Press release

Flow Battery Manufacturing Plant Setup: Capital Investment & Machinery Cost Breakdown

Setting up a flow battery manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled " Flow Battery Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a paper plate manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Get flow battery plant cost estimate report: https://www.imarcgroup.com/flow-battery-manufacturing-plant-project-report/requestsample

A flow battery manufacturing plant is a special feature designed to produce flow battery, which is a type of rechargeable energy storage system, particularly adapted to large -scale applications. Unlike traditional batteries, flow battery storage energy in liquid electrolytes placed in external tanks, allowing independent scaling of power and energy capabilities. The manufacturing process in these plants includes the assembly of electrochemical cells, integration of electrolyte management systems and quality testing to ensure safety and efficiency. These features are equipped with accurate engineering equipment, chemical processing units and automatic production lines to maintain battery performance and longevity. The materials used include vanadium, zinc-bomine, or iron-chromium electrolytes with advanced membrane and electrode technologies. Flow battery manufacturing plants also focus on research and development to increase the energy density, reduce costs and improve system reliability. With their modular design and extended life cycle, the flow battery is seen as a viable solution for grid-level energy storage, especially in renewable energy integration and off-grid power applications. The establishment of such manufacturing plants supports energy transition goals, local employment generation and technological progress in the energy storage fields.

The flow battery manufacturing plant market is mainly inspired by increasing global demand for long -term energy storage solutions, especially renewable energy sources such as solar and wind power generation portfolio. Flow battery provides distinctive benefits on traditional lithium-ion systems, including prolonged operational life, deep discharge abilities, and increased safety due to their non-fake nature. These characteristics make them highly attractive to grid-scale storage, where reliability and scalability are important. Additionally, with increasing investment in government policies that promote clean energy, grid modernization and decarbonization initiatives, flowing in flow battery technologies, combined with increasing investment. Emerging economies are also searching for flow batteries to support rural electrification and energy freedom. In addition, the rising costs associated with lithium-ion battery production and resource deficiency are motivating energy providers and industrial users to consider alternative storage technologies. Technological progress flow in electrolyte yoga and system design is improving the cost-effectiveness and performance of the flow battery, making them more commercially viable. These trends for energy flexibility and climate change mitigation are contributing to the expansion of the flow battery manufacturing plant market globally.

Buy Now: https://www.imarcgroup.com/checkout?id=22218&method=1911

Key Steps Required to Set Up a Flow Battery Plant

1. Market Analysis

The report provides insights into the landscape of the flow battery industry at the global level. The report also provides a segment-wise and region-wise breakup of the global flow battery industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of flow battery, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the flow battery manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for flow battery manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for flow battery production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a flow battery manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=22218&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Flow Battery Manufacturing Plant Setup: Capital Investment & Machinery Cost Breakdown here

News-ID: 4069639 • Views: …

More Releases from IMARC Group

India Bottled Water Market 2026: Explosive Growth, Key Players & Future Opportun …

Introduction:

According to the latest research report titled "India Bottled Water Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and Region, 2026-2034" the report offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India Bottled Water Market Overview:

The India bottled water market size was valued at USD 10.71 Billion in 2025 and is projected to reach USD 29.70 Billion by 2034, growing at…

India E-Bike Market 2026: Explosive Growth, Top Brands & Investment Opportunitie …

Introduction:

According to the recent data, the report titled "India E-Bike Market Size, Share, Trends and Forecast by Propulsion Type, Battery Type, Power, Application, and Region, 2026-2034" offers a comprehensive analysis of the industry, including market share, growth, trends, and regional insights.

India E-bike Market Overview:

The India E-bike market attained a valuation of USD 1,420.78 Million in 2025 and is forecasted to reach USD 3,007.19 Million by 2034, demonstrating a robust compound…

United States AI Governance Market Size, Growth, Latest Insights and Forecast 20 …

IMARC Group's Latest Research Reveals a CAGR of 28.10% from 2026-2034, Supported by Expanding Certification, Auditing, and Impact Assessment Processes

NEW YORK, USA - The United States artificial intelligence (AI) governance industry is witnessing rapid expansion as organizations intensify efforts to implement responsible AI practices. According to the latest market intelligence report by IMARC Group, the United States AI Governance Market, valued at USD 81.6 Million in 2025, is projected to…

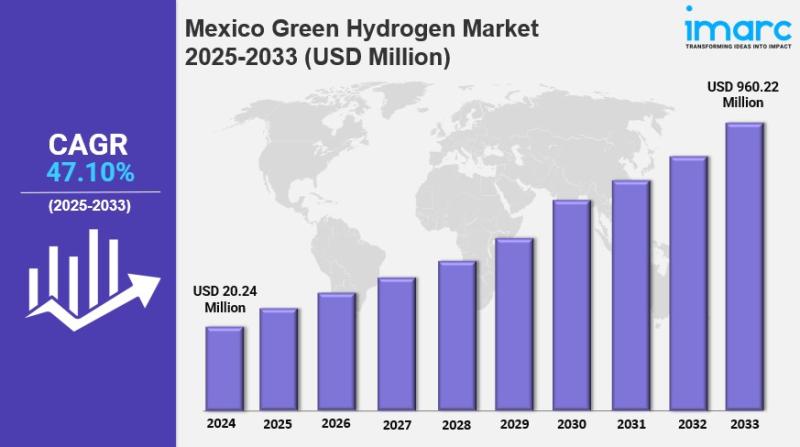

Mexico Green Hydrogen Market Size, Share, Demand, Trends & Forecast to 2033

IMARC Group's Latest Research Reveals a CAGR of 47.10% from 2025-2033, with Renewable-Powered Electrolysis and Export-Oriented Projects Accelerating Market Expansion

NEW YORK, USA - The Mexico green hydrogen industry is entering a high-growth phase, supported by national decarbonization initiatives and rising global demand for clean fuels. According to the latest report by IMARC Group, the Mexico Green Hydrogen Market reached a value of USD 20.24 Million in 2024 and is projected…

More Releases for Flow

Flow Foundation Shares Commitment to FLOW; Announces Buyback and Burn of 50 Mill …

Vancouver, Canada - Flow Foundation is taking a series of concrete actions to strengthen FLOW. This post outlines three initiatives: a token buyback & burn, continuous token acquisition with structural improvements to liquidity, and long-term inflation management.

Why This Matters

A healthy token economy underpins everything built on the network. Developers evaluate where to build based on the economic strength and sustainability of the ecosystem. Validators commit resources to networks where the…

Flow (FLOW) Price Prediction: Pepenode (PEPENODE) Gains Rapid Market Recognition

Market moves since early October have reshaped speculative flows. Bitcoin slid from roughly $126,080 to about $87,423, wiping nearly $1 trillion from total market value and pressuring Ethereum. That unwind pushed ETH down about 28% over 30 days and coincided with a $415M net outflow from spot funds in a single day.

Rising U.S. Treasury yields and shifting Federal Reserve expectations have nudged capital toward perceived safety and yield-bearing strategies. Institutional…

Flow Rate Liquid Flow Meters Market Size, Share and Growth Report, 2034

"The global liquid flow meter market was valued at approximately USD 4 billion in 2024 and is projected to reach around USD 6.5 billion by 2034, indicating a Compound Annual Growth Rate (CAGR) of about 5.2% over the forecast period from 2025 to 2034. "

Exactitude Consultancy., Ltd. released a research report titled "Flow Rate Liquid Flow Meters Market". This report covers the global Flow Rate Liquid Flow Meters market sales,…

Hybrid Flow Battery Market, By Type (Zinc Bromine Flow Batteries, Other Hybrid F …

Data Bridge Market Research analyses the hybrid flow battery market will exhibit a CAGR of 32.14% for the forecast period of 2022-2029 and is likely to reach USD 710.18 million by 2029.

View Detailed Analysis Report: https://www.databridgemarketresearch.com/reports/global-hybrid-flow-battery-market

The zinc-bromine flow battery (ZBFB) is the most well-known form of hybrid flow battery. Typically, a hybrid flow battery consists of a cell with 2 compartments separated by a microporous membrane. The battery has a…

Hybrid Flow Battery Market, By Type (Zinc Bromine Flow Batteries, Other Hybrid F …

Data Bridge Market Research analyses the hybrid flow battery market will exhibit a CAGR of 32.14% for the forecast period of 2022-2029 and is likely to reach USD 710.18 million by 2029.

View Detailed Report: https://www.databridgemarketresearch.com/reports/global-hybrid-flow-battery-market

The zinc-bromine flow battery (ZBFB) is the most well-known form of hybrid flow battery. Typically, a hybrid flow battery consists of a cell with 2 compartments separated by a microporous membrane. The battery has a conductor…

Flow Cytometry Market Size 2020-26, Agilent Technologies, Apogee Flow Systems

The latest study on the Global Flow Cytometry market report represents a deep appraisal of the international industry. The research report on the worldwide Flow Cytometry market 2020-2026 sheds light on qualitative as well as quantitative insights, historical Flow Cytometry industry status and authorized projection related to the Flow Cytometry market size. Each and every segment exhibited in this report are discovered through verifiable research methods and techniques. It also…