Press release

Industrial Agitators Market Growth Outlook: Current Scenario, Future Trends, and Forecast 2032

"The Industrial Agitators Market plays a vital role in numerous industries, ensuring efficient mixing and blending of various substances, which is critical for production processes across sectors like chemicals, pharmaceuticals, food and beverage, water treatment, and many others. The market's growth is primarily driven by the increasing demand for optimized process efficiency, stringent quality control measures, and the expansion of manufacturing activities globally. Technological advancements are at the forefront, with innovations in agitator design, materials, and control systems leading to improved performance, reduced energy consumption, and enhanced reliability. These advancements also contribute to the development of customized solutions tailored to specific industrial needs, further fueling market growth. Furthermore, the industrial agitators market contributes to addressing global challenges, particularly in areas such as water treatment and environmental remediation. Efficient mixing and blending are essential for removing pollutants and ensuring the availability of clean water. As industries worldwide increasingly focus on sustainability and environmental responsibility, the demand for advanced agitator technologies that minimize waste and energy consumption is expected to rise, solidifying the market's role in promoting sustainable industrial practices. Additionally, the pharmaceutical and biotechnology industries are heavily reliant on industrial agitators for precise mixing and blending of biopharmaceutical products, vaccines, and other life-saving medications, thus ensuring process standardization and product quality. The market's continued innovation and adaptation to evolving industry needs make it an indispensable component of modern industrial infrastructure and a key enabler of efficient and sustainable production processes.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2595

Market Size:

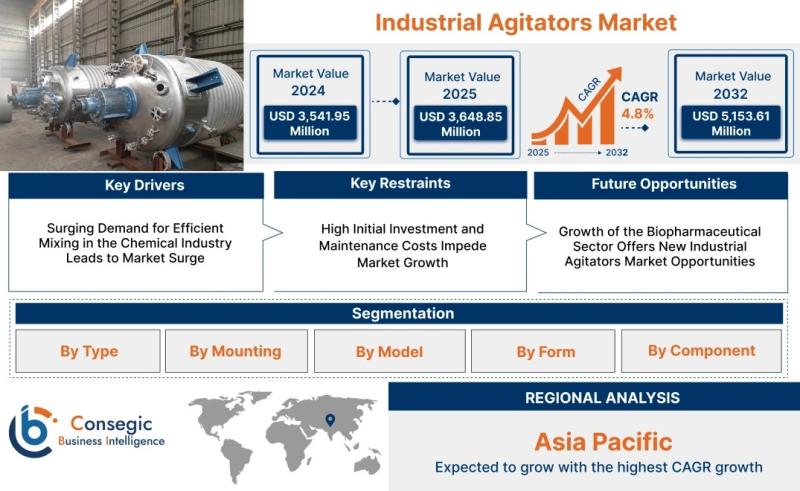

The Industrial Agitators Market size is estimated to reach over USD 5,153.61 Million by 2032 from a value of USD 3,541.95 Million in 2024 and is projected to grow by USD 3,648.85 Million in 2025, growing at a CAGR of 4.8% from 2025 to 2032.

Definition of Market:

The Industrial Agitators Market encompasses the design, manufacturing, sales, and service of equipment used to mix, blend, and suspend various substances in industrial processes. These agitators are mechanical devices engineered to create motion within a fluid or semi-fluid material contained in a tank or vessel. The primary function of industrial agitators is to achieve homogeneity, enhance reaction rates, facilitate heat transfer, and prevent sedimentation or stratification in a wide array of industrial applications.

Key components within this market include the agitator itself, comprising the motor, drive system, shaft, and impeller(s). The impeller is the component directly responsible for creating the mixing action. Sealing systems, such as mechanical seals and packing glands, are essential for preventing leakage of the process fluid. Control systems, including variable frequency drives (VFDs) and automation technologies, allow for precise adjustment and monitoring of agitator speed and performance. Vessels or tanks specifically designed to accommodate agitators are also considered part of the overall market ecosystem, particularly when sold as integrated solutions. Agitator service and maintenance, including repair, refurbishment, and spare parts supply, further contribute to the market's scope.

Key terms associated with this market include:

Impeller: The rotating component that creates fluid motion.

Baffle: Stationary plates inside the vessel that disrupt the flow pattern and enhance mixing efficiency.

Torque: The rotational force applied by the agitator motor.

Shear Rate: The rate at which adjacent layers of fluid move relative to each other, influencing mixing intensity.

Homogeneity: The degree of uniformity in the mixture.

Residence Time: The average time a substance spends in the mixing vessel.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2595

Market Scope and Overview:

The Industrial Agitators Market encompasses a broad spectrum of technologies, applications, and industries. In terms of technologies, it includes various types of agitators, such as top-entry, side-entry, bottom-entry, and portable agitators, each designed for specific mixing requirements and vessel configurations. The market also involves advanced impeller designs, including hydrofoil, pitched blade, and radial flow impellers, tailored to optimize mixing efficiency and fluid dynamics. Furthermore, it covers sophisticated control systems, such as variable frequency drives (VFDs), automation technologies, and sensors for real-time monitoring of mixing parameters. The types of fluids and mixtures that an agitator can handle includes solid-solid, liquid-liquid, solid-liquid and liquid-gas.

The scope extends across numerous industries, including chemicals, pharmaceuticals, food and beverage, water and wastewater treatment, pulp and paper, mining, and oil and gas. In the chemical industry, agitators are used for reactor mixing, blending of raw materials, and suspension of solids. In pharmaceuticals, they are crucial for sterile mixing, cell culture, and formulation processes. The food and beverage industry relies on agitators for mixing ingredients, maintaining product consistency, and pasteurization. Water and wastewater treatment plants employ agitators for chemical dosing, flocculation, and sludge homogenization. The importance of this market lies in its ability to enhance process efficiency, improve product quality, and reduce operational costs across these diverse industries. In the larger context of global trends, the Industrial Agitators Market is integral to supporting sustainable industrial practices, promoting innovation in manufacturing processes, and ensuring the efficient production of essential goods and services. As industries worldwide increasingly adopt advanced technologies and prioritize operational excellence, the demand for sophisticated agitator solutions is expected to grow, driving continued innovation and expansion in the market.

Top Key Players in this Market

SPX FLOW, Inc. (United States) Xylem Inc. (United States) Sulzer Ltd. (Switzerland) Ekato Group (Germany) Philadelphia Mixing Solutions Ltd. (United States) Dynamix Agitators Inc. (Canada) Mixer Direct Inc. (United States) Silverson Machines Inc. (United Kingdom) Statiflo International Ltd. (United Kingdom) Teralba Industries Pty Ltd. (Australia)

Market Segmentation:

The Industrial Agitators Market is segmented based on several factors. By Type, it includes Top Entry, Side Entry, Bottom Entry, Portable, and Static Agitators, each designed for specific mixing applications and vessel configurations. By Mounting, it is divided into Top-Mounted, Side-Mounted, and Bottom-Mounted Agitators, depending on the installation method and accessibility requirements. By Model, the market is segmented into Large Tank, Portable, Drum, and Other Agitators, categorized by the size and application of the mixing vessel. By Form, it includes Solid-Solid Mixture, Solid-Liquid Mixture, Liquid-Liquid Mixture, and Liquid-Gas Mixture agitators, classified by the type of materials being mixed. Finally, by Component, the market is segmented into Heads, Impellers, Sealing Systems, and Other components, reflecting the various parts that make up an agitator system. These segments contribute to market growth by catering to diverse industry needs and providing specialized solutions for specific mixing challenges.

Market Drivers:

Several factors are driving growth in the Industrial Agitators Market:

Technological Advancements: Innovations in agitator design, materials, and control systems are leading to improved performance, reduced energy consumption, and enhanced reliability.

Increasing Industrial Activity: Expanding manufacturing and processing activities across various industries, particularly in emerging economies, are driving demand for agitators.

Stringent Quality Control: Industries are increasingly focused on maintaining consistent product quality, requiring efficient mixing and blending processes facilitated by advanced agitators.

Growing Demand for Optimized Process Efficiency: Companies are seeking ways to improve process efficiency, reduce operational costs, and enhance productivity, leading to greater adoption of advanced agitator solutions.

Rising Awareness of Sustainability: Industries are increasingly focused on sustainability and environmental responsibility, driving demand for agitator technologies that minimize waste and energy consumption.

Government Policies and Regulations: Regulations promoting industrial safety, environmental protection, and quality standards are encouraging the adoption of advanced agitator technologies.

Market Key Trends:

Significant market trends in the Industrial Agitators Market include:

Adoption of Smart Agitators: Integration of sensors, data analytics, and IoT technologies for real-time monitoring, predictive maintenance, and remote control of agitator performance.

Customization and Modularization: Increasing demand for customized agitator solutions tailored to specific industrial needs, along with modular designs that allow for easy scalability and maintenance.

Use of Advanced Materials: Growing adoption of corrosion-resistant materials, such as stainless steel, titanium, and advanced polymers, to enhance agitator durability and longevity in harsh chemical environments.

Energy Efficiency Focus: Development of energy-efficient agitator designs and control systems to reduce energy consumption and minimize environmental impact.

Focus on Hygiene and Sanitation: Increasing emphasis on hygienic designs and materials in industries such as food and beverage and pharmaceuticals to ensure product safety and prevent contamination.

Market Opportunities:

The Industrial Agitators Market presents several growth opportunities:

Emerging Markets: Expansion into rapidly growing industrial sectors in emerging economies, particularly in Asia-Pacific, Latin America, and Africa.

Retrofitting and Upgrading: Opportunities to replace aging agitator systems with modern, more efficient technologies.

New Applications: Development of agitator solutions for emerging applications such as biopharmaceutical manufacturing, renewable energy production, and advanced materials processing.

Service and Maintenance: Expansion of service and maintenance offerings, including remote monitoring, predictive maintenance, and spare parts supply.

Innovations in Impeller Design: Developing advanced impeller designs that optimize mixing efficiency, reduce energy consumption, and enhance process performance.

Market Restraints:

The Industrial Agitators Market faces several restraints:

High Initial Costs: The high capital investment required for purchasing and installing advanced agitator systems can be a barrier for some smaller companies.

Complex Installations: Intricate installations and the need for specialized expertise can create challenges for certain users.

Geographic Limitations: Limited availability of advanced agitator solutions in certain regions can restrict market growth.

Technical Challenges: Difficulties in optimizing agitator performance for specific mixing requirements and process conditions.

Economic Fluctuations: Economic downturns and uncertainties can impact capital spending and delay investment decisions in industrial equipment.

Market Challenges:

The Industrial Agitators Market encounters a complex set of challenges that impact its growth and sustainability. One of the primary challenges is the increasing demand for energy efficiency. Industries are under mounting pressure to reduce their carbon footprint and minimize energy consumption. Consequently, agitator manufacturers face the challenge of developing more energy-efficient designs without compromising mixing performance. This necessitates significant investments in research and development to create innovative impeller geometries, optimize motor efficiency, and implement advanced control systems. Furthermore, the diversity of applications and process requirements poses a significant challenge. Each industry, and even each specific process, demands tailored agitator solutions to achieve optimal mixing performance. Meeting these diverse needs requires manufacturers to offer a wide range of agitator types, sizes, and configurations, which can increase production costs and logistical complexity. The market also faces challenges related to material selection and corrosion resistance. Many industrial processes involve corrosive chemicals and harsh environments, which can degrade agitator components and reduce their lifespan. Manufacturers must select appropriate materials, such as stainless steel, titanium, and advanced polymers, to ensure long-term durability and reliability. However, these materials can be more expensive, increasing the overall cost of the agitator.

Another challenge is the integration of advanced technologies, such as sensors, data analytics, and IoT, into agitator systems. While these technologies offer significant benefits, such as real-time monitoring, predictive maintenance, and remote control, their integration can be complex and costly. Manufacturers must develop user-friendly interfaces and ensure seamless integration with existing industrial automation systems. Additionally, the market faces challenges related to regulatory compliance and safety standards. Industries are subject to strict regulations regarding product quality, environmental protection, and workplace safety. Agitator manufacturers must comply with these regulations and ensure that their products meet the required standards. This can involve rigorous testing, certification, and documentation, which can add to the cost and complexity of the manufacturing process. The Covid-19 pandemic and other geopolitical tensions have also caused delays in the supply chain. This has increased the time from order to manufacturing.

Market Regional Analysis:

The Industrial Agitators Market exhibits varying dynamics across different regions. In North America, the market is driven by the presence of well-established industries, such as chemicals, pharmaceuticals, and food and beverage, coupled with a strong focus on technological innovation and automation. The region's emphasis on energy efficiency and environmental sustainability is also driving demand for advanced agitator technologies. Europe is characterized by stringent environmental regulations and a strong emphasis on sustainable industrial practices. This is driving demand for energy-efficient agitator solutions and advanced control systems. The region also benefits from a highly developed industrial infrastructure and a skilled workforce. The Asia-Pacific region is experiencing rapid industrialization and economic growth, particularly in countries such as China, India, and Southeast Asia. This is driving demand for industrial agitators across a wide range of industries, including chemicals, pharmaceuticals, food and beverage, and water treatment. The region also benefits from lower manufacturing costs and a large consumer base. The Middle East and Africa region is witnessing increasing investment in industrial infrastructure, particularly in the oil and gas, mining, and water treatment sectors. This is driving demand for robust and reliable agitator solutions capable of withstanding harsh operating conditions. The region also benefits from abundant natural resources and a growing population.

Frequently Asked Questions:

Q: What is the projected growth rate of the Industrial Agitators Market?

A: The Industrial Agitators Market is projected to grow at a CAGR of 4.8% from 2025 to 2032.

Q: What are the key trends in the Industrial Agitators Market?

A: Key trends include the adoption of smart agitators, customization and modularization, use of advanced materials, energy efficiency focus, and focus on hygiene and sanitation.

Q: What is the most popular type of Industrial Agitator?

A: The most popular type of industrial agitator varies depending on the application and industry, but top entry agitators and portable agitators are widely used due to their versatility and ease of installation.

Follow us on:

https://www.linkedin.com/company/surveypulse-trends/

https://www.linkedin.com/company/market-insight-digest/

https://www.linkedin.com/company/digital-radar-report/

https://www.linkedin.com/company/innovationtech-news/

https://www.linkedin.com/company/data-pulse-update/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Industrial Agitators Market Growth Outlook: Current Scenario, Future Trends, and Forecast 2032 here

News-ID: 4064245 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Agitator

Submersible Agitator Market: Competitive Dynamics & Global Outlook 2025

LP information released the report titled "Global Submersible Agitator Market Growth 2025-2031" This report provides a comprehensive analysis of the global Submersible Agitator landscape, with a focus on key trends related to product segmentation, Submersible Agitator top 10 manufacturers' revenue and market share, Submersible Agitator report also provides insights into the strategies of the world's leading companies, focusing on their market share, sales, revenue, market position and development prospects in…

Submersible Agitator Market Size, Share, Development by 2024

Global Info Research offers a latest published report on Submersible Agitator Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report. This report focuses on the key global Submersible Agitator players, to define, describe and analyze the value, market share, market competition landscape, SWOT analysis and development plans in next few years.

To analyze the Submersible Agitator with respect to individual growth…

Agitator Seals Market Size, Share, Development by 2024

New report published by Global Info Research which offers insights on the global Agitator Seals market.

Click to view the full report TOC, figure and tables:

https://www.globalinforesearch.com/global-agitator-seals-market_p102387.html

Global Agitator Seals Market: Forecast by Type / Application / Region

Agitator Seals are used to balance the inside pressure and atmospheric pressure in pumps and vessels.

Scope of the Report:

The worldwide market for Agitator Seals is expected to grow at a…

Global Folding Blade Agitator Market Insights, Size, Automation, Data By Type(Si …

This research report titled “Global Folding Blade Agitator Market Insights, Forecast to 2025” has been added to the wide online database managed by Market Research Hub (MRH). The study discusses the prime market growth factors along with future projections expected to impact the Folding Blade Agitator Market during the period between 2018 and 2025. The concerned sector is analyzed based on different market factors including drivers, restraints and opportunities in…

Global Platelet Agitator Market – Estimation & Forecast, 2013-2027

Summary

Platelet agitators are used to prevent the clumping of stationery platelets in blood, in order to preserve blood in its viable form.

The global platelet agitator market was valued at USD 296.3 million in 2015, and is expected to reach USD 502.5 million by 2027, at a CAGR of 4.1% during the forecast period. This growth is majorly attributed to growing investments in the biomedical industry, and technological advancements in platelet…

Global Industrial Agitator Market Research Report 2017

Summary

This report studies Industrial Agitator in Global market, especially in North America, Europe, China, Japan, Southeast Asia and India, focuses on top manufacturers in global market, with capacity, production, price, revenue and market share for each manufacturer, covering

Jongia NV

Mixel

SPX

Chemineer

CRI-MAN s.r.l.

CS UNITEC

Xylem

EIRICH MACHINES

EKATO GROUP

MILTON ROY

ErtelAlsop

FAGGIOLATI PUMPS

Philadelphia

Alfa Lava

Silverson Machines

CHARLES ROSS & SON COMPANY

DCI

Füll Systembau GmbH

Sharpe Mixers

KSB

ARDE BARINCO

RISCO

BRAWN MIXER

Sulzer Chemtech

Mixmor

GEA

Collomix

Get Sample Report @ http://www.reportbazzar.com/request-sample/?pid=833263&ptitle=Global+Industrial+Agitator+Market+Research+Report+2017&req=Sample

Market Segment by Regions, this report splits Global into several…