Press release

Epoxy Resin Production Cost Analysis 2025: A Detailed Guide from Capital to Commissioning

IntroductionEpoxy resin is a versatile thermosetting polymer known for its strong adhesive properties, chemical resistance, and durability. It is created through the reaction of epoxide compounds with hardeners and is widely used in coatings, adhesives, electronics, construction, and composite materials due to its excellent mechanical and thermal properties.

Setting up an epoxy resin production plant involves sourcing raw materials like epichlorohydrin and bisphenol-A, installing reactors, mixers, and curing units, and ensuring proper safety systems. The plant should also comply with environmental regulations and quality control standards, with a focus on efficient batch processing and scalable production capacity.

IMARC Group's report, titled "Epoxy Resin Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a epoxy resin production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/epoxy-resin-manufacturing-plant-project-report/requestsample

Epoxy Resin Industry Outlook 2025

The epoxy resin industry is set for steady growth through 2025, with the global market projected at around USD 12.33 billion and expanding at a CAGR of approximately 5.7% into the next decade. Growth is being driven by rising demand in paints and coatings-especially in construction and automotive-plus strong expansion in electrical, electronics, and composite applications. Additionally, sustainability trends are accelerating the development and uptake of bio based and low VOC epoxy formulations, positioning the industry for innovation-led competition worldwide.

Key Insights for setting up an Epoxy Resin Production Plant

Detailed Process Flow

o Product Overview

o Unit Operations Involved

o Mass Balance and Raw Material Requirements

o Quality Assurance Criteria

o Technical Tests

Project Details, Requirements and Costs Involved:

o Land, Location and Site Development

o Plant Layout

o Machinery Requirements and Costs

o Raw Material Requirements and Costs

o Packaging Requirements and Costs

o Transportation Requirements and Costs

o Utility Requirements and Costs

o Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

o Capital Investments

o Operating Costs

o Expenditure Projections

o Revenue Projections

o Taxation and Depreciation

o Profit Projections

o Financial Analysis

Profitability Analysis:

o Total Income

o Total Expenditure

o Gross Profit

o Gross Margin

o Net Profit

o Net Margin

Key Cost Components

• Raw Material Procurement: Epichlorohydrin, bisphenol-A, hardeners, solvents, and additives.

• Machinery and Equipment: Reactors, mixers, condensers, distillation units, storage tanks, and control systems.

•Land and Infrastructure: Land acquisition or leasing, civil construction, utilities (water, electricity, waste management).

• Plant Setup and Installation: Machinery installation, piping, electrical work, and automation systems.

• Labor and Staffing: Hiring skilled technicians, engineers, operators, and administrative staff.

• Quality Control and R&D: Laboratory setup, testing equipment, and formulation development costs.

• Contingency and Working Capital: Buffer funds for unforeseen expenses and initial operational costs.

Buy Now: https://www.imarcgroup.com/checkout?id=9495&method=1911

Economic Trends Influencing Epoxy Resin Plant Setup Costs 2025

• Raw material price volatility: Epoxy resin primarily relies on petrochemical feedstocks like bisphenol A and epichlorohydrin-making feedstock costs highly sensitive to global oil price swings, which can inflate project costs by 20-40% during spikes.

• Rising energy expenses: Production processes are energy-intensive (e.g., curing at 150-200 °C), and elevated electricity and gas rates-especially in regions like Europe-can boost operational costs by up to 50%.

• Supply chain instability: Shipping disruptions, regional feedstock export controls (e.g., from Russia and China), and freight cost hikes add uncertainty and increase warehousing, logistics, and working-capital needs.

• Tighter environmental regulations: Compliance with frameworks like EU REACH and carbon pricing schemes necessitates investment in catalysts, scrubbers, and emissions controls-raising CAPEX by millions per plant.

• Shift toward bio-based resins: Growing demand for sustainable alternatives drives R&D and process redesign, requiring additional capital for new feedstocks and conversion systems.

• Regional cost disparities: Location-specific factors-energy cost, regulatory burden, infrastructure-can significantly affect setup costs, making site selection critical for cost optimization.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=9495&flag=C

Challenges and Considerations for Investors

• Raw Material Dependency: Heavy reliance on petroleum-based feedstocks like epichlorohydrin and bisphenol-A makes the project vulnerable to price fluctuations and supply chain disruptions.

• Environmental Compliance: Epoxy production involves hazardous chemicals; meeting stringent environmental and safety regulations (e.g., emissions control, wastewater treatment) increases both capital and operational costs.

• Market Competition: Established global players dominate the market, requiring new entrants to differentiate through quality, pricing, or sustainable offerings.

• Initial Capital Investment: Setting up a plant involves significant upfront investment in land, equipment, infrastructure, and R&D, which may challenge ROI in the short term.

• Demand Uncertainty: Demand is influenced by cyclical industries like construction, automotive, and electronics; economic slowdowns in these sectors can impact profitability.

• Transition to Bio-Based Resins: Growing preference for eco-friendly alternatives may demand additional investment in green technologies and process innovation.

• Geopolitical Risks: Import-export restrictions and global trade tensions can affect access to raw materials and overseas markets.

• Regulatory Delays: Licensing, zoning, and environmental clearances can be time-consuming, delaying project timelines and increasing holding costs.

• Sustainability Pressures: Increasing stakeholder expectations around sustainability and circular economy practices may necessitate changes in sourcing, packaging, and waste management.

Conclusion

Investing in an epoxy resin plant presents a promising opportunity given the material's growing demand across diverse sectors like construction, automotive, electronics, and renewable energy. However, it also comes with notable challenges-including raw material volatility, strict regulatory requirements, and rising sustainability expectations. For investors, success will depend on strategic planning, technological innovation, cost management, and a strong focus on environmental compliance. With the right approach, an epoxy resin plant can offer long-term returns and a competitive edge in a steadily expanding global market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Epoxy Resin Production Cost Analysis 2025: A Detailed Guide from Capital to Commissioning here

News-ID: 4093563 • Views: …

More Releases from IMARC Group

China Tea Market Forecast CAGR of 8.13%, Innovation Trends, and Strategic Insigh …

Market Overview

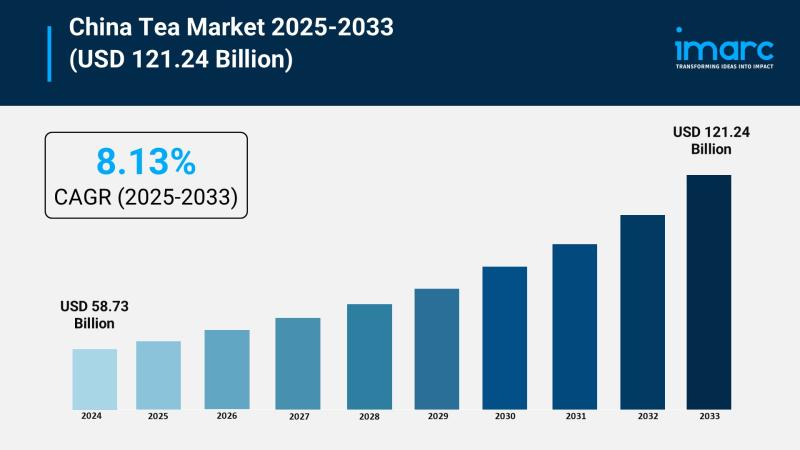

The China tea market was valued at USD 58.73 Billion in 2024 and is projected to reach USD 121.24 Billion by 2033, growing at a CAGR of 8.13% during 2025-2033. Growth is driven by rising health consciousness, premium product trends, government support, and expanding online retail. Innovation in flavors and packaging attracts younger consumers and global buyers, expanding the market.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

China Tea…

Philippines Dairy Market 2026: Expected to Reach USD 33,997.8 Million by 2034

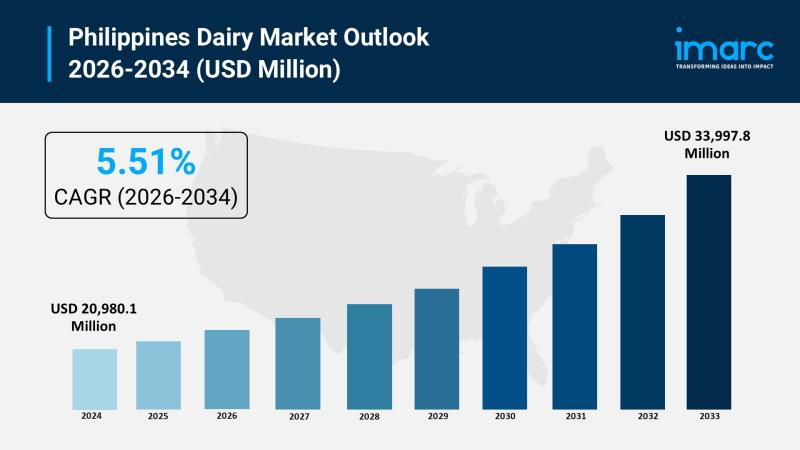

Market Overview

The Philippines dairy market reached a size of USD 20,980.1 Million and is anticipated to grow to USD 33,997.8 Million by 2034 with a significant growth rate of 5.51%. This expansion is driven by rising demand for nutritious and diverse dairy products, rapid urbanization, increased disposable incomes, improved retail infrastructure, and strong government initiatives promoting local dairy production. Health-conscious consumers and expanding food service sectors further fuel this growth…

Philippines Vitamins Market 2026 | Projected to Reach USD 556.0 Million by 2034

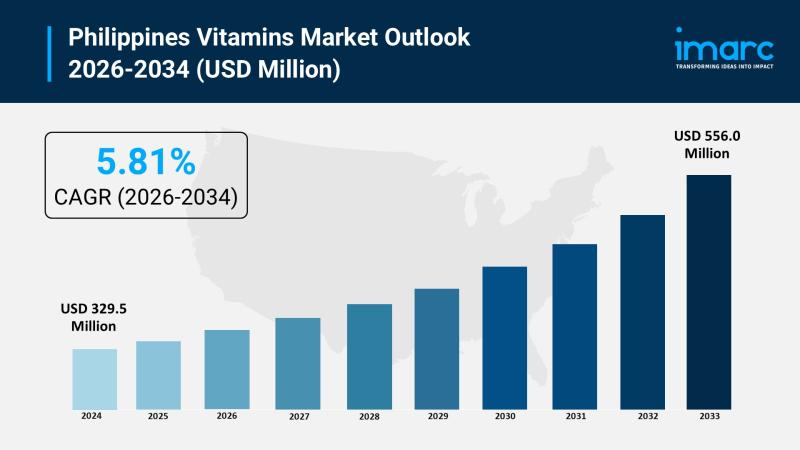

Market Overview

The Philippines vitamins market was valued at USD 329.5 Million in 2025 and is projected to reach USD 556.0 Million by 2034, growing steadily over the forecast period. The market's growth is driven by increasing health consciousness, a rising geriatric population, and escalating demand for supplements that support immunity, energy, and overall wellness due to proactive health measures. The forecast period for this expansion is 2026-2034, with a CAGR…

Australia Power Market Projected to Reach TWH 377 by 2034

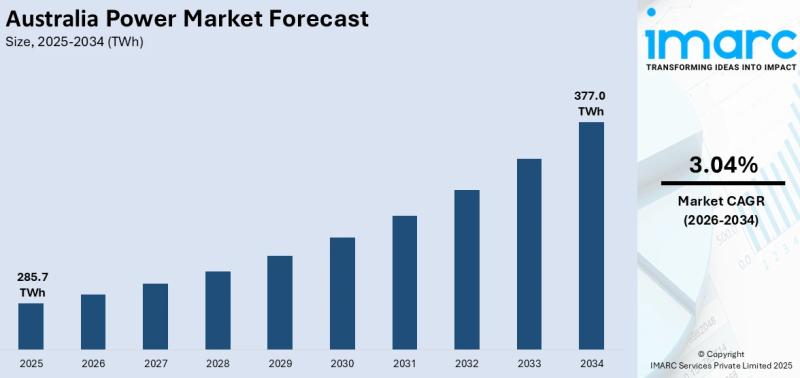

Market Overview

The Australia power market size reached 285.7 TWh in 2025 and is projected to grow to 377.0 TWh by 2034, with a CAGR of 3.04% during the forecast period of 2026-2034. This growth is driven by rising renewable energy adoption, increased electricity demand, grid modernization, battery storage expansion, transition from coal plants, and government incentives for clean power. Key strategies such as virtual power plant integration and investments in…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…