Press release

Ammonium Nitrate Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview

Introduction:Ammonium nitrate (NH4NO3) is a white, crystalline chemical compound highly soluble in water. It is a salt composed of ammonium and nitrate ions. Primarily, it is renowned as a high-nitrogen fertilizer, providing readily available nitrogen to plants for robust growth and increased crop yields. Beyond agriculture, it is also a significant component in the manufacture of commercial explosives, particularly in ANFO (Ammonium Nitrate Fuel Oil) blends used in mining and civil construction. While stable under normal conditions, ammonium nitrate is classified as an oxidizer and can decompose explosively under certain extreme conditions, such as high heat or contamination, making its storage and handling subject to strict regulations.

Setting up an ammonium nitrate production plant involves a highly exothermic reaction between ammonia and nitric acid. Key steps include raw material storage (ammonia, nitric acid), a neutralization reactor for the initial reaction, followed by concentration units (evaporators) to achieve desired purity and concentration. Solidification, often through prilling or granulation towers, forms the final product, which is then dried, cooled, and coated to prevent caking. Critical aspects include robust safety systems for handling hazardous, reactive chemicals, stringent process control to manage exothermic reactions and prevent decomposition, and comprehensive environmental controls for emissions and wastewater. Adherence to strict regulatory frameworks for explosives and fertilizers is paramount.

IMARC Group's report, titled "Ammonium Nitrate Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up an ammonium nitrate production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/ammonium-nitrate-manufacturing-plant-project-report/requestsample

Ammonium nitrate Industry outlook 2025

The ammonium nitrate industry maintains a crucial role due to persistent global demand for food security and continued mining and construction activities. With a growing world population and increasing pressure on agricultural yields, ammonium nitrate remains an essential nitrogen fertilizer. Additionally, its use in commercial explosives for infrastructure projects and quarrying ensures sustained industrial demand. The 2025 outlook shows steady growth, particularly in Asia-Pacific, including India, driven by governmental agricultural support and large-scale infrastructure development, despite ongoing regulatory scrutiny around safety.

Key Insights for Ammonium Nitrate Production Plant Setup

Detailed Process Flow

• Product Overview

• Unit Operations Involved

• Mass Balance and Raw Material Requirements

• Quality Assurance Criteria

• Technical Tests

Project Details, Requirements and Costs Involved:

• Land, Location and Site Development

• Plant Layout

• Machinery Requirements and Costs

• Raw Material Requirements and Costs

• Packaging Requirements and Costs

• Transportation Requirements and Costs

• Utility Requirements and Costs

• Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

• Capital Investments

• Operating Costs

• Expenditure Projections

• Revenue Projections

• Taxation and Depreciation

• Profit Projections

• Financial Analysis

Profitability Analysis:

• Total Income

• Total Expenditure

• Gross Profit

• Gross Margin

• Net Profit

• Net Margin

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7859&flag=C

Key Cost Components of Setting Up an Ammonium Nitrate Plant

• Reaction & Processing Equipment: Reactors, evaporators, prilling/granulation towers, dryers, coolers.

• Safety Infrastructure: Advanced explosion-proof design, fire suppression, emergency shutdown systems, secure storage.

• Raw Material Storage & Handling: Tanks for ammonia and nitric acid, piping, pumps.

• Environmental Control Systems: Emission scrubbers, NOx abatement, wastewater treatment.

• Land & Site Development: Land acquisition, civil construction, utility connections.

• Engineering & Design: Detailed plant layout, process optimization, safety assessments.

• Utilities & Power: Reliable electricity, water, steam generation.

• Quality Control: Lab equipment for purity and stability testing.

Economic Trends Influencing Ammonium Nitrate Plant Setup Costs 2025

• Raw Material Volatility: Ammonia and nitric acid prices are subject to fluctuations, directly impacting operational expenditures.

• Energy Costs: Global energy prices, especially electricity and natural gas, significantly influence production and overall plant operational costs.

• Inflationary Pressures: General inflation can increase costs for land acquisition, machinery, construction, and labor.

• Geopolitical Factors: Trade tariffs, sanctions, and supply chain disruptions due to geopolitical tensions can affect material availability and pricing.

• Labor Costs: Availability and cost of skilled labor for construction and operation remain a significant factor, particularly in regions like India.

• Technological Advancements: Investment in newer, more efficient technologies can reduce long-term operational costs but increase initial setup expenditure.

Challenges and Considerations for Investors

• Stringent Regulations: Due to its explosive nature, production, storage, and transport are highly regulated, requiring significant safety investments and permits.

• Safety Concerns & Public Perception: High-profile incidents (e.g., Beirut) raise safety concerns, impacting market trust and requiring advanced safety protocols.

• Raw Material & Energy Price Volatility: Fluctuations in ammonium nitrate, acid, and energy costs directly affect profitability.

• Import Competition: Cheaper imports, particularly from countries like Russia, can create market saturation and price pressure for domestic producers.

• Environmental Compliance: Adherence to emission and waste disposal regulations adds to operational costs.

• Land Acquisition & Location: Finding suitable, non-populated areas for plant setup is challenging due to safety norms.

Buy Now: https://www.imarcgroup.com/checkout?id=7859&method=1911

Conclusion

This report aims to serve as a practical guide for entrepreneurs, investors, and industrial planners exploring opportunities in ammonium nitrate production. By understanding the cost structure, market dynamics, and operational challenges, stakeholders can make informed decisions and devise sustainable strategies for entry and expansion in the sector.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Ammonium Nitrate Production Cost Analysis 2025: Equipment, Raw Materials, and Investment Overview here

News-ID: 4089622 • Views: …

More Releases from IMARC Group

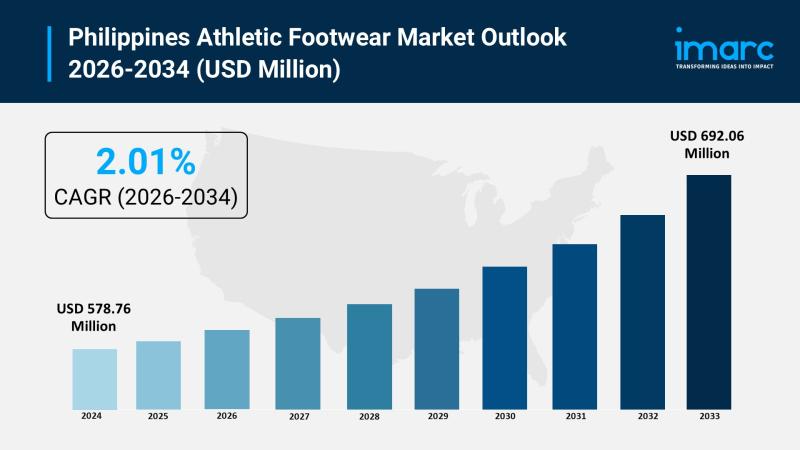

Philippines Athletic Footwear Market 2026 to Reach USD 692.06 Million by 2034 Am …

Market Overview

The Philippines athletic footwear market size was valued at USD 578.76 Million in 2025 and is projected to reach USD 692.06 Million by 2034, growing at a compound annual growth rate of 2.01% from 2026-2034. The market is expanding rapidly, driven by increasing health consciousness, fitness trends, and demand for stylish yet functional shoes. With a growing middle class and a focus on performance and comfort, the Philippines athletic…

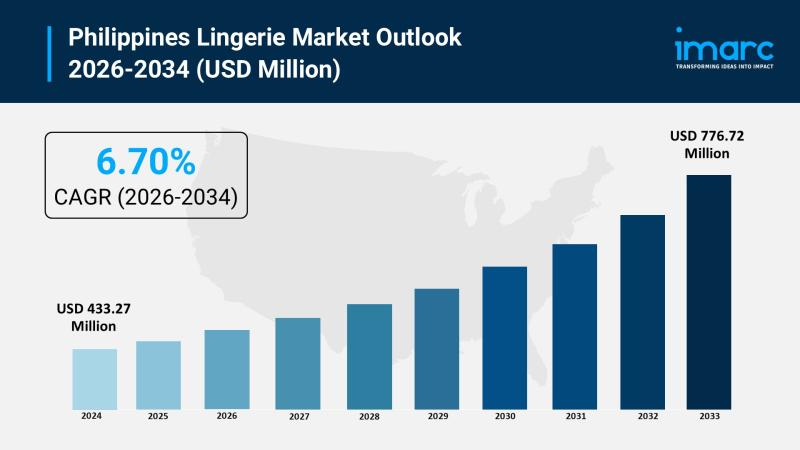

IMARC Group: Philippines Lingerie Market 2026 | Poised for Rapid Growth at 6.70% …

Market Overview

The Philippines lingerie market size was valued at USD 433.27 Million in 2025 and is projected to reach USD 776.72 Million by 2034, growing at a compound annual growth rate (CAGR) of 6.70% during 2026-2034. The market is experiencing robust expansion driven by evolving consumer preferences, rising disposable incomes, and increasing emphasis on comfort and personal expression in intimate apparel. Urbanization and expanding retail infrastructure are reshaping purchasing patterns…

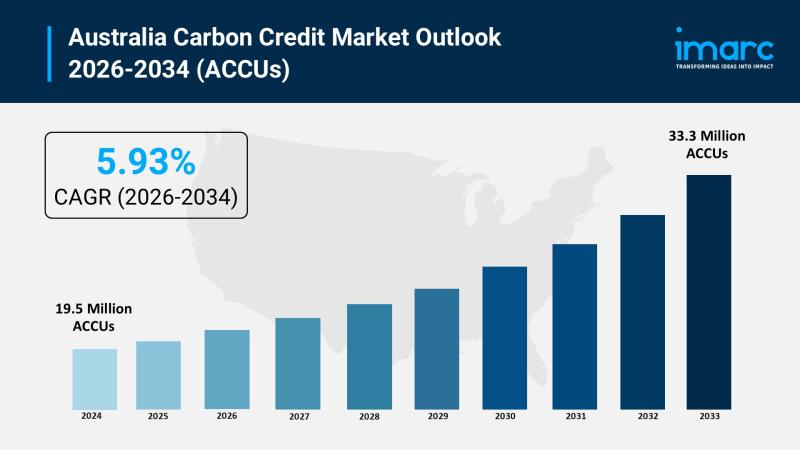

Australia Carbon Credit Market 2026 | Worth 33.3 Million ACCUs by 2034

Market Overview

The Australia carbon credit market size reached 19.5 Million ACCUs in 2025 and is projected to reach 33.3 Million ACCUs by 2034, exhibiting a CAGR of 5.93% during the forecast period 2026-2034. The industry is expanding significantly due to favorable government policies and regulations, increased dedication to corporate social responsibility, expanded international trade prospects, and significant expansion in renewable energy projects.

Request a Sample Report: https://www.imarcgroup.com/australia-carbon-credit-market/requestsample

How AI is Reshaping the…

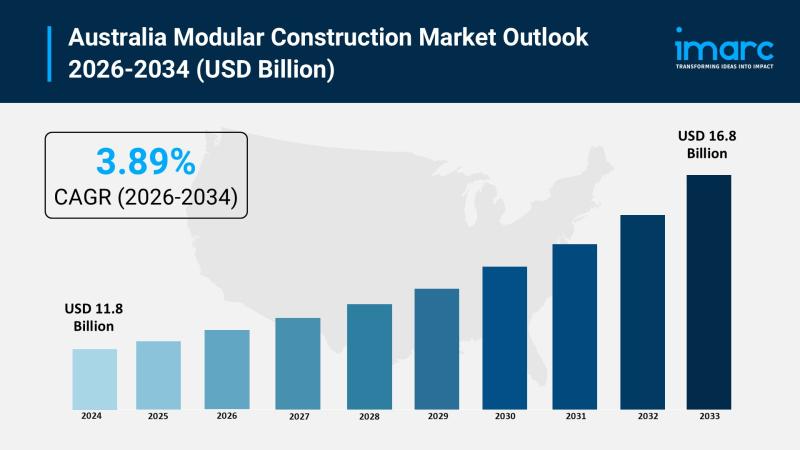

Australia Modular Construction Market 2026 | USD 16.8 Billion by 2034

Market Overview

The Australia modular construction market size reached USD 11.8 Billion in 2025 and is projected to reach USD 16.8 Billion by 2034, exhibiting a CAGR of 3.89% during the forecast period 2026-2034. The market is primarily driven by government infrastructure support, increasing housing demand, environmental considerations, and technological advances addressing the rising demand for efficient, adaptable housing solutions in urban and remote areas across the country.

Request a Sample Report:…

More Releases for Cost

Steel Production Cost - Process Economics, Raw Materials, and Cost Drivers

Steel is the backbone of modern industry, and its production cost is one of the most closely tracked indicators across construction, infrastructure, automotive, and manufacturing sectors. Unlike niche chemicals or APIs, steel economics are driven by scale, energy intensity, and raw material volatility.

Here's the thing: steel production cost isn't just about iron ore prices. It's a layered equation involving coking coal, electricity, labor, emissions compliance, logistics, and technology choice. A…

Egg Powder Manufacturing Plant Setup Cost | Cost Involved, Machinery Cost and In …

IMARC Group's report titled "Egg Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing an egg powder manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

Glucose Manufacturing Plant Cost Report 2024: Requirements and Cost Involved

IMARC Group's report titled "Glucose Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a glucose manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to the operational…

Fatty Alcohol Production Cost Analysis: Plant Cost, Price Trends, Raw Materials …

Syndicated Analytics' latest report titled "Fatty Alcohol Production Cost Analysis 2023-2028: Capital Investment, Manufacturing Process, Operating Cost, Raw Materials, Industry Trends and Revenue Statistics" includes all the essential aspects that are required to understand and venture into the fatty alcohol industry. This report is based on the latest economic data, and it presents comprehensive and detailed insights regarding the primary process flow, raw material requirements, reactions involved, utility costs, operating costs, capital…

Corn Production Cost Analysis Report: Manufacturing Process, Raw Materials Requi …

The latest report titled "Corn Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Corn. Read More: https://www.procurementresource.com/production-cost-report-store/corn

Report Features - Details

Product Name - Corn Production

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost, Auxiliary Equipment…

Crude Oil Production Cost Analysis Report: Manufacturing Process, Raw Materials …

The latest report titled "Crude Oil Production Cost Report" by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Crude Oil. Read More: https://www.procurementresource.com/production-cost-report-store/crude-oil

Report Features - Details

Product Name - Crude Oil

Segments Covered

Manufacturing Process: Process Flow, Material Flow, Material Balance

Raw Material and Product/s Specifications: Raw Material Consumption, Product and Co-Product Generation, Capital Investment

Land and Site Cost: Offsites/Civil Works, Equipment Cost,…