Press release

Urea Production Cost Analysis 2025: A Detailed Guide from Capital to Commissioning

Urea, also known as carbamide, is an organic compound with the chemical formula CO(NH2)2. It is a colourless, odorless solid that plays a vital role in agriculture as a nitrogen-rich fertilizer, promoting plant growth and crop yield. Urea is highly water-soluble and contains the highest nitrogen content among solid fertilizers, making it a preferred choice for farmers worldwide. It is also used in various industrial applications, including the manufacture of resins, adhesives, plastics, and pharmaceuticals.Setting up a urea production plant involves sourcing ammonia and carbon dioxide, installing high-pressure reactors and granulation units, and ensuring compliance with safety and environmental regulations. Key requirements include land, utilities, skilled workforce, and capital for equipment and infrastructure.

IMARC Group's report, titled "Urea Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a Urea production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/urea-manufacturing-plant-project-report/requestsample

Urea Industry Outlook 2025

The urea industry is expected to witness stable growth through 2025, driven by rising global demand for nitrogen-based fertilizers to support agricultural productivity. As the need for food security intensifies due to population growth and shrinking arable land, urea remains a critical input in enhancing crop yields. Additionally, government initiatives promoting balanced fertilizer use and sustainable farming practices are contributing to market expansion. Beyond agriculture, industrial uses of urea in resins, adhesives, and environmental control systems (such as NOx reduction in vehicles) are further broadening its application scope. Technological advancements in production efficiency, along with the growing focus on reducing emissions and energy consumption, are shaping the future of the urea industry. However, challenges such as feedstock price volatility, environmental concerns, and regulatory pressures may influence production costs and strategic investments.

Key Insights for setting up a Urea Production Plant

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Estimate Plant Setup Cost Now: https://www.imarcgroup.com/capex-calculator

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Key Cost Components

• Raw Materials:

• The primary cost driver, including ammonia (typically derived from natural gas) and carbon dioxide, both essential for urea synthesis.

• Energy Costs:

• Urea production is energy-intensive, especially for ammonia synthesis, requiring significant amounts of natural gas, electricity, and steam.

• Machinery and Equipment:

• Capital investment in high-pressure reactors, compressors, heat exchangers, granulators, and other specialized equipment, along with ongoing maintenance costs.

• Labor:

• Includes salaries, training, and benefits for skilled and unskilled workers involved in plant operation, maintenance, and quality control.

• Utilities:

• Costs for water, compressed air, cooling systems, and other utilities essential for continuous, safe production.

• Packaging and Transportation:

• Expenses related to bagging, storing, and distributing finished urea to wholesalers or end users, including logistics infrastructure.

• Depreciation and Financing:

• Depreciation of fixed assets and interest or repayment obligations for loans or capital investment in plant setup.

• Compliance and Safety:

• Investment in emission control systems, environmental compliance, safety measures, and waste treatment facilities.

• Overheads:

• Administrative costs such as insurance, office operations, licensing, marketing, and general plant management.

Economic Trends Influencing Ferrous Urea Plant Setup Costs 2025

• Natural Gas Price Volatility:

• As natural gas is the primary feedstock for ammonia-and by extension urea-fluctuating global gas prices directly impact both capital and operating costs. Higher prices raise energy expenses, making energy efficiency upgrades more critical.

• Carbon Pricing & Environmental Policies:

• Growing regulatory focus on greenhouse gas emissions increases costs related to carbon capture, waste treatment, and compliance systems. Carbon pricing mechanisms and tighter environmental rules may elevate initial capital outlay.

• Inflation & Interest Rates:

• Rising inflation inflates the cost of building materials, labor, and equipment, while higher interest rates increase the cost of loans and financing needed for plant construction and commissioning.

• Government Subsidies & Stimulus:

• Policies supporting fertilizer self-sufficiency and food security-especially in agricultural economies-can reduce setup costs through grants, low-interest loans, or tax rebates aimed at urea plant investments.

• Technological Advancements:

• Innovations in process intensification, catalyst efficiency, and heat recovery equipment can increase upfront CapEx but offer significant energy savings and lower emissions, enhancing long-term ROI.

• Supply Chain Localization:

• Efforts to reshore production and reduce import dependence are incentivizing in‐country investment in plant equipment, potentially increasing sourcing costs if domestic supply is limited-but improving security of supply.

• Labor Market Considerations:

• Shortages in skilled labor for handling high-pressure chemical processes or plant automation can drive up wages or necessitate investment in training and retention-raising initial set-up and operational expenses.

Speak to an Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=7647&flag=C

Challenges and Considerations for Investors

• Feedstock Price Volatility:

• Urea production heavily depends on natural gas or other hydrocarbon-based feedstocks. Fluctuations in global energy prices can significantly impact production costs and profit margins.

• High Capital Intensity:

• Establishing a urea plant requires substantial investment in high-pressure reactors, compressors, and emission control systems. Long payback periods can deter risk-averse investors.

• Environmental Compliance:

• Stringent environmental regulations on greenhouse gas emissions, effluent discharge, and carbon footprint require additional investment in pollution control technologies and sustainable practices.

• Government Pricing Controls:

• In many countries, fertilizer prices are subsidized or regulated, which may limit profitability and restrict the ability to pass on increased costs to end users.

• Market Competition:

• The global urea market is competitive, with several established players and excess production capacity in some regions. Investors must focus on operational efficiency or niche differentiation to remain viable.

• Logistics and Distribution:

• Transporting bulk urea requires reliable infrastructure and storage facilities. Poor logistics can lead to distribution bottlenecks and increased delivery costs.

• Technological Barriers:

• Staying competitive requires adopting advanced, energy-efficient production technologies. Outdated systems lead to higher operational costs and greater environmental impact.

• Policy and Regulatory Risks:

• Changes in government policies, such as restrictions on fertilizer exports or subsidies, can alter market dynamics abruptly and affect investment outcomes.

Conclusion

The urea industry remains a cornerstone of global agriculture and industrial manufacturing, with strong growth potential through 2025. While establishing a urea production plant offers promising returns, it also involves navigating high capital requirements, volatile feedstock prices, and stringent environmental regulations. Success depends on strategic planning, technological adoption, and compliance with evolving market and policy conditions. With rising global demand and supportive government initiatives, well-informed investors can capitalize on the sector's opportunities by building efficient, sustainable, and competitive urea production facilities.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Urea Production Cost Analysis 2025: A Detailed Guide from Capital to Commissioning here

News-ID: 4091085 • Views: …

More Releases from IMARC Group

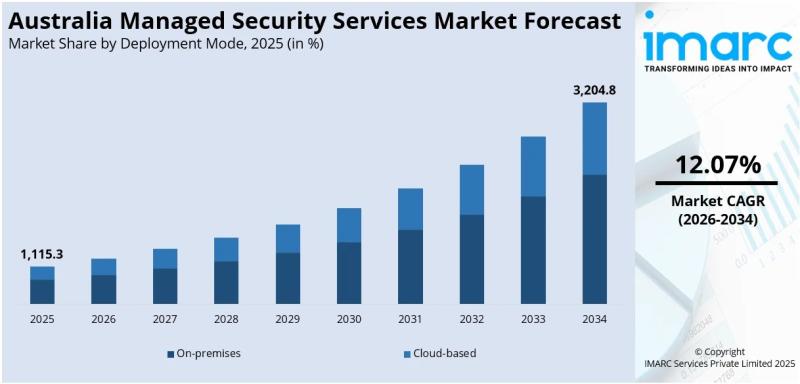

Australia Managed Security Services Market 2026 | Worth USD 3,204.8 Million by 2 …

Market Overview

The Australia managed security services market size reached USD 1,115.3 Million in 2025 and is expected to grow to USD 3,204.8 Million by 2034. The market will expand during the forecast period of 2026-2034 at a CAGR of 12.07%. Key growth drivers include rising cyberattack complexity, shortage of skilled professionals, rapid digital transformation, increasing cloud adoption, expanding remote workforces, growing regulatory pressures, demand for 24/7 threat monitoring, cost-effective security…

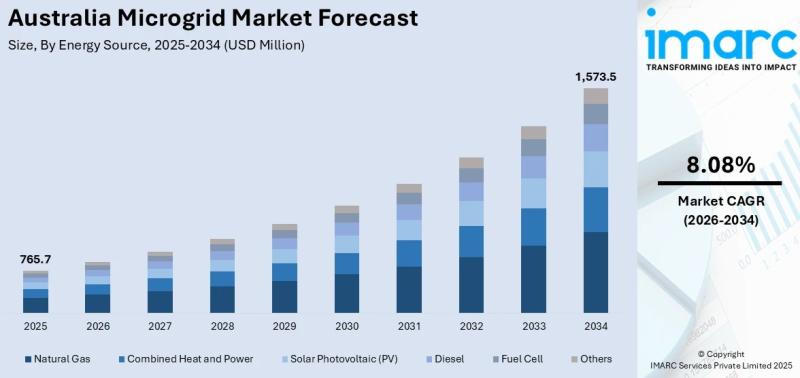

Australia Microgrid Market 2026 | Worth USD 1,573.5 Million by 2034

Market Overview

The Australia Microgrid Market size was USD 765.7 Million in 2025 and is projected to grow to USD 1,573.5 Million by 2034, with a CAGR of 8.08% over the forecast period 2026-2034. The market expansion is driven by increasing energy costs, grid instability, and government support for renewables such as solar and wind. Falling battery prices and abundant renewable resources boost microgrid feasibility, especially in remote and regional communities…

Europe Textile Market to Hit USD USD 413.5 Billion by 2034 with a Robust CAGR of …

The Europe textile market was valued at USD 273.7 Billion in 2025 and is projected to reach USD 413.5 Billion by 2034, expanding at a CAGR of 4.69% over the forecast period 2026-2034. Market growth is driven by rising demand for sustainable textiles, technological advancements in textile manufacturing, and strong fashion and home furnishings sectors. The region is also witnessing increased adoption of technical textiles and smart textiles, supported by…

Global Candle Market Edition 2025: Industry Size to Reach 16.3 Billion Metric To …

Market Overview

The global candle market was valued at USD 10.5 Billion in 2024 and is projected to reach USD 16.3 Billion by 2033, growing at a CAGR of 5.03% during the forecast period 2025-2033. Growth is driven by rising consumer interest in home ambiance, wellness trends, and demand for artisanal and premium-quality candles. Increasing preference for sustainable waxes and enhanced digital retail are also propelling the market.

Study Assumption Years

• Base Year:…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…