Press release

Cutting Tool Inserts Market Set for Precision Growth, Innovations Driving Global Demand

🌍 Market Overview & StatisticsThe cutting tool inserts market is entering a period of robust expansion, as global manufacturing shifts toward high-precision, high-efficiency machining. According to the latest Persistence Market Research findings, revenue from cutting tool inserts is expected to climb consistently through 2032, driven by increasing demand from industries such as aerospace, automotive, and heavy machinery. This surge is largely attributed to rising industrial automation, the transition to lightweight materials, and the growing adoption of advanced materials like carbide, ceramic, cermet, and polycrystalline diamond (PCD), which extend tool durability and cost efficiency.

Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): https://www.persistencemarketresearch.com/samples/21751

Among segments, carbide inserts dominate due to their versatility and balance between performance and price, targeting applications in ferrous materials. Geographically, the Asia-Pacific region leads the market, driven by the manufacturing prowess of countries like China, India, Japan, and South Korea. High output of automotive, electronics, and machinery manufacturing in the region necessitates precision tooling that supports mass production at scale. Government policies encouraging "Make in India" and China's shift toward high-tech sectors are further solidifying Asia-Pacific's leading position.

✨ Key Highlights from the Report

✦ Carbide inserts maintain largest share due to versatility and cost-effectiveness.

✦ Aerospace and automotive sectors are key demand drivers.

✦ Asia-Pacific leads global market, fueled by manufacturing strength.

✦ Technological innovations such as coated and hybrid materials boost performance.

✦ Rising automation and smart factory adoption enhance demand for advanced inserts.

🔍 Market Segmentation

The cutting tool inserts market is analyzed across several key categories that reflect material composition, application, and end-user preferences.

🛠 By Product Type:

Insert materials range from carbide, ceramic, cermet, PCD, and PCBN. Carbide remains dominant for ferrous machining due to its toughness, while ceramic and cermet inserts are increasingly used in high-temperature applications. PCD and PCBN inserts serve niche needs in non-ferrous and hard materials, respectively, offering ultra-high hardness and long tool life in specific sectors like aerospace and resource extraction.

🏭 By Application:

Cutting tool inserts find applications in turning, milling, drilling, and boring. Turning commands a large market share as it's frequently used in automotive and general engineering. Milling and drilling grow steadily due to complex part manufacturing in industries like aerospace and medical devices.

🚗 By End-User Industry:

Primary industries include automotive, aerospace, industrial machinery, medical devices, and energy. The automotive sector remains the largest consumer due to high production volumes and demand for fuel-efficient components. The aerospace sector is a fast-growing segment, driven by stricter material and tolerance standards, leading to increased usage of advanced inserts like PCD and ceramics.

🌎 Regional Insights

🇨🇳 Asia-Pacific

Asia‐Pacific clearly dominates global demand, thanks to its massive manufacturing capacity in China, India, Japan, and Korea. Growth in automotive, heavy engineering, and electronics sectors fuels the need for high-performance inserts. Localization of tool production, favorable trade policies, and increasing automation are strengthening the market in the region.

🇺🇸 North America

North American growth is hampered by relatively mature markets but sustained by advanced manufacturing hubs, especially in the U.S. Innovations like coated carbide inserts, digital integration in machining, and demand for aerospace and defense-grade materials keep the market dynamic.

🇪🇺 Europe

Europe sees emphasis on sustainability and productivity, sparking demand for longer-lasting, low-waste inserts. Germany and Italy drive extensive demand in automotive and heavy machinery manufacturing. Strict environmental regulations also encourage adoption of dry and near-dry machining, requiring robust tool materials.

🌏 Latin America & MEA

Still emerging, these regions show slow uptake yet accelerating demand in Brazil, Mexico, and South Africa. Local manufacturing initiatives and infrastructure expansion are opening opportunities. However, price sensitivity and limited adoption of advanced materials still present challenges.

🚀 Market Drivers

The global push for precision machining in aerospace, automotive, and medical device manufacturing is raising demand for cutting tool inserts that can deliver tighter tolerances and longer life. In particular, lightweight materials like aluminum alloys and titanium require inserts that offer high hardness and stability. At the same time, the rise of smart factory automation-with CNC machines operating continuously-demands durable, coated inserts to maintain consistent performance under heavy use. Additionally, manufacturers' growing preference for dry machining due to environmental concerns is boosting the use of ceramic and cermet inserts that can tolerate higher temperatures without coolant.

⛔ Market Restraints

While the demand for advanced inserts grows, high costs associated with specialty materials like PCD, PCBN, and advanced coatings pose obstacles, especially for small-to-medium manufacturers operating on tight budgets. Wear resistance comes at a price-these advanced inserts often carry unit costs several times higher than conventional carbide. Moreover, the market's dependence on cyclical sectors such as automotive, oil & gas, and capital machinery results in volatile demand tied to economic fluctuations. Lastly, skill shortages in machining technology and maintenance in developing economies limit the adoption of high-performance inserts and automation.

🌟 Market Opportunities

There is enormous potential in coated and multifunctional inserts using nanocomposite and PVD/PCVD coatings that offer enhanced wear resistance and thermal stability. High-growth sectors-electric vehicle (EV) components, aerospace composites, medical devices-offer clear demand for specialized inserts. Growth in on-line tool monitoring and digital machining intelligence presents opportunities for manufacturers to offer integrated solutions. Additive manufacturing of cutting tools offers customization potential and supply-chain efficiency. Companies investing in R&D to develop hybrid materials combining carbide base with ceramic edge layers are redefining performance benchmarks.

Do You Have Any Query Or Specific Requirement? Request Customization of Report: https://www.persistencemarketresearch.com/request-customization/21751

📌 Reasons to Buy the Report

✔ Gain comprehensive market sizing and future forecasts to 2032.

✔ Understand high-performance material technologies like coatings and PCBN.

✔ Identify industry trends across aerospace, automotive, and industrial sectors.

✔ Benchmark regional growth dynamics, including Asia‐Pacific and North America.

✔ Uncover strategic opportunities in smart machining, additive tools, and composite materials.

🏢 Company Insights

• Sandvik AB

• Kennametal Inc.

• Seco Tools AB

• Sumitomo Electric

• Mitsubishi Materials Corporation

• Iscar Ltd.

• TaeguTec Ltd.

• Korloy Inc.

• Walter AG

• OSG Corporation

Recent Developments:

In early 2025, Sandvik AB launched its new NanoTiger® coated carbide inserts, promising 30% longer tool life for high-speed steel machining. In mid-2024, Kennametal introduced hybrid PCD-PCBN inserts designed for electric-vehicle motor components, combining extreme wear resistance with precision cutting.

🧾 Conclusion

The cutting tool inserts market is set to accelerate through 2032, driven by demands for precision, efficiency, and sustainability in global manufacturing. Asia-Pacific remains at the forefront, while technological innovation in coatings, hybrid materials, and smart tooling signals transformative potential. Though challenges like cost and cyclicality persist, the push toward automation, lightweight materials, and digital machining opens promising pathways. Manufacturers, toolmakers, and investors who align with technological shifts stand to benefit substantially from growth in precision engineering and next‐gen manufacturing.

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cutting Tool Inserts Market Set for Precision Growth, Innovations Driving Global Demand here

News-ID: 4090391 • Views: …

More Releases from Persistence Market Research

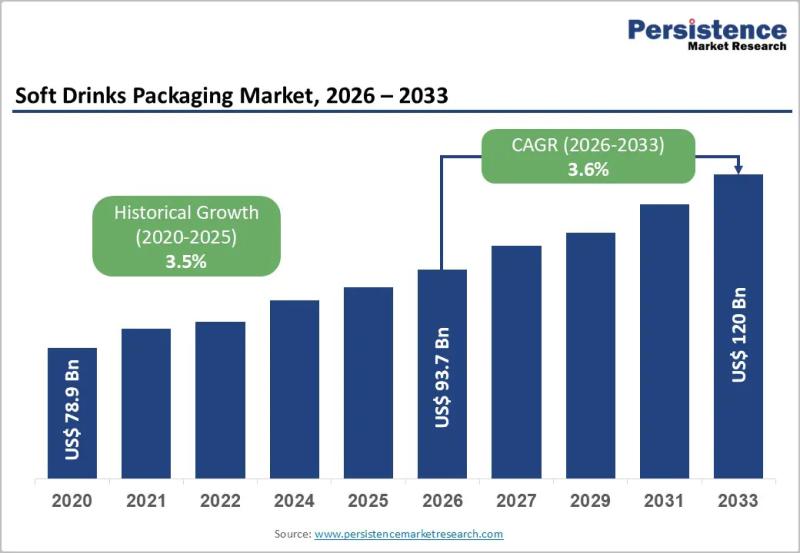

Soft Drinks Packaging Market to Reach US$120.0 Billion by 2033 - Persistence Mar …

The soft drinks packaging market plays a central role in the global beverage industry, serving carbonated drinks, juices, flavored water, energy drinks, and ready to drink teas and coffees. Packaging is no longer limited to containment and transportation; it has evolved into a critical component of branding, sustainability strategy, consumer convenience, and supply chain efficiency. Manufacturers are increasingly focusing on lightweight materials, recyclable packaging formats, and innovative designs that improve…

Christmas Tree Valves Market Size to Reach US$8.1 Billion by 2033 - Persistence …

The Christmas Tree Valves Market plays a critical role in the upstream oil and gas industry, serving as a central component in wellhead equipment systems. Christmas tree valves are installed on oil and gas wells to control pressure, regulate flow, and ensure safe extraction of hydrocarbons. These assemblies, commonly referred to as "Christmas trees," consist of multiple valves, spools, and fittings arranged in a structure that resembles a decorated tree.…

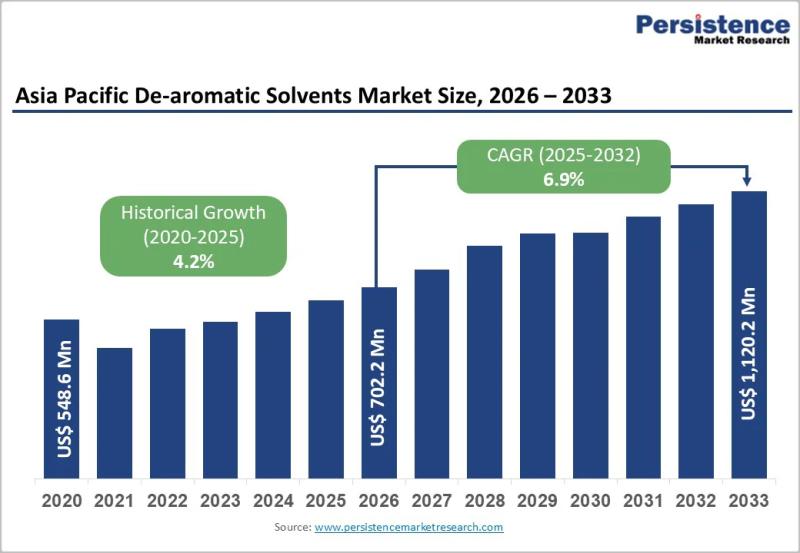

Asia Pacific De-aromatic Solvents Market to Reach US$1,120.2 Million by 2033 - P …

The Asia Pacific De-aromatic Solvents Market is gaining steady momentum as industries across the region increasingly shift toward low aromatic, high purity solvent formulations. De-aromatic solvents are hydrocarbon solvents that have significantly reduced aromatic content, making them suitable for applications requiring low odor, lower toxicity, and improved environmental performance. These solvents are widely used in paints and coatings, adhesives, inks, metalworking fluids, agrochemicals, and cleaning formulations. As regulatory scrutiny around…

Off-Highway Radiators Market to Reach US$ 7.2 Bn by 2033 as Leading Players Like …

The off-highway radiators market plays a vital role in ensuring efficient thermal management in heavy-duty equipment used across construction, agriculture, mining, and forestry sectors. These radiators regulate engine temperatures, prevent overheating, and support consistent equipment performance under extreme operating conditions. Growing mechanization and the expansion of infrastructure projects worldwide are increasing reliance on durable cooling systems. Equipment manufacturers are prioritizing high-performance radiators that offer reliability, longer service life, and resistance…

More Releases for PCD

Global PCD and PCBN Tool Material Market Outlook Report 2026

On Dec 3, Global Info Research released "Global PCD and PCBN Tool Material Market 2026 by Manufacturers, Regions, Type and Application, Forecast to 2032". This report includes an overview of the development of the PCD and PCBN Tool Material industry chain, the market status of PCD and PCBN Tool Material Market, and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends…

CBN & PCD Inserts Market Revenue Share, Insights & Future Outlook

CBN & PCD Inserts Market Size

The global market for CBN & PCD Inserts was valued at US$ 846 million in the year 2024 and is projected to reach a revised size of US$ 1283 million by 2031, growing at a CAGR of 6.3% during the forecast period.

Download Free Data: https://reports.valuates.com/request/sample/QYRE-Auto-4S19040/Global_CBN_PCD_Inserts_Market_Research_Report_2025?utm_source=Openpr&utm_medium=referral

Report Scope

This report aims to provide a comprehensive presentation of the global market for CBN & PCD Inserts, with both quantitative…

PCD Cutting Tools Market Growth Drivers and Forecast 2025 - 2031

Los Angeles, United State: A newly published report titled "Global PCD Cutting Tools Market Insights, Forecast to 2025-2031" by QY Research throws light on the industry dynamics and current and future trends that play a key role in determining the business expansion. The global PCD Cutting Tools market was valued at US$ 981 million in 2024 and is anticipated to reach US$ 1354 million by 2031, witnessing a CAGR of…

PCD Pharma Franchise with Aenor Pharmaceuticals

The pharmaceutical industry is a constantly evolving space, with increasing demand for innovative and reliable healthcare products. One of the most attractive business models in this sector is the PCD Pharma Franchise, offering a unique blend of low investment and high returns. Aenor Pharmaceuticals, a trusted name in the pharmaceutical industry, provides a golden opportunity for entrepreneurs through its PCD Pharma Franchise model. By partnering with Aenor Pharmaceuticals, you can…

PCD Market Value Projected to Expand by 2029

PCD Market Value growing at a CAGR of 6.75% during 2023-2029. PCD Market Report 2023 talks about crucial market insights with the help of segments and sub-segments analysis.

Important changes in the business allow key players to attain larger profits. This PCDMarket study report is the best way to make changes with the help of entire market condition and metrics provided here. These metrics also allow getting ahead in the…

Global PCD Diamond Tool Machine Market Research Report 2023-2029

Global PCD Diamond Tool Market: Driven factors and Restrictions factors

The research report encompasses a comprehensive analysis of the factors that affect the growth of the market. It includes an evaluation of trends, restraints, and drivers that influence the market positively or negatively. The report also outlines the potential impact of different segments and applications on the market in the future. The information presented is based on historical milestones and current…