Press release

Polycarboxylate Ether (Pce) Plant Setup Cost 2025: Equipment, Raw Materials, and Investment Overview

Introduction:Polycarboxylate Ether (PCE) is a type of chemical admixture used primarily in the construction industry as a high-range water reducer. It enhances the flowability of concrete while maintaining its strength and durability. PCE works by dispersing cement particles evenly, allowing for reduced water content in the mix. This results in improved performance of concrete, especially in demanding applications like high-rise buildings, bridges, and precast structures.

Setting up a Polycarboxylate Ether (PCE) manufacturing plant involves selecting an industrial location, installing reactors, storage tanks, and mixing systems, and ensuring access to key raw materials. Proper planning, quality control, and compliance with safety standards are essential for smooth operations and long-term profitability.

IMARC Group's report, titled "Polycarboxylate Ether (PCE) Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue," provides a complete roadmap for setting up a Polycarboxylate ether (PCE) manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/polycarboxylate-ether-manufacturing-plant-project-report/requestsample

Polycarboxylate ether (PCE) Industry outlook 2025

The Polycarboxylate Ether (PCE) industry is poised for significant growth in 2025, driven by rising demand for high-performance concrete in global infrastructure and urban development projects. With increasing construction activity in Asia-Pacific-particularly in countries like China and India-the region dominates consumption due to rapid urbanization and government-backed smart city initiatives. Moreover, the shift toward sustainable and energy-efficient building materials is fueling the adoption of PCE-based admixtures, which offer superior workability and reduced water-cement ratios. As green building standards and environmental regulations tighten, innovative and eco-friendly PCE formulations are gaining traction. While challenges such as raw material price fluctuations and competition from lower-cost alternatives exist, the overall outlook for the PCE industry in 2025 remains strong and opportunity-rich.

Key Cost Components of Setting Up a Polycarboxylate Ether (PCE) Plant

Detailed Process Flow

o Product Overview

o Unit Operations Involved

o Mass Balance and Raw Material Requirements

o Quality Assurance Criteria

o Technical Tests

Project Details, Requirements and Costs Involved:

o Land, Location and Site Development

o Plant Layout

o Machinery Requirements and Costs

o Raw Material Requirements and Costs

o Packaging Requirements and Costs

o Transportation Requirements and Costs

o Utility Requirements and Costs

o Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

o Capital Investments

o Operating Costs

o Expenditure Projections

o Revenue Projections

o Taxation and Depreciation

o Profit Projections

o Financial Analysis

Profitability Analysis:

o Total Income

o Total Expenditure

o Gross Profit

o Gross Margin

o Net Profit

o Net Margin

Key Cost Components of Setting Up a Polycarboxylate Ether (PCE) Plant

• Land and Site Development: Cost of purchasing or leasing industrial land, site grading, access roads, and utility connections.

• Machinery and Equipment: Reactors, mixers, condensers, storage tanks, pumps, distillation units, and control systems.

• Raw Material Procurement: Initial stock of core inputs like methacrylic acid, polyethylene glycol, initiators, and solvents.

• Construction and Civil Works: Building structures for production, storage, quality control labs, and administrative offices.

• Utilities Setup: Power supply, water treatment systems, steam boilers, compressed air systems, and waste management units.

• Labor and Staffing: Hiring and training of technical, production, administrative, and safety personnel.

• Licensing and Regulatory Approvals: Fees for environmental clearances, fire safety, industrial registration, and compliance certifications.

• Quality Control and R&D: Setup of laboratory equipment for product testing, quality assurance, and formula development.

• Packaging and Storage: Containers, drums, labeling systems, and warehouse infrastructure for finished product handling.

• Working Capital: Initial funds to manage operational expenses until the plant reaches breakeven.

Economic Trends Influencing Polycarboxylate ether (PCE) Plant Setup Costs 2025

• Rising raw material prices due to global oil and petrochemical market volatility.

• Higher energy costs, especially for electricity and steam, impacting production expenses.

• Inflationary pressures increasing the cost of construction materials, machinery, and labor.

• Elevated interest rates, making financing new plants more expensive.

• Supply chain disruptions leading to longer lead times and higher import costs for equipment and inputs.

• Growing environmental regulations, requiring additional investment in pollution control and compliance systems.

• Shift toward automation and digitalization, raising initial setup costs but offering long-term savings.

• Labor shortages in specialized manufacturing roles, pushing up wage demands.

• Geopolitical instability affecting international trade routes and increasing risk buffers.

• Focus on sustainability driving demand for greener technologies and eco-friendly formulations that require R&D investment.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=14777&flag=C

Challenges and Considerations for Investors

• High Capital Investment: Significant upfront costs for land, machinery, utilities, and compliance infrastructure.

• Raw Material Dependency: Reliance on volatile petrochemical-based feedstocks can impact margins.

• Regulatory Compliance: Meeting strict environmental, safety, and chemical handling standards requires ongoing monitoring and investment.

• Market Competition: Presence of established global and regional players can make market entry challenging.

• Technology Selection: Choosing the right manufacturing process and automation level is critical for efficiency and scalability.

• Quality Control: Maintaining consistent product performance is essential for customer retention in the construction industry.

• Skilled Workforce: Hiring and retaining trained chemical engineers and plant operators can be difficult in certain regions.

• Supply Chain Risks: Delays in the delivery of raw materials or equipment can disrupt production timelines.

• Economic Cycles: Demand for PCE is closely tied to the construction sector, which is sensitive to economic downturns.

• Sustainability Pressures: Investors must consider eco-friendly innovations and lifecycle emissions to meet future market and ESG expectations.

Buy Now: https://www.imarcgroup.com/checkout?id=14777&method=1911

Conclusion

In conclusion, while the Polycarboxylate Ether (PCE) industry presents strong growth potential driven by global construction demand, sustainability trends, and performance-driven concrete solutions, setting up a manufacturing plant involves significant financial, operational, and regulatory considerations. Investors must navigate challenges such as raw material volatility, high capital requirements, competitive pressures, and evolving environmental standards. However, with strategic planning, technology adoption, and a focus on long-term efficiency and innovation, the PCE sector offers promising returns and opportunities for forward-thinking stakeholders in 2025 and beyond.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Polycarboxylate Ether (Pce) Plant Setup Cost 2025: Equipment, Raw Materials, and Investment Overview here

News-ID: 4086787 • Views: …

More Releases from IMARC Group

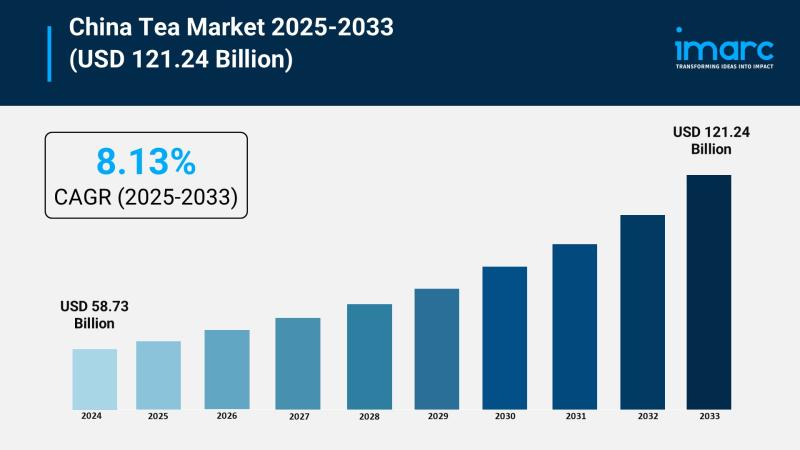

China Tea Market Forecast CAGR of 8.13%, Innovation Trends, and Strategic Insigh …

Market Overview

The China tea market was valued at USD 58.73 Billion in 2024 and is projected to reach USD 121.24 Billion by 2033, growing at a CAGR of 8.13% during 2025-2033. Growth is driven by rising health consciousness, premium product trends, government support, and expanding online retail. Innovation in flavors and packaging attracts younger consumers and global buyers, expanding the market.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

China Tea…

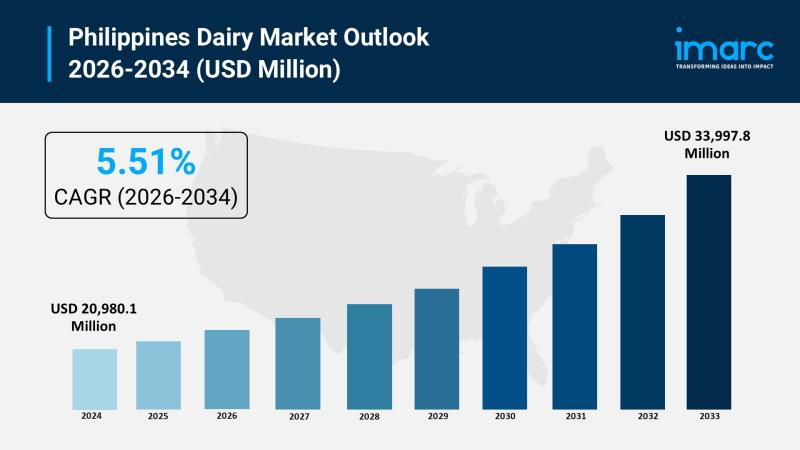

Philippines Dairy Market 2026: Expected to Reach USD 33,997.8 Million by 2034

Market Overview

The Philippines dairy market reached a size of USD 20,980.1 Million and is anticipated to grow to USD 33,997.8 Million by 2034 with a significant growth rate of 5.51%. This expansion is driven by rising demand for nutritious and diverse dairy products, rapid urbanization, increased disposable incomes, improved retail infrastructure, and strong government initiatives promoting local dairy production. Health-conscious consumers and expanding food service sectors further fuel this growth…

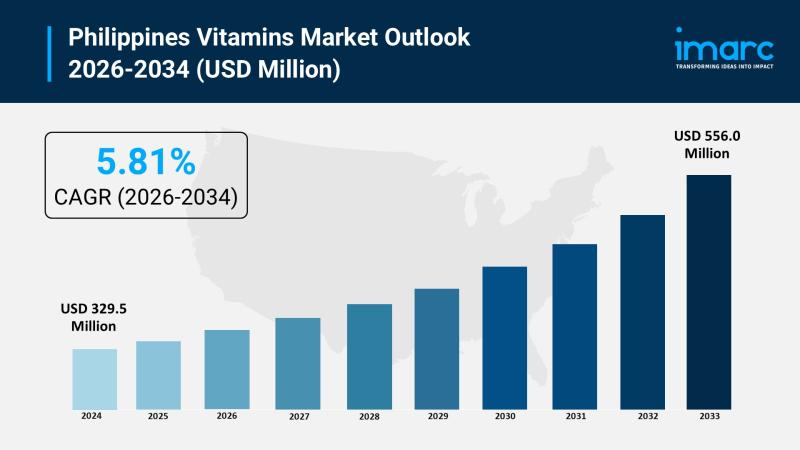

Philippines Vitamins Market 2026 | Projected to Reach USD 556.0 Million by 2034

Market Overview

The Philippines vitamins market was valued at USD 329.5 Million in 2025 and is projected to reach USD 556.0 Million by 2034, growing steadily over the forecast period. The market's growth is driven by increasing health consciousness, a rising geriatric population, and escalating demand for supplements that support immunity, energy, and overall wellness due to proactive health measures. The forecast period for this expansion is 2026-2034, with a CAGR…

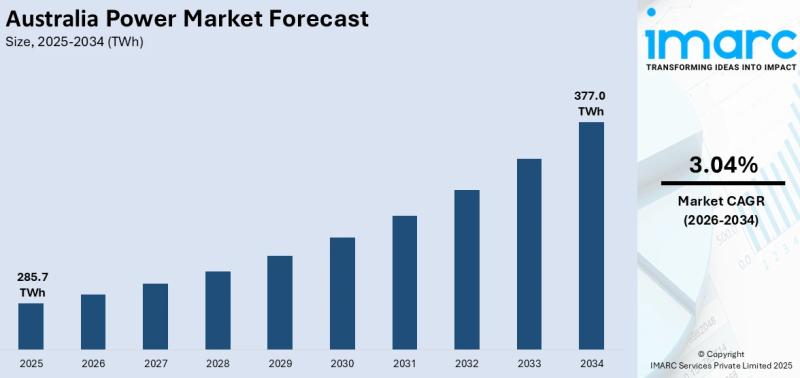

Australia Power Market Projected to Reach TWH 377 by 2034

Market Overview

The Australia power market size reached 285.7 TWh in 2025 and is projected to grow to 377.0 TWh by 2034, with a CAGR of 3.04% during the forecast period of 2026-2034. This growth is driven by rising renewable energy adoption, increased electricity demand, grid modernization, battery storage expansion, transition from coal plants, and government incentives for clean power. Key strategies such as virtual power plant integration and investments in…

More Releases for PCE

Why Professionals Choose the PCE Instruments PCE-IDM 3D: A Revolution in Digital …

When it comes to precision inspection, the tools you use can make all the difference. Whether it's electronics manufacturing, medical device analysis, or advanced material testing, professionals understand that clarity, accuracy, and control define the outcome. That's exactly why experts around the world are turning to the PCE Instruments PCE-IDM 3D 3D Digital Microscope https://megatop.com/product/pce-instruments-pce-idm-3d - a next-generation inspection system that redefines what's possible in digital imaging.

Seeing Beyond the…

How To Setup a Polycarboxylate Ether (Pce) Manufacturing Plant

Setting up a polycarboxylate ether (pce) manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.

IMARC Group's report titled "Polycarboxylate Ether (Pce) Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a…

Asia Pacific Dominates PCE Market, Capturing 41% Share Amid Construction Boom

The polycarboxylate ether (PCE) market is expected to grow from USD 8.26 billion in 2024 to USD 12.07 billion by 2031, with a CAGR of 5.6%. This growth is primarily driven by the rising demand for eco-friendly construction materials in developing regions like Asia-Pacific. Government initiatives promoting green building and infrastructure development, such as India's roadmap toward a net-zero footprint by 2070, are supporting the shift toward sustainable construction. Asia-Pacific…

High-performance Polycarboxylate Ether (PCE) Superplasticizer | L'BESTE GAT

L'BESTE GAT polycarboxylate ether (PCE) superplasticizer is a high-performance admixture used in concrete to enhance its workability, flowability, and overall performance. It is particularly effective in reducing water content while maintaining or improving the fluidity of the concrete mix.

Characteristics and benefits of PCE superplasticizers:

PCE superplasticizers allow for a significant reduction in water content (up to 40%) without sacrificing mix workability. They improve the ease of installation, pumpability, and finishing…

Elevate Your Market Game: Polycarboxylate Ether (PCE) Superplasticizer Market St …

𝐆𝐫𝐨𝐰𝐭𝐡 𝐌𝐚𝐫𝐤𝐞𝐭 𝐑𝐞𝐩𝐨𝐫𝐭𝐬, a prominent Market research firm, has recently released a comprehensive report on the Polycarboxylate Ether (PCE) Superplasticizer Market. This report offers a complete overview of the key aspects of the market, providing a robust assessment of the current Market situation and its anticipated scope. The report spans the forecast period from 𝟐𝟎𝟐𝟒 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐊𝐞𝐲 𝐇𝐢𝐠𝐡𝐥𝐢𝐠𝐡𝐭𝐬 𝐨𝐟 𝐭𝐡𝐞 𝐑𝐞𝐩𝐨𝐫𝐭:

- In-depth Analysis of 𝐂𝐎𝐕𝐈𝐃-𝟏𝟗 𝐈𝐦𝐩𝐚𝐜𝐭: The report includes a…

Polycarboxylate Ether (PCE) Superplasticizer Market Size, Share, Development by …

LP INFORMATION recently released a research report on the Polycarboxylate Ether (PCE) Superplasticizer market analysis and elaborate the industry coverage, current market competitive status, and market outlook and forecast by 2025. Moreover, it categorizes the global Polycarboxylate Ether (PCE) Superplasticizermarket by key players, product type, applications and regions,etc.

The main objective of this market research is to help the readers understand the structure of Polycarboxylate Ether (PCE) Superplasticizermarket, market definition,…