Press release

Lauric Acid Manufacturing Plant Setup: Capital Investment and Machinery Cost Analysis

Setting up a lauric acid manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled " Lauric Acid Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a paper plate manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Get lauric acid plant cost estimate report: https://www.imarcgroup.com/lauric-acid-manufacturing-plant-project-report/requestsample

A lauric acid manufacturing plant is a special industrial feature designed to extract, process and purify lauric acid, a saturated medium-series fatty acid is mainly found in coconut oil, palm kernel oil and some other plant-based fat. The production process typically includes hydrolysis or saponification of triglycerides present in natural oils, followed by separation and purification using distillation or crystallization techniques. These plants are equipped with advanced machinery such as reactors, centrifuge and distillation columns to ensure high yield and high purity output. Lauric acid is used widely in many industries including food and drinks, pharmaceuticals, cosmetics, and personal care, where it acts as a thicker agent, antimicrobial compound and surfactant. The convenience must follow strict quality and environmental standards to meet the regulatory requirements of the target markets. Technological progresses and automation are rapidly integrated into these plants to optimize efficiency and reduce operating costs. Additionally, manufacturers focus on permanent sourcing and waste minimalization to align with environmental criteria. The design and scale of a lauric acid manufacturing plant may vary depending on the desired application and the amount of production, including small scale special units to large -scale industrial operations serving global markets.

Lauric Acid Manufacturing Plant Market is inspired by the increasing global demand for personal care, natural and durable materials in individual care, cosmetic and food industries. Increasing consumer preference for plant-based and organic products has increased the use of lauric acid due to its antimicrobial, surfactant and emulsion properties. The expansion of cosmetics and individual care sectors, especially in emerging economies, contribute significantly to market development, as lauric acid is a major component in soap, shampoos and lotions. Additionally, the interest of the pharmaceutical industry in lauric acid for its potential therapeutic and antimicrobial properties stimulate more demand. The food processing industry also supports market expansion, taking advantage of lauric acid in yogas that require stable and functional fat. In addition, increasing availability of raw materials such as coconut and palm kernel oil in Southeast Asia and other tropical regions increases the feasibility of production. Technological progress in extraction and purification methods has also improved process efficiency, reduced production costs and environmental impacts. Regulatory support for bio-based and biodegradable materials promotes additional development opportunities. These factors collectively pursue the market for lauric acid manufacturing plants, encouraging capacity expansion and investment in infrastructure development worldwide.

Buy Now: https://www.imarcgroup.com/checkout?id=10290&method=1911

Key Steps Required to Set Up a Lauric Acid Plant

1. Market Analysis

The report provides insights into the landscape of the Lauric acid industry at the global level. The report also provides a segment-wise and region-wise breakup of the global Lauric acid industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of Lauric acid, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the Lauric acid manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for Lauric acid manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for Lauric acid production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a Lauric acid manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=10290&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Lauric Acid Manufacturing Plant Setup: Capital Investment and Machinery Cost Analysis here

News-ID: 4071624 • Views: …

More Releases from IMARC Group

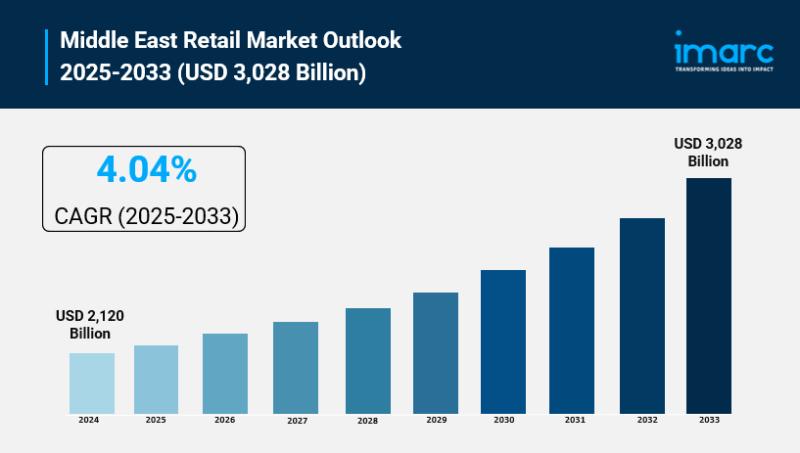

Middle East Retail Market Size to Surpass USD 3,028 Billion by 2033 | With a 4.0 …

Middle East Retail Market Overview

Market Size in 2024: USD 2,120 Billion

Market Size in 2033: USD 3,028 Billion

Market Growth Rate 2025-2033: 4.04%

According to IMARC Group's latest research publication, "Middle East Retail Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Middle East retail market size was valued at USD 2,120 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 3,028 Billion by 2033, exhibiting a…

Potassium Nitrate Prices 2025, Latest Trend, Demand, Index & Uses

Northeast Asia Potassium Nitrate Prices Movement August 2025:

In August 2025, Potassium Nitrate Prices in Northeast Asia settled at USD 0.64/KG, reflecting a 6.2% decline. Softer agricultural demand and improved regional supply availability weighed on pricing. Stable raw material input costs and comfortable inventories further contributed to the downward market adjustment.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/potassium-nitrate-pricing-report/requestsample

Note: The analysis can be tailored to align with the customer's specific needs.

Europe Potassium Nitrate Prices…

Saudi Arabia Kitchen Furniture Market Set to Surge to USD 3.8 Billion by 2033 at …

Saudi Arabia Kitchen Furniture Market Overview

Market Size in 2024: USD 2.2 Billion

Market Forecast in 2033: USD 3.8 Billion

Market Growth Rate 2025-2033: 5.9%

According to IMARC Group's latest research publication, "Saudi Arabia Kitchen Furniture Market Report by Furniture Type (Kitchen Cabinets, Kitchen Chairs, Kitchen Tables, and Others), Distribution Channel (Supermarkets and Hypermarkets, Specialty Stores, E-Commerce, and Others), and Region 2025-2033", The Saudi Arabia kitchen furniture market size reached USD 2.2 Billion in…

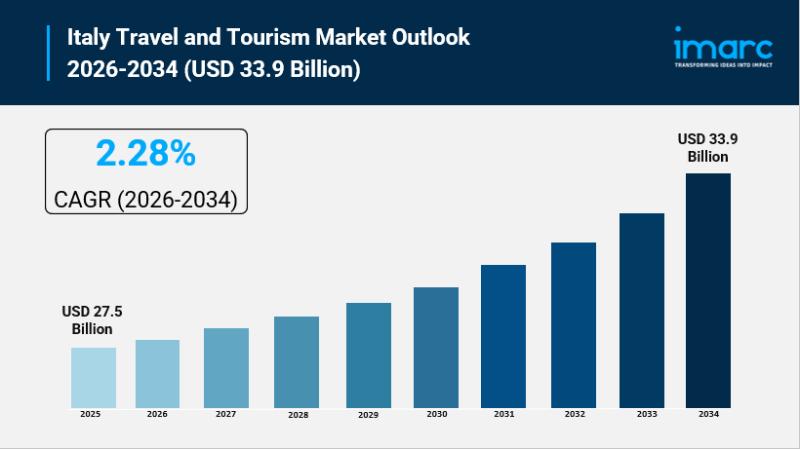

Italy Travel and Tourism Market Set to Surge to USD 33.9 Billion by 2034 at a 2. …

Italy Travel and Tourism Market Overview

Market Size in 2025: USD 27.5 Billion

Market Size in 2034: USD 33.9 Billion

Market Growth Rate 2026-2034: 2.28%

According to IMARC Group's latest research publication, "Italy Travel and Tourism Market Size, Share, Trends and Forecast by Type, Service Offering, Purpose of Visit, Booking Type, and Region, 2026-2034", the Italy travel and tourism market size was valued at USD 27.5 Billion in 2025. Looking forward, IMARC Group estimates…

More Releases for Lauric

Lauric Aldehyde Market Size, Share, Industry, Forecast to 2030

The Lauric Aldehyde Market 2023 Report makes available the current and forthcoming technical and financial details of the industry. It is one of the most comprehensive and important additions to the Prudent Markets archive of market research studies. It offers detailed research and analysis of key aspects of the global Lauric Aldehyde market. This report explores all the key factors affecting the growth of the global Lauric Aldehyde market, including…

Lauric Oil Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Lauric Oil Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. The report contains 102 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Click to view the full report TOC, figure and tables:

https://www.globalinforesearch.com/global-lauric-oil-market_p130190.html

Scope of the Report:

The worldwide market for Lauric…

Lauric Oil Global Industry Report - History, Present and Future 2025

The global market size of Lauric Oil is $XX million in 2017 with XX CAGR from 2013 to 2017, and it is expected to reach $XX million by the end of 2023 with a CAGR of XX% from 2018 to 2023.

There are 3 key segments covered in this report: geography segment, end use/application segment and competitor segment.

For geography segment, regional supply, application-wise and type-wise demand, major players, price is presented…

Lauric Aldehyde market 2018-19 Metadynea, AlliChem, Fleurchem, Indukern

Lauric Aldehyde market Competitor Analysis:

Global Lauric Aldehyde market 2019 by Future Market Reports presents a professional and complete analysis of on the current Industry situation. The Global report includes Lauric Aldehyde Revenue, market Share, industry volume, Trends, Growth aspects. It analyses the important factors of the based on present industry situations, demands, business strategies utilized by Lauric Aldehyde market players and the future prospects from various angles in detail. Industry…

Global Lauric Aldehyde Market 2017 - Metadynea, Kalpsutra Chemicals, Astier Dema …

Global Lauric Aldehyde Market 2017, presents a professional and in-depth study on the current state of the Lauric Aldehyde market globally, providing basic overview of Lauric Aldehyde market including definitions, classifications, applications and industry chain structure, Lauric Aldehyde Market report provides development policies and plans are discussed as well as manufacturing processes and cost structures. Lauric Aldehyde market size, share and end users are analyzed as well as segment markets…

Global Lauric Acid Sales Market Report 2017

This report studies sales (consumption) of Lauric Acid in Global market, especially in United States, China, Europe and Japan, focuses on top players in these regions/countries, with sales, price, revenue and market share for each player in these regions, covering

Wilmar

KLK OLEO

IOI Oleochemicals

Musim Mas

Oleon

KAO

…