Press release

Wet Scrubber Manufacturing Plant Setup Cost - Unit Operations and Machinery Cost

Setting up a wet scrubber plant facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "Wet Scrubber Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a wet scrubber manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Request for a Sample Report: https://www.imarcgroup.com/wet-scrubber-manufacturing-plant-project-report/requestsample

Wet scrubbers are a type of air pollution control device that remove pollutants from an industrial exhaust gas stream by bringing it into intimate contact with a scrubbing liquid, typically water or a solution. The pollutant can be particulate matter, gaseous contaminants, or both. The basic principle involves the dirty gas passing through a chamber where it meets the scrubbing liquid in various forms, such as sprays, packed beds, or agitated pools. As the gas and liquid mix, pollutants are absorbed into the liquid, captured by liquid droplets, or chemically reacted with components in the liquid. The cleaned gas then exits the scrubber, while the contaminated scrubbing liquid is collected for treatment or disposal. Wet scrubbers are highly effective for a wide range of pollutants and can simultaneously control multiple contaminants.

The Wet Scrubber market is experiencing robust growth, primarily propelled by increasingly stringent environmental regulations globally aimed at curbing industrial air pollution. This regulatory pressure, coupled with rising industrialization and urbanization in many regions, directly drives the demand for effective air pollution control solutions. A key trend is the continuous technological advancement in wet scrubber design, leading to the development of higher-efficiency systems capable of removing a wider spectrum of pollutants, including fine particulates and diverse gases. Furthermore, the integration of smart technologies, such as IoT sensors and AI for real-time monitoring and predictive maintenance, is enhancing operational efficiency and compliance, making wet scrubbers more attractive. The growing awareness of air quality issues and the need for comprehensive pollution control across various industries, including power generation, chemical processing, and manufacturing, further contribute to the expanding market for these versatile and effective air purification systems.

Ask An Analyst: https://www.imarcgroup.com/request?type=report&id=31211&flag=C

Key Steps Required to Set Up a Wet Scrubber Plant.

1. Market Analysis

The report provides insights into the landscape of the wet scrubber industry at the global level. The report also provides a segment-wise and region-wise breakup of the global wet scrubber industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of wet scrubber, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the wet scrubber manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

Buy Now: https://www.imarcgroup.com/checkout?id=31211&method=1911

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for wet scrubber manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for wet scrubber production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labour, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up a wet scrubber manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labour, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modelling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Wet Scrubber Manufacturing Plant Setup Cost - Unit Operations and Machinery Cost here

News-ID: 4065279 • Views: …

More Releases from IMACR Group

Sodium Lauryl Ether Sulfate Prices Rise Amid Surging Detergent Industry Demand

North America Sodium Lauryl Ether Sulfate (SLES) Prices Movement Q4 2025:

Sodium Lauryl Ether Sulfate (SLES) Prices in United States:

In Q4 2025, sodium lauryl ether sulfate (SLES) prices in the USA averaged USD 812/MT, supported by steady demand from personal care and household cleaning product manufacturers. Stable supply of ethylene oxide and fatty alcohol feedstocks helped maintain balanced production costs. Consistent domestic consumption contributed to relatively stable market conditions.

Get the Real-Time…

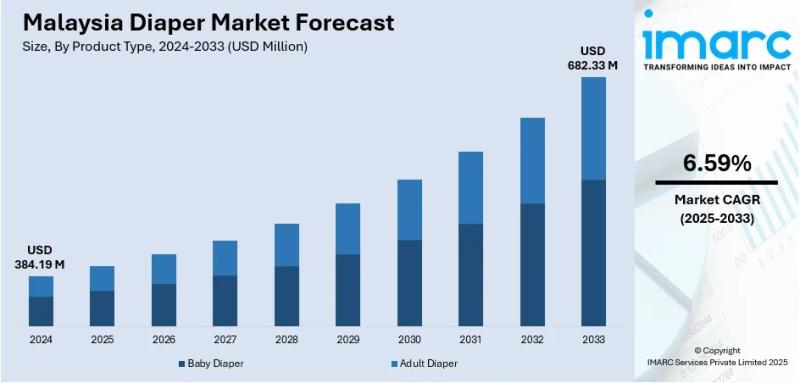

Malaysia Diaper Market to Reach USD 682.33 Million by 2033, Growing at 6.59% CAG …

Source: IMARC Group | Category: Consumer Goods | Author Name: Gaurav

Report Introduction

According to IMARC Group's latest report titled "Malaysia Diaper Market Size, Share, Trends and Forecast by Product Type, Distribution Channel, and State, 2025-2033", the market is growing steadily due to the rising awareness regarding infant hygiene and the increasing number of working parents opting for convenient baby care solutions. The study offers a profound analysis of the industry, encompassing…

Mineral Water Processing Plant DPR - 2026: Investment Cost, Market Growth and Ma …

The global beverage and safe drinking water industry is experiencing transformative growth driven by rising awareness regarding safe drinking water, increasing urbanization, growth of the hospitality sector, and higher consumption of packaged beverages. At the forefront of this health and safety revolution stands mineral water-a drinkable water valued for its natural mineral content, consistent quality, and compliance with food safety standards across household consumption, hospitality and tourism sector, healthcare facilities,…

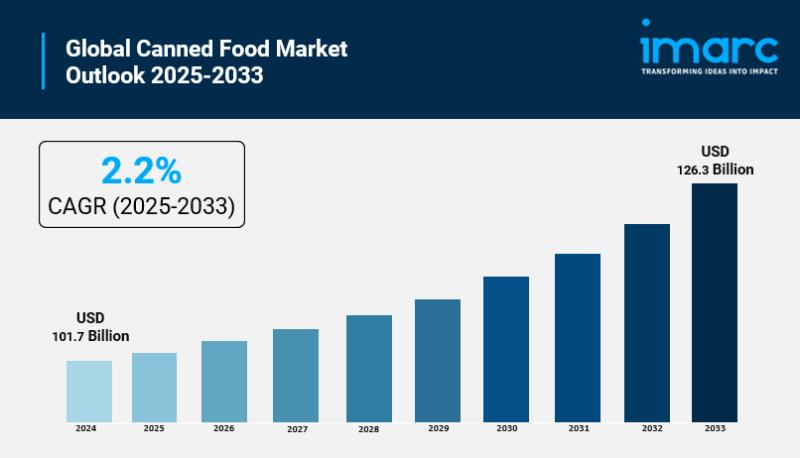

Canned Food Market Size, Share, Latest Insights and Forecast to 2033

IMARC Group, a leading market research company, has recently released a report titled "Canned Food Market Report by Product Type (Canned Meat and Seafood, Canned Fruit and Vegetables, Canned Ready Meals, and Others), Type (Organic, Conventional), Distribution Channel (Supermarkets and Hypermarkets, Convenience Stores, E-commerce, and Others), and Region 2025-2033". The study provides a detailed analysis of the industry, including the canned food market report, growth, size, and industry growth forecast.…

More Releases for Wet

Wet Age-Related Macular Degeneration (Wet AMD) market is expected to reach USD 1 …

Wet age-related macular degeneration (Wet AMD) is a chronic, progressive eye disorder and one of the leading causes of severe vision loss in people over 60. Unlike the dry form of AMD, Wet AMD is characterized by the growth of abnormal blood vessels under the retina that leak fluid or blood, leading to rapid central vision loss. While Wet AMD accounts for only about 10-15% of all AMD cases, it…

Wet And Cold Appliance Market Size Analysis by Application, Type, and Region: Fo …

USA, New Jersey- According to Market Research Intellect, the global Wet And Cold Appliance market in the Internet, Communication and Technology category is projected to witness significant growth from 2025 to 2032. Market dynamics, technological advancements, and evolving consumer demand are expected to drive expansion during this period.

The wet and cold appliance market is expanding steadily, driven by changing consumer lifestyles, increasing urbanization, and rising demand for home automation. Appliances…

Semiconductor Electronic Wet Chemicals Market

Semiconductor Electronic Wet Chemicals Market Overview

Electronic wet chemicals are ultra-pure nature due to which they are extensively used in cleaning and etching application during semiconductor production and processing.

This report provides a deep insight into the global Semiconductor Electronic Wet Chemicals market covering all its essential aspects. This ranges from a macro overview of the market to micro details of the market size, competitive landscape, development trend, niche market, key market…

Wet and Dry Vacuum Cleaner Market

The "Wet and Dry Vacuum Cleaner Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Wet and Dry Vacuum Cleaner Market, 2024-2031

Verified Market Research's most recent report, "Wet and Dry Vacuum Cleaner Market: Global Industry Trends, Share, Size,…

Wet Filtered Downdraught Workbench Market

Wet filtered downdraught workbench is the industry's leading solution for the collection of combustible metal dust which can safely removes combustible materials while complying with NFPA and OSHA combustible dust guidelines.

The global Wet Filtered Downdraught Workbench market was valued at US$ million in 2022 and is anticipated to reach US$ million by 2029, witnessing a CAGR of % during the forecast period 2023-2029. The influence of COVID-19 and the Russia-Ukraine…

Corn Wet-milling Market Corn Wet Milling Market Share, Size, Demand, Key Players …

Market Analysis and Insights of Global Corn Wet-milling Market

The corn wet-milling market is expected to witness market growth at a rate of 5.70% in the forecast period of 2022 to 2029. Data Bridge Market Research report on corn wet-milling market provides analysis and insights regarding the various factors expected to be prevalent throughout the forecast period while providing their impacts on the market's growth. The growth in awareness globally is…