Press release

Europe Ceramic Setter Plates Market Research Report (2025) By Leading Players, Emerging Technologies, Opportunity 2032

Introduction:The Ceramic Setter Plates market is experiencing robust growth, driven by the increasing demand for high-performance materials in various industries. These plates, crucial for supporting and protecting ceramic components during high-temperature processes, are witnessing heightened adoption due to advancements in material science and manufacturing techniques. Key drivers include the expanding electronics sector, particularly in the production of semiconductors and electronic components, where precise and reliable setter plates are essential. The automotive industry's shift towards electric vehicles and advanced driver-assistance systems (ADAS) also fuels demand, as ceramic setter plates play a vital role in manufacturing sensors and other critical components. Furthermore, the aerospace sector's continuous pursuit of lightweight and high-temperature resistant materials contributes to the market's expansion. Technological advancements, such as the development of setter plates with improved thermal conductivity and resistance to chemical corrosion, are enhancing their performance and broadening their applications. The ceramic setter plates market is also contributing to addressing global challenges by enabling the production of more efficient and durable materials, which are essential for energy conservation and environmental sustainability. This market is poised for continued growth as industries increasingly rely on advanced ceramic components to meet performance and efficiency demands.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/1902

Market Size:

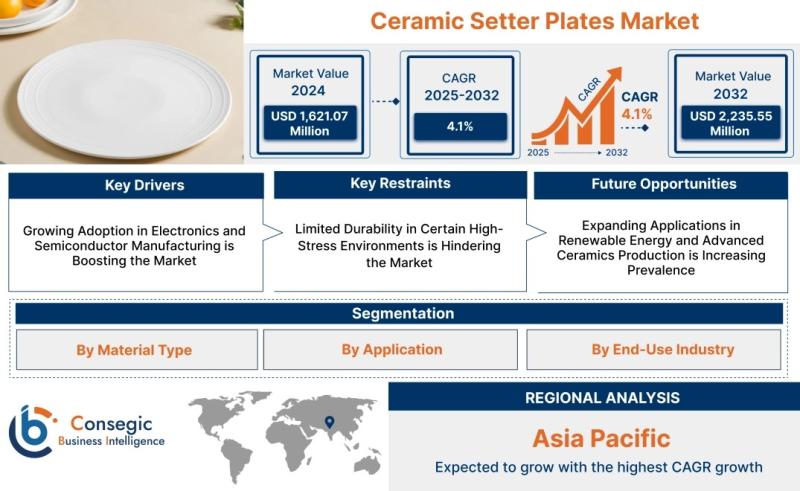

The Ceramic Setter Plates market size is estimated to reach over USD 2,235.55 Million by 2032 from a value of USD 1,621.07 Million in 2024 and is projected to grow by USD 1,658.65 Million in 2025, growing at a CAGR of 4.1% from 2025 to 2032.

Definition of Market:

The Ceramic Setter Plates market encompasses the production, distribution, and application of ceramic plates specifically designed to support and protect ceramic components during high-temperature manufacturing processes. These plates are essential in industries where ceramic parts are fired, sintered, or heat-treated, ensuring dimensional stability and preventing deformation or damage. The market includes various material compositions, such as alumina, silicon carbide, mullite, and zirconia, each offering unique properties tailored to specific applications.

Key terms related to this market include:

Setter Plate: The ceramic plate used to support and protect ceramic parts during firing, sintering, or heat treatment.

Alumina: A ceramic material known for its high hardness, wear resistance, and electrical insulation properties.

Silicon Carbide: A ceramic material prized for its exceptional hardness, high thermal conductivity, and resistance to high temperatures and chemical corrosion.

Mullite: A ceramic material with excellent thermal shock resistance and high-temperature stability.

Zirconia: A ceramic material characterized by its high strength, toughness, and resistance to high temperatures and corrosion.

Firing: The process of heating ceramic greenware to a high temperature to densify and harden the material.

Sintering: A process where powdered materials are compacted and heated to form a solid mass without melting.

Heat Treatment: The process of heating and cooling materials to alter their physical and mechanical properties.

Kiln Furniture: Refractory materials used to support ware in a kiln during firing. Setter plates are a type of kiln furniture.

Thermal Conductivity: The measure of a material's ability to conduct heat.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/1902

Market Scope and Overview:

The scope of the Ceramic Setter Plates market spans across diverse industries, technologies, and applications, positioning it as a critical enabler in manufacturing processes involving high-temperature treatments of ceramic materials. The market encompasses various setter plate compositions like alumina, silicon carbide, mullite, and zirconia, each tailored to specific thermal, mechanical, and chemical resistance requirements. These plates find applications in the firing of ceramic components, heat treatment processes, sintering of powdered metals, and act as vital kiln furniture. The end-use industries benefiting from these plates are vast, including electronics, automotive, aerospace, industrial manufacturing, healthcare, and others. Technologies involved range from traditional ceramic processing methods to advanced techniques such as powder metallurgy and additive manufacturing, where precision and material integrity are paramount.

The Ceramic Setter Plates market holds substantial importance within the larger context of global technological and industrial trends. As industries worldwide increasingly demand higher performance, efficiency, and sustainability, the role of advanced ceramics and related processes becomes more critical. The ongoing shift towards electric vehicles, for instance, necessitates high-quality ceramic components for batteries and electronic control systems, driving demand for setter plates that can withstand rigorous manufacturing conditions. Similarly, the aerospace sector's focus on lightweight and high-temperature materials relies heavily on advanced ceramic components, further emphasizing the market's significance. The development of innovative materials and processes, supported by the Ceramic Setter Plates market, enables advancements in energy conservation, pollution control, and overall industrial efficiency, aligning with global sustainability goals. In summary, the Ceramic Setter Plates market plays a pivotal role in facilitating technological progress and addressing critical global challenges by enabling the production of high-performance ceramic materials across a broad spectrum of industries.

Market Segmentation:

The Ceramic Setter Plates market can be segmented based on several key factors:

By Material Type: This segment includes Alumina, Silicon Carbide, Mullite, Zirconia, and Others. Alumina plates are widely used due to their cost-effectiveness and good mechanical properties, while Silicon Carbide plates are favored for their high thermal conductivity and resistance to extreme temperatures. Mullite and Zirconia plates are chosen for specific applications requiring thermal shock resistance and high strength, respectively.

By Application: This segment covers Firing of Ceramic Components, Heat Treatment Processes, Sintering of Powdered Metals, Kiln Furniture, and Others. Setter plates are essential in firing ceramic components to prevent deformation, in heat treatment to ensure uniform heating, and in sintering powdered metals to achieve desired density and strength. As kiln furniture, they provide stable support during high-temperature processes.

By End-Use Industry: This segment includes Electronics, Automotive, Aerospace, Industrial Manufacturing, Healthcare, and Others. The electronics industry uses setter plates in manufacturing semiconductors and other electronic components. The automotive sector relies on them for producing sensors and other critical parts for vehicles. The aerospace industry utilizes setter plates for manufacturing high-temperature resistant components. Industrial manufacturing employs them in various ceramic processing applications, while the healthcare sector uses them in producing medical-grade ceramics.

Market Drivers:

Several factors are driving growth in the Ceramic Setter Plates market:

Technological Advancements: Innovations in ceramic materials and manufacturing processes are leading to the development of setter plates with improved thermal conductivity, chemical resistance, and dimensional stability. These advancements enable higher-performance ceramic components across various industries.

Expanding Electronics Industry: The growing demand for electronic devices and components, particularly in sectors like smartphones, computers, and IoT devices, is driving the need for high-precision setter plates used in manufacturing semiconductor components.

Automotive Industry Shift: The increasing adoption of electric vehicles (EVs) and advanced driver-assistance systems (ADAS) is fueling demand for ceramic components used in batteries, sensors, and other critical parts.

Aerospace Industry Demands: The aerospace sector's continuous pursuit of lightweight and high-temperature resistant materials is driving the demand for advanced ceramic components manufactured using high-quality setter plates.

Industrial Growth: The expansion of industrial manufacturing activities globally, particularly in emerging economies, is contributing to the increased demand for ceramic setter plates used in various high-temperature processes.

Increasing Demand for Sustainability: The need for energy-efficient and environmentally friendly manufacturing processes is driving the adoption of advanced ceramic components, which in turn boosts the demand for setter plates.

Market Key Trends:

Significant trends in the Ceramic Setter Plates market include:

Development of High-Performance Materials: The focus on developing setter plates made from advanced materials like silicon carbide and zirconia to withstand extreme temperatures and corrosive environments.

Customization and Precision Manufacturing: Increasing demand for customized setter plates tailored to specific component shapes and sizes to optimize manufacturing processes.

Automation and Digitalization: Integration of automation and digital technologies in the manufacturing of setter plates to improve efficiency, reduce costs, and enhance product quality.

Focus on Sustainable Practices: Growing emphasis on environmentally friendly manufacturing processes, including the use of recycled materials and energy-efficient production methods.

Adoption of Additive Manufacturing: Exploration of additive manufacturing techniques (3D printing) for producing complex setter plate geometries and customized designs.

Market Opportunities:

The Ceramic Setter Plates market presents several growth prospects:

Expanding Applications in Emerging Industries: Opportunities to expand the use of ceramic setter plates in emerging industries such as renewable energy, biotechnology, and advanced materials.

Development of Innovative Materials: Potential to develop setter plates from new materials with enhanced properties, such as higher thermal conductivity, improved chemical resistance, and increased mechanical strength.

Penetration into New Geographies: Opportunities to expand market presence in developing regions with growing industrial sectors and increasing demand for advanced ceramic components.

Strategic Partnerships and Collaborations: Collaborations with ceramic component manufacturers and end-use industries to develop customized setter plate solutions tailored to specific applications.

Innovations in Coating Technologies: Innovations in coating technologies to improve the surface properties of setter plates, such as reducing friction and preventing sticking.

Market Restraints:

The Ceramic Setter Plates market faces several challenges:

High Initial Costs: The high cost of advanced ceramic materials and manufacturing processes can be a barrier to entry for some smaller companies.

Technical Complexity: The design and manufacturing of high-performance setter plates require specialized knowledge and expertise, which may be a limiting factor.

Geographic Limitations: The availability of raw materials and skilled labor can be a constraint in certain regions, impacting production capacity and costs.

Market Volatility: Fluctuations in raw material prices and changes in economic conditions can affect the profitability of setter plate manufacturers.

Stringent Regulations: Compliance with environmental regulations and safety standards can add to the cost and complexity of manufacturing ceramic setter plates.

Market Challenges:

The Ceramic Setter Plates market, while poised for substantial growth, faces a complex array of challenges that could hinder its progress. These challenges span technological, economic, and environmental dimensions, requiring strategic solutions and proactive measures from industry participants.

One of the foremost challenges lies in the realm of material science and manufacturing. Developing ceramic setter plates that can withstand increasingly harsh operating conditions - higher temperatures, corrosive environments, and mechanical stresses - demands continuous innovation in material formulations and processing techniques. This involves not only identifying and synthesizing new ceramic materials but also optimizing manufacturing processes to ensure consistent quality and performance. The high cost of research and development (R&D) and the long lead times associated with bringing new materials to market can pose significant hurdles.

Economic factors also present considerable challenges. The global economy's inherent volatility can impact the demand for ceramic components and, consequently, setter plates. Fluctuations in raw material prices, energy costs, and currency exchange rates can affect the profitability of manufacturers. Additionally, the capital-intensive nature of ceramic manufacturing, coupled with the need for specialized equipment and skilled labor, can create barriers to entry for smaller players.

Environmental concerns are becoming increasingly prominent. The ceramic manufacturing process is energy-intensive and can generate significant waste. Addressing these environmental impacts requires adopting sustainable practices, such as using recycled materials, reducing energy consumption, and minimizing waste generation. However, implementing these practices can require substantial investments and may increase production costs in the short term.

Another critical challenge lies in supply chain management. The ceramic setter plate market relies on a global network of suppliers for raw materials, equipment, and components. Disruptions in the supply chain, whether due to geopolitical events, natural disasters, or other unforeseen circumstances, can lead to delays, increased costs, and supply shortages. Building resilient and diversified supply chains is therefore essential.

Finally, competition within the market is intensifying. As the demand for ceramic setter plates grows, more companies are entering the market, leading to increased price pressure and a need for differentiation. Companies must focus on offering innovative products, providing superior customer service, and building strong brand reputations to maintain a competitive edge.

Market Regional Analysis:

The Ceramic Setter Plates market exhibits varying dynamics across different regions, each influenced by unique factors.

North America: This region benefits from a strong presence of electronics and automotive industries, driving demand for high-performance setter plates. Technological advancements and investments in R&D also contribute to market growth.

Europe: Europe's focus on sustainability and environmental regulations influences the adoption of energy-efficient ceramic materials and manufacturing processes. The automotive and aerospace sectors are key drivers of market demand.

Asia-Pacific: The Asia-Pacific region, particularly China and India, is experiencing rapid industrial growth, leading to increased demand for ceramic components and setter plates. The electronics and manufacturing sectors are major contributors to market expansion. Lower manufacturing costs and favorable government policies also support market growth.

Rest of the World: The Rest of the World region, including Latin America, the Middle East, and Africa, presents growth opportunities due to expanding industrial activities and increasing investments in infrastructure development. The mining and construction sectors are potential drivers of market demand.

Frequently Asked Questions:

Q: What is the projected growth rate of the Ceramic Setter Plates market?

A: The Ceramic Setter Plates market is projected to grow at a CAGR of 4.1% from 2025 to 2032.

Q: What are the key trends in the Ceramic Setter Plates market?

A: Key trends include the development of high-performance materials, customization and precision manufacturing, automation and digitalization, focus on sustainable practices, and adoption of additive manufacturing.

Q: What are the most popular Ceramic Setter Plate types?

A: The most popular Ceramic Setter Plate types include Alumina and Silicon Carbide, due to their versatility, cost-effectiveness, and high-performance characteristics.

Our Other Pages

https://www.linkedin.com/company/tech-evolutionary/

https://www.linkedin.com/company/inspire-innovators/

https://www.linkedin.com/company/insight-peak/

https://www.linkedin.com/company/info-curve/

https://www.linkedin.com/company/tech-innovationn/

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

+1-252-552-1404

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Europe Ceramic Setter Plates Market Research Report (2025) By Leading Players, Emerging Technologies, Opportunity 2032 here

News-ID: 4099603 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Setter

Revolutionizing CNC Machining with Silvercnc's Advanced Tool Setter Technology

Silvercnc, a leading innovator in the CNC machining sector, is excited to announce the launch of its state-of-the-art Tool Setter solutions designed to improve productivity, reduce downtime, and enhance tool performance. This breakthrough technology is set to redefine CNC machining practices, offering industries across the globe a more efficient, reliable, and cost-effective approach to tool management.

Silvercnc is proud to introduce its latest CNC Tool Setter technology, a comprehensive solution that…

Ceramic Setter Plates Market: Size, Share, Growth, Analysis, Key Players, Revenu …

Ceramic Setter Plates Market

Traditional ceramic plates are produced from unrefined clay. Alumina and aluminum nitride ceramics offer certain advantages over conventional setters because they enable energy and cost efficient processing of high precision sintering components.Ceramic setter plates have rails on two parallel sides and can be used for stack firing. They are known to have certain benefits, which include low surface roughness, high thermal shock resistance, and high mechanical stability.…

Flexo Plate Setter Market Overview: 2019-2029 Gross Revenue vs. Net Revenue Repo …

Flexo Plate Setter report published by QYResearch reveals that COVID-19 and Russia-Ukraine War impacted the market dually in 2022. Global Flexo Plate Setter market is projected to reach US$ million in 2029, increasing from US$ million in 2022, with the CAGR of % during the period of 2023 to 2029. Demand from Paper Packaging and Plastic Packaging are the major drivers for the industry.

Global Leading Market Research Publisher QYResearch announces…

Laser Tool Setter Market Analysis,Demand,Trends and Forecast 2029

Global Info Research announces the release of the report "Global Laser Tool Setter Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets.…

silverCNC Introduces CNC Tool Setter Solutions For Machine Tools

SilverCNC has announced a revolutionary new way for machine tool operators to save time and money when setting up their tools. The system provides easy access to the necessary components, allowing for quick and convenient tool setup in a fraction of the time it would take otherwise. SilverCNC's CNC tool setter solutions not only provide stability and accuracy while setting up machines but also require minimal maintenance so that users…

Financial Technology (FinTech) Market Next Big Thing | Major Giants Zopa, Lendix …

The Latest research study released by HTF MI “Financial Technology (FinTech) Market” with 100+ pages of analysis on business Strategy taken up by key and emerging industry players and delivers know how of the current market development, landscape, technologies, drivers, opportunities, market viewpoint and status. Understanding the segments helps in identifying the importance of different factors that aid the market growth. Some of the Major Companies covered in this Research…