Press release

2 Shot Injection Molding Market Growth Outlook: Current Scenario, Future Trends, and Forecast 2032

"The 2 Shot Injection Molding market is experiencing significant expansion, fueled by the increasing demand for complex, multi-material components across various industries. This growth is driven by the technology's ability to produce parts with enhanced functionality, improved aesthetics, and reduced assembly costs. Technological advancements, such as more precise control systems and advanced material formulations, are continuously refining the process, enabling the creation of increasingly sophisticated products. The market plays a crucial role in addressing global challenges related to manufacturing efficiency, material usage, and product performance. As industries strive for lighter, stronger, and more sustainable components, 2 Shot Injection Molding offers a viable solution, allowing for the combination of different materials with tailored properties within a single molded part. This capability is particularly relevant in sectors like automotive, where weight reduction and improved performance are paramount, and in medical device manufacturing, where precision and biocompatibility are essential. The continuous innovation in materials and processing techniques is expected to further propel the growth of the 2 Shot Injection Molding market, solidifying its position as a key technology in modern manufacturing.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2668

Market Size:

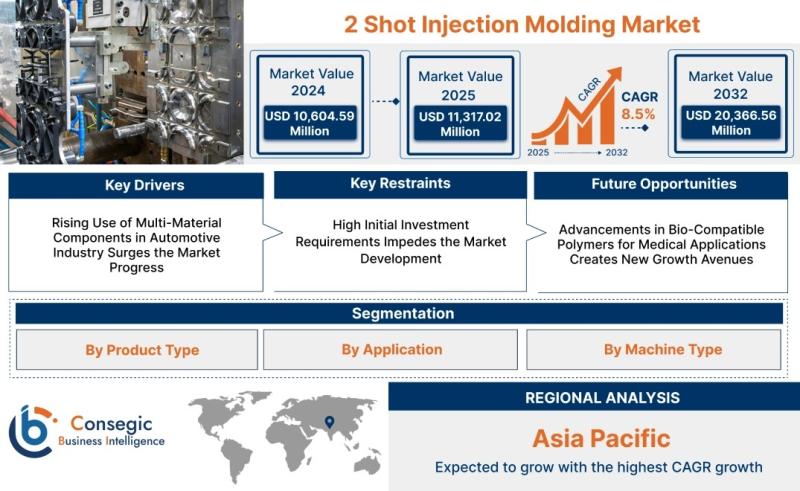

The 2 Shot Injection Molding Market size is estimated to reach over USD 20,366.56 Million by 2032 from a value of USD 10,604.59 Million in 2024 and is projected to grow by USD 11,317.02 Million in 2025, growing at a CAGR of 8.5% from 2025 to 2032.

Definition of Market:

The 2 Shot Injection Molding market encompasses the production and sale of equipment, materials, and services related to the 2 Shot Injection Molding process. This process, also known as multi-component injection molding, involves injecting two or more different materials into a single mold during a single molding cycle. This enables the creation of complex parts with varied properties, such as rigid and flexible sections, multiple colors, or different textures, all within a single component.

Key components of this market include:

2 Shot Injection Molding Machines: Specialized equipment designed to handle multiple injection units and precise mold manipulation.

Molds: Highly engineered tools that define the shape and features of the final product, crucial for accurate material placement and bonding.

Materials: A wide range of polymers, including thermoplastics, elastomers, and specialized compounds, tailored for specific applications.

Services: This includes design assistance, mold fabrication, contract manufacturing, and process optimization services.

Key terms related to the market include:

Multi-component Molding: A broader term encompassing various methods of molding parts with multiple materials.

Overmolding: A process where one material is molded over another, often to create a soft-touch surface or improve grip.

Co-injection Molding: A technique where two materials are injected simultaneously into the mold cavity.

Thermoplastics: Polymers that can be repeatedly softened by heating and hardened by cooling.

Elastomers: Polymers with elastic properties, capable of returning to their original shape after deformation.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2668

Market Scope and Overview:

The 2 Shot Injection Molding market covers a wide range of applications across diverse industries. The technology's ability to combine different materials with distinct properties within a single molded part makes it invaluable for manufacturing complex components with enhanced functionality and aesthetic appeal. The scope of the market extends to various technologies, including horizontal, vertical, and rotary injection molding machines. Applications range from automotive parts, such as interior trim and seals, to medical devices requiring biocompatible materials and intricate designs. The market also serves the consumer goods sector, producing items like toothbrush handles and power tool grips, and the electrical & electronics industry, where it's used for connectors and housings.

The importance of the 2 Shot Injection Molding market is amplified by global trends towards increased product complexity, demand for lightweight materials, and emphasis on sustainable manufacturing practices. As industries seek to optimize material usage, reduce assembly steps, and improve product performance, 2 Shot Injection Molding offers a compelling solution. The technology aligns with the growing demand for customized products and personalized experiences, enabling manufacturers to create unique designs and functional features. Furthermore, the market contributes to the reduction of waste and energy consumption by streamlining production processes and minimizing the need for secondary operations like welding or gluing. In the context of global trends, the 2 Shot Injection Molding market is poised for continued growth and innovation, playing a critical role in shaping the future of manufacturing.

Top Key Players in this Market

Arburg GmbH + Co KG (Germany) ENGEL Austria GmbH (Austria) Husky Injection Molding Systems (Canada) KraussMaffei Group GmbH (Germany) Sumitomo (SHI) Demag Plastics Machinery (Japan) Toshiba Machine Co., Ltd. (Japan) Milacron LLC (United States) Wittma nn Battenfeld GmbH (Austria) Co., Ltd. (Japan) Chen Hsong Holdings Limited (Hong Kong)

Market Segmentation:

The 2 Shot Injection Molding market can be segmented by:

By Product Type: Includes Thermoplastics (Polypropylene, Polycarbonate, Acrylonitrile butadiene styrene (ABS), Polystyrene, Other thermoplastics) and Elastomers (Thermoplastic elastomers (TPE), Styrene-butadiene rubber (SBR), Silicone, Others). Thermoplastics are widely used due to their versatility, while elastomers provide flexibility and impact resistance.

By Application: Spans Automotive (interior components, seals), Medical (devices, components), Consumer goods (handles, housings), Electrical & electronics (connectors, enclosures), Industrial (machine parts), Packaging, and Others. Automotive and medical applications drive significant demand due to stringent quality and performance requirements.

By Machine Type: Consists of Horizontal injection molding machines, Vertical injection molding machines, and Rotary injection molding machines. Horizontal machines are common for high-volume production, while vertical machines are suitable for insert molding and specific part geometries. Rotary machines offer high efficiency for multi-component molding.

Each segment contributes uniquely to the market's overall growth. The broad range of materials and applications enables the technology to cater to diverse industry needs, while the different machine types provide flexibility in production processes.

Market Drivers:

Technological Advancements: Innovations in injection molding machinery, control systems, and material formulations are enhancing the precision, efficiency, and capabilities of the 2 Shot Injection Molding process.

Increasing Demand for Complex Parts: The technology's ability to produce intricate, multi-material components with varying properties in a single molding cycle drives its adoption across industries.

Cost Reduction: By eliminating secondary assembly steps and reducing material waste, 2 Shot Injection Molding can lower overall manufacturing costs.

Improved Product Performance: The combination of different materials allows for the creation of products with enhanced functionality, durability, and aesthetics.

Growing Automotive Industry: The automotive sector's demand for lightweight, high-performance components is a key driver for the 2 Shot Injection Molding market.

Market Key Trends:

Integration of Automation: Increased use of robotic systems for material handling, part removal, and quality control is improving efficiency and reducing labor costs.

Development of New Materials: Ongoing research and development efforts are leading to the creation of advanced polymers and composites tailored for 2 Shot Injection Molding applications.

Adoption of Digital Technologies: The implementation of advanced simulation and analysis tools is optimizing mold design, process parameters, and part performance.

Focus on Sustainability: Growing emphasis on the use of recycled materials and energy-efficient processes is driving the development of sustainable 2 Shot Injection Molding solutions.

Miniaturization: Increasing demand for smaller and more complex components is driving the development of more precise and sophisticated 2 Shot Injection Molding equipment and processes.

Market Opportunities:

Expansion into New Applications: Exploring opportunities in emerging sectors like renewable energy, aerospace, and advanced electronics can drive market growth.

Development of Customized Solutions: Offering tailored 2 Shot Injection Molding services and material formulations to meet specific customer needs can enhance competitiveness.

Integration of Smart Manufacturing Technologies: Implementing real-time monitoring, predictive maintenance, and data analytics can optimize production processes and improve overall efficiency.

Geographic Expansion: Targeting high-growth markets in developing regions can unlock new revenue streams and broaden market reach.

Focus on Sustainability: Offering bio-based materials or process optimization for reduced waste and energy consumption.

Market Restraints:

High Initial Investment Costs: The capital expenditure associated with purchasing specialized 2 Shot Injection Molding equipment and molds can be a barrier to entry for some companies.

Technical Complexity: The 2 Shot Injection Molding process requires a high level of expertise and technical know-how, which can limit its adoption by smaller manufacturers.

Material Compatibility: Ensuring compatibility between different materials used in the molding process can be challenging and requires careful selection and testing.

Mold Design Complexity: The design and fabrication of molds for 2 Shot Injection Molding can be intricate and time-consuming, requiring specialized skills and equipment.

Limited Material Selection: While the range of materials suitable for 2 Shot Injection Molding is expanding, it is still limited compared to single-shot molding.

Market Challenges:

The 2 Shot Injection Molding market, while promising significant growth, faces several key challenges that must be addressed to realize its full potential. One major challenge is the **complexity of the process itself**. Unlike traditional single-shot molding, 2 Shot Injection Molding requires precise control over multiple injection units, mold temperatures, and material flow rates. This complexity demands highly skilled operators and sophisticated process monitoring systems to ensure consistent quality and minimize defects. Furthermore, achieving optimal bonding between the different materials used in the process can be particularly challenging, as material compatibility, surface preparation, and injection parameters must be carefully controlled to prevent delamination or weak points in the final product.

Another significant challenge is the **high upfront investment costs** associated with setting up a 2 Shot Injection Molding operation. Specialized machinery, complex molds, and advanced control systems can represent a substantial financial burden, especially for smaller manufacturers or those new to the technology. These high costs can limit the adoption of 2 Shot Injection Molding, particularly in price-sensitive markets or industries where alternative manufacturing methods are more readily available. To overcome this challenge, manufacturers need to demonstrate a clear return on investment by highlighting the cost savings achieved through reduced assembly steps, improved product performance, and enhanced design flexibility.

**Material selection and compatibility** also pose a significant hurdle in the 2 Shot Injection Molding market. Not all materials are suitable for use in the process, and the choice of materials must be carefully considered to ensure that they bond effectively and exhibit the desired properties in the final product. Furthermore, variations in material properties, such as shrinkage rates and thermal expansion coefficients, can lead to warping or dimensional inaccuracies if not properly accounted for. This challenge necessitates thorough material testing and validation, as well as close collaboration between material suppliers and molders to develop optimized material combinations and processing parameters.

Finally, **competition from alternative manufacturing technologies** presents a persistent challenge to the 2 Shot Injection Molding market. Techniques such as overmolding, insert molding, and multi-material 3D printing offer alternative solutions for producing complex, multi-material parts. These technologies may be more cost-effective or better suited for certain applications, depending on factors such as production volume, part complexity, and material requirements. To maintain its competitive edge, the 2 Shot Injection Molding market must continue to innovate and improve its efficiency, precision, and material capabilities, while also demonstrating its unique advantages over alternative manufacturing methods.

Market Regional Analysis:

The 2 Shot Injection Molding market exhibits varying dynamics across different regions, influenced by factors such as industrial development, technological adoption, and end-user demand.

North America: This region is characterized by a strong focus on technological innovation and high demand from the automotive, medical, and aerospace industries. Stringent quality standards and a skilled workforce contribute to the growth of the 2 Shot Injection Molding market in North America.

Europe: With a strong emphasis on sustainability and environmental regulations, Europe is witnessing increasing adoption of eco-friendly materials and energy-efficient processes in 2 Shot Injection Molding. The automotive and consumer goods sectors are key drivers of market growth in this region.

Asia Pacific: This region represents the fastest-growing market for 2 Shot Injection Molding, driven by rapid industrialization, increasing manufacturing activities, and growing demand from the automotive, electronics, and packaging industries. The presence of cost-competitive manufacturers and a large consumer base contributes to the region's market expansion.

Rest of the World: The market in the rest of the world is relatively smaller but is expected to grow steadily due to increasing industrialization and rising demand for advanced manufacturing technologies in regions like Latin America and the Middle East.

Frequently Asked Questions:

Q: What is the projected growth rate of the 2 Shot Injection Molding market?

A: The 2 Shot Injection Molding market is projected to grow at a CAGR of 8.5% from 2025 to 2032.

Q: What are the key trends in the 2 Shot Injection Molding market?

A: Key trends include the integration of automation, development of new materials, adoption of digital technologies, and a focus on sustainability.

Q: What are the most popular 2 Shot Injection Molding types?

A: Thermoplastics and Thermoplastic Elastomers are most popular product types.

Follow us on:

https://www.linkedin.com/company/marseille-news-digest/

https://www.linkedin.com/company/indepth-industry-insights/

https://www.linkedin.com/company/open-industry-insights/

https://www.linkedin.com/company/innovation-spotlight-360/

https://www.linkedin.com/company/emerging-markets-research-24/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release 2 Shot Injection Molding Market Growth Outlook: Current Scenario, Future Trends, and Forecast 2032 here

News-ID: 4064523 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Mold

South Florida Mold Remediation: Why Residents Continually Choose Mold Only

In the steamy embrace of South Florida, where palm trees sway and ocean breezes carry the scent of salt, homeowners face an unwelcome intruder: mold. It's not just an eyesore-it's a health hazard that thrives in the region's relentless humidity, frequent downpours, and the occasional fury of a tropical storm. Yet amid the sweltering challenges, one name keeps rising to the top of recommendation lists and frantic Google searches: Mold…

Houston Mold Removal Recognized for Excellence in Mold Remediation Services

Houston, TX - Houston Mold Removal [http://houstonmoldremoval.org], a leading provider of mold remediation and water damage restoration services in the Greater Houston area, has been honored with the Excellence in Environmental Safety Award for its outstanding commitment to mold inspection, removal, and indoor air quality improvement.

This prestigious recognition highlights the company's expertise in black mold removal, moisture control, and structural drying, as well as its dedication to creating healthier living…

Greensboro Mold Removal Recognized with Excellence in Mold Remediation Award

Greensboro, NC - Greensboro Mold Removal [https://greensboromoldremoval.org/], a trusted leader in mold remediation and removal services in the Greensboro, NC area, is proud to announce that the company has received the prestigious Excellence in Mold Remediation Award. This honor acknowledges their continued commitment to delivering top-notch mold removal services and ensuring safe, healthy environments for homes and businesses across the region.

Known for their expertise in mold inspection, remediation, and prevention,…

Absolute Mold Removal Helps Toronto Combat Seasonal Mold Growth

Image: https://www.globalnewslines.com/uploads/2024/12/1735233700.jpg

The recognized mold removal experts share how they help homeowners mitigate the gruelling mold problems during winter.

Toronto, Ontario - December 26, 2024 - As winter sets in, Toronto homeowners face a heightened risk of mold growth due to increased indoor humidity and poor ventilation. Absolute Mold Removal is stepping up to help residents protect their homes and health with expert mold removal services tailored to combat seasonal challenges.

Image: https://i.ibb.co/yq9sHbP/Best-Mold-Removal-Toronto.png

Winter…

Hero Mold Company Shares Insights into Commercial Mold Remediation

Image: https://www.getnews.info/wp-content/uploads/2024/06/1719550230.jpeg

Hero Mold Company is a top-rated mold remediation contractor. In a recent update, the contractor shared insights into commercial mold remediation.

Fayetteville, NC - In a website post, Hero Mold Company shared insights into commercial mold remediation.

The experts said that unlike readily visible mold growth in residential environments, commercial mold can be a clandestine adversary. Extensive HVAC systems, hidden crawl spaces, and intricate building layouts offer a breeding ground…

Crown Mold Specialists: Leading the Fight Against Mold

Comprehensive Mold Removal & Water Damage Restoration Services

Crown Mold Specialists is a premier company dedicated to safeguarding homes and businesses from the harmful effects of mold. With a commitment to excellence, Crown Mold Specialists has established itself as a leader in mold removal services, offering comprehensive solutions to ensure healthy and safe living environments.

Founded on the principles of expertise and reliability, Crown Mold Specialists employs state-of-the-art technology and proven methodologies…