Press release

Europe Packed Bed Reactor Market Share, Growth, Size, Industry Trends, Analysis, Segments, and Forecast 2025 to 2032

Introduction:The global Packed Bed Reactor market is experiencing significant growth, driven by increasing demand for efficient and sustainable chemical processes across various industries. These reactors play a vital role in a wide array of applications, from petrochemical production and polymer synthesis to pharmaceutical manufacturing and food processing. Technological advancements, such as improved catalyst designs, enhanced process control systems, and the integration of digital technologies, are further fueling market expansion. Moreover, growing awareness regarding environmental sustainability and the need for cleaner production methods are prompting industries to adopt packed bed reactors, which offer superior efficiency and reduced waste generation compared to conventional reactor types. The ongoing pursuit of novel materials, innovative reactor designs, and process intensification strategies is propelling the market forward, creating new opportunities for vendors and end-users alike. The packed bed reactor market is also crucial in addressing global challenges related to resource scarcity, climate change, and pollution control by enabling the efficient conversion of raw materials into valuable products while minimizing environmental impact. Through ongoing research, development, and strategic collaborations, the market is poised to play a pivotal role in shaping the future of the chemical industry and contributing to a more sustainable and prosperous world.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/3135

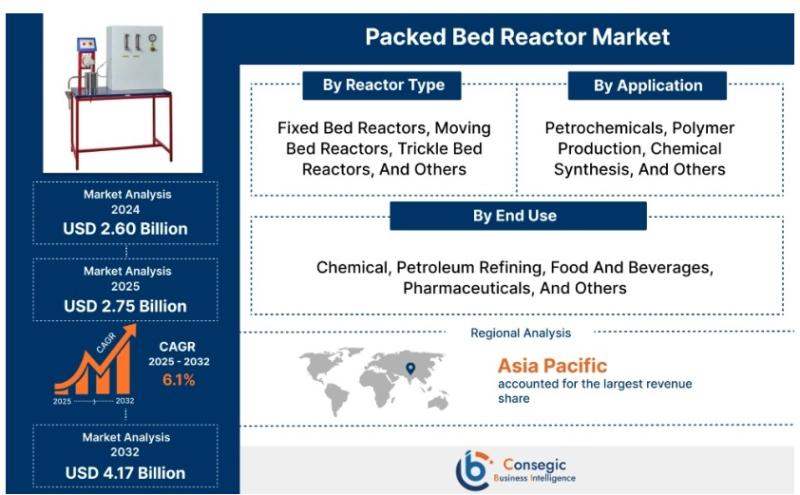

Market Size:

The Packed Bed Reactor Market is projected to reach USD 4.17 Billion by 2032, growing from USD 2.60 Billion in 2024. The market is expected to value USD 2.75 Billion in 2025, exhibiting a CAGR of 6.1% during the forecast period (2025-2032).

Definition of Market:

The Packed Bed Reactor Market encompasses the design, manufacturing, sales, and services associated with packed bed reactor systems. A packed bed reactor is a chemical reactor that uses a packed bed to contain a solid catalyst. The packed bed typically consists of granular catalyst particles, which can be of various sizes and shapes depending on the specific application. The reactants flow through the packed bed, where they come into contact with the catalyst, initiating a chemical reaction.

Key terms related to this market include:

Packed Bed: The core component of the reactor, consisting of catalyst particles packed into a cylindrical or other shaped vessel.

Catalyst: A substance that speeds up a chemical reaction without being consumed in the process.

Reactants: The input materials that undergo a chemical transformation within the reactor.

Products: The output materials resulting from the chemical reaction within the reactor.

Conversion Rate: The percentage of reactants that are converted into products.

Selectivity: The ratio of desired product formed compared to total product formed.

Pressure Drop: The decrease in pressure as reactants flow through the packed bed.

Void Fraction: The ratio of empty space to total volume within the packed bed.

Fluid Dynamics: The study of how fluids (liquids or gases) flow through the packed bed.

Heat Transfer: The process of transferring heat into or out of the reactor to maintain the desired reaction temperature.

The market includes various reactor types (fixed, moving, trickle bed), materials of construction (stainless steel, carbon steel, alloys), and applications in various industries.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/3135

Market Scope and Overview:

The Packed Bed Reactor Market spans a wide array of technologies, applications, and industries. From a technology standpoint, the market includes various reactor designs (e.g., fixed-bed, moving-bed, trickle-bed), catalyst types (e.g., heterogeneous, homogeneous), and process control systems (e.g., temperature control, pressure regulation, flow control). In terms of applications, packed bed reactors are utilized in petrochemical refining, polymer production, chemical synthesis, environmental remediation, and pharmaceutical manufacturing. The industries served by this market are diverse, encompassing chemicals, petroleum refining, food and beverages, pharmaceuticals, and environmental services. The market scope also includes services such as reactor design, fabrication, installation, maintenance, and optimization.

The Packed Bed Reactor Market plays a crucial role in addressing global trends such as increasing demand for chemicals, rising energy consumption, and growing environmental concerns. As the world population continues to grow and living standards improve, the demand for chemicals used in manufacturing, agriculture, and consumer goods is expected to rise. Packed bed reactors enable the efficient and cost-effective production of these chemicals. Furthermore, the need for energy-efficient processes and reduced greenhouse gas emissions is driving the adoption of packed bed reactors in various industries. These reactors offer superior thermal efficiency and reduced waste generation compared to traditional reactor types, contributing to a more sustainable and environmentally friendly industrial sector. Innovations in catalyst technology, reactor design, and process control are further enhancing the performance and versatility of packed bed reactors, making them an indispensable tool for addressing the challenges and opportunities of the 21st century.

Market Segmentation:

The Packed Bed Reactor Market can be segmented based on several factors:

By Reactor Type:

Fixed Bed Reactors: Catalyst remains stationary.

Moving Bed Reactors: Catalyst is continuously or intermittently moved through the reactor.

Trickle Bed Reactors: Liquid and gas reactants flow concurrently downward over a packed bed of catalyst.

Others: Includes specialized reactor types for specific applications.

By Application:

Petrochemicals: Production of basic chemicals from petroleum feedstocks.

Polymer Production: Synthesis of polymers and plastics.

Chemical Synthesis: Production of various chemicals and specialty chemicals.

Others: Includes applications in biofuels, fertilizers, and other sectors.

By End Use:

Chemical: Manufacturing of chemical products.

Petroleum Refining: Processing of crude oil into refined products.

Food and Beverages: Production of food and beverage products.

Pharmaceuticals: Manufacturing of pharmaceutical drugs and active ingredients.

Others: Includes applications in environmental, water treatment and other industries.

Each segment contributes to the overall market growth, with demand for specific reactor types and applications driven by factors such as process requirements, catalyst properties, and industry-specific regulations.

Market Drivers:

Technological Advancements: Innovations in catalyst technology, reactor design, and process control systems are improving the efficiency, selectivity, and reliability of packed bed reactors, driving their adoption across various industries.

Government Policies: Stringent environmental regulations and incentives for sustainable manufacturing practices are encouraging companies to invest in packed bed reactors, which offer reduced emissions and waste generation compared to conventional reactors.

Increasing Demand for Sustainability: Growing consumer awareness and corporate social responsibility are driving demand for products made using sustainable processes, leading to increased adoption of packed bed reactors in various industries.

Growing Demand for Chemicals and Petrochemicals: The continuous growth of the chemical and petrochemical industries, especially in developing countries, is driving the demand for packed bed reactors, which are essential for the production of various chemicals and materials.

Market Key Trends:

Modular Reactor Designs: Increasing adoption of modular packed bed reactors that offer flexibility, scalability, and ease of installation, reducing capital expenditure and time to market.

Process Intensification: Focus on process intensification strategies to enhance the performance and efficiency of packed bed reactors, such as using structured packings, microreactors, and advanced process control techniques.

Integration of Digital Technologies: Adoption of digital technologies such as IoT, AI, and machine learning for real-time monitoring, optimization, and predictive maintenance of packed bed reactors.

Development of Novel Catalysts: Ongoing research and development of novel catalysts with enhanced activity, selectivity, and stability, enabling the efficient production of a wider range of chemicals and materials.

Market Opportunities:

Expansion in Emerging Economies: Rapid industrialization and increasing demand for chemicals in emerging economies such as Asia-Pacific and Latin America present significant growth opportunities for packed bed reactor manufacturers.

Development of Novel Applications: Exploration of new applications for packed bed reactors in areas such as biofuels production, carbon capture and utilization, and waste valorization.

Retrofitting and Upgrading Existing Reactors: Opportunities for retrofitting and upgrading existing reactors with advanced technologies and catalysts to improve their performance and efficiency.

Collaboration and Partnerships: Opportunities for collaboration and partnerships between reactor manufacturers, catalyst suppliers, and end-users to develop innovative solutions and address specific market needs.

Process innovation: Intensifying processes through the use of microreactors and membrane reactors could create new application avenues.

Market Restraints:

High Initial Costs: The high initial investment required for purchasing and installing packed bed reactors can be a barrier for small and medium-sized enterprises (SMEs).

Technical Complexity: The design, operation, and maintenance of packed bed reactors require specialized knowledge and expertise, which can be a challenge for some end-users.

Geographic Limitations: The market for packed bed reactors is concentrated in regions with strong chemical and petrochemical industries, limiting growth opportunities in other areas.

Catalyst Deactivation: Catalyst deactivation due to fouling, poisoning, or sintering can reduce the performance and lifespan of packed bed reactors, requiring periodic replacement or regeneration of the catalyst.

Market Challenges:

The Packed Bed Reactor Market, while experiencing robust growth, faces several significant challenges that could impact its future trajectory. One primary challenge is the complexity associated with reactor design and optimization. Achieving optimal performance requires a deep understanding of fluid dynamics, heat transfer, and chemical kinetics, necessitating advanced modeling and simulation capabilities. Furthermore, the selection of appropriate catalysts and packing materials is crucial, demanding expertise in materials science and chemical engineering. The diverse range of applications, each with unique operating conditions and performance requirements, adds another layer of complexity.

Another significant challenge is the increasing stringency of environmental regulations. As governments worldwide implement stricter emission standards and waste disposal regulations, manufacturers must adopt more sustainable and eco-friendly processes. This necessitates the development of packed bed reactors that minimize waste generation, reduce energy consumption, and utilize environmentally benign catalysts. Addressing this challenge requires significant investments in research and development to develop innovative reactor designs and catalyst formulations. Moreover, the high initial costs associated with packed bed reactors can be a barrier for small and medium-sized enterprises (SMEs). The capital expenditure for reactor design, fabrication, installation, and commissioning can be substantial, limiting the adoption of these reactors by smaller companies with limited financial resources.

The market also faces technical challenges related to catalyst deactivation and fouling. Over time, catalysts can lose their activity due to poisoning, sintering, or the deposition of unwanted byproducts. This reduces reactor performance and necessitates periodic catalyst replacement or regeneration, increasing operating costs and downtime. Addressing this challenge requires the development of more robust and durable catalysts, as well as the implementation of effective reactor cleaning and maintenance strategies. Additionally, ensuring uniform flow distribution within the packed bed is crucial for achieving optimal reactor performance. Non-uniform flow can lead to localized hot spots, reduced catalyst utilization, and increased pressure drop. Achieving uniform flow distribution requires careful reactor design and packing optimization, which can be challenging in large-scale reactors.

Furthermore, competition from alternative reactor technologies, such as continuous stirred-tank reactors (CSTRs) and microreactors, poses a significant challenge. While packed bed reactors offer several advantages, such as high conversion rates and selectivity, they may not be suitable for all applications. CSTRs, for example, may be preferred for reactions that require high mixing intensity, while microreactors may be more suitable for highly exothermic reactions or reactions involving hazardous materials. Addressing this challenge requires manufacturers to continuously innovate and develop packed bed reactors that offer superior performance and versatility compared to competing technologies. Finally, the shortage of skilled labor in the chemical and process engineering industries can be a challenge for the Packed Bed Reactor Market. The design, operation, and maintenance of these reactors require specialized knowledge and expertise, which may not be readily available in all regions. Addressing this challenge requires investing in education and training programs to develop a skilled workforce capable of supporting the growth of the market.

Market Regional Analysis:

The Packed Bed Reactor Market exhibits varying dynamics across different regions due to factors such as industrial infrastructure, regulatory landscape, and economic development. North America and Europe are established markets with a strong emphasis on technological innovation and sustainable practices. These regions are characterized by stringent environmental regulations and a high demand for energy-efficient and low-emission processes, driving the adoption of advanced packed bed reactor technologies. The presence of leading chemical and pharmaceutical companies, coupled with significant investments in research and development, further fuels market growth in these regions.

Asia-Pacific is the fastest-growing market, driven by rapid industrialization, increasing demand for chemicals, and favorable government policies. The region is home to major chemical and petrochemical producers, particularly in China, India, and Southeast Asia, which are investing heavily in expanding their production capacities. The increasing adoption of advanced technologies, coupled with a growing focus on environmental sustainability, is driving the demand for packed bed reactors in this region. Latin America and the Middle East & Africa are also emerging markets with significant growth potential. The abundance of natural resources, particularly oil and gas, is driving the growth of the petrochemical industry in these regions, creating opportunities for packed bed reactor manufacturers. However, factors such as political instability, economic uncertainty, and a lack of infrastructure development may pose challenges to market growth in some countries.

Each region exhibits distinct market trends and competitive landscapes. In North America and Europe, the market is characterized by a high degree of consolidation and a focus on advanced technologies and sustainable practices. In Asia-Pacific, the market is more fragmented, with a mix of local and international players competing for market share. Latin America and the Middle East & Africa are characterized by a relatively low level of industrialization and a dependence on imports, creating opportunities for foreign manufacturers to establish a presence in these regions.

Frequently Asked Questions:

What is the projected growth rate of the Packed Bed Reactor Market?

The market is projected to grow at a CAGR of 6.1% during the forecast period (2025-2032).

What are the key trends shaping the market?

Key trends include modular reactor designs, process intensification, integration of digital technologies, and the development of novel catalysts.

What are the most popular reactor types?

Fixed Bed Reactors, Moving Bed Reactors, and Trickle Bed Reactors are among the most popular types, each suited to specific applications and process requirements.

Our Other Pages

https://www.linkedin.com/company/trendhive-digital/

https://www.linkedin.com/company/performance-digital-lab/

https://www.linkedin.com/company/insightarc-360/

https://www.linkedin.com/company/elevate-market-signals/

https://www.linkedin.com/company/forecast-nexus/

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

+1-252-552-1404

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Europe Packed Bed Reactor Market Share, Growth, Size, Industry Trends, Analysis, Segments, and Forecast 2025 to 2032 here

News-ID: 4101238 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Reactor

Adiabatic Fixed Bed Reactor Reactor Market Research: at a CAGR of 3.0% during th …

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report "Adiabatic Fixed Bed Reactor Reactor- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032". Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2026-2032), this report provides a comprehensive analysis of the global Adiabatic Fixed Bed Reactor Reactor market, including market size, share, demand, industry development status, and…

Stirred Autoclave Reactor Market Report 2025

Global Info Research's report offers an in-depth look into the current and future trends in Stirred Autoclave Reactor, making it an invaluable resource for businesses involved in the sector. This data will help companies make informed decisions on research and development, product design, and marketing strategies. It also provides insights into Stirred Autoclave Reactor' cost structure, raw material sources, and production processes. Additionally, it offers an understanding of the regulations…

Emerging Trends to Reshape the Small Modular Reactor Market: Advances In Small M …

Use code ONLINE20 to get 20% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts.

Second Opinion Tele-Radiology App Market Size Valuation Forecast: What Will the Market Be Worth by 2025?

The market valuation for second opinion teleradiology applications has seen substantial expansion lately, projected to ascend from $1.29 billion in 2024 to $1.51 billion the subsequent year, reflecting a compound annual growth rate…

Top Trends Transforming the Small Modular Reactor Market Landscape in 2025: Adva …

Use code ONLINE30 to get 30% off on global market reports and stay ahead of tariff changes, macro trends, and global economic shifts

What Will the Small Modular Reactor Industry Market Size Be by 2025?

The market size of small modular reactors has seen a significant expansion in the past few years. Its growth is projected to rise from $0.27 billion in 2024 to $0.67 billion in 2025, with a compound annual…

Prominent Small Modular Reactor Market Trend for 2025: Advances In Small Modular …

What Are the Projected Growth and Market Size Trends for the Small Modular Reactor Market?

The small modular reactor market has grown exponentially in recent years. It will rise from $0.27 billion in 2024 to $0.67 billion in 2025, at a CAGR of 152.1%. The growth is driven by concerns over energy security, regulatory support, increasing electricity demand, the need for carbon emission reduction, and the desire for decentralized power generation.

The…

Nuclear Reactor Market

Construction of new nuclear across the globe is one of the primary reasons behind the accelerating growth of the global nuclear reactor market, states TMR Research in a new research report. The report is titled, “Nuclear Reactor Market – Global Industry Analysis, Size, Share, Trends, Analysis, Growth, and Forecast 2017 – 2025.”

Click on the link below to request a sample copy of the report

https://www.tmrresearch.com/sample/sample?flag=B&rep_id=335

The worldwide market for nuclear reactors is…