines are invisible, and the rubber adhesives demonstrate excellent bond strength on a great variety of elastomer blends.

Due to its extremely low viscosity Vitralit® VBB-2N LV is suitable for large area bonding as well as applications where the gap size is very small. When cured, it demonstrates excellent flexibility and environmental stability. Vitralit® VBB-2N LV is a solvent-free transparent adhesive and provides very good adhesion to most elastomeric materials like TPE (Thermal Plastic Elastomer) and rubber (natural rubber latex, NBR, SBR etc).

If at least one assembly material is transparent, Vitralit® VBB-2N LV cures in seconds with UV-A light to produce a strong and reliable bond. UV-blocking materials like polycarbonate can be cured due to the adhesive’s ability to cure with visible light (>400nm). Both gas discharge lamps and LEDs are suitable for curing. Excellent curing results were achieved with the Hoenle 405nm Blue Point LED light available from Techsil.

For use in medical applications Techsil can provide an alternative product with similar properties that meets the requirements for USP Class VI and is compatible with sterilization by autoclaving, gamma irradiation and EtO.

For more information a technical datasheet or for a sample contact: technical@techsil.co.uk

About Techsil

Trading since 1989, UK based Techsil has grown into a global supplier of industrial RTV silicones, adhesives, sealants, encapsulants, conformal coatings, tapes, casting and mould making materials to a wide range of manufacturing industries including Aerospace, Automotive, Medical, Electronics, Packaging, LED Lighting and Rapid Prototyping.

About Panacol

Panacol-Elosol GmbH, a member of global Hoenle group, is an international supplier of adhesives with a broad product range that includes UV curable adhesives, structural adhesives, and conductive adhesives. Hoenle is a global technology leader and manufacturer of industrial UV curing devices and systems.

Techsil Limited

34 Bidavon Industrial Estate

Waterloo Road

Bidford on Avon

Warwickshire

B50 4JN

England

Tel: +44 1789 773232

Fax: +44 1789 774239

www.techsil.co.uk

technical@techsil.co.uk

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release New UV-adhesive for Bonding Elastomeric Materials here

News-ID: 411551 • Views: …

More Releases from Techsil Ltd

New Techsil Catalogue Published - Adhesives, Sealants, Coatings, O-Rings & Tapes

UK based Techsil is a global distributor of industrial adhesives, sealants, encapsulants, coatings tapes, seals, o-rings and dispensing equipment. Supplying high performance materials to manufacturing industries such as electronics, aerospace, automotive, defence, lighting, packaging and medical devices; Techsil work together with customers and suppliers to deliver technical and application knowledge. They have been awarded A1 distributor status two years running from Momentive for going the extra mile.

Techsil has just published…

The Future is Orange - Techsil Launch New Biocompatible Plastics Adhesive which …

Adhesive specialists Techsil introduce a new orange, fluorescing, UV curing adhesive designed for bonding plastics. Manufactured by Panacol, Vitralit® 7311 FO is certified according to USP Class VI standards. A perfect adhesive for medical devices but it can also be used in electronics, optics and general assembly.

Vitralit® 7311 FO is a transparent acrylic adhesive that cures under UV or visible light. It offers very high bond strength to many…

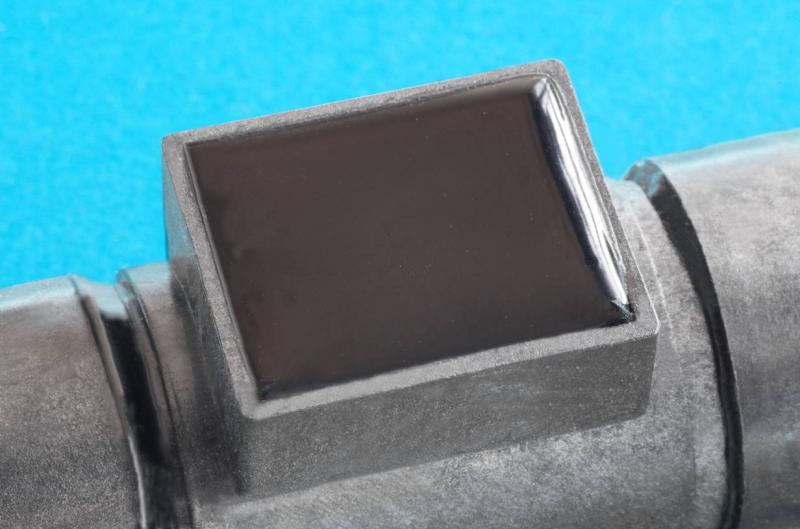

Techsil Launch New Optically Clear Flexible Adhesive for Bonding Displays

Adhesive suppliers, Techsil have launched a new optically clear, low viscosity, UV curable adhesive into the UK market. Manufactured by Panacol, Vitralit® 50004 is a one-component acrylic adhesive so it requires no mixing. The adhesive has been designed to use for bonding display screens and laminating optics.

Vitralit® 50004 adheres to a variety of substrates including coated glass, PET and other plastics and films. Its low viscosity means that it can…

New Epoxy Potting Compound with Excellent Flow Properties

UK adhesive specialists Techsil have launched a new potting compound for electronics with medium viscosity and small filler particle size: Structalit® 5894-1 is the perfect choice for large-volume potting or glob top sealing of power electronics.

Structalit® 5894-1 is a black, one part epoxy resin which requires no mixing. The combination of optimised viscosity and the small particle size of its fillers means it flows well and makes an excellent electrical…

More Releases for Elastomer

Evolving Market Trends In The Thermoplastic Elastomer Industry: Innovative Therm …

The Thermoplastic Elastomer Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Expected Thermoplastic Elastomer Market Size During the Forecast Period?

In the previous years, the thermoplastic elastomer market size has seen substantial growth. It is projected to expand from $28.67 billion in 2024…

Thermoplastic Elastomer Market Size And Forecast

𝐔𝐒𝐀, 𝐍𝐞𝐰 𝐉𝐞𝐫𝐬𝐞𝐲- Thermoplastic Elastomer Market size was valued at USD 26.70 Billion in 2021 and is projected to reach USD 41.78 Billion by 2030, growing at a CAGR of 5.1% from 2023 to 2030.

The thermoplastic elastomer (TPE) market has witnessed significant growth in recent years due to its versatility and the increasing demand for eco-friendly, high-performance materials across a wide range of industries. TPEs combine the elasticity of rubber…

Elastomer Mounts Market 2021 | Detailed Report

Global Elastomer Mounts Market 2021-2027, has been prepared based on an in-depth market analysis with inputs from industry experts. The report covers the market landscape and its growth prospects in the coming years. The report includes a discussion of the key vendors operating in this market. An exclusive data offered in this report is collected by research and industry experts team.

Get Free Sample PDF (including full TOC, Tables and Figures)…

Polyurethane Elastomer Market Insights, Forecast to 2025

Abstract

This report researches the worldwide Polyurethane Elastomer market size (value, capacity, production and consumption) in key regions like United States, Europe, Asia Pacific (China, Japan) and other regions.This study categorizes the global Polyurethane Elastomer breakdown data by manufacturers, region, type and application, also analyzes the market status, market share, growth rate, future trends, market drivers, opportunities and challenges, risks and entry barriers, sales channels, distributors and Porter’s Five Forces Analysis.

Polyurethane…

Spray Polyurea Elastomer Market -Analysis by Application 2025| Spray Polyurea El …

Global Spray Polyurea Elastomer Market: Overview

The global spray polyurea elastomer market is treading a growth path on the back of protective properties of spray polyurea elastomers. Spray polyurea elastomers offer higher anti-corrosion and abrasion protection than what is offered by regular protection systems such as paints and rubber linings. Spray polyurea elastomers are resilient as against chemically aggressive fluids that seek and exploit vulnerabilities in paint and rubber linings.

Request Sample…

Global Conductive Elastomer Gasket Market Research Report

Global Conductive Elastomer Gasket Market Research Report is a deep market research report in this market.

This report focused on global and regional market, major manufacturers, as well as the segment market details on different classifications and applications.

Get Sample Copy from here @ https://goo.gl/k8V81N

First, this report analyzed the basic scope of this industry like definition, specification, classification, application, industry policy and news in Chapter 1.

Second, the analysis on industry chain…