Press release

Friction Materials Market to Reach USD 8.9 Bn by 2034: Key Growth Insights

The global friction materials market was valued at USD 5.6 billion in 2023 and is projected to reach USD 8.9 billion by 2034, expanding at a CAGR of 4.4% from 2024 to 2034. This growth is driven by increasing demand across automotive, rail, and industrial machinery sectors due to rising safety standards, technological advancements in braking systems, and the expansion of transportation infrastructure worldwide.Expansion in automotive and railway sectors and increase in sales of automobiles across the world are primarily responsible for the friction materials market growth.

Rise in migration toward urban centers in developing countries and increase in capacity of the people to afford automobiles are also fostering market progress.

Unlock Full Market Insights: Get a Sample Report Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=54027

However, surge in adoption of electric vehicles with advanced braking systems is hampering the friction materials market size to a certain extent. Friction materials are also used in the construction of high-speed railway networks and metro railway systems.

Market Segmentation

The friction materials market is segmented based on material type, product type, application, end-use industry, and geography.

By Material Type:

Organic Friction Materials: Held the largest market share (around 55% in 2023), offering good friction properties and relatively low cost.

Metallic Friction Materials: Accounted for approximately 25% of the market share in 2023, known for their durability and heat resistance.

Sintered Friction Materials: Expected to witness the highest growth rate due to their superior performance, high durability, and ability to withstand extreme temperatures, making them suitable for heavy-duty applications.

Ceramic Friction Materials: Gaining traction for their improved performance, lower dust generation, and reduced noise.

Semi-Metallic Friction Materials: Dominate the global market, accounting for approximately 44% market share in 2024, offering excellent friction and heat resistance for effective braking even at high speeds and temperatures.

Aramid Fibers: Used for their strength and heat resistance in asbestos-free formulations.

Asbestos: Historically used but now largely phased out due to health concerns, though some legacy applications or regions may still have minimal presence.

Carbon-based Composite Materials: Developed for high-performance applications, improving overall durability.

By Product Type:

Brake Pads: The largest product segment and anticipated to hold the largest market share, essential for brake systems in vehicles, prone to wear and tear due to high friction.

Brake Linings: Used in drum braking systems.

Brake Discs: Often paired with brake pads in disc braking systems.

Clutch Facings: Critical for power transmission in vehicle clutch systems.

Transmission Plates: Essential for smooth gear changes and power transfer within transmissions.

Blocks: Used in certain industrial braking systems.

Others: Includes rolls, sheets, and other specialized friction components.

By Business Type:

Aftermarket: Expected to lead the market, driven by the continuous demand for replacement friction products in the automotive industry due to wear and tear.

Original Equipment (OE): Refers to friction materials supplied directly to vehicle manufacturers for new vehicle assembly.

By Application:

Brakes: The most consumed product and dominant application segment, crucial for slowing down or stopping vehicles and machinery. This includes both automotive brakes and industrial brakes.

Clutches: Essential for power transfer and transmission control in vehicles and machinery.

Industrial Brakes & Transmission Systems: Encompassing a wide range of industrial machinery that requires friction for operation and control.

By End-Use Industry:

Automotive: The dominant end-use industry, accounting for over 40% of consumption and 45% of revenue in 2024. This segment includes passenger cars, commercial vehicles (heavy commercial vehicles (HCVs) and light commercial vehicles (LCVs)), and two-wheelers. The rise in vehicle production, increasing vehicle mileage, and the growing electric vehicle (EV) market are key drivers.

Industrial Commercial: Diverse applications across manufacturing, mining, oil & gas, and other industrial machinery.

Aerospace & Marine: High-performance friction materials for aircraft braking systems, landing gear, and marine vessel propulsion and control systems.

Rail Transit: Essential for braking systems in trains, including passenger trains, freight trains, and high-speed railway networks.

Construction: Used in heavy machinery and equipment for braking and power transmission.

Others: Includes agriculture, wind energy, and other niche applications.

Regional Analysis

The friction materials market exhibits strong regional growth, with Asia Pacific leading the charge.

Asia Pacific: Expected to be the leading market and show the maximum growth potential, accounting for the largest share (e.g., 41% in 2021 and largest share in 2024). Rapid industrialization, increasing vehicle production and sales in countries like China and India, and significant infrastructure development are key drivers. The region's focus on urbanization and the modernization of public transportation (especially high-speed rail) also fuels demand.

North America: A significant market, driven by a large existing automotive fleet, a strong aftermarket, and substantial investments in advanced manufacturing and aerospace sectors. The increasing demand for high-performance braking systems and the growing adoption of EVs contribute to market expansion.

Europe: A mature market with stringent safety and environmental regulations, driving demand for advanced and eco-friendly friction materials. The robust automotive industry and a focus on renewable energy and smart infrastructure contribute to its growth.

Latin America & Middle East & Africa: Emerging markets with increasing industrialization, urbanization, and growing automotive industries. These regions are projected to witness steady growth as economic development progresses.

Market Drivers and Challenges

Market Drivers:

Rising Automotive Production and Sales: The continuous increase in global production and sales of passenger cars, commercial vehicles, and two-wheelers is the most significant driver for friction materials, particularly in braking and clutch systems.

Growing Adoption of Electric Vehicles (EVs): EVs require specialized friction materials due to regenerative braking and different weight distribution, creating new opportunities for material development.

Stringent Safety Regulations: Increasing governmental regulations and consumer emphasis on vehicle safety are driving the demand for high-performance and reliable braking systems, leading to the use of advanced friction materials.

Expansion of Industrial and Heavy Machinery Sectors: Growth in manufacturing, construction, mining, and other industrial sectors necessitates robust friction materials for industrial brakes, clutches, and transmission systems.

Aftermarket Demand for Replacements: The wear and tear of friction components ensure a consistent and growing demand in the aftermarket for replacement brake pads, linings, and clutch facings.

Technological Advancements: Innovations in material science, leading to the development of asbestos-free, ceramic, sintered, and carbon-based composite materials with improved durability, reduced noise, and better performance under extreme conditions.

Market Challenges:

Volatile Raw Material Prices: Fluctuations in the cost of raw materials (metals, fibers, resins) can impact production costs and profit margins for friction material manufacturers.

Stringent Environmental Regulations: Regulations regarding emissions (e.g., copper dust from brake pads) and the use of hazardous materials (e.g., asbestos ban) necessitate continuous R&D and reformulation, increasing compliance costs.

Counterfeit Products: The prevalence of low-quality, counterfeit friction products in the market poses significant safety risks and undermines the market for legitimate manufacturers.

Impact of Regenerative Braking in EVs: While EVs create new demand, regenerative braking systems reduce the reliance on conventional friction brakes, potentially impacting the aftermarket for traditional brake pads over the long term.

High Maintenance and Replacement Costs: The wear and tear nature of friction materials leads to regular replacement and maintenance, which can be perceived as a cost challenge by end-users.

Supply Chain Disruptions: Geopolitical tensions and global events (like the Russia-Ukraine conflict impacting metal and mineral supplies) can lead to raw material shortages and price hikes.

Market Trends

Shift Towards Asbestos-Free and Eco-Friendly Materials: A strong trend towards developing and adopting copper-free and other environmentally benign friction materials due to health and environmental concerns.

Focus on High-Performance and Lightweight Materials: Increasing demand for materials that offer superior braking performance, durability, and reduced weight to improve fuel efficiency and vehicle dynamics.

Advanced Ceramics and Sintered Materials: Growing adoption of ceramic and sintered friction materials, particularly in high-performance vehicles, heavy-duty machinery, and industrial applications, due to their enhanced heat resistance and wear properties.

Development of Smart Friction Materials: Integration of sensors and IoT devices for real-time monitoring of brake performance, wear, and temperature, enabling predictive maintenance.

Noise and Dust Reduction: Significant R&D efforts focused on developing friction materials that minimize brake noise and reduce the generation of harmful dust particles.

Evolution of Braking Systems: Transition towards advanced braking technologies like brake-by-wire systems and hydraulic wet brakes (in off-highway equipment), requiring specialized friction material formulations.

Aftermarket Innovation: Continuous innovation in aftermarket products to meet diverse vehicle requirements and offer improved performance and lifespan.

Future Outlook

The friction materials market is poised for sustained growth, driven by the expanding automotive industry, particularly the surging adoption of electric vehicles, and ongoing modernization in industrial and transportation sectors. While challenges related to raw material costs and environmental regulations persist, continuous innovation in material science and manufacturing processes will lead to more efficient, durable, and sustainable friction solutions. The emphasis on vehicle safety and environmental protection will continue to shape product development, ensuring a dynamic and evolving market landscape.

Key Market Study Points

Analyze the impact of global vehicle production trends, especially the growth of EVs, on the demand for different types of friction materials.

Evaluate the effectiveness of new material formulations (e.g., ceramics, sintered composites) in addressing performance and environmental requirements.

Assess the influence of evolving safety and environmental regulations on product development and market entry strategies.

Examine the growth dynamics of the aftermarket segment for replacement friction products.

Monitor investments in R&D for smart friction materials and advanced manufacturing technologies.

Understand the regional variations in market growth drivers, challenges, and competitive strategies.

Competitive Landscape

The friction materials market is highly competitive, featuring a mix of large multinational corporations and specialized manufacturers. Companies are actively engaged in research and development to introduce innovative and high-performance products, expand their market share, and comply with evolving environmental standards. Strategic alliances, mergers, and acquisitions are common strategies to enhance technological capabilities and global reach.

Key Players in the Friction Materials Market include:

Akebono Brake Industry Co. Ltd.

Brembo S.p.A.

Continental AG

Federal-Mogul (Tenneco Inc.)

TMD Friction

Aisin Seiki Co., Ltd.

Nisshinbo Holdings Inc.

Valeo S.A.

Mando Corporation

Honeywell International Inc.

Robert Bosch GmbH

Carlisle Companies Inc. (Carlisle Brake and Friction)

Fras-le S.A.

Hindustan Composites Ltd.

ITD Inc.

ABS Friction Inc.

Miba AG

Tokai Rika Co., Ltd.

Hyundai Mobis Co., Ltd.

Advics Co., Ltd.

BREMSKERL Reibbelagwerke Emmerling GmbH & Co. KG

Icer Brakes S.A.

ASK Automotive Ltd.

General Metals Powder Co. LLC

Yantai Hi-Pad Brake Technology

Bendix Commercial Vehicles Systems

ZF Friedrichshafen AG

TTX Brakes

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=54027<ype=S

Recent Developments

November 2024: TTX Brakes launched a premium lineup of brake pads for commercial vehicles and fleets, featuring five customized formulations, including first-to-market CeraPhite and SuperMet technologies, addressing the aftermarket needs for Heavy Commercial Vehicles (HCVs).

January 2024: CNH Industrial integrated upgraded wet disc brake systems in its next-gen Case IH tractors, citing improved heat dissipation and reduced wear, indicating a growing trend in off-highway equipment.

Explore Latest Research Reports by Transparency Market Research:

Ethyl Tertiary-butyl Ether Market - https://www.transparencymarketresearch.com/ethyl-tertiary-butyl-ether-market.html

Paint Remover Market - https://www.transparencymarketresearch.com/paint-remover-market.html

Toluene Derivatives Market - https://www.transparencymarketresearch.com/toluene-derivatives-market.html

Paint Defoamers Market - https://www.transparencymarketresearch.com/paint-defoamers-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Want to know more? Get in touch now. -https://www.transparencymarketresearch.com/contact-us.html

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Friction Materials Market to Reach USD 8.9 Bn by 2034: Key Growth Insights here

News-ID: 4096532 • Views: …

More Releases from transparencymarketresearch

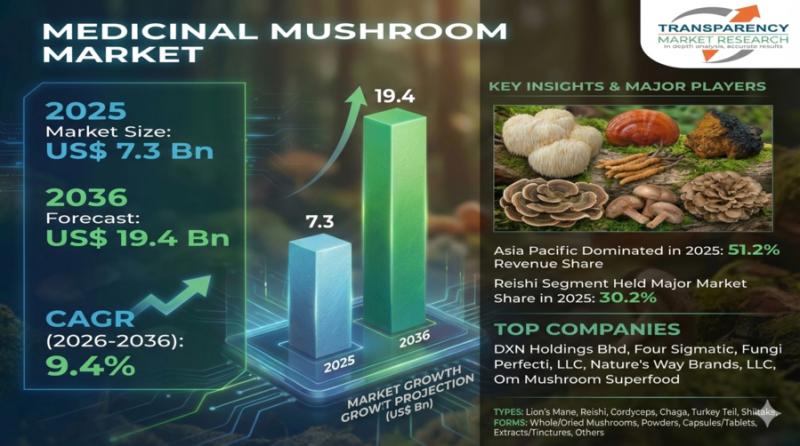

Medicinal Mushrooms Market to Reach USD 19.4 Bn by 2036, Growing at 9.4% CAGR

The global Medicinal Mushrooms Market size was valued at US$ 7.3 Bn in 2025 and is projected to reach US$ 19.4 Bn by 2036, expanding at a CAGR of 9.4% from 2026 to 2036. The global Medicinal Mushrooms industry is expanding due to increased awareness of natural health solutions, rising chronic disease prevalence, wider acceptance of traditional medicine, growing use in supplements and pharmaceuticals, and enhanced accessibility through e-Commerce and…

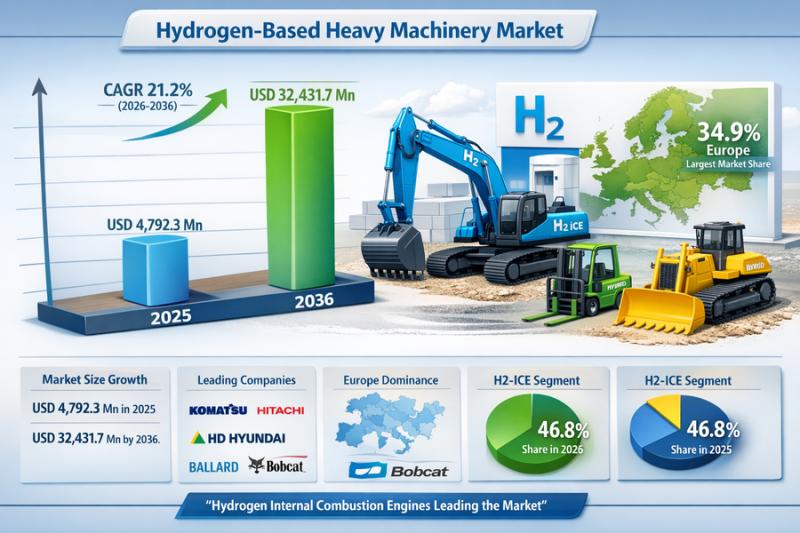

Hydrogen-Based Heavy Machinery Market Set to Reach USD 32.4 Billion by 2036 | TM …

The hydrogen-based heavy machinery market was valued at USD 4,792.3 million in 2025 and is projected to surge to USD 32,431.7 million by 2036. Driven by rapid adoption of clean energy technologies and stringent emission regulations, the industry is expected to grow at a robust CAGR of 21.2% during the forecast period from 2026 to 2036.

The hydrogen-powered heavy machinery market is gaining recognition and is slowly but surely emerging. Referring…

Online Dermatology Consultation Market to Reach USD 9.2 Billion by 2035, Growing …

The online dermatology consultation market was valued at USD 2.8 billion in 2024 and is projected to reach USD 9.2 billion by 2035. Driven by the rising adoption of telemedicine, increasing prevalence of skin disorders, and growing demand for convenient, remote healthcare services, the industry is expected to expand at a CAGR of 11.4% from 2025 to 2035, reflecting strong long-term growth potential.

Technological advancements in telemedicine and artificial intelligence is…

Human Milk Bank Market to Reach USD 843.1 Million by 2035, Growing at a CAGR of …

The global human milk bank market was valued at USD 422.7 million in 2024 and is projected to grow steadily, reaching USD 843.1 million by 2035. This growth reflects the rising awareness of the benefits of donor human milk, the increasing prevalence of preterm births, and the expanding neonatal care infrastructure worldwide. The industry is expected to expand at a CAGR of 6.4% from 2025 to 2035, supported by favourable…

More Releases for Material

Firestop Material Market

LOS ANGELES, United States: The global Firestop Material market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Firestop Material market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and…

New Material Direction for Electric Toothbrushes - Si-TPV Soft Over Molded Mater …

When it comes to factors such as consumer experience or ergonomics, Si-TPV Soft Over Molded Material has had a huge impact on the improvement of various products such as electric toothbrushes, etc. Si-TPV is a Silicone Combine TPU developed and produced by SILIKE, a Thermoplastic Elastomer Manufacturer (Thermoplastic Elastomer Suppliers). Si-TPV material adopts Innovative Soft Slip Technology and Sustainable Overmolding Techniques, which can be used to make Stain Resistance Soft…

A new light on a misjudged material - Plastic waste: material for art

Used plastic bottles are not waste, but a valuable resource. They can be reprocessed in a variety of ways and transformed into new products or fresh energy. And into art. This is exactly what Ve-ronika Richterová does. The Czech artist creates fascinating sculp-tures made out of old PET bottles.

Plastic has inspired artists from the very beginning. The reason: plas-tic meets almost all technical and aesthetic requirements. It is a uni-versal…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

The Future of Smart Material Market Runs Through the Material Industry

Smart Materials Market is expected to garner $72.63 billion by 2022, registering a CAGR of 14.9% during the forecast period 2016-2022. Smart materials are adaptive or intelligent materials which pose intrinsic and extrinsic capabilities. These can be altered by external stimuli, such as moisture, temperature, electromagnetic field, and pressure to obtain the desired functional effects. In addition, these materials are dynamic in nature and respond to their immediate interaction environments…

Global Regenerative Artificial Skin Sales Market Research Report 2017 (Temporary …

The report "Global Regenerative Artificial Skin Sales Market Report 2017", has been prepared based on an in-depth market analysis with inputs from industry experts.

This report studies sales (consumption) of Regenerative Artificial Skin in Global market, especially in United States, China, Europe and Japan, focuses on top players in these regions/countries, with sales, price, revenue and market share for each player in these regions, covering

Integra Life Sciences Corporation

Mylan N.V

Johnson & Johnson…