Press release

Aluminum Die Casting Market Overview: Global Size, Share, Analysis, and Forecast till 2032

"The Aluminum Die Casting Market is experiencing significant growth, driven by the increasing demand for lightweight, high-strength components across various industries. This market is propelled by the automotive sector's shift towards electric vehicles (EVs) and the need for lighter materials to improve fuel efficiency and reduce emissions. Technological advancements in die casting processes, such as high-pressure die casting (HPDC) and vacuum die casting, are enabling the production of complex and intricate parts with improved mechanical properties and dimensional accuracy. The market also benefits from the growing emphasis on sustainability, as aluminum is a recyclable material, aligning with global efforts to reduce carbon footprint and promote circular economy practices. Moreover, the expansion of the aerospace, electronics, and healthcare industries further contributes to the demand for aluminum die-casted components. As global manufacturers seek cost-effective and efficient solutions for producing high-quality parts, the Aluminum Die Casting Market plays a pivotal role in addressing these challenges and driving innovation across diverse sectors. This market not only caters to the production of structural parts, but also electronic enclosures, heat sinks, and other critical components. By offering a balance of strength, lightness, and corrosion resistance, aluminum die casting presents a compelling solution for industries striving to enhance product performance and durability, and to improve resource efficiency. The market is constantly evolving with the development of novel alloy formulations and process control technologies, positioning it as a cornerstone of modern manufacturing.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2516

Market Size:

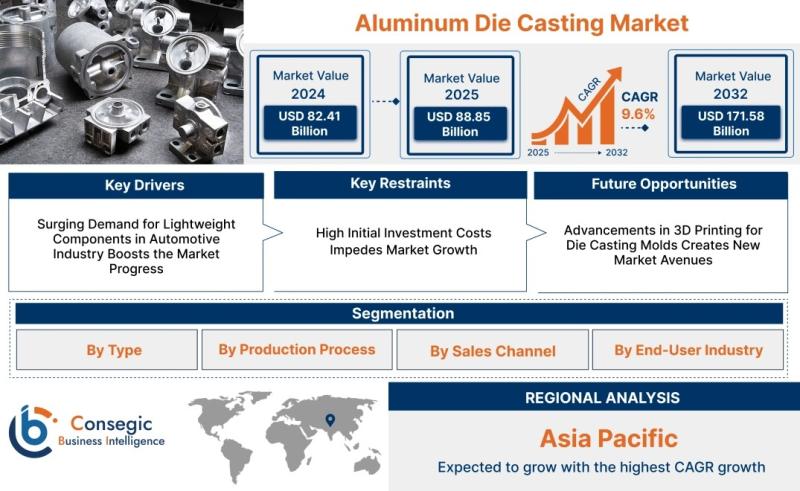

The Aluminum Die Casting Market size is estimated to reach over USD 171.58 Billion by 2032 from a value of USD 82.41 Billion in 2024. It is projected to grow by USD 88.85 Billion in 2025, growing at a CAGR of 9.6% from 2025 to 2032.

Definition of Market:

The Aluminum Die Casting Market encompasses the production and sale of aluminum components manufactured using various die casting processes. Die casting is a manufacturing process where molten aluminum is injected into a mold cavity under high pressure. This process results in parts with high precision, repeatability, and intricate designs.

Key components within this market include:

Aluminum Alloys: The specific types of aluminum used, each with unique properties suited to different applications. Common alloys include those from the A380, A360, and A356 series, each offering different levels of strength, corrosion resistance, and castability.

Die Casting Equipment: This includes die casting machines (both hot and cold chamber), molds (or dies), and associated equipment for controlling temperature, pressure, and injection rates.

Die Casting Services: These services range from design and prototyping to manufacturing and finishing of aluminum die-cast parts. This also includes services like post-casting machining, surface treatment, and assembly.

Key terms related to this market include:

High-Pressure Die Casting (HPDC): A process that involves injecting molten aluminum into a mold cavity at high pressure to produce parts with excellent dimensional accuracy and surface finish.

Low-Pressure Die Casting (LPDC): A process using lower pressures, often for larger and simpler parts.

Vacuum Die Casting: A process where a vacuum is applied to the mold cavity to remove air and gases, reducing porosity and improving mechanical properties.

Die (Mold): The reusable tool used to create the shape of the die-cast part. These are typically made of steel or specialized alloys.

Gate: The opening through which the molten aluminum enters the die cavity.

Riser: A reservoir of molten aluminum that feeds the casting as it solidifies to compensate for shrinkage.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2516

Market Scope and Overview:

The Aluminum Die Casting Market spans a wide range of industries and applications, leveraging various technologies to produce components for diverse uses. Key technologies involved include high-pressure die casting, low-pressure die casting, vacuum die casting, gravity die casting, and squeeze die casting, each offering distinct advantages in terms of production volume, part complexity, and material properties. These technologies enable the manufacturing of intricate and precise aluminum parts, catering to industries such as automotive, aerospace, electronics, industrial machinery, consumer goods, and healthcare.

The market's scope is extensive, encompassing everything from small, intricate electronic components to large, structural automotive parts. The automotive sector, for instance, uses aluminum die castings for engine blocks, transmission housings, and structural components to reduce vehicle weight and improve fuel efficiency. In the aerospace industry, aluminum die castings are used for aircraft components due to their high strength-to-weight ratio and corrosion resistance. The electronics industry utilizes aluminum die castings for enclosures, heat sinks, and connectors, while industrial machinery benefits from their durability and ability to withstand harsh operating conditions. The consumer goods sector incorporates aluminum die castings in products ranging from appliances to power tools, valued for their aesthetic appeal and functionality. The healthcare industry also relies on aluminum die castings for medical devices and equipment due to their hygienic properties and durability. Overall, the Aluminum Die Casting Market serves as a critical link in the global supply chain, providing essential components for numerous industries and driving innovation in manufacturing processes and material science.

Top Key Players in this Market

Nemak, S.A.B. de C.V. (Mexico) Ryobi Limited (Japan) Gibbs Die Casting Corporation (United States) Die Casting Corporation of Florida, Inc. (United States) Pace Industries, LLC (United States) Handtmann Group (Germany) BÃÂ1⁄4hler Group (Switzerland) Finkl Steel (United States) KumKang Kind (South Korea) Rautaruukki Oyj (Finland)

Market Segmentation:

The Aluminum Die Casting Market is segmented based on various parameters, each contributing uniquely to its growth:

By Type: High Pressure Die Casting offers high precision and volume production; Low Pressure Die Casting is suitable for larger, simpler parts; Vacuum Die Casting reduces porosity, enhancing mechanical properties; Gravity Die Casting is cost-effective for moderate volumes; and Squeeze Die Casting improves material density.

By Production Process: Die Casting Machines are the core equipment; Cold Chamber Die Casting Machines are used for high-melting-point alloys; Hot Chamber Die Casting Machines are efficient for lower-melting-point alloys; Tooling Steel Tooling ensures durability; and Aluminum Tooling provides cost efficiency for shorter runs.

By Sales Channel: OEMs (Original Equipment Manufacturers) represent direct sales to manufacturers; Aftermarket sales cater to replacement parts and upgrades.

By End-Use Industry: Automotive drives significant demand due to lightweighting trends; Electronics utilizes aluminum for heat dissipation and enclosures; Aerospace requires high-strength, lightweight components; Industrial Machinery uses aluminum for durable parts; Consumer Goods benefit from aesthetic and functional properties; Healthcare & Medical Devices rely on hygienic and durable aluminum components; and Others include diverse applications across various sectors. Each segment plays a vital role, driving demand and innovation within the Aluminum Die Casting Market.

Market Drivers:

Several factors are driving growth in the Aluminum Die Casting Market. One key driver is the increasing demand for lightweight materials in the automotive industry to improve fuel efficiency and reduce emissions, especially with the rise of electric vehicles (EVs). Technological advancements in die casting processes, such as high-pressure die casting (HPDC) and vacuum die casting, are enabling the production of more complex and intricate parts with improved mechanical properties. Favorable government policies and regulations promoting the use of lightweight materials and energy-efficient manufacturing processes also contribute to market growth. The increasing demand for aluminum die castings in the aerospace, electronics, and healthcare industries is another significant driver. Furthermore, the inherent recyclability of aluminum aligns with global sustainability trends, making it an attractive material choice for manufacturers seeking to reduce their environmental impact. Finally, the cost-effectiveness of aluminum die casting in producing high-volume parts with consistent quality drives its adoption across diverse applications.

Market Key Trends:

Significant trends shaping the Aluminum Die Casting Market include the increasing adoption of automation and robotics in die casting processes to improve efficiency and reduce labor costs. Another trend is the development of new aluminum alloys with enhanced properties, such as higher strength, improved corrosion resistance, and better thermal conductivity, catering to specific application requirements. The integration of digital technologies, such as IoT and data analytics, for process monitoring and optimization is also gaining traction. Furthermore, there is a growing emphasis on sustainable manufacturing practices, including the use of recycled aluminum, energy-efficient die casting equipment, and waste reduction strategies. The rise of electric vehicles (EVs) and the demand for lightweight automotive components are driving innovations in aluminum die casting for structural parts, battery housings, and powertrain components. Additionally, the market is witnessing a shift towards customized and application-specific aluminum die casting solutions, driven by the increasing complexity of product designs and performance requirements.

Market Opportunities:

The Aluminum Die Casting Market presents several growth opportunities. The expanding electric vehicle (EV) market creates a significant opportunity for aluminum die casting in manufacturing battery housings, structural components, and powertrain parts. The increasing demand for lightweight materials in aerospace, automotive, and electronics industries opens avenues for developing high-strength aluminum alloys and advanced die casting processes. The growing adoption of automation and robotics in die casting facilities presents an opportunity for equipment manufacturers and technology providers to offer innovative solutions for process optimization and cost reduction. The increasing emphasis on sustainability and circular economy practices creates opportunities for aluminum recyclers and die casters to promote the use of recycled aluminum and implement energy-efficient manufacturing processes. Furthermore, the development of new applications for aluminum die castings in healthcare, medical devices, and renewable energy systems offers significant growth potential. Innovations in die casting technology, such as additive manufacturing and 3D-printed molds, can enable the production of complex and customized aluminum parts with improved performance and functionality. Moreover, the expansion of manufacturing activities in emerging economies presents opportunities for die casting service providers to cater to the growing demand for aluminum components in these regions.

Market Restraints:

The Aluminum Die Casting Market faces several challenges and restraints. High initial costs associated with setting up die casting facilities, including the purchase of equipment, molds, and tooling, can be a barrier for new entrants and small-scale manufacturers. Geographic limitations, such as the concentration of die casting facilities in specific regions, can restrict market access for customers in other areas. Fluctuations in aluminum prices and supply chain disruptions can impact the profitability of die casting operations. Technical challenges, such as porosity, dimensional accuracy, and surface finish issues, can affect the quality and performance of aluminum die-cast parts. Environmental regulations and concerns regarding the energy consumption and emissions associated with die casting processes can pose challenges for manufacturers. Competition from alternative materials, such as plastics and composites, can limit the adoption of aluminum die castings in certain applications. Furthermore, skilled labor shortages and the need for specialized training in die casting processes can hinder market growth. Social factors, such as concerns about worker safety and labor rights in die casting facilities, can also impact the reputation and sustainability of the industry.

Market Challenges:

The Aluminum Die Casting Market, while robust and growing, faces a complex array of challenges that require strategic navigation and innovative solutions. One of the foremost challenges lies in maintaining consistent quality in the face of increasing complexity and demand. As applications for aluminum die castings expand into more intricate and demanding areas like electric vehicles and aerospace, the requirements for dimensional accuracy, surface finish, and mechanical properties become more stringent. Porosity, a common defect in die-cast parts, can compromise structural integrity and necessitate costly rework or rejection. Overcoming this requires advanced process control, optimized die designs, and innovative alloy formulations.

Another significant hurdle is the fluctuating cost of raw materials, particularly aluminum. Price volatility can significantly impact the profitability of die casting operations, especially for smaller manufacturers with limited bargaining power. To mitigate this risk, companies need to explore strategies such as long-term supply contracts, hedging mechanisms, and the incorporation of recycled aluminum. The environmental impact of die casting processes also presents a growing challenge. Traditional die casting methods are energy-intensive and generate significant waste, including aluminum and emissions. Meeting increasingly stringent environmental regulations requires investments in energy-efficient equipment, waste reduction technologies, and closed-loop recycling systems. The industry must also address concerns about the use of hazardous chemicals in die casting processes and explore more sustainable alternatives.

Furthermore, the Aluminum Die Casting Market is experiencing a shortage of skilled labor, particularly in areas like die design, process engineering, and machine operation. This skills gap can hinder innovation and limit the ability of companies to adopt advanced technologies. Addressing this challenge requires investments in training programs, apprenticeships, and collaborations with educational institutions. Automation and robotics offer a potential solution to labor shortages, but their implementation requires significant capital investment and expertise. Finally, the Aluminum Die Casting Market faces competition from alternative materials such as plastics, composites, and magnesium alloys. These materials offer advantages in terms of weight, cost, or specific performance characteristics, and manufacturers must continuously innovate to maintain the competitiveness of aluminum die castings. This includes developing new alloys with enhanced properties, optimizing die casting processes to reduce costs, and exploring new applications where aluminum die castings offer a superior value proposition. In summary, the Aluminum Die Casting Market's long-term success hinges on addressing challenges related to quality control, material costs, environmental impact, labor shortages, and competition from alternative materials.

Market Regional Analysis:

The Aluminum Die Casting Market exhibits varying dynamics across different regions, influenced by local economic conditions, industrial development, and end-use industry presence. North America is characterized by a mature automotive industry and a growing aerospace sector, driving demand for high-quality aluminum die castings. Europe benefits from stringent environmental regulations, promoting the use of lightweight materials in automotive and industrial applications. Asia-Pacific is experiencing rapid growth, driven by expanding automotive production in countries like China and India, as well as increasing demand from the electronics and consumer goods sectors. The region's cost-competitive manufacturing base and growing industrialization make it a key hub for aluminum die casting production.

Latin America presents opportunities for growth, particularly in the automotive and industrial sectors, driven by increasing investment and infrastructure development. The Middle East and Africa are witnessing rising demand for aluminum die castings in construction, automotive, and infrastructure projects, fueled by economic diversification efforts and population growth. Each region's market dynamics are also influenced by local government policies, trade agreements, and technological advancements, shaping the competitive landscape and growth potential of the Aluminum Die Casting Market.

Frequently Asked Questions:

Q: What is the projected growth rate of the Aluminum Die Casting Market?

A: The Aluminum Die Casting Market is projected to grow at a CAGR of 9.6% from 2025 to 2032.

Q: What are the key trends in the Aluminum Die Casting Market?

A: Key trends include the increasing adoption of automation and robotics, the development of new aluminum alloys, the integration of digital technologies, and the emphasis on sustainable manufacturing practices.

Q: What are the most popular Aluminum Die Casting Market types?

A: High Pressure Die Casting, Low Pressure Die Casting, and Vacuum Die Casting are among the most popular market types, each catering to specific application requirements.

Follow us on:

https://www.linkedin.com/company/consegic-insights-analytics/

https://www.linkedin.com/company/market-research-insightss/

https://www.linkedin.com/company/marketinsightshublinkedin/

https://www.linkedin.com/company/edgetech-news/

https://www.linkedin.com/company/info-pulse-insights/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminum Die Casting Market Overview: Global Size, Share, Analysis, and Forecast till 2032 here

News-ID: 4063611 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Die

U.S. Die Casting Market Set for Dynamic Growth with Key Players Ryobi Die Castin …

Coherent Market Insights has released a report titled "U.S. Die Casting Market: Industry Trends, Share, Size, Growth, Opportunity, and Forecast 2025-2032", which includes market percentage records and a thorough enterprise analysis. This report looks at the market's competition, geographic distribution, and growth potential. This comprehensive report encompasses industry performance, critical success factors, risk assessment, manufacturing prerequisites, project expenses, economic analysis, anticipated return on investment (ROI), and profit margins.

This comprehensive report…

Automotive Parts Die Casting Market Global outlook 2021 to 2026: Gibbs Die-casti …

The report presents an in-depth assessment of the Automotive Parts Die Casting Market including enabling technologies, key trends, market drivers, challenges, standardization, regulatory landscape, deployment models, operator case studies, opportunities, future roadmap, value chain, ecosystem player profiles and strategies. The report also presents SWOT Analysis and forecast for Automotive Parts Die Casting investments. The final report copy provides the impact analysis of novel COVID-19 pandemic on the Automotive Parts Die Casting market…

Automotive Parts Die Casting Market Global Outlook 2019-2025 | Leading Vendors- …

Up Market Research published a detailed report on “Automotive Parts Die Casting Market”. The report provides an in-depth overview of industry and competitive landscape, covering multiple market segments and elaborates market outlook and status to 2025.

Get Sample Copy Of This Report @

https://www.upmarketresearch.com/home/requested_sample/109602

The report contains 115 pages which highly exhibit on current market analysis scenario, upcoming as well as future opportunities, revenue growth, pricing and profitability.

Automotive Parts Die Casting…

Automotive Parts Die Casting Market 2019 Global Key Country Analysis: Alcast Com …

Automotive Parts Die Casting Market Research Report, by Production Process Type (Pressure, Vacuum, Squeeze and Semi-Solid), Raw Material Type (Aluminum, Zinc, Magnesium and Others), By Application Type, Vehicle Type, and by Regions - Forecast till 2023

The Key Players In Automotive Parts Die Casting Market Are:

Alcast Company (U.S.), Dynacast, LLC (U.S.), Endurance Technologies Limited (India), Gibbs Die Casting Corp (U.S.), and Rockman Industries (India). Ryobi Die Casting Inc. (U.S.), Kinetic Die…

Automotive Parts Aluminium & Magnesium Die Casting Market Report 2018: Segmentat …

Global Automotive Parts Aluminium & Magnesium Die Casting market research report provides company profile for Magic Precision Inc, Kinetic Die Casting Company, Texas Die Casting, Endurance Group, Sandhar technologies limited, Meridian Lightweight Technologies Inc, Sunbeam Auto Pvt. Ltd, Dynacast, Rockman Industries Ltd, Castwel Autoparts Pvt Ltd. and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market…

Global Automotive Parts Aluminium Die Casting Market Forecasat 2017 Texas Die Ca …

Automotive Parts Aluminium Die Casting Market

A market study ” Global Automotive Parts Aluminium Die Casting Market ” examines the performance of the Automotive Parts Aluminium Die Casting market 2017. It encloses an in-depth Research of the Automotive Parts Aluminium Die Casting market state and the competitive landscape globally. This report analyzes the potential of Automotive Parts Aluminium Die Casting market in the present and the future prospects from various angles…