Press release

Silylated Polymers Market to Hit USD 1.6 Billion by 2034, Driven by 5.5% CAGR Growth

The Silylated Polymers Market was valued at USD 890.5 million in 2023 and is projected to reach approximately USD 1.6 billion by 2034, expanding at a CAGR of 5.5% from 2024 to 2034. This growth is driven by increasing demand for durable and flexible adhesives and sealants across industries such as construction, automotive, and electronics. The market is also benefiting from advancements in polymer technology and rising adoption of environmentally friendly and moisture-curing materials.Surge in demand for sustainable adhesives is augmenting the silylated polymers market progress. The rise in need for more sustainable adhesive formulations has presented the possibility of using silane-based adhesives in various end-use industries.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86033

Expansion in paints & coatings sector is also driving the silylated polymers market value. Silanes are employed in high-solids and waterborne coatings as they increase pigment dispersion and improve end-use properties.

Market Segmentation

The silylated polymers market can be segmented by product type, technology, application, end-use industry, and region.

By Product Type:

Silyl Modified Polyethers (MS Polymers): These are polyether-based polymers terminated with silyl groups. They are known for their good adhesion, flexibility, and excellent weathering resistance. They are widely used in sealants and adhesives, particularly for construction and general industrial applications.

Silyl Modified Polyurethanes (SPUR Polymers): These combine the robust mechanical properties of polyurethanes with the benefits of silyl curing. They offer high strength, durability, and improved mechanical performance, making them suitable for demanding applications.

Other Types: This category includes other silylated polymer chemistries designed for specific niche applications.

By Technology:

One-component Systems: These systems typically cure with atmospheric moisture and are convenient for various applications, offering ease of use.

Two-component Systems: These involve mixing two components just before application, allowing for more controlled curing times and often higher performance properties.

By Application:

Adhesives: Silylated polymers are increasingly used as high-performance adhesives due to their strong bonding capabilities, flexibility, and environmental benefits. They are replacing traditional adhesives in various sectors.

Sealants: Their excellent elasticity, weather resistance, and adhesion make them ideal for sealing applications in construction (e.g., windows, facades, roofing), automotive (e.g., body panels, glass bonding), and general industrial settings.

Coatings: Silylated polymers are used in functional coatings for improved durability, weatherability, and protective properties on various surfaces.

Other Applications: Include specialty applications in electronics, consumer goods, and other industrial uses.

By End-Use Industry:

Construction & Infrastructure: The largest application segment, utilizing silylated polymers for flooring, tiling, waterproofing, roofing, facade bonding, and general sealing in residential, commercial, and civil engineering projects.

Automotive & Transportation: Crucial for vehicle assembly, body panel bonding, glass bonding, interior fixtures, and various sealing applications due to their flexibility, durability, and ability to contribute to lightweighting.

General Industry: Diverse applications including industrial assembly, white goods, and other manufacturing processes where high-performance bonding and sealing are required.

Electronics: Used for encapsulation, bonding components, and creating durable seals in electronic devices.

Others: Includes applications in marine, aerospace (for non-critical parts), and consumer goods.

Regional Analysis

The global silylated polymers market exhibits a distinct regional distribution and growth pattern:

Asia Pacific: Expected to be the fastest-growing market and currently holds the largest market share (around 35%). This is primarily driven by rapid industrialization, urbanization, and significant infrastructure development in countries like China, India, and Japan. The booming automotive and construction sectors in these economies, coupled with government initiatives promoting sustainable products, are key growth drivers.

North America: A substantial market (estimated at 30% market share in 2023), propelled by the presence of major end-use industries (automotive, construction, electronics) and increasing demand for eco-friendly products. High investment in research and development and ongoing innovation in polymer technology contribute to its robust growth.

Europe: Another dominant region (approximately 25% market share), characterized by a strong automotive sector, a growing construction industry, and stringent environmental regulations that favor low-VOC and isocyanate-free solutions. Germany, the UK, and France are key contributors.

Rest of the World (Latin America and Middle East & Africa): Expected to witness moderate growth as these regions gradually adopt advanced technologies and experience economic growth, leading to increased demand for silylated polymers in developing infrastructure and industries.

Market Drivers and Challenges

Market Drivers:

Growing Demand for Environmentally Friendly Products: The absence of isocyanates and solvents, leading to low VOC emissions and reduced health hazards, is a significant driver, especially with stricter environmental regulations worldwide.

Increasing Construction Activities: Rapid urbanization and infrastructure development globally are fueling the demand for high-performance, durable adhesives and sealants in the building and construction sector.

Growth in the Automotive Industry: The automotive sector's continuous need for strong, flexible, and lightweight bonding solutions for vehicle assembly, including the increasing production of electric vehicles, boosts demand for silylated polymers.

Superior Performance Properties: Silylated polymers offer excellent adhesion, elasticity, weatherability, UV resistance, and chemical stability, making them suitable for demanding applications.

Versatility: Their ability to bond to a wide range of substrates (metals, plastics, glass, ceramics) makes them highly versatile across various industries.

Replacement of Traditional Chemistries: Silylated polymers are increasingly replacing conventional polyurethane and silicone-based systems due to their improved performance, environmental profile, and ease of use.

Technological Advancements: Continuous innovation in product formulation and polymer technology leads to enhanced durability, curing efficiency, and new application possibilities.

Market Challenges:

Volatility of Raw Material Prices: Fluctuations in the prices of key raw materials, particularly those derived from polyurethane and silicone precursors, can impact production costs and market pricing.

Lower Initial Cure Speed (for some formulations): Compared to some fast-curing traditional systems, certain silylated polymer formulations might have a slightly slower initial cure, which can be a limiting factor in some high-speed manufacturing processes.

Awareness and Adoption: While gaining traction, there is still a need for broader awareness and acceptance of silylated polymers as alternatives to more established chemistries in some industrial segments.

Specific Application Limitations: Despite their versatility, silylated polymers may not be suitable for all applications, particularly those requiring extremely high heat resistance or very rigid bonds.

Market Trends

Focus on Advanced Adhesives and Sealants: Continuous innovation in product formulation to achieve enhanced durability, faster curing times, and improved adhesion to challenging substrates.

Sustainable and Eco-Friendly Formulations: A strong emphasis on developing even greener silylated polymers, potentially incorporating bio-based components or further reducing environmental footprints.

Growth in Flexible and Wearable Electronics: Silylated polymers are finding new niches in flexible displays, wearable devices, and other compact electronic applications due to their flexibility and reliable bonding.

Hybrid Systems: Research and development into hybrid systems that combine silylated polymers with other resin types (e.g., epoxy resins) to achieve a broader range of properties and address specific performance requirements.

Increased Use in Roofing and Waterproofing: Their excellent elasticity and weather resistance make them increasingly popular for roofing membranes, liquid waterproofing systems, and other exterior applications.

Automation in Application: The development of silylated polymer formulations optimized for automated application processes in industrial and automotive assembly lines.

Future Outlook

The silylated polymers market is poised for continued expansion, driven by the ongoing global shift towards sustainable and high-performance materials. The construction and automotive industries will remain major growth engines, while emerging applications in electronics and specialized industrial sectors will further diversify demand. As research and development lead to even more advanced formulations with improved properties and cost-effectiveness, silylated polymers are expected to capture an increasing share of the adhesives, sealants, and coatings market. The drive for "green" solutions and the reduction of hazardous chemicals will solidify their position as a preferred choice for manufacturers worldwide.

Key Market Study Points

Environmental Impact and Regulations: Analyze the evolving regulatory landscape concerning VOC emissions and hazardous chemicals, and its influence on market growth.

Application-Specific Performance: Evaluate the specific performance advantages of silylated polymers in various applications (e.g., adhesion to different substrates, UV resistance, flexibility).

Cost-Benefit Analysis: Assess the overall economic benefits of using silylated polymers, considering their performance, longevity, and environmental advantages compared to alternatives.

Technological Advancements: Monitor R&D efforts aimed at improving cure speed, mechanical properties, and expanding the range of compatible substrates.

Regional Market Dynamics: Understand the specific drivers and challenges influencing growth in key regions, particularly the rapid expansion in Asia Pacific.

Competitive Landscape

The silylated polymers market is characterized by the presence of several established chemical companies and specialty polymer manufacturers. Competition revolves around product innovation, technical support, global reach, and the ability to offer customized solutions for diverse industrial needs. Companies are investing in R&D to develop superior formulations and expand their application portfolios.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=86033<ype=S

Key Players include:

3M Company

Avery Dennison Corporation

BASF SE

Dow Chemical Company

DuPont de Nemours, Inc.

Evonik Industries AG

Henkel AG & Co. KGaA

Kaneka Corporation

Momentive Performance Materials Inc.

Shin-Etsu Chemical Co., Ltd.

Wacker Chemie AG

AGC Chemicals

Hexion

Nippon Paint Holdings Co., Ltd.

Sika AG

Recent Developments

July 2024: Mohm Chemical launched x'traseal MS-602 MS Polymer Sealant, targeting the construction industry with an advanced formulation.

November 2023: Research highlighted the mechanical properties of a dual-cure two-component prototype adhesive combining silylated polyurethane resin (SPUR) with standard epoxy resin, showcasing efforts to create hybrid systems for enhanced performance, particularly in transportation applications.

July 2020: Evonik Industries AG began production at a new multi-purpose silicone facility in Germany, producing silicones and silyl-terminated polymers (SMPs) for applications like parquet adhesive flooring and liquid membranes for roofing.

June 2021: Wacker AG started building a liquid resins unit in Germany, using silanes and liquid resins to formulate specialty silicones, including those for building protection agents and corrosion-resistant coatings.

Explore Latest Research Reports by Transparency Market Research:

Thermal Fluids for Industrial Heaters Market - https://www.transparencymarketresearch.com/thermal-fluids-for-industrial-heaters-market.html

Toughened Glass Market - https://www.transparencymarketresearch.com/toughened-glass-market.html

Refinery Cleaning Chemicals Market - https://www.transparencymarketresearch.com/refinery-cleaning-chemicals-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Want to know more? Get in touch now. -https://www.transparencymarketresearch.com/contact-us.html

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Silylated Polymers Market to Hit USD 1.6 Billion by 2034, Driven by 5.5% CAGR Growth here

News-ID: 4093058 • Views: …

More Releases from transparencymarketresearch

Air Fryer Market to Reach USD 2,343.9 Mn by 2036 Driven by Health-Focused Cookin …

The global air fryer market was valued at USD 1,103.4 Mn in 2025 and is projected to reach USD 2,343.9 Mn by 2036, expanding at a CAGR of 7.8% from 2026 to 2036. Market growth is primarily driven by rising health consciousness and increasing demand for low-oil cooking appliances among consumers. Busy urban lifestyles, compact kitchen trends, and the growing preference for convenient home-cooking solutions are further supporting adoption. Additionally,…

Global Yeast Market to Reach US$ 16.9 Bn by 2036 Driven by Bakery and Beverage D …

The global yeast market was valued at USD 9.7 Bn in 2025 and is projected to reach USD 16.9 Bn by 2036, expanding at a CAGR of 5.1% from 2026 to 2036. Market growth is primarily driven by increasing demand from the bakery and food processing industries, along with the steady expansion of alcoholic and non-alcoholic beverage production. Rising consumption of convenience foods and fermented products continues to support sustained…

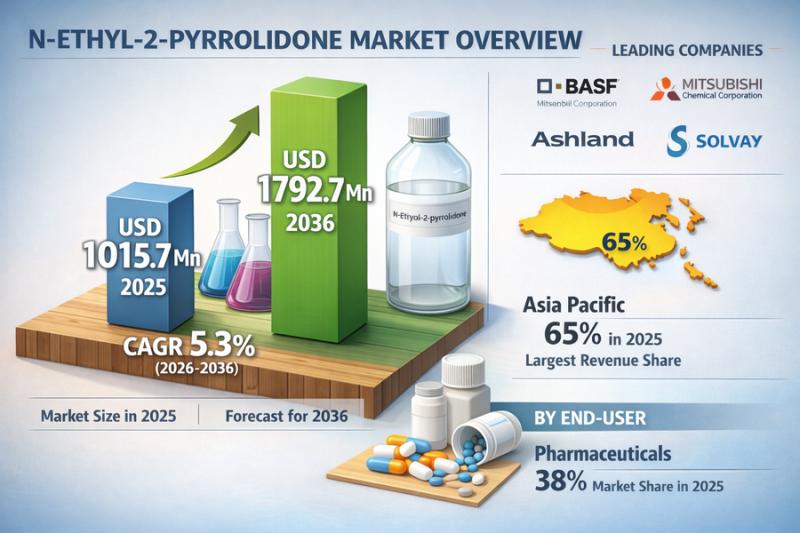

N-Ethyl-2-pyrrolidone Market to Reach USD 1,792.7 Million by 2036 at 5.3% CAGR

The N-Ethyl-2-pyrrolidone market was valued at USD 1,015.7 million in 2025 and is projected to reach USD 1,792.7 million by 2036. The industry is expected to grow at a CAGR of 5.3% from 2026 to 2036, supported by increasing demand across pharmaceuticals, electronics, petrochemicals, and industrial cleaning applications.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85529

Market Overview

N-Ethyl-2-pyrrolidone (NEP) is a colorless to yellowish liquid with a characteristic odor. It…

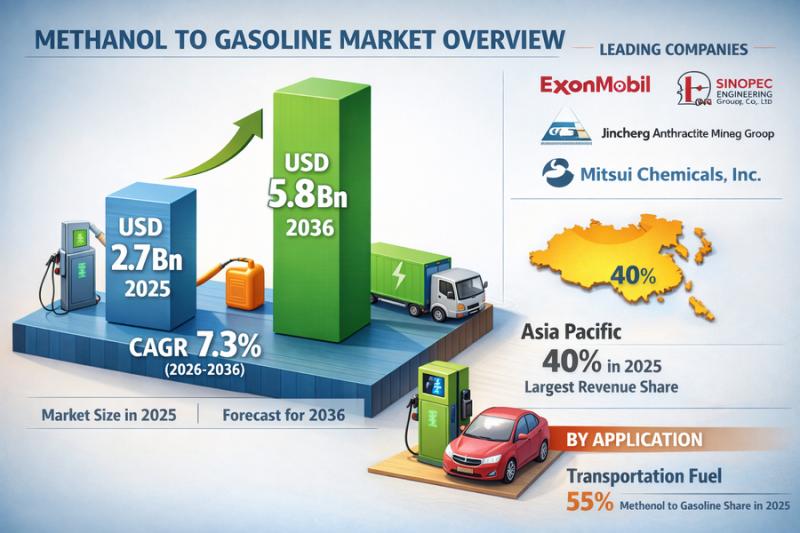

Methanol to Gasoline Market to Reach USD 5.8 Billion by 2036 at 7.3% CAGR

The methanol to gasoline market was valued at USD 2.7 billion in 2025 and is projected to reach USD 5.8 billion by 2036. The industry is expected to expand at a CAGR of 7.3% from 2026 to 2036, driven by growing interest in alternative fuels, efforts to enhance energy security, and increasing investments in methanol-to-fuel conversion technologies.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85466

Market Overview

Methanol to Gasoline (MTG)…

More Releases for Silyl

Silyl Acrylate Polymer Market Size,Volume,Revenue Trends Analysis Report 2023-20 …

Global Info Research announces the release of the report "Global Silyl Acrylate Polymer Market 2023 by Manufacturers, Regions, Type and Application, Forecast to 2029" . The report is a detailed and comprehensive analysis presented by region and country, type and application. As the market is constantly changing, the report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets.…

Silyl Modified Polymers Market Trends and Dynamic Demand by 2030

Global Silyl Modified Polymers Market: Snapshot

The global silyl modified polymers market is foreseen to witness stupendous sales avenues during the forecast period of 2020 to 2030. One of the key reasons attributed to this growth is growing use of silyl modified polymers in diverse end-use applications. Silyl modified polymers are widely used in the manufacturing of isocyanate-free and solvent-free sealant and adhesive products. Thus, growing demand for sealant and adhesive…

Silyl Modified Polymer Market to Witness Robust Expansion by 2025

LP INFORMATION recently released a research report on the Silyl Modified Polymer market analysis and elaborate the industry coverage, current market competitive status, and market outlook and forecast by 2025. Moreover, it categorizes the global Silyl Modified Polymermarket by key players, product type, applications and regions,etc.

The main objective of this market research is to help the readers understand the structure of Silyl Modified Polymermarket, market definition, overview, industry opportunities…

Global Silyl-Terminated Polyethers Industry Professional Market Overview Report …

This report also researches and evaluates the impact of Covid-19 outbreak on the Silyl-Terminated Polyethers industry, involving potential opportunity and challenges, drivers and risks. We present the impact assessment of Covid-19 effects on Silyl-Terminated Polyethers and market growth forecast based on different scenario (optimistic, pessimistic, very optimistic, most likely etc.).

Global Silyl-Terminated Polyethers Market Overview:

GLOBAL INFO RESEARCH has evaluated the global Silyl-Terminated Polyethers market in its latest research report. The research report, titled [Global and China…

Silyl Modified Polymers Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Silyl Modified Polymers Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Silyl Modified Polymers players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Silyl Modified Polymers with respect…

Silyl Modified Polymers Market Competitive Industry Report 2019: QY Research

The Silyl Modified Polymers market was valued at Million US$ in 2017 and is projected to reach Million US$ by 2025, at a CAGR of during the forecast period. In this study, 2017 has been considered as the base year and 2018 to 2025 as the forecast period to estimate the market size for Silyl Modified Polymers.

This study focuses on the production side and consumption side of Silyl Modified Polymers,…