Press release

Computer Numerical Control (CNC) Machine Market Insights: Emerging Opportunities, Size Estimation & Forecast to 2032

"The Computer Numerical Control (CNC) Machine market is experiencing robust growth, driven by the increasing demand for precision manufacturing, automation, and efficiency across diverse industries. Technological advancements in CNC machining, such as multi-axis machining, automation integration, and advanced control systems, are key drivers fueling this expansion. The market's growth is also significantly influenced by the rising adoption of Industry 4.0 principles, which emphasize interconnectedness and data-driven decision-making in manufacturing processes. The need for higher productivity, reduced waste, and improved product quality are compelling manufacturers to invest in CNC technology. CNC machines are playing a vital role in addressing global challenges related to manufacturing competitiveness, supply chain resilience, and the need for sustainable production practices. They allow for greater design flexibility and can handle a wider range of materials, furthering innovation across industries like aerospace, automotive, healthcare, and electronics. Furthermore, the growing complexity of products and the increasing demand for customized solutions are pushing manufacturers towards CNC machining for its superior precision and repeatability. The convergence of digital technologies with traditional manufacturing methods, epitomized by CNC machines, is fundamentally transforming the manufacturing landscape and solidifying the market's pivotal role in modern industrial production. The demand for skilled professionals to operate and maintain these machines also adds to the complexity and dynamism of this evolving market.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2521

Market Size:

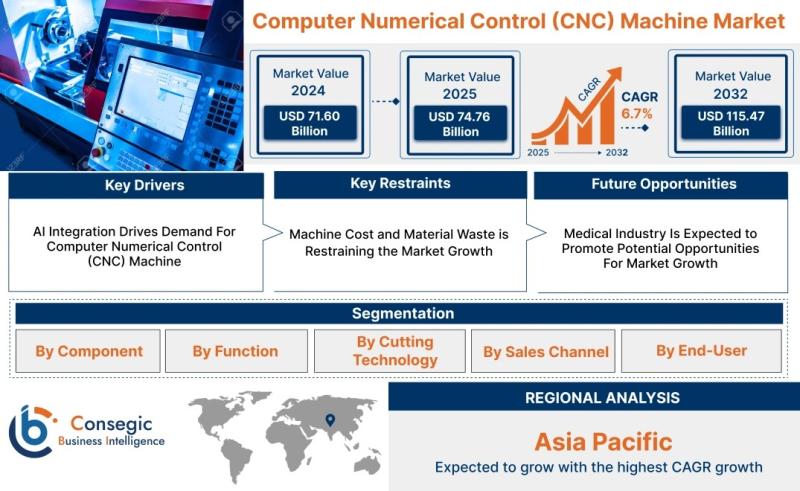

The Computer Numerical Control (CNC) Machine Market is estimated to reach over USD 115.47 Billion by 2032 from a value of USD 71.60 Billion in 2024 and is projected to grow by USD 74.76 Billion in 2025, growing at a CAGR of 6.7% from 2025 to 2032.

Definition of Market:

The Computer Numerical Control (CNC) Machine market encompasses the global industry involved in the design, manufacturing, sales, and servicing of CNC machines. These machines are automated cutting tools that use computer programming to precisely shape materials, such as metal, plastic, wood, and composites. The market includes various components, such as:

CNC Machines: The core product, which includes various types like milling machines, turning machines, grinding machines, and laser cutting machines.

CNC Controllers: The computer system that controls the machine's movements and functions based on pre-programmed instructions.

CNC Software: Programs used to design parts (CAD), create toolpaths (CAM), and simulate machining processes.

CNC Services: Includes installation, maintenance, repair, and training related to CNC machines.

Key terms associated with this market include:

G-code: A programming language used to instruct CNC machines.

CAD/CAM: Computer-Aided Design and Computer-Aided Manufacturing software used to design parts and generate toolpaths.

Multi-axis Machining: CNC machines that can move in multiple axes simultaneously, allowing for complex geometries.

Automation: The integration of CNC machines with robots and other automated systems for increased efficiency.

Precision Machining: Machining processes that achieve very tight tolerances and high surface finishes. The market includes suppliers of components, software developers, machine manufacturers, distributors, and end-users who utilize CNC machines for manufacturing purposes.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2521

Market Scope and Overview:

The scope of the CNC Machine market is extensive, encompassing a wide range of technologies, applications, and industries. The market includes various CNC machine types, such as milling machines, turning machines, grinding machines, laser cutting machines, and electrical discharge machines (EDM). These machines employ diverse cutting technologies, including traditional mechanical cutting, laser cutting, water jet cutting, and plasma cutting. CNC machines find applications across numerous industries, including automotive, aerospace, electronics, healthcare, construction, and energy. In the automotive industry, CNC machines are used for manufacturing engine components, transmission parts, and body panels. In aerospace, they are critical for producing complex aircraft components with high precision and reliability. In electronics, CNC machines are used for manufacturing printed circuit boards (PCBs), semiconductor devices, and consumer electronics components. In healthcare, they are used for producing medical implants, surgical instruments, and diagnostic equipment.

The CNC Machine market plays a critical role in the larger context of global trends in manufacturing and industrial production. The increasing adoption of Industry 4.0, which emphasizes digitalization, automation, and connectivity in manufacturing processes, is driving the demand for CNC machines. The need for higher productivity, reduced costs, and improved product quality is also fueling the growth of the CNC Machine market. Furthermore, the increasing demand for customized products and the growing complexity of manufacturing processes are driving the adoption of CNC machines. The CNC Machine market is also influenced by global economic trends, such as the growth of emerging economies and the increasing demand for manufactured goods in developing countries. The CNC Machine market is expected to continue to grow in the coming years, driven by technological advancements, increasing demand from various industries, and favorable economic conditions.

Top Key Players in this Market

DMG MORI (Japan) Waycon Manufacturing Ltd. (USA) FANUC America Corporation (USA) Trevisan Machine Tool (USA) Jaewoo CNC Machine (India) Esprit Automation Ltd (UK) KTM Technology & Innovations (India) Pvt. Ltd. (India) Okuma Corporation (Japan) Makino Milling Machine Co., Ltd. (Japan) CHIRON Group SE (Germany)

Market Segmentation:

The CNC Machine market is segmented based on several factors:

By Component: Hardware (CPU, Input devices, Machine Control Panel, Display Unit, Programmable Logic Controller (PLC), Others), Software, and Services. Hardware forms the core of CNC machines, software enables programming and control, and services provide maintenance and support.

By Function: Milling, Turning, Grinding, Routing, Boring, Punching, and Others. Each function represents a specific machining process catered to various manufacturing needs.

By Cutting Technology: Water, Laser. Laser cutting is valued for its precision on specific materials, while water cutting handles unique materials.

By Sales Channel: Direct, Indirect. Direct sales involve manufacturers selling directly to end-users, while indirect sales involve distributors and resellers.

By End-User: Automotive, Aerospace, Electronics, Construction, Healthcare, Textiles, Military, Others. Automotive and aerospace are significant end-users, requiring CNC machines for high-precision manufacturing.

Market Drivers:

Several factors are driving growth in the CNC Machine market:

Technological Advancements: Innovations in CNC technology, such as multi-axis machining, high-speed machining, and advanced control systems, are improving the efficiency, precision, and capabilities of CNC machines.

Industry 4.0 Adoption: The increasing adoption of Industry 4.0 principles, such as digitalization, automation, and connectivity, is driving the demand for CNC machines that can be integrated into smart manufacturing systems.

Increasing Demand for Automation: The need for higher productivity, reduced labor costs, and improved product quality is driving the demand for automated manufacturing solutions, including CNC machines.

Government Policies: Government initiatives promoting manufacturing, innovation, and technological development are supporting the growth of the CNC Machine market.

Increasing Demand for Sustainability: The growing emphasis on sustainable manufacturing practices is driving the adoption of CNC machines that can reduce waste, conserve energy, and minimize environmental impact.

Market Key Trends:

Significant market trends shaping the CNC Machine market include:

Integration of AI and Machine Learning: The incorporation of AI and machine learning algorithms into CNC machines is enabling predictive maintenance, adaptive machining, and automated process optimization.

Adoption of Digital Twins: The use of digital twins to simulate and optimize CNC machining processes is improving efficiency, reducing errors, and accelerating product development.

Cloud-Based CNC Solutions: The emergence of cloud-based CNC software and services is providing greater flexibility, scalability, and accessibility for CNC machine users.

Focus on Energy Efficiency: The development of energy-efficient CNC machines and the implementation of energy-saving practices are becoming increasingly important for manufacturers.

Emphasis on Cybersecurity: The growing concern about cyber threats to manufacturing systems is driving the demand for CNC machines with robust cybersecurity features.

Market Opportunities:

The CNC Machine market presents several growth opportunities:

Expanding Applications in Emerging Industries: The use of CNC machines in new and emerging industries, such as additive manufacturing, biotechnology, and renewable energy, is creating new growth avenues.

Development of Advanced CNC Materials: The development of new materials for CNC machining, such as advanced composites and ceramics, is expanding the range of applications for CNC machines.

Integration with Additive Manufacturing: Combining CNC machining with additive manufacturing processes is enabling the creation of complex parts with unique geometries and properties.

Development of User-Friendly CNC Software: The development of intuitive and user-friendly CNC software is making CNC technology more accessible to a wider range of users.

Expansion in Emerging Markets: The increasing demand for manufactured goods in emerging markets is creating significant growth opportunities for CNC machine manufacturers.

Market Restraints:

The CNC Machine market faces several challenges and restraints:

High Initial Costs: The high initial cost of CNC machines can be a barrier for small and medium-sized enterprises (SMEs).

Lack of Skilled Workforce: The shortage of skilled CNC programmers and operators is hindering the adoption of CNC technology.

Complexity of Programming: The complexity of CNC programming can be a challenge for users with limited experience.

Integration Challenges: Integrating CNC machines with existing manufacturing systems can be complex and time-consuming.

Cybersecurity Risks: The increasing risk of cyberattacks on CNC machines and manufacturing systems is a growing concern.

Market Challenges:

The CNC Machine market faces a complex array of challenges that can hinder its growth and development. One of the most significant challenges is the high initial investment cost associated with acquiring CNC machines. These costs can be prohibitive for small and medium-sized enterprises (SMEs), which may lack the financial resources to invest in this technology. The cost of CNC machines includes not only the purchase price but also the cost of installation, training, and ongoing maintenance.

Another major challenge is the shortage of skilled workers capable of programming, operating, and maintaining CNC machines. The complexity of CNC technology requires specialized training and expertise, and there is a growing demand for skilled professionals in this field. The lack of a skilled workforce can limit the adoption of CNC machines and hinder their effective utilization.

The complexity of CNC programming can also be a challenge for users, especially those with limited experience. CNC programming requires a thorough understanding of G-code and other programming languages, as well as knowledge of machining processes and tooling. The complexity of CNC programming can make it difficult for users to create efficient and accurate programs, which can lead to errors, delays, and increased costs.

Integrating CNC machines with existing manufacturing systems can also be a challenge. CNC machines need to be seamlessly integrated with other systems, such as CAD/CAM software, enterprise resource planning (ERP) systems, and quality control systems, to ensure efficient data flow and optimal performance. The integration process can be complex and time-consuming, and it may require specialized expertise.

Finally, the increasing risk of cyberattacks on CNC machines and manufacturing systems is a growing concern. CNC machines are increasingly connected to the internet, which makes them vulnerable to cyberattacks. Cyberattacks can disrupt manufacturing operations, steal sensitive data, and damage equipment. It is essential to implement robust cybersecurity measures to protect CNC machines and manufacturing systems from cyber threats.

Market Regional Analysis:

The CNC Machine market exhibits varying dynamics across different regions. North America and Europe are mature markets with a strong focus on technological innovation and high-precision manufacturing. These regions benefit from established industrial infrastructure, skilled workforces, and government support for advanced manufacturing technologies. Asia-Pacific is the fastest-growing market, driven by the rapid industrialization of countries like China and India. The region's large manufacturing base, low labor costs, and increasing investments in automation are fueling the demand for CNC machines. Latin America and the Middle East and Africa (MEA) are emerging markets with significant growth potential. These regions are characterized by increasing industrialization, growing demand for manufactured goods, and rising investments in infrastructure. However, these regions also face challenges such as limited access to technology, a shortage of skilled workers, and political instability. Each region presents unique opportunities and challenges for CNC machine manufacturers, requiring tailored strategies to address local market conditions and customer needs. Global trade policies and regional economic partnerships also significantly influence the distribution and adoption of CNC technology across different geographic areas.

Frequently Asked Questions:

Q: What is the projected growth of the CNC Machine Market?

A: The Computer Numerical Control (CNC) Machine Market is projected to grow at a CAGR of 6.7% from 2025 to 2032, reaching over USD 115.47 Billion by 2032.

Q: What are the key trends in the CNC Machine Market?

A: Key trends include the integration of AI and machine learning, adoption of digital twins, cloud-based CNC solutions, focus on energy efficiency, and emphasis on cybersecurity.

Q: What is the most popular CNC machine type?

A: The popularity varies by industry, but milling and turning machines are generally the most widely used due to their versatility.

Follow us on:

https://www.linkedin.com/company/visionary-leaders-networks/

https://www.linkedin.com/company/sustainable-success-solutions/

https://www.linkedin.com/company/boston-s-tech-hub/

https://www.linkedin.com/company/the-autonomous-frontier/

https://www.linkedin.com/company/vanguards-ventures/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Computer Numerical Control (CNC) Machine Market Insights: Emerging Opportunities, Size Estimation & Forecast to 2032 here

News-ID: 4063959 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for CNC

XTJ CNC Elevates Custom CNC Machining for Highly Precise Industrial Applications

Carmel, IN 46032, United States, 28th Jan 2026 - XTJ CNC, a prominent provider of custom CNC machining servicesa prominent provider of custom CNC machining services, has announced significant advancements in its capabilities to better serve industries requiring high-precision components. With a focus on custom CNC machining, the company is reinforcing its reputation as a trusted partner in the aerospace, automotive, and electronics sectors. These advancements reflect XTJ CNC's commitment…

Benefits of CNC Machining for Custom Robotic Projects - Tuofa CNC Machining

Robotics is evolving quickly, and higher-performance robots demand stronger mechanical consistency. As DOF increases, joint stacks and mounting interfaces must align accurately to preserve smooth, repeatable motion. CNC machining delivers custom parts with controlled dimensions and reliable quality, reducing fit issues during assembly. It also shortens prototype cycles and supports small-batch production, helping robotics teams convert designs into dependable hardware.

Robotics is getting smarter and smarter. Better perception, smarter control loops,…

CNC Controller Market Report 2024 - CNC Controller Market Trends, Opportunities …

"The Business Research Company recently released a comprehensive report on the Global CNC Controller Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

CNC Controller Global Market to Generate $3.84 Billion By 2028, Registering at a …

"The new report published by The Business Research Company, titled CNC Controller Global Market Report 2024 - Market Size, Trends, And Global Forecast 2024-2033, delivers an in-depth analysis of the leading size and forecasts, investment opportunities, winning strategies, market drivers and trends, competitive landscape, and evolving market trends.

As per the report, the cnc controller market size has grown strongly in recent years. It will grow from $2.82 billion…

Silver CNC Now Offers CNC Rotary Tables for CNC Machining Centers

Silver CNC is now offering a new line of CNC rotary tables that are perfect for use with CNC machining centers. The rotary tables are available in three different sizes, and each one is made from high-quality cast iron to ensure durability and precision. With a built-in indexing system, the rotary tables make it easy to position your workpiece exactly where you need it. Plus, they're backed by a full…

Trending 2020: CNC Machine (CNC Machine Tools) Market Booming Worldwide

Prophecy Market Insights recently presented CNC Machine (CNC Machine Tools) market report which provides reliable and sincere insights related to the various segments and sub-segments of the market. The market study throws light on the various factors that are projected to impact the overall dynamics of the CNC Machine (CNC Machine Tools) market over the forecast period (2019-2029).

The CNC Machine (CNC Machine Tools) research study contains 100+ market data Tables,…