Press release

Global Semiconductor Fabrication Materials Market Poised for Near Double-Digit Growth, Reaching USD 99 Billion by 2035

The global market for semiconductor fabrication materials is on the cusp of unprecedented expansion, projected to surge from an estimated USD 53.2 billion in 2025 to a staggering USD 99.0 billion by 2035, exhibiting a robust Compound Annual Growth Rate (CAGR) of 6.4%. This remarkable growth is fueled by a confluence of factors, including escalating investments in fabrication plants, a strategic geopolitical realignment of semiconductor production, and relentless technological innovation.The period spanning 2020-2024 saw the industry navigate supply chain disruptions and trade tensions, yet it emerged stronger, propelled by the insatiable demand from 5G, AI, cloud computing, and automotive electronics. A recent FMI industry survey underscores this optimism, with 83% of experts anticipating increased demand for next-generation semiconductor materials, primarily driven by AI, quantum computing, and advanced automotive applications. Material innovation is unanimously seen as a critical competitive differentiator for the coming decade.

To Gain More Insights about this Research, Visit! https://www.futuremarketinsights.com/reports/semiconductor-fabrication-materials-market

Geopolitical Shifts and Localized Supply Chains Drive Demand

A defining trend is the global push for semiconductor self-reliance. Leading economies, including the USA, China, and the European Union, are aggressively ramping up local production through substantial subsidies and strategic trade agreements. The US CHIPS and Science Act (USD 52 billion), the European Chips Act (€43 billion), and India's Semicon Program (USD 10 billion) are pouring investments into domestic fabrication, directly stimulating demand for high-purity chemicals, silicon wafers, and advanced lithography materials. China's ambitious "Made in China 2025" policy continues its drive for self-sufficiency, leading to the highest projected CAGR of 7.5% in its domestic fabrication materials industry. This geopolitical realignment is compelling over 70% of industry respondents to explore regionalized supply chains and alternative sourcing strategies to mitigate risks and ensure material availability.

Technological Advancements Fuel Material Innovation

The relentless pursuit of miniaturization is a core growth driver. Semiconductor nodes are dipping below 5 nanometers (nm), necessitating specialized fabrication materials like EUV (Extreme Ultraviolet) resists and next-generation photoresists. The 1-5 nm range is identified as the fastest-growing segment, with significant activity in Gate-All-Around (GAA) FET transistors and stacked nanosheets. Looking towards 2035, manufacturing at 2 nm and below will demand entirely new materials such as HKMG dielectrics, carbon nanotube transistors, and graphene-based interconnects.

Beyond miniaturization, the rapid adoption of AI-based chip designs, automotive-grade semiconductors, and 3D packaging technologies are creating a surge in demand for custom fabrication materials. This includes high-performance bonding materials, underfill materials, and advanced substrates crucial for heterogeneous integration and multi-chipset designs.

Sustainability Takes Center Stage

Sustainability is no longer an option but a strategic imperative. 65% of surveyed companies are actively investing in eco-friendly fabrication materials, emphasizing reduced water consumption, recyclable chemicals, and low-carbon manufacturing processes. This push is driven by both compliance and the increasing recognition of brand value associated with ESG (Environmental, Social, and Governance) efforts. Material suppliers are urged to invest in greener formulations, such as fluorine-free etchants and low-GWP deposition gases, to gain a competitive edge.

Request Your Sample and Stay Ahead with Our Insightful Report! https://www.futuremarketinsights.com/reports/sample/rep-gb-17230

Competitive Landscape and Key Developments

The market is characterized by intense competition, with key players like Applied Materials, ASML Holding NV, Lam Research Corporation, Tokyo Electron Limited (TEL), and KLA Corporation holding significant market shares. These leaders are focusing on strategic pricing, continuous innovation, and global expansion.

Notable developments in 2025 include:

- Applied Materials' introduction of new materials and equipment for advanced packaging, bolstering heterogeneous integration for AI and HPC.

- ASML's successful shipment of its first high-NA EUV lithography systems to mega foundries, enabling sub-2nm chip production and solidifying its market dominance.

- Lam Research's acquisition of a next-generation chemical mechanical planarization (CMP) materials supplier, enhancing its wafer surface preparation portfolio.

- Tokyo Electron's partnership to develop next-generation EUV photoresists for sub-3nm nodes.

- KLA Corporation's launch of AI-based metrology solutions for real-time defect identification and yield optimization.

These developments highlight the industry's commitment to advancing fabrication capabilities and addressing the complex material requirements of future semiconductor technologies.

Strategic Outlook

To capitalize on this growth, stakeholders must prioritize R&D partnerships with chipmakers and research institutions, focusing on materials for AI accelerators, quantum computing, and 3D NAND. Securing preferred vendor status will increasingly depend on aligning with government incentives and regionalization strategies, moving manufacturing closer to new fabs in the USA, Europe, and India. The semiconductor fabrication materials market is not just growing; it's evolving into a highly strategic and sustainable industry, critical for the digital future.

Related Reports:

Rubber Molding Market: https://www.futuremarketinsights.com/reports/rubber-molding-market

Performance Elastomer Market: https://www.futuremarketinsights.com/reports/performance-elastomer-market

High Performance Fluoropolymer Market: https://www.futuremarketinsights.com/reports/high-performance-fluoropolymer-market

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Global Semiconductor Fabrication Materials Market Poised for Near Double-Digit Growth, Reaching USD 99 Billion by 2035 here

News-ID: 4114720 • Views: …

More Releases from Future Market Insights

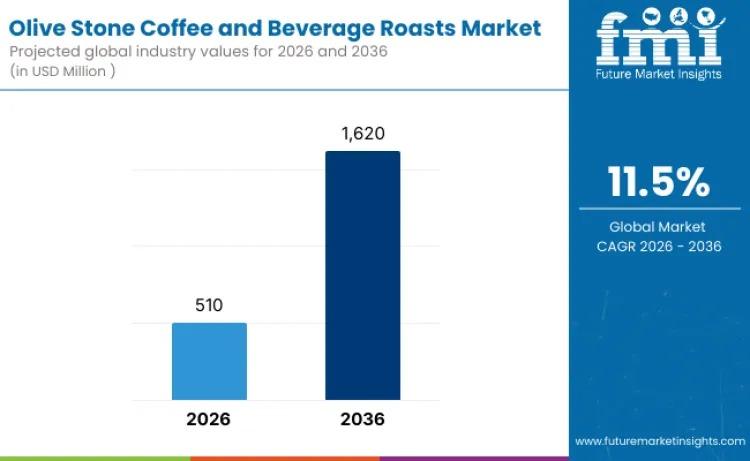

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

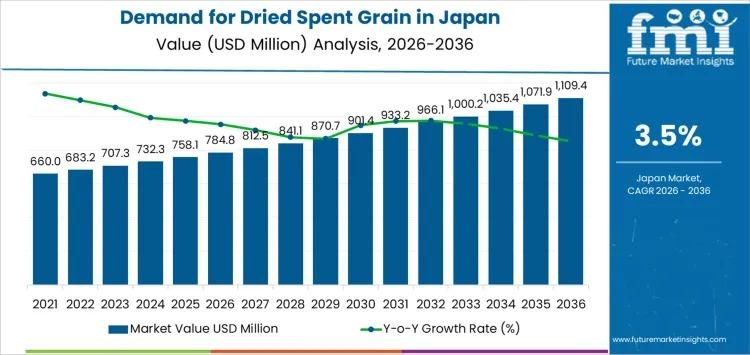

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

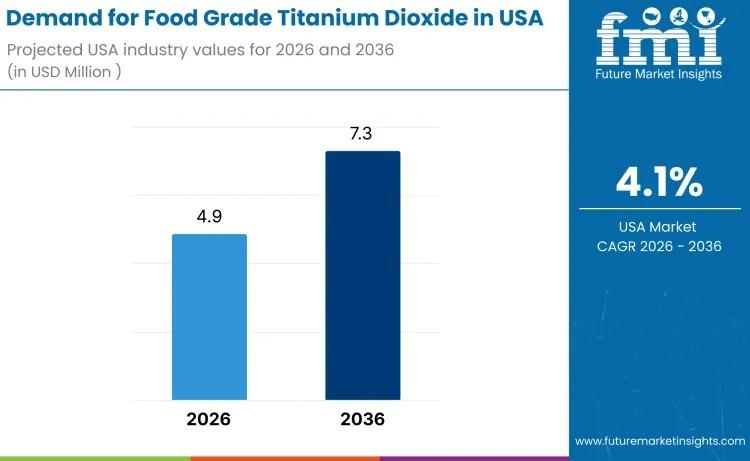

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

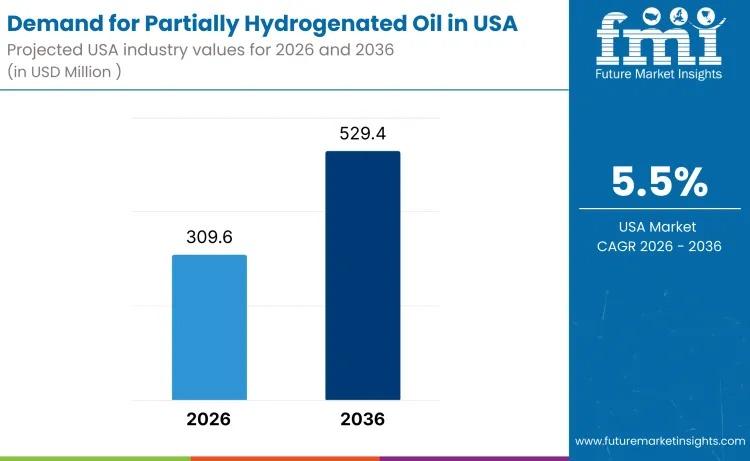

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for Material

Firestop Material Market

LOS ANGELES, United States: The global Firestop Material market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Firestop Material market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and…

New Material Direction for Electric Toothbrushes - Si-TPV Soft Over Molded Mater …

When it comes to factors such as consumer experience or ergonomics, Si-TPV Soft Over Molded Material has had a huge impact on the improvement of various products such as electric toothbrushes, etc. Si-TPV is a Silicone Combine TPU developed and produced by SILIKE, a Thermoplastic Elastomer Manufacturer (Thermoplastic Elastomer Suppliers). Si-TPV material adopts Innovative Soft Slip Technology and Sustainable Overmolding Techniques, which can be used to make Stain Resistance Soft…

A new light on a misjudged material - Plastic waste: material for art

Used plastic bottles are not waste, but a valuable resource. They can be reprocessed in a variety of ways and transformed into new products or fresh energy. And into art. This is exactly what Ve-ronika Richterová does. The Czech artist creates fascinating sculp-tures made out of old PET bottles.

Plastic has inspired artists from the very beginning. The reason: plas-tic meets almost all technical and aesthetic requirements. It is a uni-versal…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

The Future of Smart Material Market Runs Through the Material Industry

Smart Materials Market is expected to garner $72.63 billion by 2022, registering a CAGR of 14.9% during the forecast period 2016-2022. Smart materials are adaptive or intelligent materials which pose intrinsic and extrinsic capabilities. These can be altered by external stimuli, such as moisture, temperature, electromagnetic field, and pressure to obtain the desired functional effects. In addition, these materials are dynamic in nature and respond to their immediate interaction environments…

Global Regenerative Artificial Skin Sales Market Research Report 2017 (Temporary …

The report "Global Regenerative Artificial Skin Sales Market Report 2017", has been prepared based on an in-depth market analysis with inputs from industry experts.

This report studies sales (consumption) of Regenerative Artificial Skin in Global market, especially in United States, China, Europe and Japan, focuses on top players in these regions/countries, with sales, price, revenue and market share for each player in these regions, covering

Integra Life Sciences Corporation

Mylan N.V

Johnson & Johnson…