Press release

Watch Out: Teflon Heat Exchanger Market Is Thriving Worldwide in 2025-2032 by Size, Share, Trends

"The Teflon heat exchanger market is experiencing significant growth, driven by the increasing demand for highly corrosion-resistant and chemically inert heat transfer solutions across various industries. Key growth drivers include the rising adoption of these exchangers in sectors like pharmaceuticals, semiconductors, and specialty chemicals, where maintaining product purity and preventing contamination is paramount. Technological advancements in Teflon material science and heat exchanger design are also contributing to market expansion. Innovations such as improved heat transfer coefficients and compact designs are making Teflon heat exchangers more efficient and cost-effective. Furthermore, stringent environmental regulations are pushing industries to adopt Teflon heat exchangers for handling corrosive fluids and waste streams, playing a vital role in mitigating environmental pollution and promoting sustainable industrial practices. These heat exchangers are integral to processes requiring precise temperature control and material integrity, addressing challenges related to harsh chemical environments and high purity standards. The market's role is crucial in advancing process efficiency and ensuring safety across diverse industrial applications. The unique properties of Teflon, including its non-stick surface and broad chemical compatibility, position it as an indispensable material in heat exchange applications, thereby fostering a robust and expanding market landscape.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2826

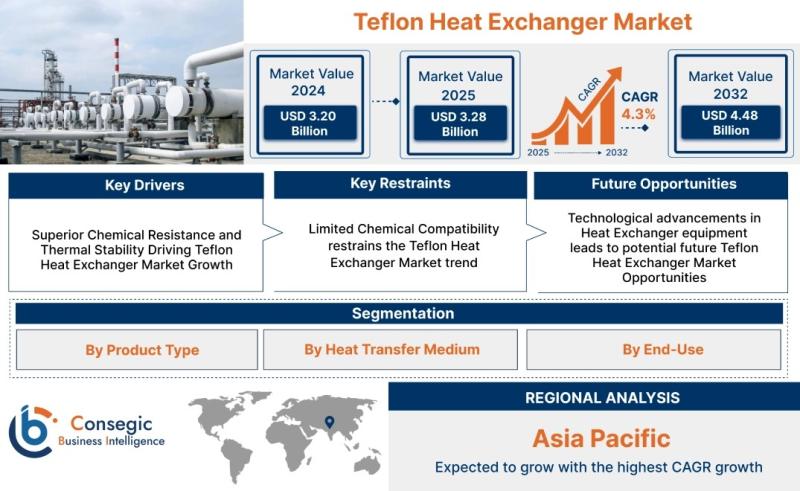

Market Size:

The Teflon Heat Exchanger Market is estimated to reach over USD 4.48 Billion by 2032, growing from USD 3.20 Billion in 2024. The market is projected to grow by USD 3.28 Billion in 2025, demonstrating a CAGR of 4.3% from 2025 to 2032.

Definition of Market:

The Teflon Heat Exchanger Market encompasses the manufacturing, distribution, and application of heat exchangers that utilize Teflon (specifically PTFE, PFA, and FEP) or other fluoropolymers as the primary material for heat transfer surfaces. These heat exchangers are designed to facilitate the transfer of heat between two or more fluids without direct contact, leveraging the unique chemical resistance and non-stick properties of Teflon.

Key components and aspects of this market include:

Products: Shell and tube heat exchangers, plate heat exchangers, air-cooled heat exchangers, and specialty designs customized for specific applications.

Materials: Predominantly Teflon (PTFE, PFA, FEP), which provides resistance to corrosive chemicals and high temperatures.

Applications: Used in chemical processing, pharmaceutical manufacturing, semiconductor fabrication, food and beverage production, HVAC systems, and other industrial processes.

Services: Installation, maintenance, and repair services for Teflon heat exchangers, as well as custom design and engineering solutions.

Key Terms:

PTFE: Polytetrafluoroethylene, a synthetic fluoropolymer known for its high chemical resistance and low coefficient of friction.

PFA: Perfluoroalkoxy, another fluoropolymer with similar properties to PTFE but with improved melt processability.

FEP: Fluorinated Ethylene Propylene, a copolymer of tetrafluoroethylene and hexafluoropropylene, offering good chemical resistance and flexibility.

Heat Transfer Coefficient: A measure of how effectively heat is transferred across the heat exchanger surface.

Corrosion Resistance: The ability of the material to withstand degradation from chemical exposure.

The market also involves related equipment and technologies, such as pumps, valves, and control systems that are integrated with Teflon heat exchangers to optimize performance and efficiency. The market participants include manufacturers, distributors, engineering firms, and end-users who operate in diverse sectors requiring reliable and corrosion-resistant heat transfer solutions.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2826

Market Scope and Overview:

The scope of the Teflon Heat Exchanger Market is broad, encompassing a range of technologies, applications, and industries. These exchangers are used for heating, cooling, condensation, and evaporation processes across various sectors where corrosive chemicals and high-purity requirements are critical. The technologies include diverse heat exchanger designs tailored to specific applications, such as shell and tube, plate, and air-cooled configurations. Teflon's exceptional chemical inertness, high-temperature resistance, and anti-stick properties make it ideal for handling aggressive media like strong acids, alkalis, and organic solvents. This is particularly crucial in chemical processing, pharmaceutical manufacturing, and semiconductor fabrication, where maintaining product purity and preventing contamination are essential. The market also includes customized solutions for specific industrial needs, incorporating advanced materials and innovative designs to enhance heat transfer efficiency and minimize downtime.

The Teflon Heat Exchanger Market plays a pivotal role in addressing global trends related to industrial efficiency, sustainability, and safety. As industries face increasing pressure to reduce their environmental footprint and comply with stringent regulations, the demand for corrosion-resistant and energy-efficient heat transfer solutions is growing. Teflon heat exchangers enable the safe and reliable handling of corrosive fluids and waste streams, minimizing the risk of leaks and environmental damage. Furthermore, their ability to operate at high temperatures and pressures contributes to process optimization and energy savings. In the pharmaceutical and semiconductor industries, where product purity is paramount, Teflon heat exchangers ensure that materials are processed without contamination, safeguarding product quality and regulatory compliance. The market's contribution to sustainable industrial practices, combined with its ability to enhance process efficiency and safety, underscores its importance in the larger context of global industrial trends.

Top Key Players in this Market

Parker Hannifin (US) Alfa Laval (Sweden) API Heat Transfer (US) EVERSUPP technology corp. (Taiwan) Engiplas (Israel) Fluorotherm (US) Unison process solutions (Ireland) Boyd (US) Tridan International, Inc. (US) International Energy Agency (France)

Market Segmentation:

The Teflon Heat Exchanger Market can be segmented based on several factors:

By Product Type: Shell and Tube heat exchangers, which are widely used due to their robustness and suitability for high-pressure applications; Plate heat exchangers, offering high thermal efficiency and compact design; Air-cooled heat exchangers, utilized for cooling processes where water is scarce; and Others, including specialized designs tailored for unique applications.

By Heat Transfer Medium: Water, which is commonly used for cooling and heating processes; Oil, often used in high-temperature applications; Gas and Steam, employed for heating and condensation processes respectively.

By End-Use: Semiconductor industry, where ultra-pure materials are essential; Chemical industry, requiring resistance to corrosive substances; Pharmaceutical industry, demanding high levels of hygiene and purity; Food and Beverage industry, needing materials compliant with food safety standards; and HVAC industry, utilizing heat exchangers for climate control systems.

Each segment contributes to the market's growth by catering to specific industry needs and application requirements. For instance, the increasing demand for semiconductors drives the adoption of high-purity Teflon heat exchangers, while stringent regulations in the chemical industry propel the use of corrosion-resistant solutions.

Market Drivers:

Technological Advancements: Ongoing innovations in Teflon material science and heat exchanger design are enhancing their efficiency, durability, and cost-effectiveness, driving market growth.

Government Policies: Stricter environmental regulations and safety standards are pushing industries to adopt Teflon heat exchangers for handling corrosive fluids and waste streams, boosting demand.

Increasing Demand for Sustainability: The growing focus on sustainable industrial practices is leading to the adoption of Teflon heat exchangers, which reduce environmental impact and energy consumption.

Growth in End-Use Industries: Expansion in key sectors like pharmaceuticals, semiconductors, and chemicals is driving the demand for high-purity and corrosion-resistant heat transfer solutions.

Superior Material Properties: Teflon's exceptional chemical inertness, high-temperature resistance, and non-stick properties make it ideal for a wide range of applications, fueling market growth.

Market Key Trends:

Miniaturization and Compact Designs: There's a growing trend towards smaller, more efficient Teflon heat exchangers, particularly for applications in the semiconductor and pharmaceutical industries.

Customization: Increasing demand for customized heat exchanger solutions tailored to specific industrial processes and requirements.

Integration with Digital Technologies: The integration of sensors and control systems for real-time monitoring and optimization of heat exchanger performance.

Focus on Energy Efficiency: Emphasis on developing Teflon heat exchangers with improved heat transfer coefficients to reduce energy consumption and operating costs.

Adoption of Advanced Materials: Exploration of new fluoropolymer formulations and composite materials to enhance the performance and durability of Teflon heat exchangers.

Market Opportunities:

Expansion in Emerging Markets: Untapped potential in developing regions with growing industrial sectors and increasing demand for corrosion-resistant solutions.

Development of High-Efficiency Designs: Opportunities to create innovative heat exchanger designs that maximize heat transfer efficiency and minimize energy consumption.

Penetration in New Applications: Exploring new applications for Teflon heat exchangers in sectors such as renewable energy, water treatment, and advanced materials manufacturing.

Customized Solutions for Niche Markets: Tailoring heat exchanger designs to meet the specific needs of niche markets, such as biotechnology and microelectronics.

Advancements in Material Science: Innovations in Teflon material science can lead to the development of heat exchangers with enhanced properties and performance.

Market Restraints:

High Initial Costs: The relatively high cost of Teflon materials and specialized manufacturing processes can be a barrier to adoption, especially for smaller businesses.

Geographic Limitations: The market may be limited by the availability of raw materials and specialized manufacturing facilities in certain regions.

Technical Challenges: Certain applications may present technical challenges related to heat transfer efficiency, pressure drop, and material compatibility.

Competition from Alternatives: Competition from other corrosion-resistant materials and heat exchanger technologies may limit market growth.

Limited Temperature Range: While Teflon has good temperature resistance, it may not be suitable for extremely high-temperature applications.

Market Challenges:

The Teflon Heat Exchanger Market faces several significant challenges that could impact its growth trajectory. One of the primary challenges is the high initial cost associated with Teflon materials and the specialized manufacturing processes required to produce these heat exchangers. This cost can be a significant barrier, particularly for small and medium-sized enterprises (SMEs) looking to adopt corrosion-resistant solutions. Furthermore, the price volatility of raw materials used in Teflon production can affect the overall cost-effectiveness of these heat exchangers, making it difficult for manufacturers to offer competitive pricing.

Another challenge lies in the limitations of Teflon's thermal conductivity. While Teflon is exceptionally resistant to chemical corrosion and offers excellent non-stick properties, its relatively low thermal conductivity compared to metals like stainless steel or copper can reduce the efficiency of heat transfer. This necessitates the development of innovative designs and material formulations to enhance heat transfer performance without compromising corrosion resistance. Technical challenges also arise in ensuring the structural integrity and long-term reliability of Teflon heat exchangers, especially in high-pressure and high-temperature applications. Maintaining tight seals and preventing material degradation over time requires advanced engineering and quality control measures.

Competition from alternative materials and heat exchanger technologies also poses a considerable challenge. Other corrosion-resistant materials, such as titanium and specialty alloys, offer comparable performance in certain applications and may be more cost-effective. Furthermore, the emergence of advanced heat exchanger designs using these alternative materials could erode the market share of Teflon heat exchangers. Regulatory compliance and environmental concerns add another layer of complexity. Stringent environmental regulations regarding the use and disposal of fluorinated polymers may limit the application of Teflon heat exchangers in certain regions or industries. The need for sustainable and environmentally friendly solutions is driving research and development efforts towards alternative materials and technologies that can reduce the environmental impact of heat transfer processes.

Lastly, the limited awareness and understanding of the benefits of Teflon heat exchangers in some end-use industries can hinder market adoption. Educating potential customers about the unique properties and advantages of Teflon, as well as providing comprehensive technical support and training, is crucial to overcoming this challenge. Overcoming these challenges will require a concerted effort from manufacturers, researchers, and policymakers to drive innovation, reduce costs, and promote the sustainable use of Teflon heat exchangers.

Market Regional Analysis:

The Teflon Heat Exchanger Market exhibits varying dynamics across different regions, influenced by local industrial landscapes, regulatory environments, and economic conditions. In North America and Europe, stringent environmental regulations and a strong focus on sustainability drive the demand for corrosion-resistant and energy-efficient heat transfer solutions. These regions are characterized by mature industrial sectors such as pharmaceuticals, chemicals, and semiconductors, where Teflon heat exchangers are widely used to ensure product purity and prevent contamination. Technological advancements and a high level of awareness regarding the benefits of Teflon also contribute to market growth in these regions.

In the Asia-Pacific region, rapid industrialization and economic growth are driving significant demand for Teflon heat exchangers. Countries like China, India, and Japan are witnessing substantial investments in sectors such as chemicals, pharmaceuticals, and food and beverage, which require reliable and corrosion-resistant heat transfer solutions. The Asia-Pacific market is also characterized by a growing focus on regulatory compliance and environmental protection, further boosting the adoption of Teflon heat exchangers. However, the region also faces challenges such as price sensitivity and competition from local manufacturers offering lower-cost alternatives.

Latin America and the Middle East & Africa (MEA) represent emerging markets for Teflon heat exchangers, with increasing investments in industrial infrastructure and growing awareness of the benefits of corrosion-resistant materials. The chemical and oil & gas industries in these regions are key drivers of market growth, as they require robust and reliable heat transfer solutions for handling aggressive media. However, these regions also face challenges such as political instability, economic volatility, and limited access to advanced technologies, which can hinder market expansion. Overall, the Teflon Heat Exchanger Market is shaped by a complex interplay of regional factors, requiring manufacturers to tailor their strategies to meet the specific needs and challenges of each region.

Frequently Asked Questions:

What is the projected growth of the Teflon Heat Exchanger Market?

The market is projected to grow at a CAGR of 4.3% from 2025 to 2032, reaching over USD 4.48 Billion by 2032.

What are the key trends in the market?

Key trends include miniaturization and compact designs, customization, integration with digital technologies, a focus on energy efficiency, and the adoption of advanced materials.

What are the most popular types of Teflon Heat Exchangers?

Shell and tube heat exchangers and plate heat exchangers are among the most popular types due to their versatility and efficiency in various applications.

"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Watch Out: Teflon Heat Exchanger Market Is Thriving Worldwide in 2025-2032 by Size, Share, Trends here

News-ID: 4066604 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Teflon

Teflon Capacitor Market Size, In-Deep Analysis Details, Application, Regional De …

QY Research has recently published a new report, titled Teflon Capacitor Market Report, History and Forecast 2015-2026, Breakdown Data by Manufacturers, Key Regions, Types and Application. The report has been put together using primary and secondary research methodologies, which offer an accurate and precise understanding of the Teflon Capacitor market. Analysts have used a top-down and bottom-up approach to evaluate the segments and provide a fair assessment of their impact on…

Teflon Mesh Belt Market: Competitive Dynamics & Global Outlook 2025

LP INFORMATION recently released a research report on the Teflon Mesh Belt analysis, which studies the Electrical Cord Reels's industry coverage, current market competitive status, and market outlook and forecast by 2025.

Global “Teflon Mesh Belt 2020-2025” Research Report categorizes the global Teflon Mesh Belt by key players, product type, applications and regions,etc. The report also covers the latest industry data, key players analysis, market share,…

Teflon Thailand: Where There's Crisis There's Opportunity

Amazing Thailand. That is the official slogan for the Tourism Authority of Thailand because it's beauty and culture. Thailand is also amazing as it has bounced back from every modern economic setbacks and headwinds and emerged stronger, smarter and more powerful.

From the 1997 Asian Financial crisis, SARS, Boxing Day Tsunami 2004, 2006 coup, 2008 Financial Crisis, 2014 coup Thailand has recovered steady and successfully and…

Teflon Tape Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Teflon Tape Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Teflon Tape players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Teflon Tape with respect to individual growth…

Rubber Teflon Market 2017 Industry Analysis Report

Here comes the New Version of Rubber Teflon Market Research Report is a core market research report in this current market.

This report majorly discuss the global and regional market, major manufacturers and segment market details various classifications and mode of applications.

Do u Want Sample of report then visit at: https://www.1marketresearch.com/sample/?flag=rs&rep_id=3084&sku=1655

First and foremost, Rubber Teflon report gives the basic analytic scope of this industry like definition, classification, specification, industry policy,application and…

Global Teflon fabric Market 2016-2020- Research Report

“Global Teflon fabric Industry 2020 Market Research Report” Order This Report by calling ResearchnReports.com at +1-888-631-6977.

This market intelligence report is a comprehensive analysis of the situation of Teflon fabric market. A detailed investigation of the past progress, present market scenario, and future prospects has been offered in the report. It also gives accurate data of the main strategies, market share, and products of the leading companies in this market sector.

This…