Press release

Cutting Equipment Market, Powering Precision, Performance, and Industrial Productivity

Market Overview: Advancing the Edge of Industrial Cutting SolutionsThe Cutting Equipment Market is witnessing steady growth driven by increasing demand from industries such as automotive, aerospace, construction, shipbuilding, and manufacturing. Cutting equipment refers to tools and machinery used to slice or shape materials with high accuracy and efficiency, including laser cutting machines, plasma cutters, waterjet systems, and mechanical cutting tools. These solutions are critical in modern industrial workflows, offering enhanced productivity, speed, and precision. The market is being propelled by automation trends, demand for cost-effective fabrication processes, and innovations in laser and CNC-based technologies.

Get a Sample PDF Brochure of the Report (Use Corporate Email ID for a Quick Response): https://www.persistencemarketresearch.com/samples/13255

Among the different types of cutting solutions, laser cutting systems represent the leading segment, owing to their versatility, precision, and wide application across metalworking and electronics industries. These systems are increasingly being adopted due to their non-contact operation, which minimizes material deformation and enables complex geometries. Asia-Pacific is the dominant geographical region in the cutting equipment market, largely because of the booming manufacturing sector in countries such as China, India, Japan, and South Korea. The region benefits from lower production costs, rapid urbanization, and significant investments in industrial automation, which together create a high demand for advanced cutting solutions.

✦ Key Highlights from the Report:

✦ Asia-Pacific leads the global market due to strong industrial output and infrastructure growth.

✦ Laser cutting systems hold the largest share, driven by high accuracy and energy efficiency.

✦ Rising demand from the automotive and construction sectors boosts market expansion.

✦ Automation and smart factory trends are accelerating the adoption of CNC cutting systems.

✦ Small and medium manufacturers are increasingly investing in cost-effective cutting technologies.

✦ Innovations in fiber laser and portable plasma cutters are reshaping the competitive landscape.

🧩 Market Segmentation

The Cutting Equipment Market is segmented based on product type, technology, and end-user industry, each offering distinct market dynamics and growth prospects.

By product type, the market includes manual cutting equipment, semi-automatic cutting systems, and automatic cutting machines. While manual tools remain relevant in small-scale applications, automatic systems dominate the market due to their role in high-volume industrial production and minimal human intervention requirements.

By cutting technology, the market is classified into laser cutting, plasma cutting, waterjet cutting, oxy-fuel cutting, and mechanical cutting. Laser cutting leads this segment due to its unmatched precision, speed, and growing compatibility with automation and CAD/CAM technologies. Waterjet cutting is gaining momentum in applications where heat-sensitive materials are involved. Plasma cutting is favored for thick metal sheets, especially in the shipbuilding and heavy machinery sectors.

In terms of end-user industry, the market spans automotive, aerospace, construction, metal fabrication, electronics, and shipbuilding. Among these, the metal fabrication sector accounts for the largest share, with automotive and construction following closely. The increasing need for lightweight components and customization in these industries drives the uptake of advanced cutting solutions that enable complex shapes and reduced material waste.

🌍 Regional Insights

The Asia-Pacific region remains the epicenter of the global cutting equipment market. Countries like China, Japan, South Korea, and India contribute significantly to regional demand due to their expansive manufacturing ecosystems and continuous investments in industrial automation. China's "Made in China 2025" initiative, along with India's "Make in India" program, further incentivize the modernization of production processes, thereby driving the adoption of cutting technologies.

North America holds a strong position, primarily led by the United States and Canada, where there is robust demand for laser and plasma cutting in aerospace, automotive, and shipbuilding industries. High labor costs in the region are motivating industries to adopt automation and CNC-based systems to optimize productivity.

In Europe, countries such as Germany, Italy, and France are at the forefront, driven by precision engineering and the strong presence of machinery manufacturers. The emphasis on Industry 4.0 and sustainability has encouraged the integration of energy-efficient cutting systems in production facilities.

Meanwhile, Latin America and the Middle East & Africa are emerging markets, showing increasing interest in modernizing their manufacturing capabilities. Infrastructure development, automotive investments, and defense sector expansion in these regions are gradually contributing to higher market penetration for cutting equipment.

🚀 Market Drivers

A primary driver for the cutting equipment market is the surging demand for automation and precision in industrial operations. With the advent of Industry 4.0, manufacturers are increasingly relying on intelligent cutting solutions that can be seamlessly integrated into smart production lines. The shift toward lightweight materials in automotive and aerospace industries, such as aluminum and composites, further drives the need for high-precision, non-thermal cutting methods like waterjet and laser cutting. Additionally, the construction boom and urban development projects across emerging economies are elevating demand for robust cutting tools for metal and concrete structures. The global focus on reducing production costs and improving throughput is also prompting industries to upgrade to automated and energy-efficient cutting systems.

⛔ Market Restraints

Despite its positive trajectory, the market faces notable restraints. High capital costs associated with advanced cutting machines, particularly laser and waterjet systems, present a barrier for small and medium enterprises (SMEs). The need for skilled labor to operate and maintain technologically complex systems also limits adoption in developing regions. Furthermore, fluctuating raw material prices-especially in the metals and electronics sectors-can affect the profitability of end-users and delay investment in new equipment. Environmental concerns linked to gas emissions in oxy-fuel and plasma cutting may also hinder market growth unless offset by eco-friendly innovations.

🌱 Market Opportunities

The cutting equipment market is brimming with opportunities, particularly in the realm of smart manufacturing and sustainability. The adoption of AI-enabled cutting systems, real-time monitoring, and predictive maintenance capabilities is paving the way for intelligent, connected equipment that enhances productivity and reduces downtime. The growing interest in portable and modular cutting machines is opening avenues in field services and remote industrial applications. Additionally, government incentives promoting green manufacturing and energy-efficient solutions are expected to boost the uptake of environmentally friendly technologies such as fiber laser cutters. With the global economy recovering and reshoring trends picking up in manufacturing, new opportunities are emerging in regions previously underpenetrated by cutting-edge fabrication technologies.

Do You Have Any Query Or Specific Requirement? Request Customization of Report: https://www.persistencemarketresearch.com/request-customization/13255

✔ Reasons to Buy the Report:

✔ Understand emerging trends and evolving technologies in the global cutting equipment industry.

✔ Gain insights into high-growth application sectors like automotive, aerospace, and construction.

✔ Identify key regional opportunities and track investment trends in automation.

✔ Benchmark against major competitors and evaluate strategic positioning.

✔ Access accurate market forecasts to guide purchasing and business expansion strategies.

🏢 Company Insights

• Lincoln Electric Holdings, Inc.

• ESAB Corporation

• TRUMPF Group

• Messer Cutting Systems GmbH

• Hypertherm, Inc.

• Koike Aronson, Inc.

• Amada Co., Ltd.

• Bystronic Laser AG

• Hornet Cutting Systems

• Flow International Corporation

Recent Developments:

In March 2024, TRUMPF Group launched a new fiber laser cutting solution with integrated AI capabilities for real-time quality control, aimed at the automotive and aerospace sectors.

In October 2023, Hypertherm Inc. introduced an upgraded plasma cutting system with modular components for quick deployment in remote construction sites, boosting versatility and efficiency.

🧾 Conclusion

The Cutting Equipment Market is at a transformative juncture, fueled by innovations in automation, precision engineering, and smart manufacturing practices. As industries worldwide strive for efficiency, accuracy, and sustainability, the adoption of advanced cutting solutions continues to rise. Laser, plasma, and waterjet technologies are leading the charge, supported by the growing integration of AI, IoT, and CNC automation. While challenges such as high initial costs and skill shortages remain, the outlook is promising-particularly in Asia-Pacific and other emerging markets where industrial growth is booming. With continued investment in R&D and strong demand across end-use industries, cutting equipment will remain a cornerstone of modern manufacturing well into the next decade.

Persistence Market Research

G04 Golden Mile House, Clayponds Lane

Brentford, London, TW8 0GU UK

USA Phone: +1 646-878-6329

UK Phone: +44 203-837-5656

Email: sales@persistencemarketresearch.com

Web:

https://www.persistencemarketresearch.com

About Persistence Market Research:

At Persistence Market Research, we specialize in creating research studies that serve as strategic tools for driving business growth. Established as a proprietary firm in 2012, we have evolved into a registered company in England and Wales in 2023 under the name Persistence Research & Consultancy Services Ltd. With a solid foundation, we have completed over 3600 custom and syndicate market research projects, and delivered more than 2700 projects for other leading market research companies' clients.

Our approach combines traditional market research methods with modern tools to offer comprehensive research solutions. With a decade of experience, we pride ourselves on deriving actionable insights from data to help businesses stay ahead of the competition. Our client base spans multinational corporations, leading consulting firms, investment funds, and government departments. A significant portion of our sales comes from repeat clients, a testament to the value and trust we've built over the years.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cutting Equipment Market, Powering Precision, Performance, and Industrial Productivity here

News-ID: 4086143 • Views: …

More Releases from Persistence Market Research

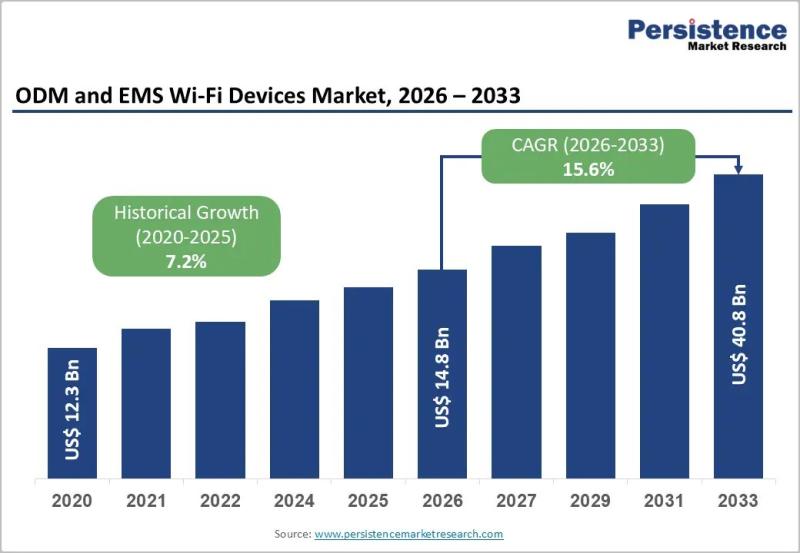

ODM and EMS Wi-Fi Devices Market to Reach US$ 40.8 Billion by 2033 at 15.6% CAGR

The global ODM and EMS Wi-Fi devices market is projected to be valued at US$ 14.8 billion in 2026 and is forecast to surge to US$ 40.8 billion by 2033, registering a robust CAGR of 15.6% between 2026 and 2033. This rapid growth reflects the accelerating demand for advanced wireless connectivity solutions across residential, enterprise, and industrial environments. The expansion of 5G infrastructure, enterprise digital transformation strategies, and large-scale IoT…

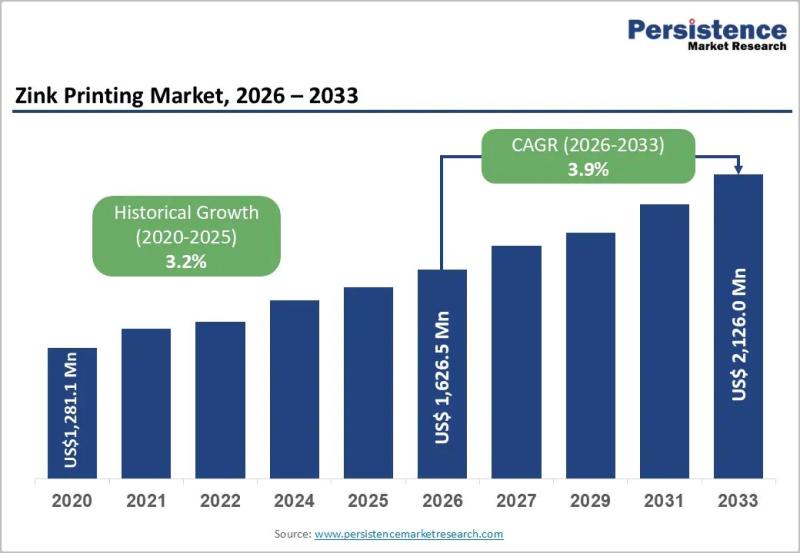

Zink Printing Market to Reach US$ 2,126.0 Million by 2033 at 3.9% CAGR

Zink Printing Market Size and Trends Analysis

The global Zink printing market is projected to be valued at US$ 1,626.5 million in 2026 and is expected to reach US$ 2,126.0 million by 2033, expanding at a CAGR of 3.9% between 2026 and 2033. Zink (Zero Ink) printing technology eliminates the need for ink cartridges by using heat-activated color crystals embedded within specialized paper. This innovation has positioned Zink printers as a…

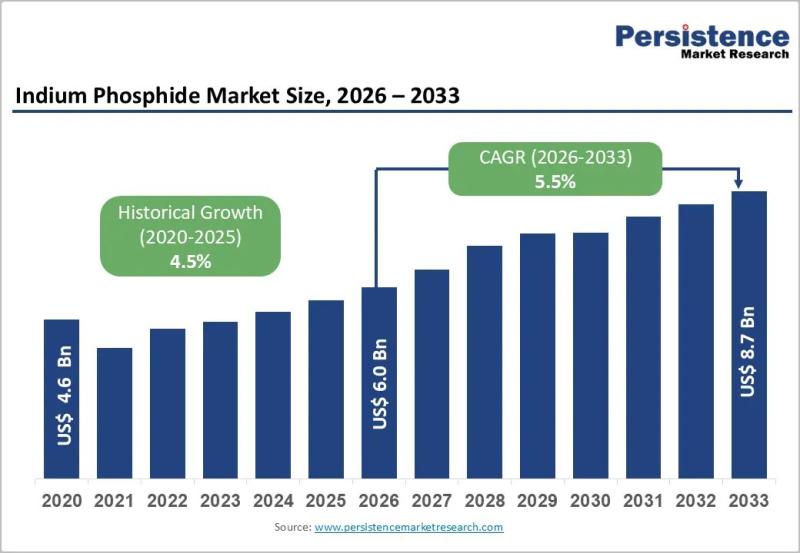

Indium Phosphide Market to Reach US$ 8.7 Billion by 2033 at 5.5% CAGR

The global Indium Phosphide (InP) market is poised for steady expansion, with its valuation expected to reach US$ 6.0 billion by 2026 and further grow to US$ 8.7 billion by 2033, registering a CAGR of 5.5% between 2026 and 2033. Indium phosphide, a high-performance compound semiconductor material, is widely used in optoelectronics, high-frequency electronics, and photonic integrated circuits (PICs). The market growth is largely fueled by the accelerating deployment of…

Roasted Corn Market to Reach $5.5B by 2033 Driven by Rising Snack Demand

The global roasted corn market is poised for steady expansion, driven by rising consumer preference for convenient, ready-to-eat snacks and increasing awareness of healthier alternatives to traditional fried snack options. Current market estimates indicate that the roasted corn market is valued at approximately US$ 3.8 billion in 2026 and is projected to reach US$ 5.5 billion by 2033, reflecting a compound annual growth rate (CAGR) of 5.4% between 2026 and…

More Releases for Cutting

Comparing CO2 Laser Cutting to Other Fabric Cutting Methods

Choosing the Right Tool for Precision and Efficiency

Choosing the correct focal length for your CO2 laser is crucial for achieving precise cuts, especially when working with laser cutting fabric. The focal length determines the laser beam's spot size and depth of focus, directly impacting cutting quality. Shorter focal lengths (e.g., 1.5" to 2") are ideal for fine details on thin materials, while longer focal lengths (e.g., 4" to 5") suit…

Cutting Edge Solutions: Analyzing the Booming Cutting Fluid Market

The global cutting fluid industry is poised for significant growth, with projections indicating a Compound Annual Growth Rate (CAGR) of 4.1% from 2023 to 2033. By 2033, the market is expected to achieve a valuation of USD 16.3 billion, underscoring its critical role in industrial manufacturing and machining processes.

Cutting fluids, often referred to as coolants or lubricants, play a pivotal role in industrial metalworking. These fluids are designed to reduce…

Is Die Cutting The Same As Cricut? What Is The Difference Between Die Cutting An …

Die cutting and Cricut are related but not exactly the same. Die cutting is a general term for the process of using a die to cut out shapes from various materials, such as paper, fabric, or metal. This can be done manually with a die cutting machine or press, or with the help of electronic die cutting machines like the Cricut.

Cricut is a brand of electronic die cutting machines that…

Profboard launches cutting-edge cutting board on Kickstarter

Image: https://www.getnews.info/wp-content/uploads/2024/06/1718783865.png

Revolutionizing Kitchen Safety and Convenience for Home Chefs

Profboard, the premier manufacturer of innovative cutting board systems, is proud to announce the launch of the Profboard Private edition. Since 2006, Profboard has been a trusted name among chefs and culinary enthusiasts worldwide. Now, the same professional-grade quality and innovation can be experienced in home kitchens.

Profboard sets a new standard with its cutting-edge cutting board system designed to revolutionize your kitchen.…

Fiber Laser Metal Cutting Machines Market Cutting-Edge Technology for Efficient …

Global Fiber Laser Metal Cutting Machines Market Overview:

The Fiber Laser Metal Cutting Machines market is a broad category that includes a wide range of products and services related to various industries. This market comprises companies that operate in areas such as consumer goods, technology, healthcare, and finance, among others.

In recent years, the Fiber Laser Metal Cutting Machines market has experienced significant growth, driven by factors such as increasing consumer demand,…

Metal Cutting Fluids Market Report 2018: Segmentation by Type (Emulsion Metal Cu …

Global Metal Cutting Fluids market research report provides company profile for Blaser, Idemitsu Kosan, Daido Chemical Industry, COSMO Oil, Master, Exxon Mobil Corporation, Houghton (Gulf Oil), BP, Fuchs, Yushiro Chemical, Quaker and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for…