Press release

How to Set Up an Acrylic Foam Tape Manufacturing Plant: Capital Investment and Equipment Cost Breakdown

Setting up a acrylic foam tape manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled " Acrylic Foam Tape Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a paper plate manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Get Acrylic foam tape plant cost estimate report: https://www.imarcgroup.com/acrylic-foam-tape-manufacturing-plant-project-report/requestsample

An acrylic foam tape manufacturing plant is a special industrial feature designed for the production of high-demonstration adhesive tapes made of acrylic foam content. These tapes are known for their strong adhesion, durability and environmental factors such as moisture, UV radiation and resistance to temperature ups and downs. The manufacturing process involves preparation of acrylic foam base material, coating them with pressure-sensitive adhesive, and converting coated rolls into various sizes and forms is suitable for end-use applications. The major stages in the plant include foam extrusion, adhesive coating, sliting, and packaging. Advanced machinery such as coating lines, treatment ovens, accurate slitors, and integral parts of the quality control system plant. This feature usually follows strict environment and safety standards to ensure frequent product quality and regulatory compliance. The acrylic foam tape produced in such plants is widely used in motor vehicle, electronics, construction and general industrial applications, where strong bonding solutions are required. Plant layout and operational efficiency are important to meet the high-demonstration standards sought by these industries. Investment, automation, and quality assurance system in R&D is required to maintain competition and respond to develop customers' requirements in global markets.

The growth of acrylic foam tape manufacturing plant market is inspired by growing demand from major inter-use sectors including automotive, construction, electronics and renewable energy. In the automotive industry, changes and bonding towards light materials, reduction in noise and increasing use of tapes for vibration control have greatly increased the demand for acrylic foam tape. In the construction sector, these tapes contribute to the market expansion by adopting these tapes in attachment systems, structural glazing, and insulation applications. Additionally, compact, consumer electronics and rapid dissemination of wearable devices requiring compact, durable adhesive solutions support the development of the industry. Better aesthetics and trends on the trend to replace mechanical fasteners with high-performance adhesive systems for better aesthetics and performance to lead to performance. Increasing environmental awareness and strict rules are also encouraging the use of solvent-free, low-walk adhesive, low-walk adhesive in favor of acrylic-based yogas. Technological progresses in tape manufacture, including increased adhesives and automated production lines, are increasing production efficiency and quality, which attract new investment. In addition, the expansion of manufacturing capabilities in emerging economies due to low operating costs and rising local demand is further increasing the increase in market. Overall, a combination of technological innovation, end-user industry expansion, and global infrastructure development is carrying forward the acrylic foam tape manufacturing plant market.

Buy Now: https://www.imarcgroup.com/checkout?id=12147&method=1911

Key Steps Required to Set Up a Acrylic Foam Tape Plant

1. Market Analysis

The report provides insights into the landscape of the Acrylic foam tape industry at the global level. The report also provides a segment-wise and region-wise breakup of the global Acrylic foam tape industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of Acrylic foam tape, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the acrylic foam tape manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for Acrylic foam tape manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for Acrylic foam tape production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a Acrylic foam tape manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=12147&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release How to Set Up an Acrylic Foam Tape Manufacturing Plant: Capital Investment and Equipment Cost Breakdown here

News-ID: 4067924 • Views: …

More Releases from IMARC Group

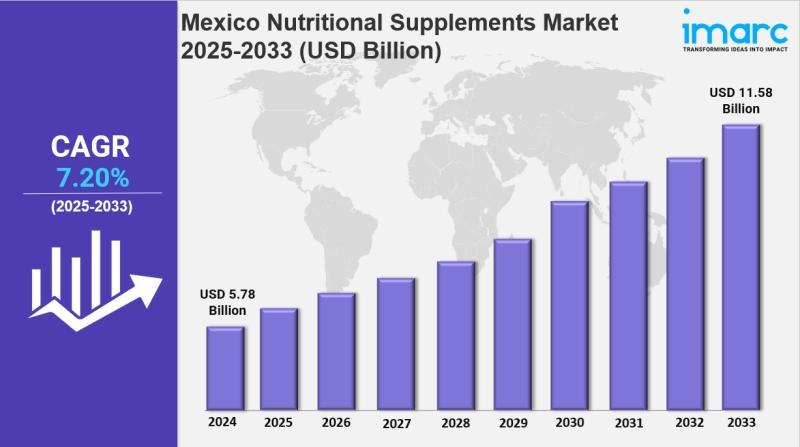

Mexico Nutritional Supplements Market Size, Growth, Latest Trends and Forecast 2 …

IMARC Group has recently released a new research study titled "Mexico Nutritional Supplements Market Size, Share, Trends and Forecast by Product Type, Form, Distribution Channel, Consumer Group, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The Mexico nutritional supplements market size was valued at USD 5.78 Billion in 2024. It is…

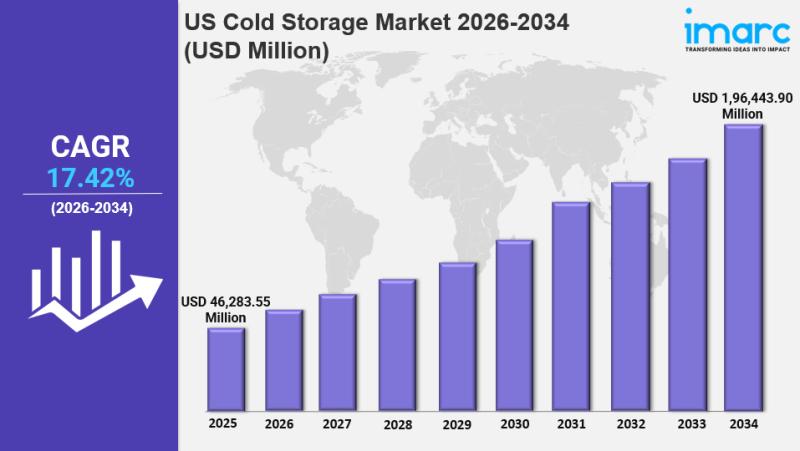

US Cold Storage Market Size, Trends, Growth and Forecast 2026-2034

IMARC Group has recently released a new research study titled "US Cold Storage Market Size, Share, Trends and Forecast by Warehouse Type, Construction Type, Temperature Type, Application, and Region, 2026-2034", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The US cold storage market size reached USD 46,283.55 Million in 2025 and is projected to grow…

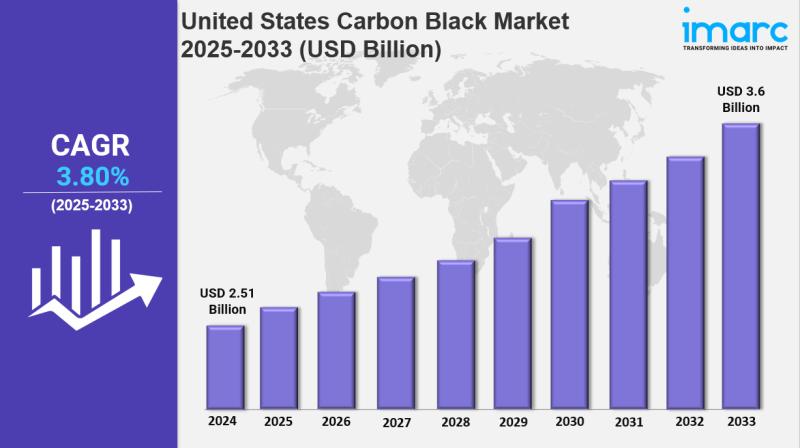

United States Carbon Black Market Size, Trends, Growth and Forecast 2025-2033

IMARC Group has recently released a new research study titled "United States Carbon Black Market Size, Share, Trends and Forecast by Type, Grade, Application, and Region, 2025-2033" which offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends, and competitive landscape to understand the current and future market scenarios.

Market Overview

The United States carbon black market size was valued at USD 2.51 Billion in 2024 and is projected to…

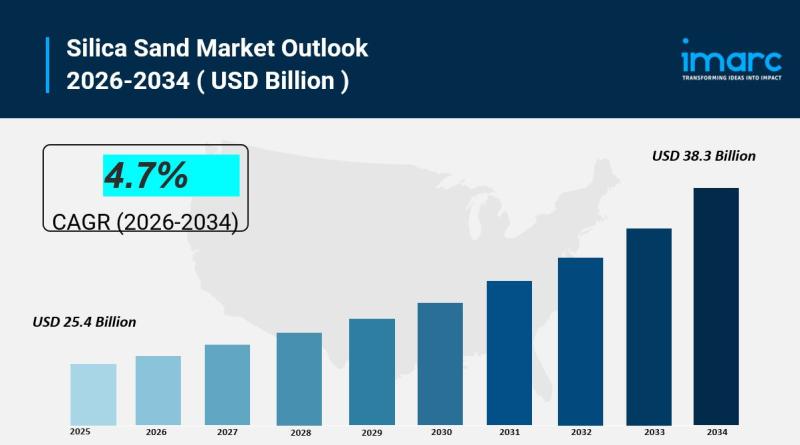

Silica Sand Market is Projected to Reach USD 38.3 Billion by 2034 | At CAGR 4.7%

Silica Sand Market Overview:

The global Silica Sand Market was valued at USD 25.4 Billion in 2025 and is forecast to reach USD 38.3 Billion by 2034, growing at a CAGR of 4.7% during 2026-2034. This growth is driven by increasing demand from the construction and glass manufacturing industries, continual advancements in hydraulic fracturing technology in oil and gas extraction, and rapid changes in environmental and regulatory landscapes.

The silica sand market…

More Releases for Acrylic

Acrylic Polymer Market

𝐓𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐚𝐜𝐫𝐲𝐥𝐢𝐜 𝐩𝐨𝐥𝐲𝐦𝐞𝐫 𝐦𝐚𝐫𝐤𝐞𝐭 𝐰𝐚𝐬 𝐯𝐚𝐥𝐮𝐞𝐝 𝐚𝐭 𝐚𝐩𝐩𝐫𝐨𝐱𝐢𝐦𝐚𝐭𝐞𝐥𝐲 𝐔𝐒𝐃 𝟐𝟎 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐢𝐧 𝟐𝟎𝟐𝟐 𝐚𝐧𝐝 𝐢𝐬 𝐩𝐫𝐨𝐣𝐞𝐜𝐭𝐞𝐝 𝐭𝐨 𝐫𝐞𝐚𝐜𝐡 𝐔𝐒𝐃 𝟑𝟔.𝟗 𝐛𝐢𝐥𝐥𝐢𝐨𝐧 𝐛𝐲 𝟐𝟎𝟑𝟐, 𝐠𝐫𝐨𝐰𝐢𝐧𝐠 𝐚𝐭 𝐚 𝐜𝐨𝐦𝐩𝐨𝐮𝐧𝐝 𝐚𝐧𝐧𝐮𝐚𝐥 𝐠𝐫𝐨𝐰𝐭𝐡 𝐫𝐚𝐭𝐞 (𝐂𝐀𝐆𝐑) 𝐨𝐟 𝟔.𝟒% 𝐟𝐫𝐨𝐦 𝟐𝟎𝟐𝟑 𝐭𝐨 𝟐𝟎𝟑𝟐.

𝐀𝐜𝐫𝐲𝐥𝐢𝐜 𝐏𝐨𝐥𝐲𝐦𝐞𝐫 𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰

The acrylic polymer market has experienced significant growth due to its versatile applications across various industries, including paints and coatings, adhesives, textiles, and construction. Acrylic polymers are favored for…

Application of acrylic cup

Application of acrylic cup

When buying an acrylic cup, you will consider many issues, such as whether the acrylic cup is more durable than cups made of other materials, whether its material is safe, how is its load-bearing capacity different from cups made of other materials, and whether it is easy to clean after use. Here are the answers to these questions[ https://acryliccup.com/ ]

Durable acrylic cup

Acrylic cups are indeed more durable…

Acrylic cup with straw

Acrylic cup with straw

Acrylic cup with straw is convenient, but the sealing of the lid of the acrylic cup with straw becomes one of our most concerned issues when we need to carry it out. Acrylic cup with straw with poor sealing will leak. However, the sealing of acrylic cup with straw of good quality adopts high-quality silicone sealing design, which can effectively prevent liquid from spilling. In addition, the…

Global Acrylic Coating Additives Market

To stand apart from the competition, a careful idea about the competitive landscape, their product range, their strategies, and future prospects is very important. This Acrylic Coating Additives Market research report also contains a comprehensive study of the product specifications, revenue, cost, price, gross capacity and production. Acrylic Coating Additives Market industry research report is a verified and consistent source of information that puts forth a telescopic view of the…

Acrylic Sheets Market 2019 by | Donchamp, Jumei, Jiushixing, Guang Shun Plastic, …

“Poly(methyl methacrylate) (PMMA), also known as acrylic or acrylic glass as well as by the trade names Plexiglas, Acrylite, Lucite, and Perspex among several others (see below), is a transparent thermoplastic often used in sheet form as a lightweight or shatter-resistant alternative to glass.”

Acrylic Sheets Market research report peaks the detailed analysis of industry share, growth factors, development trends, size, majors manufacturers and 2024 forecast. The report also analyses innovative…

Acrylic Acid Copolymer Market Report 2018: Segmentation by Type (Ethylene/Acryli …

Global Acrylic Acid Copolymer market research report provides company profile for Lyondellbasell, Michelman, NIPPON SHOKUBAI, Shandong Taihe Water Treatment, Zouping Dongfang Chemical, DuPont, DOW (SK), Exxonmobil, Honeywell and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to…