Press release

Step-by-Step Guide to Setting Up a Petroleum Coke Manufacturing Plant

Setting up a petroleum coke manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Petroleum Coke Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a Petroleum coke manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/petroleum-coke-manufacturing-plant-project-report/requestsample

Petroleum coke, commonly referred to as petcoke, is a carbon-rich solid material derived from the oil refining process. It is produced through the thermal cracking of heavy petroleum fractions, resulting in a substance that is primarily composed of carbon, along with varying amounts of sulfur, metals, and other impurities. Petcoke is categorized into two main types: fuel-grade and anode-grade. Fuel-grade petcoke is primarily used as a fuel source in various industries, while anode-grade petcoke is utilized in the production of electrodes for aluminum and steel manufacturing. Its high carbon content and calorific value make it a valuable commodity in energy generation and industrial applications.

The petroleum coke market is influenced by several dynamic factors, including the growing demand for energy and the increasing use of petcoke in various industrial processes. One of the primary drivers of this market is the rising production of oil and gas, particularly in regions like North America and the Middle East, which leads to an increase in petcoke output. Additionally, the shift towards more efficient and cost-effective energy sources has propelled the use of petcoke as a cheaper alternative to coal in power generation. Environmental regulations, while posing challenges, are also driving innovations in cleaner technologies to utilize petcoke more sustainably. Furthermore, the expansion of the aluminum and steel industries, particularly in emerging economies, is expected to sustain demand for anode-grade petcoke, further shaping the market landscape.

Buy Now: https://www.imarcgroup.com/checkout?id=8386&method=402

Key Steps Required to Set Up a Petroleum Coke Plant

1. Market Analysis

The report provides insights into the landscape of the Petroleum coke industry at the global level. The report also provides a segment-wise and region-wise breakup of the global Petroleum coke industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of Petroleum coke, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the Petroleum coke manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for Petroleum coke manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for Petroleum coke production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a Petroleum coke manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=8386&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Step-by-Step Guide to Setting Up a Petroleum Coke Manufacturing Plant here

News-ID: 4071355 • Views: …

More Releases from IMARC Group

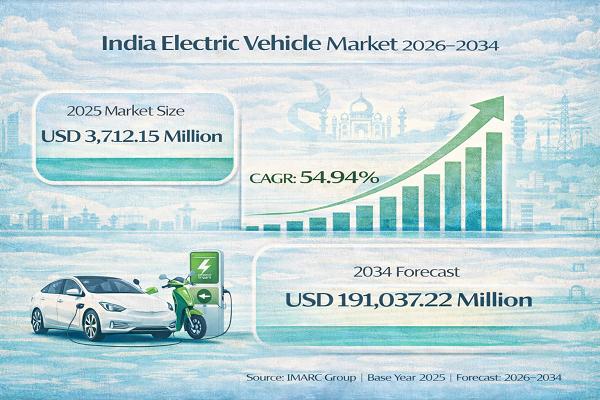

India Electric Vehicle Market Set to Reach USD 191,037.22 Million by 2034, Expan …

India Electric Vehicle Market : Report Introduction

According to IMARC Group's report titled "India Electric Vehicle Market Size, Share, Trends and Forecast by Vehicle Type, Price Category, Propulsion Type, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

Free Sample Download PDF (Exclusive Offer on Corporate Email) : https://www.imarcgroup.com/india-electric-vehicle-market/requestsample

India Electric Vehicle Market Overview

The India electric vehicle market size was valued at…

United States Revenue Cycle Management Market Size, Trends, Growth and Forecast …

IMARC Group has recently released a new research study titled "United States Revenue Cycle Management Market Size, Share, Trends and Forecast by Type, Component, Deployment, End User, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Connect with a Research Analyst Now:

https://www.imarcgroup.com/united-states-revenue-cycle-management-market/requestsample

United States Revenue Cycle Management Market Summary:

The United States revenue cycle…

LED Chip Manufacturing Plant Cost Report 2026: Demand Analysis, CapEx/OpEx & ROI …

Setting up an LED chip manufacturing plant involves strategic planning, substantial capital investment, and comprehensive understanding of semiconductor fabrication technologies. These high-performance components power everything from general illumination and displays to automotive lighting and consumer electronics. Success requires careful site selection, advanced epitaxial growth processes, sophisticated cleanroom facilities, reliable raw material sourcing, and compliance with stringent quality and environmental regulations to ensure profitable and sustainable operations.

IMARC Group's report, "LED Chip…

Eyewear Manufacturing Plant DPR & Unit Setup - 2026: Machinery Cost, CapEx/OpEx, …

Setting up an eyewear manufacturing plant positions investors within a strategically important segment of the global optical and fashion accessories industry, driven by increasing demand for vision correction solutions, rising awareness of eye health, and growing fashion consciousness. As modern lifestyles advance, digital device usage expands, and the need for protective and corrective eyewear grows, eyewear continues to gain traction across prescription glasses, sunglasses, safety eyewear, and fashion accessories worldwide.…

More Releases for Petroleum

Green Petroleum Coke and Calcined Petroleum Coke Market : An Overview

Introduction:

Green petroleum coke (GPC) and calcined petroleum coke (CPC) are key by-products of the oil refining process. GPC, a carbon-rich material, is used primarily as a fuel in industries such as power generation and cement manufacturing. When subjected to high temperatures, GPC is transformed into CPC, which finds applications in aluminum smelting, steel manufacturing, and titanium dioxide production. Both materials are critical in various industrial processes due to their high…

Green Petroleum Coke and Calcined Petroleum Coke Market : An Overview

Introduction:

The green petroleum coke (GPC) and calcined petroleum coke (CPC) market is a critical segment of the global energy and materials industries. Green petroleum coke, a byproduct of crude oil refining, is an unprocessed carbon material used in various industrial applications. Calcined petroleum coke, produced by heating GPC at high temperatures, is primarily used in aluminum smelting, steel manufacturing, and chemical processes. With increasing demand for energy and industrial materials,…

Petroleum Jelly Petroleum Jelly Market Innovative Strategy by 2031 | Major Giant …

Petroleum Jelly Market: Introduction

Transparency Market Research delivers key insights on the global petroleum jelly market. In terms of value, the global petroleum jelly market is expected to expand at a CAGR of 4.26% during the forecast period, owing to numerous factors regarding which TMR offers thorough insights and forecasts in its report on the global petroleum jelly market.

Get a Sample Copy of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=72726

Petroleum jelly is used in the…

Global Liquefied Petroleum Gas Market 2020 Business Strategies – Chevron Corpo …

The market report titled “Liquefied Petroleum Gas Market By Source (Refinery, Associated Gas, and Non-Associated Gas) and By End-User (Residential & Commercial, Petrochemical & Refineries, Industrial, and Transportation): Global Industry Perspective, Comprehensive Analysis, and Forecast, 2018–2025” and published by Zion Market Research will put forth a systematizedevaluation of the vital facets of the global Liquefied Petroleum Gas Market market. The report willfunction as a medium for the better assessment of…

Natural Gas Market to Witness Huge Growth by 2025 | Qatar Petroleum, Sempra Ener …

The Global Natural Gas Market has witnessed continuous growth in the past few years and may grow further during the forecast period (2019-2025). The assessment provides a 360° view and insights, outlining the key outcomes of the industry, current scenario witnesses a slowdown and study aims to unique strategies followed by key players. These insights also help the business decision-makers to formulate better business plans and make informed decisions for…

Petroleum Coke Market Players British Petroleum, Marathon Petroleum Corporation

Introduction:

Petroleum coke or petcoke, a solid rock material is a byproduct of crude oil refining and other cracking processes. Although a refining byproduct, petroleum coke is considered as a valued commodity since 2008, all over the world. Crude oil remained after separating other valuable petroleum products from refining process such as diesel, lubricants, waxes, etc. can be processed further in cokers or other cracking processes to produce petroleum coke. Different…