Press release

Tile Adhesive Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview

Tile adhesive is a specially formulated bonding material used to securely fix tiles to surfaces such as floors, walls, and ceilings. Typically made from a blend of cement, polymers, sand, and additives, it offers excellent adhesion, flexibility, and water resistance. It ensures long-lasting tile installations and is suitable for ceramic, porcelain, vitrified, and natural stone tiles in residential, commercial, and industrial settings.Setting up a tile adhesive production plant involves procuring raw materials, installing mixers, silos, and packing units, and ensuring quality control systems. A small to medium-scale plant can be established with moderate investment, offering good market potential in construction and renovation sectors.

IMARC Group's report, titled "Tile Adhesive Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a Tile adhesive production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/tile-adhesive-manufacturing-plant-project-report/requestsample

Tile Adhesive Industry Outlook 2025

The tile adhesive industry is poised for strong growth through 2025, driven by rapid urbanization, expanding construction activities, and increasing demand for durable, easy-to-apply bonding solutions. Shifts from traditional cement mortar to ready-mix adhesives are becoming more prominent due to their superior bonding strength, faster installation, and reduced material wastage. The rise in residential renovations, commercial infrastructure projects, and smart city developments further boosts demand. Additionally, advancements in product formulations, including polymer-modified and eco-friendly variants, are aligning with sustainability trends and performance expectations, making the tile adhesive market increasingly competitive and innovation-focused.

Key Insights for setting up a Tile Adhesive Production Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Estimate Plant Setup Cost Now: https://www.imarcgroup.com/capex-calculator

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components

• Raw Materials

Cement (e.g., white/grey Portland cement)

Sand / Aggregates (graded silica/quartz sand)

Polymers (e.g., redispersible polymer powder - RDP)

Additives (e.g., cellulose ethers, defoamers, retarders, thickeners)

This forms the largest share of total costs, typically 60-70%.

• Packaging Materials

Laminated paper bags, valve bags, or HDPE bags

Printing, labeling, sealing costs

• Utilities and Energy

Electricity for mixers, conveyors, and packing machines

Compressed air (if used)

Water (minimal use, mostly for cleaning or dust control)

• Labor Costs

Skilled and unskilled labor for operations, QC, and maintenance

• Machinery and Equipment Depreciation

Dry mix plant, ribbon blender/paddle mixer, silos, packaging line

Maintenance and wear-and-tear allowances

• Overheads and Administration

Rent, administration, licenses, insurance, and security

Quality control and R&D expenses

• Logistics and Distribution

Transport of raw materials and finished goods

Warehousing and handling charges

Economic Trends Influencing Ferrous Tile Adhesive Plant Setup Costs 2025

• Raw Material Price Volatility

Fluctuations in the prices of cement, redispersible polymer powder (RDP), silica sand, and specialty additives-driven by global supply-chain shifts and commodity market instability-are significantly affecting initial inventory and production cost planning.

• Inflation and Interest Rates

Persistent inflationary pressure has led to higher prices for construction materials, machinery, and skilled labor. Additionally, elevated interest rates are increasing the cost of capital, impacting financing for plant infrastructure and equipment purchases.

• Energy and Utility Costs

Rising energy costs, especially electricity and fuel for transportation and production, are inflating operational expenditures. This also impacts the cost of running mixers, dryers, and automated packaging lines.

• Import Dependency and Currency Fluctuations

Many key ingredients like polymers and certain chemical additives are imported. Exchange rate fluctuations are raising the landed cost of these inputs, affecting plant cost modeling.

• Government Incentives and Regulatory Costs

While some governments are offering subsidies for construction chemical manufacturing under Make-in-India or similar schemes, compliance costs related to environmental, safety, and construction norms have also risen, adding to setup expenses.

• Technological Shifts

The trend toward automation and sustainable production is prompting investment in modern, energy-efficient, and digital equipment-raising upfront capital costs but offering long-term savings.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=7805&flag=C

Challenges and Considerations for Investors

• Raw Material Volatility:

Price fluctuations in cement, polymers (like RDP), and specialty additives can affect margins and forecasting.

• Market Competition:

The sector is highly fragmented with both local and multinational players. Competing on quality, price, and brand trust is critical.

• Technology & Formulation:

Developing high-performance, polymer-modified adhesives requires technical expertise and R&D investment, especially to meet varying tile types and substrate conditions.

• Regulatory Compliance:

Adhering to environmental norms, material safety standards, and packaging laws can increase operational complexity.

• Distribution & Brand Building:

Establishing a reliable distribution network and brand reputation in a price-sensitive market requires time and strategic marketing.

Conclusion

The tile adhesive industry offers promising investment opportunities, driven by growing demand in residential and commercial construction. With rising awareness of quality, efficiency, and sustainability in tiling solutions, the shift from conventional mortars to ready-mix adhesives is accelerating. While raw material costs and regulatory factors pose challenges, strategic planning, modern technology, and market understanding can lead to a profitable and scalable venture. Setting up a tile adhesive production plant, with proper guidance and feasibility analysis, can position investors for long-term success in this expanding sector.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Tile Adhesive Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview here

News-ID: 4093616 • Views: …

More Releases from IMARC Group

India Digital Health Market is Expected to Reach USD 84,076.5 Million by 2034 | …

Introduction

According to IMARC Group's report titled "India Digital Health Market Size, Share, Trends and Forecast by Type, Component, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including India digital health market share, growth, trends, and regional insights.

How Big is the India Digital Health Market?

The India digital health market size reached USD 19,145.3 Million in 2025. Looking forward, IMARC Group expects the market to reach USD 84,076.5…

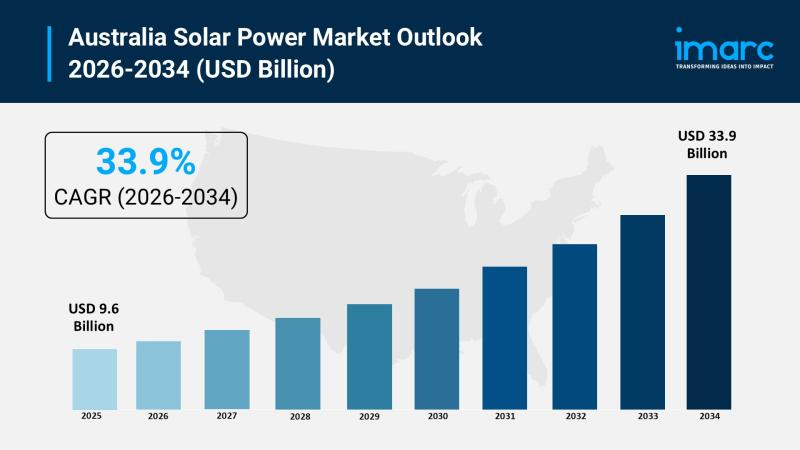

Australia Solar Power Market 2026 | Projected to Reach USD 33.9 Billion by 2034

Market Overview

The Australia solar power market reached USD 9.6 Billion in 2025 and is forecast to grow to USD 33.9 Billion by 2034. The market exhibits a robust growth rate of 15.00% during the forecast period 2026-2034. This expansion is driven by supportive government policies, technological advancements, and increasing adoption across residential, commercial, and utility sectors, positioning solar energy as a cornerstone of Australia's clean energy future.

Grab a sample PDF…

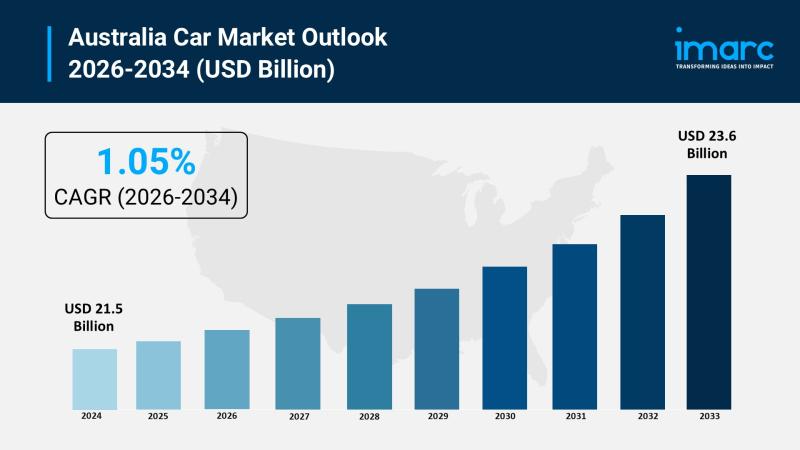

Australia Car Market 2026 | Surge to Grow to USD 23.6 Billion by 2034

Market Overview

The Australia car market reached a size of USD 21.5 Billion in 2025 and is forecasted to grow to USD 23.6 Billion by 2034. The market is expected to expand at a CAGR of 1.05% throughout the forecast period from 2026 to 2034. Growth is driven primarily by increasing demand for electric vehicles, SUVs, and connected car technologies, spurred by environmental awareness, lifestyle changes, and technological innovation toward sustainable…

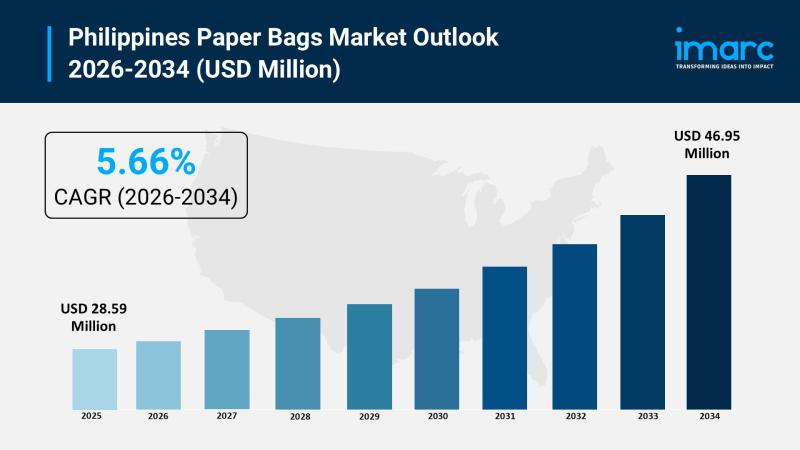

Philippines Paper Bags Market 2026 | Expected to Reach USD 46.95 Million by 2034

Market Overview

The Philippines paper bags market size was valued at USD 28.59 Million in 2025 and is expected to reach USD 46.95 Million by 2034, with a growth rate of 5.66% CAGR from 2026 to 2034. This growth is driven by increasing environmental concerns, government bans on single-use plastics, and rising adoption by retailers and foodservice providers. The expanding food and beverage sector, coupled with heightened awareness of plastic pollution,…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…