Press release

Emerging Trends in Carbide Tools Market 2032: New Study Forecasts Key Trend to Drive Growth

"The Carbide Tools Market is experiencing robust growth, driven by the increasing demand for high-performance cutting tools across various industries. Key factors fueling this expansion include the rising need for precision and efficiency in manufacturing processes, particularly in sectors like automotive, aerospace, and electronics. Technological advancements, such as the development of advanced coatings and geometries, are significantly enhancing the performance and lifespan of carbide tools, making them a preferred choice over traditional materials. Moreover, the global emphasis on sustainable manufacturing practices is driving the adoption of carbide tools due to their ability to reduce waste and improve overall energy efficiency. The market plays a crucial role in addressing global challenges by enabling the production of high-quality components with minimal environmental impact. This contributes to the development of more efficient and sustainable manufacturing processes, essential for meeting the demands of a rapidly evolving global landscape.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2950

Market Size:

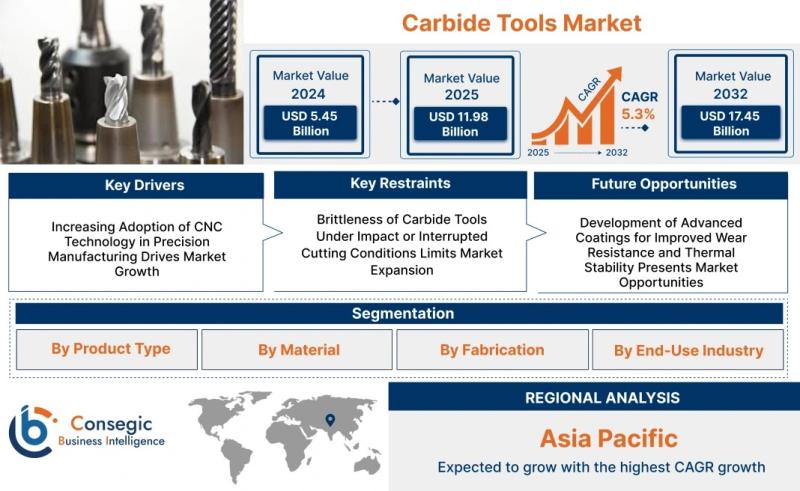

The Carbide Tools Market size is estimated to reach over USD 17.45 Billion by 2032 from a value of USD 11.58 Billion in 2024 and is projected to grow by USD 11.98 Billion in 2025, growing at a CAGR of 5.3% from 2025 to 2032.

Definition of Market:

The Carbide Tools Market encompasses the production, distribution, and application of cutting tools made primarily from tungsten carbide (WC) and other metal carbides, often combined with a binder metal such as cobalt. These tools are renowned for their exceptional hardness, wear resistance, and ability to maintain sharp cutting edges at high temperatures, making them ideal for machining a wide range of materials, including metals, composites, and plastics.

Key terms related to this market include:

Carbide: A compound composed of carbon and a less electronegative element, typically a metal. Tungsten carbide is the most common type used in cutting tools.

Cutting Tools: Instruments used to remove material from a workpiece by shear deformation. These include drills, end mills, inserts, reamers, and taps.

Coating: A thin layer applied to the surface of a carbide tool to enhance its properties, such as wear resistance, heat resistance, and lubricity. Common coatings include titanium nitride (TiN), titanium carbonitride (TiCN), and aluminum oxide (Al2O3).

Grade: Refers to the specific composition and properties of the carbide material, which are tailored to suit different machining applications.

Geometry: The shape and design of the cutting tool's edge, which affects its cutting performance, chip formation, and surface finish.

The market also includes related services such as tool regrinding, reconditioning, and application support. The Carbide Tools Market plays a vital role in enabling efficient and precise machining processes across various industries.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2950

Market Scope and Overview:

The scope of the Carbide Tools Market is extensive, encompassing a wide array of technologies, applications, and industries. The technologies involved range from the production of raw carbide powders and the sintering process used to create solid carbide tools to the application of advanced coatings and the development of innovative tool geometries. The market includes various types of carbide tools, such as drills, end mills, inserts, reamers, taps, and other specialized cutting tools. These tools are used for a diverse range of applications, including milling, turning, drilling, threading, and broaching.

The Carbide Tools Market's significance extends far beyond the individual products and services it encompasses. It is a critical enabler of global trends in manufacturing, automation, and sustainability. As industries increasingly adopt advanced manufacturing techniques such as CNC machining and additive manufacturing, the demand for high-performance carbide tools rises. These tools enable the production of complex parts with greater precision and efficiency, driving innovation and productivity gains. Moreover, the focus on sustainability is also influencing the market. Carbide tools contribute to reducing waste and improving energy efficiency in machining processes, aligning with the global push for more environmentally responsible manufacturing practices. The market is integral to the larger context of global trends, supporting industries as they adapt to new technologies, embrace automation, and strive for greater sustainability.

Top Key Players in this Market

Sandvik AB (Sweden) ISCAR Ltd. (Israel) Kennametal Inc. (USA) Mitsubishi Materials Corporation (Japan) Sumitomo Electric Industries, Ltd. (Japan) Guhring GmbH (Germany) Zhuzhou Cemented Carbide Cutting Tools Co., Ltd. (ZCCCT) (China) YG-1 Co., Ltd. (South Korea) Walter AG (Germany) CeramTec GmbH (Germany)

Market Segmentation:

The Carbide Tools Market is segmented based on several factors:

By Product Type: Cutting Tools, Drills, End Mills, Inserts, Reamers, Taps, Others. Each type serves specific machining needs, with cutting tools being a broad category and others representing niche applications.

By Material: Solid Carbide, Carbide-Tipped, Carbide-Coated, Others. Solid carbide offers superior performance, while tipped and coated options balance cost and performance.

By Fabrication: Coated, Uncoated. Coatings enhance tool life and performance, while uncoated tools are suitable for specific applications.

By End-Use Industry: Automotive, Aerospace, Construction, Manufacturing, Electronics, Others. Each industry has unique tooling requirements, driving demand for specific carbide tool types.

Each segment contributes uniquely to market growth. For instance, the automotive and aerospace industries drive demand for high-precision, durable carbide tools, while manufacturing relies on a broader range of tools for diverse applications. Material choices impact tool performance and cost-effectiveness, influencing adoption across different industries.

Market Drivers:

Technological Advancements: Continuous innovations in carbide materials, coatings, and tool geometries enhance cutting performance, tool life, and machining efficiency.

Increasing Demand for Precision and Efficiency: Industries like automotive, aerospace, and electronics require high-precision components, driving the adoption of carbide tools for superior machining accuracy.

Growing Automation in Manufacturing: The rise of CNC machining and other automated processes necessitates high-performance cutting tools that can withstand demanding operating conditions.

Expansion of End-Use Industries: The growth of key industries such as automotive, aerospace, and construction fuels demand for carbide tools used in their manufacturing processes.

Emphasis on Sustainable Manufacturing: Carbide tools contribute to reducing waste and improving energy efficiency in machining, aligning with the global push for more sustainable manufacturing practices.

Market Key Trends:

Advanced Coatings: Development of innovative coatings like diamond-like carbon (DLC) and nanocomposite coatings enhances tool performance and lifespan.

Customized Tool Geometries: Increasing demand for tools tailored to specific machining applications optimizes cutting performance and reduces cycle times.

Digitalization of Tool Management: Integration of sensors and data analytics for real-time monitoring of tool wear and performance improves efficiency and reduces downtime.

Adoption of Additive Manufacturing: 3D printing of carbide tools enables the creation of complex geometries and customized designs, expanding application possibilities.

Growing Focus on Circular Economy: Increasing emphasis on tool regrinding and recycling reduces waste and promotes sustainable resource management.

Market Opportunities:

Development of High-Performance Carbide Grades: Creating new carbide materials with enhanced hardness, wear resistance, and thermal stability can open up new applications in demanding industries.

Expansion in Emerging Markets: Growing industrialization and manufacturing activities in emerging economies like Asia-Pacific and Latin America present significant growth opportunities.

Penetration of Untapped Applications: Exploring new applications for carbide tools in sectors like medical devices and renewable energy can drive market expansion.

Offering Value-Added Services: Providing services like tool design, application support, and training can enhance customer relationships and drive revenue growth.

Integrating Digital Technologies: Developing smart tools with embedded sensors and data analytics capabilities can improve machining efficiency and reduce downtime.

Market Restraints:

High Initial Costs: The upfront investment in carbide tools can be significant, especially for small and medium-sized enterprises (SMEs).

Price Volatility of Raw Materials: Fluctuations in the prices of tungsten, cobalt, and other raw materials can impact the profitability of carbide tool manufacturers.

Availability of Substitutes: Competing materials like high-speed steel (HSS) and ceramics may be used in certain applications, limiting the market share of carbide tools.

Skilled Labor Shortage: The operation and maintenance of advanced machining equipment require skilled technicians, which can be a challenge in some regions.

Environmental Regulations: Increasing regulations on the use of certain materials and processes in carbide tool manufacturing can add to production costs.

Market Challenges:

The Carbide Tools Market faces several significant challenges that could impact its growth and profitability. One of the primary challenges is the fluctuating cost of raw materials, particularly tungsten and cobalt, which are essential components in carbide production. These price fluctuations can significantly affect the manufacturing costs of carbide tools, potentially leading to reduced profit margins for manufacturers. Moreover, the market faces intense competition from alternative cutting tool materials such as high-speed steel (HSS) and ceramics. While carbide tools offer superior performance in many applications, these alternatives may be more cost-effective for certain machining operations, particularly in less demanding environments.

Another challenge is the increasing complexity of machining processes. As industries demand more intricate and precise components, the requirements for cutting tool performance become more stringent. This necessitates continuous innovation in carbide materials, coatings, and tool geometries to meet the evolving needs of end-users. Furthermore, environmental concerns are becoming increasingly important. The carbide tool manufacturing process can generate hazardous waste and consume significant amounts of energy. As a result, manufacturers are under pressure to adopt more sustainable practices, such as reducing waste, recycling materials, and minimizing energy consumption. This requires investments in new technologies and processes, adding to the overall cost of production.

Additionally, the market faces challenges related to skilled labor. Operating and maintaining advanced machining equipment requires a skilled workforce, and shortages of qualified technicians can hinder the adoption of new technologies and limit the efficiency of manufacturing operations. Moreover, the global economic environment can significantly impact the demand for carbide tools. Economic downturns or slowdowns in key industries such as automotive, aerospace, and construction can lead to reduced demand for cutting tools, affecting the overall market growth. Finally, the market faces challenges related to counterfeit products. The availability of low-quality, counterfeit carbide tools can undermine the reputation of legitimate manufacturers and create unfair competition.

Market Regional Analysis:

The Carbide Tools Market exhibits varying dynamics across different regions, influenced by factors such as industrial development, economic conditions, and technological adoption. In North America, the market is driven by the automotive, aerospace, and manufacturing sectors, with a strong emphasis on high-precision machining and advanced materials. Europe boasts a mature market with a focus on innovation and sustainable manufacturing practices, particularly in the automotive and aerospace industries. The Asia-Pacific region is experiencing rapid growth, fueled by expanding manufacturing activities in countries like China, India, and Japan. This region presents significant opportunities for carbide tool manufacturers due to the increasing demand for high-performance cutting tools.

Latin America and the Middle East & Africa represent emerging markets with potential for growth, driven by increasing industrialization and infrastructure development. These regions require a range of carbide tools for various applications, including construction, oil and gas, and manufacturing. However, factors such as political instability and economic uncertainty can impact market growth in these regions. The unique market dynamics in each region require carbide tool manufacturers to adopt tailored strategies to effectively serve their customers.

Frequently Asked Questions:

What is the growth projection for the Carbide Tools Market?

The Carbide Tools Market is projected to grow at a CAGR of 5.3% from 2025 to 2032, reaching over USD 17.45 Billion by 2032.

What are the key trends in the Carbide Tools Market?

Key trends include the development of advanced coatings, customized tool geometries, digitalization of tool management, adoption of additive manufacturing, and a growing focus on the circular economy.

What are the most popular Carbide Tool types?

Popular Carbide Tool types include drills, end mills, inserts, reamers, and taps, each serving specific machining needs across various industries.

"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Emerging Trends in Carbide Tools Market 2032: New Study Forecasts Key Trend to Drive Growth here

News-ID: 4068322 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Carbide

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…

Repair of Tungsten Carbide Cemented Carbide Tools?

Repair of Tungsten Carbide Cemented Carbide Tools

After a period of use, a customer's blade has developed some flaws that are affecting production quality and speed. What can be done now?

Can Tungsten Carbide Blades be refurbished if problems occur?

The answer is definitely yes, they can be refurbished. During refurbishment, the following situations may be addressed:

1. Surface Treatment

What surface problems can occur?

Flaws, cracks. Examples: scratches, minor wear, coating peeling.

These issues can be…