Press release

Strategic Analysis of Food Automation Market: Trends, Size, Share, and Forecast by 2032

"The food automation market is undergoing a period of significant expansion, driven by a confluence of factors including the increasing need for efficiency, enhanced food safety, and consistent quality in food production. Technological advancements in robotics, artificial intelligence (AI), and the Internet of Things (IoT) are revolutionizing food processing, packaging, and distribution. The market addresses critical global challenges, such as labor shortages, rising operational costs, and the need to meet the demands of a growing global population with evolving dietary preferences. Automation reduces manual labor, minimizes human error, and optimizes resource utilization, contributing to sustainable and resilient food systems. Furthermore, the integration of data analytics and machine learning enables real-time monitoring and control of food production processes, improving traceability and reducing waste. As consumer demand for processed and packaged foods continues to rise, automation is becoming indispensable for food manufacturers to maintain competitiveness, comply with stringent regulations, and ensure product safety and consistency. This transformative shift is not only boosting productivity but also paving the way for innovative solutions that address the challenges of food security and sustainability in the 21st century.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2972

Market Size:

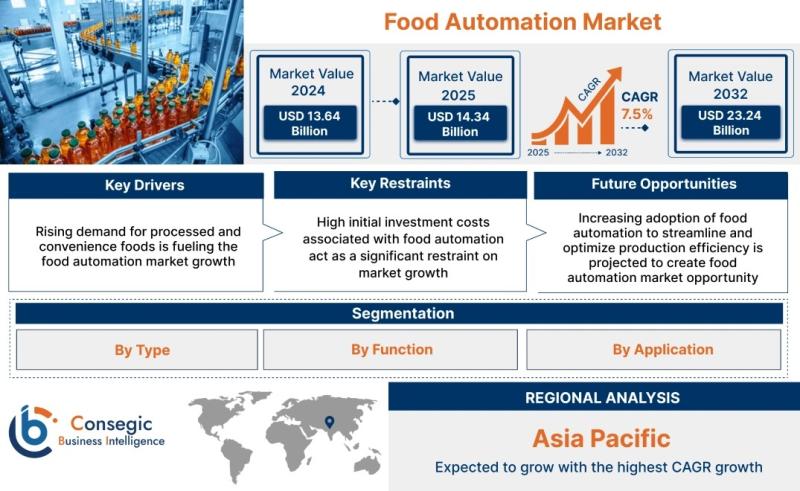

The Food Automation Market size is estimated to reach over USD 23.24 Billion by 2032 from a value of USD 13.64 Billion in 2024 and is projected to grow by USD 14.34 Billion in 2025, growing at a CAGR of 7.5% from 2025 to 2032.

Definition of Market:

The Food Automation Market encompasses the integration of automated technologies and systems into various stages of the food production and processing chain. This includes, but is not limited to, automated machinery, robotic systems, control systems, and software solutions designed to streamline operations, enhance efficiency, and improve product quality within the food industry.

Key components of this market include:

* **Automated Machinery:** Equipment designed to perform specific tasks with minimal human intervention, such as slicing, dicing, mixing, and cooking.

* **Robotic Systems:** Programmable robots used for tasks like picking, placing, packaging, and palletizing food products.

* **Control Systems:** Advanced electronic and computer-based systems that monitor and regulate various aspects of the food production process, including temperature, pressure, and speed.

* **Software Solutions:** Programs that enable data analysis, process optimization, and predictive maintenance within food processing facilities.

Key terms related to this market include:

* **PLC (Programmable Logic Controller):** A digital computer used to automate electromechanical processes, such as control of machinery on factory assembly lines.

* **SCADA (Supervisory Control and Data Acquisition):** A control system architecture that uses computers, networked data communications and graphical user interfaces for high-level process supervisory management.

* **HMI (Human Machine Interface):** The user interface or dashboard that connects a person to a machine, system, or device.

* **Robotics:** The design, construction, operation, and application of robots.

* **Machine Vision:** The technology and methods used to provide imaging-based automatic inspection and analysis for such applications as robotic guidance.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2972

Market Scope and Overview:

The scope of the Food Automation Market is vast, spanning a wide range of technologies, applications, and industries within the food sector. Technologies include robotics, sensors, control systems, software, and vision systems, all integrated to automate various processes. Applications range from primary processing (such as meat cutting and produce sorting) to secondary processing (such as mixing and baking) to packaging and distribution. Industries served include meat, poultry, seafood, dairy, bakery, confectionery, fruits and vegetables, and beverages. This market addresses the increasing need for higher efficiency, improved food safety, and reduced labor costs, transforming how food products are manufactured, packaged, and distributed.

The Food Automation Market plays a crucial role in the larger context of global trends. As the world's population grows and consumer demands evolve, the food industry faces increasing pressure to produce more food with fewer resources while adhering to stringent safety and quality standards. Automation addresses these challenges by increasing productivity, reducing waste, and minimizing the risk of contamination. It supports the shift towards more sustainable and resilient food systems, enabling food manufacturers to optimize their operations and meet the demands of a global market. Furthermore, the integration of technologies like IoT and data analytics allows for real-time monitoring and traceability, ensuring food safety and building consumer trust. This market is not just about improving efficiency; it is about creating a more secure, sustainable, and responsive food supply chain.

Top Key Players in this Market

ABB (Switzerland) Siemens AG (Germany) Rockwell Automation Inc. (USA) Mitsubishi Electric Corporation (Japan) Schneider Electric SE (France) GEA Group (Germany) Emerson Electric Co. (USA) Yokogawa Electric Corporation (Japan) FANUC (Japan) KUKA AG (Germany) Honeywell International Inc. (USA) Omron Automation (Japan) Yaskawa Electric Corporation (Japan) Rexnord Corporation (Regal Rexnord Corporation) (USA) Fortive Corporation (USA)

Market Segmentation:

The Food Automation Market is segmented by Type, Function, and Application.

* **By Type:** This includes Motors & Generators, Motor Controls, Discrete Controllers & Visualization, Rotary Products, Linear Products, and Others. Motors and generators drive the machinery, while controls and visualization tools manage and monitor the automated processes. Rotary and linear products facilitate movement and positioning of food items within the production line.

* **By Function:** The market is divided into Processing, Packaging & Repackaging, Palletizing, Sorting & Grading, Picking & Placing, and Others. These segments reflect the diverse stages of food production where automation is applied, from initial processing to final packaging and distribution.

* **By Application:** Segments include Dairy, Bakery & Confectionery, Fruit & Vegetable, Meat, Poultry, and Seafood, and Beverages. Each segment represents a specific food industry where automation is tailored to the unique requirements of producing those goods.

Market Drivers:

**Labor Shortages and Rising Labor Costs:** The food industry often faces challenges in attracting and retaining workers, particularly for physically demanding or repetitive tasks. Automation reduces the reliance on manual labor, mitigating the impact of labor shortages and controlling rising labor costs.

**Enhanced Food Safety and Hygiene Standards:** Automated systems reduce human contact with food products, minimizing the risk of contamination and improving overall hygiene. This is particularly important in meeting increasingly stringent food safety regulations.

**Increased Efficiency and Productivity:** Automation streamlines processes, reduces downtime, and optimizes resource utilization, leading to increased efficiency and higher production volumes.

**Improved Product Quality and Consistency:** Automated systems ensure consistent execution of tasks, resulting in uniform product quality and reducing the risk of errors.

**Technological Advancements:** Rapid advancements in robotics, AI, and IoT technologies are making automation solutions more sophisticated, reliable, and cost-effective, driving adoption across the food industry.

**Growing Demand for Packaged and Processed Foods:** As consumer lifestyles become busier, there is a growing demand for convenient, packaged, and processed foods. Automation enables food manufacturers to meet this demand efficiently and effectively.

**Stringent Regulatory Compliance:** The food industry is subject to strict regulations regarding safety, labeling, and traceability. Automation helps companies comply with these regulations by providing real-time monitoring and data logging capabilities.

Market Key Trends:

**Integration of Artificial Intelligence (AI) and Machine Learning (ML):** AI and ML are being used to optimize processes, predict equipment failures, and improve quality control through real-time data analysis.

**Increased Adoption of Robotics:** Robots are becoming more versatile and affordable, leading to their widespread use in tasks such as picking, placing, and packaging.

**Development of Flexible and Modular Automation Solutions:** Food manufacturers are increasingly seeking automation solutions that can be easily adapted to different products and production lines.

**Focus on Hygienic Design:** Automation equipment is being designed with a greater emphasis on hygiene, using materials and designs that minimize the risk of contamination.

**Cloud-Based Solutions and Remote Monitoring:** Cloud-based platforms are enabling remote monitoring and control of automation systems, allowing for improved efficiency and reduced downtime.

**Sustainability and Waste Reduction:** Automation is being used to optimize resource utilization, reduce waste, and improve the overall sustainability of food production processes.

Market Opportunities:

**Expansion into Emerging Markets:** As food production in emerging economies grows, there is a significant opportunity to introduce automation technologies to improve efficiency and safety.

**Development of Specialized Automation Solutions:** There is a growing demand for automation solutions tailored to the specific needs of different food products and processes.

**Retrofitting Existing Food Processing Facilities:** Many older food processing facilities can benefit from retrofitting with automation technologies to improve efficiency and reduce costs.

**Integration with Supply Chain Management Systems:** Integrating automation systems with supply chain management systems can improve traceability and reduce waste across the entire food supply chain.

**Advancements in Sensor Technology:** Innovations in sensor technology provide opportunities for real-time monitoring of food quality and safety, enabling better control and optimization of production processes.

Market Restraints:

**High Initial Investment Costs:** The initial cost of implementing automation systems can be a significant barrier for smaller food manufacturers.

**Complexity of Integration:** Integrating automation systems into existing production lines can be complex and require specialized expertise.

**Lack of Skilled Workforce:** There is a shortage of skilled workers who can operate and maintain automation systems.

**Regulatory Hurdles:** Certain regulations may limit the use of automation in specific food production processes.

**Resistance to Change:** Some food manufacturers may be resistant to adopting new technologies due to concerns about disruption or lack of familiarity.

**Concerns About Job Displacement:** The adoption of automation may raise concerns about potential job displacement, requiring companies to address workforce retraining and redeployment strategies.

Market Challenges:

The Food Automation Market, despite its promising growth trajectory, faces several significant challenges that could impede its progress. One of the foremost challenges is the **high initial investment cost** associated with implementing automation systems. Many small and medium-sized enterprises (SMEs) in the food industry may find it difficult to justify the large capital expenditure required for purchasing and integrating advanced automated machinery and software. This cost barrier can hinder the widespread adoption of automation, particularly in regions where financial resources are limited.

Another critical challenge lies in the **complexity of integrating automation systems into existing infrastructure**. Many food processing plants operate with legacy equipment and outdated systems, making it challenging to seamlessly integrate new automation technologies. Compatibility issues, data integration challenges, and the need for extensive system modifications can create significant hurdles. Overcoming these integration complexities requires specialized expertise and careful planning, further increasing the overall cost and time required for implementation.

The **shortage of skilled workforce** capable of operating, maintaining, and troubleshooting automation systems presents another significant obstacle. The food industry needs professionals with expertise in robotics, automation engineering, and data analytics to effectively manage and optimize automated processes. The lack of such skilled personnel can limit the potential benefits of automation and lead to operational inefficiencies. Addressing this challenge requires investments in training programs, educational initiatives, and partnerships with technical institutions to develop a pipeline of qualified professionals.

Furthermore, the food industry is subject to **stringent regulatory requirements** related to safety, hygiene, and traceability. Ensuring that automation systems comply with these regulations can be complex and time-consuming. Food manufacturers must carefully evaluate the impact of automation on regulatory compliance and implement appropriate measures to meet the required standards. This may involve additional investments in testing, validation, and documentation, further adding to the overall cost.

Finally, **resistance to change** within the food industry can also pose a significant challenge. Some food manufacturers may be hesitant to adopt new technologies due to concerns about disruption, lack of familiarity, or perceived risks. Overcoming this resistance requires effective communication, education, and demonstration of the tangible benefits of automation, such as improved efficiency, reduced costs, and enhanced product quality. Building trust and demonstrating the value proposition of automation are crucial for driving adoption and overcoming organizational inertia.

Market Regional Analysis:

The Food Automation Market exhibits diverse dynamics across different regions. **North America** is a mature market with high adoption rates due to stringent food safety regulations and labor shortages. The region focuses on advanced automation technologies, including AI and IoT-enabled solutions.

**Europe** also demonstrates strong market growth, driven by increasing consumer demand for processed foods and the need for sustainable production practices. The region prioritizes energy-efficient and eco-friendly automation solutions to meet environmental goals. Government initiatives and funding programs further support the adoption of food automation in Europe.

The **Asia-Pacific** region represents the fastest-growing market, fueled by rapid industrialization, increasing disposable incomes, and a growing demand for processed foods. Countries like China and India are investing heavily in food processing infrastructure and automation technologies to enhance productivity and meet the needs of their large populations. The region offers significant opportunities for automation solution providers due to its large market size and growth potential.

Frequently Asked Questions:

**Q: What are the growth projections for the Food Automation Market?**

A: The Food Automation Market is projected to grow from USD 13.64 Billion in 2024 to over USD 23.24 Billion by 2032, exhibiting a CAGR of 7.5% from 2025 to 2032.

**Q: What are the key trends shaping the Food Automation Market?**

A: Key trends include the integration of AI and ML, increased adoption of robotics, the development of flexible and modular automation solutions, and a focus on hygienic design.

**Q: What are the most popular types of automation used in the Food Automation Market?**

A: Popular automation types include robotics, sensors, control systems, and software solutions. These are applied in processing, packaging, palletizing, and sorting & grading functions.

"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Strategic Analysis of Food Automation Market: Trends, Size, Share, and Forecast by 2032 here

News-ID: 4068464 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Automation

Amvel Automation: Revolutionizing Industrial Processes through Automation

Amvel Automation, a leading automatic gates manufacturer in India, is transforming the industrial landscape with its cutting-edge automation solutions. With a strong focus on innovation and excellence, Amvel Automation is empowering industries to increase efficiency, productivity, and safety.

Comprehensive Automation Solutions

Amvel Automation offers a wide range of automation products and services, including:

Automatic Gates: Sliding gates, swinging gates, and rolling shutters for secure and convenient access control.

Industrial Automation: PLC-based automation solutions for…

Linear Transfer Systems Market to Witness Huge Growth by 2028 | ATS Automation, …

Linear Transfer Systems Market research report provides in-depth information about lucrative emerging markets and analyzes penetration across mature segments of the markets. It also offers an in-depth examination of new product launches, recent developments, untapped geographies, and recent developments. Moreover, the report also provides intelligent insights on future technologies, R&D activities, and breakthrough product developments.

Click Here For Free Sample + Related Graphs of the Report at: https://www.reportsnreports.com/contacts/requestsample.aspx?name=6210965

This research report…

Linear Transfer Systems Market Top Key Players Focused - ATS Automation, Rockwel …

“Linear Transfer Systems Market” report explores manufacturer’s competitive scenario and provides market share for all major players of this market based on production capacity, sales, revenue, geographical presence and other major factors. The report also covers import/export data across all major regions covered in this report.

Download Sample PDF copy of this report @ https://www.upmarketresearch.com/home/requested_sample/65246

The key players covered in this study

ATS Automation

Rockwell Automation

Beckhoff Automation

Preh IMA Automation

Ruhlamat

Afag

Motion Index Drives

Pematech

TAKTOMAT

Haberkorn

Innovative Automation

Mecsmart Systems

Meto-Fer

This…

Linear Transfer Automation Market Size 2018 by Top Key Players and Application w …

The Linear Transfer Automation report offers a comprehensive evaluation of the market. It does so via in-depth insights, understanding market evolution by tracking historical developments, and analyzing the present scenario and future projections based on optimistic and likely scenarios. Each research report serves as a repository of analysis and information for every facet of the market

This report studies the global Linear Transfer Automation market status and forecast, categorizes…

Home Automation and Control Market Report 2018: Segmentation by Type (Home Autom …

Global Home Automation and Control market research report provides company profile for Schneider Electric SA, Vantage Controls, Crestron Electronics, Inc., iControl Networks Inc., Control4 Corporation, Honeywell International Inc., AMX LLC, Johnson Controls, ADT Corporation, Siemens AG, 2GIG Technologies and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume,…

Digital Process Automation Market Report 2018: Segmentation by Component, Busine …

Global Digital Process Automation market research report provides company profile for IBM (US), Appian (US), DST Systems (US), OpenText (Canada), K2 (US), Bizagi (England), DXC (US), Infosys (India), Oracle (US), Pegasystems (US), Tibco (US) and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY…