Press release

Industrial Robotics Market Research Report 2025: Size, Segmentation, Regional Outlook & Forecast 2032

"The industrial robotics market is experiencing significant growth, driven by the increasing need for automation across various industries. Factors such as rising labor costs, stringent quality control requirements, and the desire for enhanced productivity are fueling the adoption of robotic solutions. Technological advancements, including improved sensor technology, artificial intelligence (AI), and machine learning (ML), are enhancing the capabilities and versatility of industrial robots. These advancements enable robots to perform more complex tasks, adapt to changing environments, and collaborate safely with human workers. Furthermore, the market is playing a crucial role in addressing global challenges such as labor shortages, supply chain disruptions, and the need for sustainable manufacturing practices. By automating repetitive and hazardous tasks, industrial robots improve workplace safety and reduce the risk of injuries. They also contribute to energy efficiency and waste reduction, supporting environmentally conscious operations. The market's ability to drive efficiency, improve quality, and address critical challenges positions it as a key enabler of industrial transformation and sustainable economic growth.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2964

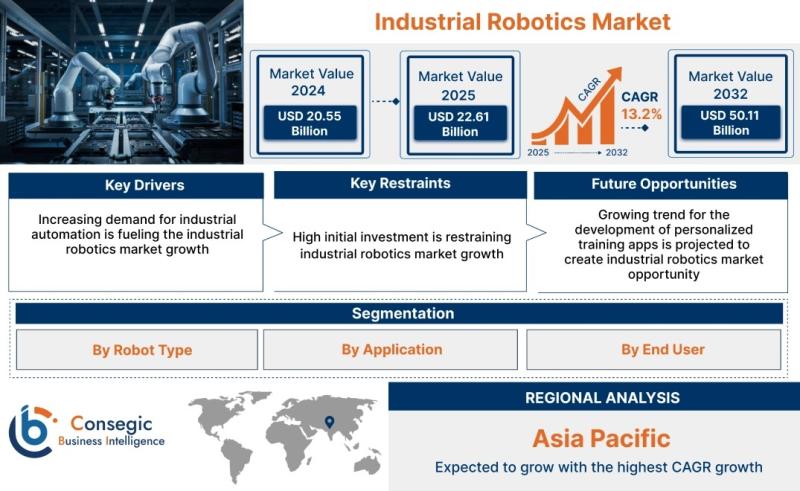

Market Size:

The Industrial Robotics Market Size is estimated to reach over USD 50.11 Billion by 2032 from a value of USD 20.55 Billion in 2024 and is projected to grow by USD 22.61 Billion in 2025, growing at a CAGR of 13.2% from 2025 to 2032.

Definition of Market:

The Industrial Robotics Market encompasses the design, development, manufacturing, and deployment of robots used in industrial settings to automate various tasks. These robots are typically programmable and capable of performing a wide range of functions with precision and repeatability. Key components of this market include:

Industrial Robots: The core product, encompassing various types such as articulated, SCARA, cylindrical, Cartesian, parallel, and collaborative robots (cobots).

Software and Control Systems: Essential for programming, controlling, and monitoring robot operations. This includes simulation software for designing robotic workcells and optimizing performance.

Peripherals and Accessories: Includes end-of-arm tooling (EOAT) such as grippers, welders, and spray guns, as well as sensors, cameras, and other devices that enhance robot capabilities.

System Integration Services: Involves designing, installing, and commissioning robotic systems, ensuring seamless integration with existing production processes.

Maintenance and Support Services: Provides ongoing maintenance, repair, and technical support to ensure optimal robot performance and minimize downtime.

Key terms related to the market include: Automation (the use of technology to perform tasks with minimal human intervention), Payload (the maximum weight a robot can carry), Reach (the maximum distance a robot's arm can extend), Repeatability (the robot's ability to return to the same position consistently), and Degrees of Freedom (DOF) (the number of independent movements a robot can make).

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2964

Market Scope and Overview:

The industrial robotics market's scope is broad, encompassing a wide array of technologies, applications, and industries. The technologies driving this market include advanced sensors, machine learning algorithms, computer vision, and high-performance computing. These technologies enable robots to perform complex tasks with greater accuracy, speed, and adaptability. Applications range from simple pick-and-place operations to intricate welding, painting, assembly, and inspection processes. The industries served by industrial robots are diverse, including automotive, electronics, healthcare, food and beverage, pharmaceuticals, and many more. The market's growth is underpinned by the increasing demand for automation across these sectors, driven by factors such as labor shortages, rising costs, and the need for improved quality and efficiency.

In the larger context of global trends, the industrial robotics market is pivotal in driving the Fourth Industrial Revolution, also known as Industry 4.0. This revolution is characterized by the integration of digital technologies into manufacturing processes, creating smart factories that are more efficient, flexible, and responsive. Industrial robots are a key component of these smart factories, enabling manufacturers to automate tasks, collect data, and optimize their operations in real-time. Furthermore, the market is contributing to the reshoring of manufacturing activities to developed countries, as companies seek to reduce their reliance on low-cost labor in emerging markets. By enabling manufacturers to produce goods more efficiently and cost-effectively, industrial robots are helping to create new jobs and strengthen domestic economies. The rise of collaborative robots (cobots), which can work safely alongside human workers, is also transforming the nature of work in manufacturing, creating opportunities for humans and robots to collaborate on tasks and leverage their respective strengths.

Top Key Players in this Market

ABB (Switzerland) FANUC (Japan) Yaskawa Motoman (Japan) KUKA AG (Germany) Universal Robots (Denmark) Kawasaki Robotics (Japan) Mitsubishi Electric (Japan) Omron Automation (Japan) Stäubli Robotics (Switzerland) Comau Robotics (Italy) Epson Robots (Japan) Denso Robotics (Japan) Hyundai Robotics (South Korea) Techman Robot (Taiwan) Doosan Robotics (South Korea)

Market Segmentation:

The industrial robotics market can be segmented based on various factors:

By Robot Type: Articulated robots offer high flexibility and are used in complex tasks; SCARA robots excel in high-speed pick-and-place applications; Cylindrical and Cartesian robots are suitable for linear movements; Parallel robots provide high speed and precision; Cobots enable human-robot collaboration; and other types cater to specialized needs.

By Application: Pick & Place robots are used for material handling; Welding & Soldering robots enhance accuracy and speed; Material Handling robots automate logistics; Assembling robots streamline production lines; Cutting & Processing robots improve precision; and other applications cater to specific industry requirements.

By End User: The Automotive industry heavily relies on robots for manufacturing; Electrical & Electronics uses robots for precision assembly; Healthcare & Pharmaceutical benefits from automation in drug development and production; Food & Beverages employs robots for hygiene and efficiency; Rubber & Plastic integrates robots for molding and handling; Metals & Machinery uses robots for heavy-duty tasks; and other sectors adopt robots for diverse applications.

Market Drivers:

Technological Advancements: Continuous innovations in robotics technology, such as improved sensors, AI, and machine learning, are enhancing robot capabilities and driving market growth.

Government Policies: Government initiatives and subsidies promoting automation and robotics adoption are incentivizing companies to invest in robotic solutions.

Increasing Demand for Sustainability: The growing focus on sustainability is driving the adoption of robots, as they can improve energy efficiency, reduce waste, and optimize resource utilization.

Rising Labor Costs: The increasing cost of labor, especially in developed countries, is making automation more attractive to manufacturers.

Stringent Quality Control Requirements: Robots can perform tasks with greater precision and repeatability than humans, leading to improved product quality and reduced defects.

Market Key Trends:

Growing Adoption of Collaborative Robots (Cobots): Cobots are designed to work safely alongside human workers, making them ideal for tasks that require both human and robotic capabilities.

Integration of AI and Machine Learning: AI and ML are being integrated into industrial robots to enable them to perform more complex tasks, adapt to changing environments, and learn from experience.

Increasing Use of Simulation Software: Simulation software is being used to design and optimize robotic workcells, reducing the time and cost of deployment.

Rise of Robot-as-a-Service (RaaS): RaaS models are making robots more accessible to small and medium-sized enterprises (SMEs) by reducing the upfront investment required.

Focus on Digital Twins: Digital twins are virtual representations of physical assets that can be used to monitor and optimize robot performance in real-time.

Market Opportunities:

Expanding into New Industries: There is significant potential for industrial robots to be adopted in new industries, such as agriculture, logistics, and construction.

Developing New Applications: Continuous innovation in robotics technology is creating opportunities for new applications, such as autonomous mobile robots (AMRs) and robotic process automation (RPA).

Offering Value-Added Services: Companies can differentiate themselves by offering value-added services, such as system integration, maintenance, and training.

Focusing on Emerging Markets: Emerging markets, such as China and India, are experiencing rapid industrial growth and offer significant opportunities for robot adoption.

Creating Customized Solutions: Developing customized robotic solutions that are tailored to the specific needs of individual customers can provide a competitive advantage.

Market Restraints:

High Initial Costs: The initial cost of purchasing and installing industrial robots can be a significant barrier for some companies, especially SMEs.

Lack of Skilled Workforce: There is a shortage of skilled workers who can program, operate, and maintain industrial robots.

Safety Concerns: Ensuring the safety of human workers in robotic workcells is a critical concern.

Complexity of Integration: Integrating robots into existing production processes can be complex and time-consuming.

Resistance to Change: Some workers may resist the adoption of robots due to concerns about job displacement.

Market Challenges:

The industrial robotics market faces several significant challenges that could impact its growth trajectory. One of the primary challenges is the high initial investment required for purchasing and implementing robotic systems. This can be a significant barrier, particularly for small and medium-sized enterprises (SMEs) that may lack the capital resources to invest in automation. The high upfront costs associated with robots, software, integration, and training can make it difficult for these businesses to justify the investment, even if they recognize the long-term benefits.

Another major challenge is the skills gap in the workforce. The increasing complexity of robotic systems requires specialized skills in programming, maintenance, and operation. However, there is a shortage of qualified personnel who possess these skills, which can hinder the adoption and effective utilization of robots. Addressing this skills gap requires investments in education and training programs to develop a workforce capable of supporting the growing robotics industry. Furthermore, the integration of robots into existing production processes can be complex and challenging. It requires careful planning and coordination to ensure that robots are seamlessly integrated with other equipment and systems. The integration process can also be time-consuming and costly, requiring specialized expertise and resources.

Safety concerns are also a significant challenge in the industrial robotics market. Ensuring the safety of human workers who interact with robots is paramount. This requires the implementation of robust safety measures, such as safety sensors, emergency stops, and proper training. The rise of collaborative robots (cobots) has further complicated the safety landscape, as these robots are designed to work alongside humans in shared workspaces. It is essential to develop and enforce safety standards and regulations that address the unique challenges posed by cobots. In addition to these challenges, the industrial robotics market also faces resistance to change from some workers who may fear job displacement. It is important to address these concerns through open communication and training programs that highlight the benefits of automation and the opportunities for workers to acquire new skills.

Moreover, the complexity of programming and maintaining industrial robots poses a barrier to entry for some companies. User-friendly programming interfaces and simplified maintenance procedures are needed to make robots more accessible to a wider range of users. Finally, the ongoing evolution of robotics technology presents a challenge for companies that must keep up with the latest advancements to remain competitive. This requires continuous investment in research and development and a willingness to adopt new technologies. Overcoming these challenges will be critical to unlocking the full potential of the industrial robotics market and driving its continued growth.

Market Regional Analysis:

The industrial robotics market exhibits varying dynamics across different regions. North America is characterized by a strong focus on advanced manufacturing and a high adoption rate in industries like automotive and aerospace. Europe, with its emphasis on sustainability and innovation, sees significant demand for energy-efficient and collaborative robots. The Asia-Pacific region, particularly China, is experiencing rapid growth due to its expanding manufacturing sector and government support for automation. Each region's market dynamics are influenced by unique factors such as economic conditions, labor costs, regulatory environments, and technological infrastructure. For example, stringent safety regulations in Europe drive demand for advanced safety features in robots, while labor shortages in North America accelerate the adoption of automation. In Asia-Pacific, the growing middle class and increasing consumer demand fuel the need for mass production and automation. Therefore, understanding these regional nuances is crucial for companies seeking to capitalize on the global industrial robotics market.

Frequently Asked Questions:

What are the growth projections for the Industrial Robotics Market? The market is projected to grow at a CAGR of 13.2% from 2025 to 2032, reaching over USD 50.11 Billion by 2032.

What are the key trends in the Industrial Robotics Market? Key trends include the growing adoption of collaborative robots (cobots), the integration of AI and machine learning, and the rise of Robot-as-a-Service (RaaS).

What are the most popular Industrial Robotics Market types? Articulated and SCARA robots are among the most popular types, widely used in various manufacturing applications due to their flexibility and speed.

"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial Robotics Market Research Report 2025: Size, Segmentation, Regional Outlook & Forecast 2032 here

News-ID: 4068347 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Robot

RoboPaw Robot Puppy Review: Is This Robot Dog Worth Buying?

RoboPaw Robot Puppy Review: Is This Robot Dog Worth Buying?

The rise of smart robotic pets has transformed how families introduce companionship, creativity, and safe entertainment into their daily routines. Among the newest innovations gaining massive attention is the RoboPaw Robot Puppy, a highly interactive, expressive, and surprisingly intelligent robotic companion designed for kids, adults, and even seniors who want play, comfort, and engagement without the responsibility of a real pet.

The…

Wuffy Robot Dog Reviews: All Truth about Wuffy Robot Dog (wuffy the robot dog)

Parents around the world are asking the same question right now: can a robot puppy really replace some of the comfort and fun of a real dog? In a time when many families live in apartments, juggle allergies, or simply cannot handle the responsibility of a pet, wuffy robot dog reviews are starting to stand out online for one simple reason. This is not another plastic gadget that flashes once…

Major Market Shift in Robot Kitchen Industry: Robot-Operated Or AI-Powered Resta …

What Is the Forecasted Market Size and Growth Rate for the Robot Kitchen Market?

The robot kitchen market has grown strongly in recent years. It is projected to grow from $3.35 billion in 2024 to $3.66 billion in 2025, at a CAGR of 9.3%. The growth is driven by automation and efficiency, rising labor costs, consumer demand for convenience, innovation and competition, and the emphasis on food safety and hygiene.

The robot…

AI Robot Toy Market Likely to Enjoy Massive Growth (2024-2029)ROYBI AI Robot , D …

According to HTF Market Intelligence, the Global AI Robot Toy market to witness a CAGR of 17.8% during the forecast period (2024-2029). The Latest Released AI Robot Toy Market Research assesses the future growth potential of the AI Robot Toy market and provides information and useful statistics on market structure and size.

This report aims to provide market intelligence and strategic insights to help decision-makers make sound investment decisions and identify…

TPA Robot launches a new industrial linear robot

The single axis robot KK Series, developed by TPA ROBOT, uses partially hardened U-shaped steel base track to significantly increase the robot's strength and load capacity. Due to the different environments, we have three type of linear robot series, KSR, KNR and KFR, depending on the type of cover used.

For the return system between the track and the slider, the contact surface between the ball and the ball groove adopts…

Robot Battery Market 2023- 2028 Global Insights by Industry Volume, Opportunitie …

The Robot Battery Market research report gives consistent conveyance of the substance. Information gathered in the notification is from verified and reliable sources. Besides, the report additionally breaks down the forthcoming patterns and openings likely to propel the Robot Battery Market. Moreover, the Robot Battery Market provides creative strategies and plans that help market players to stay ahead of the competition. Besides, the Robot Battery Market research report likewise evaluates…