Press release

Emerging Trends in Metal Coil Lamination Market 2032: New Study Forecasts Key Trend to Drive Growth

"The Metal Coil Lamination market is experiencing robust growth, driven by increasing demand for lightweight, durable, and corrosion-resistant materials across various industries. Key drivers include the rising adoption of laminated metal coils in automotive, aerospace, and construction sectors, where they offer enhanced performance and longevity. Technological advancements in lamination processes, such as improved adhesion techniques and the development of high-performance laminates, are further fueling market expansion. Moreover, the market plays a crucial role in addressing global challenges related to sustainability and resource efficiency. Laminated metal coils enable the creation of products with reduced material consumption and improved recyclability, contributing to a circular economy. The increasing focus on energy efficiency in buildings and vehicles is also driving the demand for laminated metal coils, as they offer superior insulation properties and can reduce energy consumption. As industries continue to prioritize performance, durability, and sustainability, the Metal Coil Lamination market is poised for continued growth and innovation.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2453

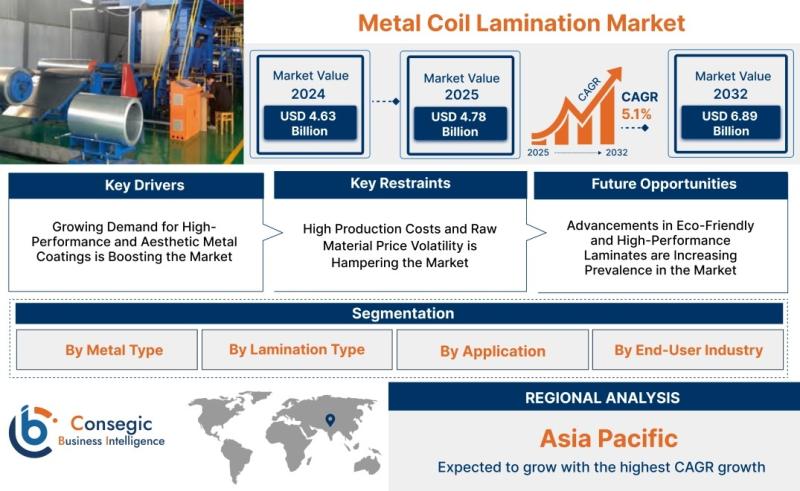

Market Size:

The Metal Coil Lamination market size is estimated to reach over USD 6.89 Billion by 2032 from a value of USD 4.63 Billion in 2024 and is projected to grow by USD 4.78 Billion in 2025, growing at a CAGR of 5.1% from 2025 to 2032.

Definition of Market:

The Metal Coil Lamination market refers to the industry involved in bonding or layering different materials onto metal coils to enhance their properties and performance. This process typically involves applying a layer of film, powder coating, adhesive, or hot melt material onto the metal surface. The laminated metal coil is then used in a wide range of applications across various industries.

Key terms related to this market include:

Metal Coil: A continuous strip or sheet of metal wound into a roll for ease of handling and processing.

Lamination: The process of bonding two or more layers of materials together.

Film Lamination: Applying a thin plastic film onto the metal surface for protection or aesthetic purposes.

Powder Coating Lamination: Applying a powder coating to the metal surface and curing it to form a durable finish.

Hot Melt Lamination: Using a hot melt adhesive to bond materials onto the metal surface.

Adhesive Lamination: Using a liquid adhesive to bond materials onto the metal surface.

Substrate: The metal coil onto which the lamination is applied.

Laminate: The material being applied to the metal coil.

Applications: The specific uses of laminated metal coils in different industries, such as building & construction, automotive, aerospace, electronics, industrial machinery, and packaging.

The Metal Coil Lamination market encompasses the production of laminated metal coils, the technologies and equipment used in the lamination process, and the distribution and sale of these products to end-user industries.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2453

Market Scope and Overview:

The scope of the Metal Coil Lamination market encompasses a wide array of technologies, applications, and industries. The technologies involved include various lamination processes such as film lamination, powder coating lamination, hot melt lamination, and adhesive lamination. These processes are used to apply different types of laminates onto metal coils, enhancing their properties and performance. The market serves a diverse range of applications, including building & construction (roofing, wall panels, cladding), automotive (interior and exterior components), aerospace (aircraft panels, structural components), electronics (electronic enclosures, heat sinks), industrial machinery (machine guards, equipment housings), packaging (food packaging, beverage cans), and more. These applications utilize laminated metal coils for their superior durability, corrosion resistance, aesthetic appeal, and other enhanced properties.

The Metal Coil Lamination market plays a crucial role in the context of global trends. As industries increasingly focus on sustainability, lightweighting, and improved performance, the demand for laminated metal coils is expected to grow. Laminated metal coils offer a sustainable alternative to traditional materials by reducing material consumption, improving recyclability, and enhancing energy efficiency. In the automotive industry, laminated metal coils contribute to vehicle lightweighting, improving fuel efficiency and reducing emissions. In the construction industry, they offer durable and energy-efficient building materials. The increasing adoption of electric vehicles and renewable energy systems is also driving the demand for laminated metal coils in the electronics and electrical industries. Overall, the Metal Coil Lamination market is poised for continued growth as it addresses the evolving needs of various industries and contributes to global sustainability goals.

Top Key Players in this Market

ArcelorMittal (Luxembourg) Nippon Steel Corporation (Japan) United States Steel Corporation (U.S. Steel) (USA) BASF SE (Germany) JFE Steel Corporation (Japan) Reliance Steel & Aluminum Co. (USA) Swastik Industrial Works Pvt. Ltd. (India) Jindal Steel & Power Ltd. (India) U.S. Steel KoÃ...¡ice (Slovakia) Hindalco Industries Ltd. (India)

Market Segmentation:

The Metal Coil Lamination market can be segmented based on several factors:

By Metal Type:

Aluminum: Known for its lightweight and corrosion-resistant properties, widely used in aerospace and automotive applications.

Steel: Offers high strength and durability, commonly used in construction and industrial machinery.

Copper: Excellent electrical conductivity, used in electronics and electrical applications.

Others: Includes metals such as titanium, zinc, and various alloys, catering to niche applications.

By Lamination Type:

Film Lamination: Provides a protective layer and enhances aesthetic appeal.

Powder Coating Lamination: Offers a durable and corrosion-resistant finish.

Hot Melt Lamination: Provides strong bonding and is suitable for high-speed applications.

Adhesive Lamination: Offers flexibility and can be used with a wide range of materials.

By Application:

Building & Construction: Roofing, wall panels, cladding, and other building components.

Automotive: Interior and exterior components, such as body panels and trims.

Aerospace: Aircraft panels, structural components, and interior fittings.

Electronics: Electronic enclosures, heat sinks, and circuit boards.

Industrial Machinery: Machine guards, equipment housings, and structural components.

Packaging: Food packaging, beverage cans, and other protective packaging.

Others: Includes applications in various other industries.

By End-User Industry:

Construction: Utilizes laminated metal coils for various building components.

Automotive & Transportation: Employs laminated metal coils for vehicle components and transportation infrastructure.

Aerospace & Defense: Uses laminated metal coils in aircraft and defense equipment.

Electronics & Electrical: Employs laminated metal coils in electronic devices and electrical equipment.

Industrial Manufacturing: Utilizes laminated metal coils in machinery and equipment manufacturing.

Packaging Industry: Employs laminated metal coils in packaging applications.

Market Drivers:

Technological Advancements: Innovations in lamination processes, such as improved adhesion techniques and the development of high-performance laminates, are driving market growth.

Government Policies: Regulations promoting energy efficiency, sustainability, and the use of lightweight materials are boosting the demand for laminated metal coils.

Increasing Demand for Sustainability: Growing awareness of environmental issues and the need for sustainable materials is driving the adoption of laminated metal coils, which offer improved recyclability and reduced material consumption.

Superior Performance: Laminated metal coils offer enhanced durability, corrosion resistance, and aesthetic appeal compared to traditional materials, making them a preferred choice in various applications.

Lightweighting Trends: The automotive and aerospace industries are increasingly focusing on lightweighting to improve fuel efficiency and reduce emissions, driving the demand for lightweight laminated metal coils.

Market Key Trends:

Development of High-Performance Laminates: The market is witnessing the development of advanced laminates with improved properties, such as enhanced corrosion resistance, UV protection, and thermal insulation.

Adoption of Digital Printing Techniques: Digital printing on laminated metal coils is gaining popularity, allowing for customized designs and branding.

Increasing Use of Recycled Materials: The use of recycled metal and laminate materials is on the rise, driven by sustainability concerns and the desire to reduce environmental impact.

Focus on Lightweighting: The trend towards lightweighting in the automotive and aerospace industries is driving innovation in lightweight laminated metal coil solutions.

Integration of Smart Technologies: Integrating sensors and other smart technologies into laminated metal coils is emerging as a trend, enabling applications such as structural health monitoring and smart buildings.

Market Opportunities:

Expansion into Emerging Markets: The growing industrialization and infrastructure development in emerging markets present significant growth opportunities for the Metal Coil Lamination market.

Development of New Applications: Continued research and development can lead to the discovery of new applications for laminated metal coils in various industries.

Increased Adoption of Sustainable Materials: The increasing focus on sustainability creates opportunities for the development and adoption of eco-friendly laminated metal coil solutions.

Customization and Value-Added Services: Offering customized laminated metal coil solutions and value-added services, such as design and engineering support, can attract new customers and increase market share.

Integration with Smart Technologies: Integrating sensors and other smart technologies into laminated metal coils can open up new opportunities in areas such as smart buildings, infrastructure monitoring, and predictive maintenance.

Market Restraints:

High Initial Costs: The initial investment required for setting up a metal coil lamination facility can be significant, limiting market entry for small and medium-sized enterprises.

Geographic Limitations: The availability of raw materials and skilled labor can be a constraint in certain regions, hindering market growth.

Technical Challenges: Ensuring consistent quality and adhesion in the lamination process can be technically challenging, requiring advanced equipment and expertise.

Environmental Regulations: Stringent environmental regulations regarding the use of certain laminates and chemicals can pose a challenge for manufacturers.

Price Volatility of Raw Materials: Fluctuations in the prices of metal and laminate materials can impact the profitability of manufacturers.

Market Challenges:

The Metal Coil Lamination market, despite its growth potential, faces several significant challenges. One of the primary challenges is the **high initial investment** required to establish a lamination facility. This includes the cost of specialized equipment, such as coil handling systems, laminators, coating machines, and quality control instruments. The high capital expenditure can be a significant barrier to entry, especially for small and medium-sized enterprises (SMEs) that may lack the financial resources to compete with larger, more established players. This can lead to a concentration of market share among a few dominant companies, limiting competition and potentially stifling innovation.

Another challenge is the **complexity of the lamination process** itself. Achieving consistent quality and adhesion across different metal types and laminate materials requires precise control over various parameters, such as temperature, pressure, and coating thickness. Variations in these parameters can lead to defects, such as delamination, blistering, and uneven coating, which can compromise the performance and durability of the laminated metal coil. Manufacturers must invest in advanced process control systems and employ skilled technicians to ensure consistent quality and minimize defects. Moreover, the selection of appropriate adhesives and laminates for specific applications can be challenging, as different materials have different properties and compatibility requirements. The lack of standardized testing methods and performance criteria can further complicate the selection process and increase the risk of failure.

The **environmental impact of the lamination process** is also a growing concern. Many traditional laminates and adhesives contain volatile organic compounds (VOCs) and other hazardous substances that can contribute to air pollution and pose risks to human health. The disposal of waste materials, such as metal and used laminates, can also be problematic, as they may contain hazardous substances that require special handling and treatment. To address these environmental concerns, manufacturers are increasingly adopting more sustainable lamination technologies, such as powder coating lamination and water-based adhesive lamination. However, these technologies may have higher initial costs or require significant modifications to existing production processes, which can pose a challenge for some manufacturers. Furthermore, the development and adoption of biodegradable and recyclable laminates is still in its early stages, and more research and development is needed to make them commercially viable.

Finally, the **fluctuating prices of raw materials** can pose a significant challenge to manufacturers in the Metal Coil Lamination market. The prices of metal coils, laminates, and adhesives can vary widely depending on market conditions and supply chain disruptions. These fluctuations can make it difficult for manufacturers to accurately predict their costs and set competitive prices for their products. To mitigate this risk, manufacturers may need to diversify their sourcing strategies, establish long-term contracts with suppliers, and implement hedging strategies to protect against price volatility. However, these measures may not always be effective, and manufacturers may still be exposed to significant financial risks if raw material prices rise unexpectedly.

Market Regional Analysis:

The Metal Coil Lamination market exhibits varying dynamics across different regions. In North America, the market is driven by the strong automotive and aerospace industries, with a focus on lightweighting and fuel efficiency. Government regulations promoting the use of sustainable materials are also contributing to market growth. Europe benefits from stringent environmental regulations and a well-established industrial base, driving the demand for eco-friendly laminated metal coil solutions. The region is witnessing significant investments in research and development to develop advanced lamination technologies and materials.

The Asia-Pacific region is experiencing rapid growth due to increasing industrialization, infrastructure development, and the rising demand for consumer goods. China, India, and Southeast Asian countries are key markets in the region, driven by their growing automotive, construction, and electronics industries. The availability of low-cost labor and raw materials is also contributing to market growth in the region. Latin America and the Middle East & Africa are emerging markets with significant growth potential. Increasing investments in infrastructure development and the construction sector are driving the demand for laminated metal coils in these regions.

Each region presents unique opportunities and challenges for the Metal Coil Lamination market. Understanding the specific market dynamics in each region is crucial for manufacturers and suppliers to develop effective market entry and growth strategies. Factors such as government regulations, economic conditions, industry trends, and consumer preferences must be carefully considered to succeed in these diverse markets.

Frequently Asked Questions:

Q: What is the projected growth of the Metal Coil Lamination market?

A: The Metal Coil Lamination market is projected to grow at a CAGR of 5.1% from 2025 to 2032, reaching over USD 6.89 Billion by 2032.

Q: What are the key trends in the Metal Coil Lamination market?

A: Key trends include the development of high-performance laminates, adoption of digital printing techniques, increasing use of recycled materials, focus on lightweighting, and integration of smart technologies.

Q: What are the most popular Metal Coil Lamination types?

A: The most popular Metal Coil Lamination types include film lamination, powder coating lamination, hot melt lamination, and adhesive lamination.

Follow us on:

https://www.linkedin.com/company/consegic-insights-analytics/

https://www.linkedin.com/company/market-research-insightss/

https://www.linkedin.com/company/marketinsightshublinkedin/

https://www.linkedin.com/company/edgetech-news/

https://www.linkedin.com/company/info-pulse-insights/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Emerging Trends in Metal Coil Lamination Market 2032: New Study Forecasts Key Trend to Drive Growth here

News-ID: 4063272 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Lamination

Extrusion Coating Lamination Machine for Packaging :Extrusion Coating Lamination …

QY Research Inc. (Global Market Report Research Publisher) announces the release of 2025 latest report "Extrusion Coating Lamination Machine for Packaging- Global Market Share and Ranking, Overall Sales and Demand Forecast 2026-2032". Based on current situation and impact historical analysis (2020-2024) and forecast calculations (2026-2032), this report provides a comprehensive analysis of the global Extrusion Coating Lamination Machine for Packaging market, including market size, share, demand, industry development status, and…

The Impact of Increasing Vehicle Sales On The Motor Lamination Market: A Signifi …

The Motor Lamination Market Report by The Business Research Company delivers a detailed market assessment, covering size projections from 2025 to 2034. This report explores crucial market trends, major drivers and market segmentation by [key segment categories].

What Is the Motor Lamination Market Size and Projected Growth Rate?

The motor lamination market has experienced significant growth recently. It will expand from $21.6 billion in 2024 to $23.09 billion in 2025 at a…

The Distinguish Between Common Embossing and Glue Lamination

What is the difference between common embossing and glue lamination [https://www.hxpapermachine.com/]?

Common embossing and glue lamination are common processes in the processing of household paper products, and are widely used in all types of hygienic paper products. They are all for embossing patterns on the product and bonding multiple layers of jumbo roll paper. , what is the difference or the difference between the two?

First. Both are used before the process…

Soft Touch Lamination Films Market

The "Soft Touch Lamination Films Market" is expected to reach USD xx.x billion by 2031, indicating a compound annual growth rate (CAGR) of xx.x percent from 2024 to 2031. The market was valued at USD xx.x billion In 2023.

Growing Demand and Growth Potential in the Global Soft Touch Lamination Films Market, 2024-2031

Verified Market Research's most recent report, "Soft Touch Lamination Films Market: Global Industry Trends, Share, Size, Growth, Opportunity and…

Bonding for Success: Lamination Adhesives Market

The global Lamination Adhesives Market for flexible packaging market in 2016 is estimated at US$ 1.3 Billion and this is likely to increase to US$ 2.2 Billion by 2024, projected to increase at a CAGR of 6.4% throughout the forecast period (2016-2024). In a new report titled "Lamination Adhesives for Flexible Packaging Market: Global Industry Analysis and Forecast, 2016-2024", Persistence Market Research throws light on the market growth of lamination…

Surface Protection Films Market is Segmentation By Technology Type - Adhesion La …

Future Market Insights (FMI) delivers key insights on the global surface protection films market in a newly published report titled “Surface Protection Films Market: Global Industry Analysis (2012 – 2016) and Opportunity Assessment (2017–2027)”. In terms of revenue, the global surface protection films market is estimated to expand at a CAGR of 5.7% over the forecast period owing to numerous factors, about which FMI offers thorough insights and information in this report.

Market Segmentation…