Press release

Emerging Trends in Braze Alloys Market 2032: New Study Forecasts Key Trend to Drive Growth

"The Braze Alloys Market is experiencing significant growth, fueled by the increasing demand for strong, reliable joints in various industries. These alloys play a crucial role in joining dissimilar metals, enhancing component performance, and extending product lifecycles. Key drivers for this growth include technological advancements in brazing techniques, the rising adoption of lightweight materials in automotive and aerospace industries, and stringent quality standards across sectors. Furthermore, the market is increasingly focused on developing eco-friendly braze alloys to meet sustainability goals and reduce environmental impact. As industries strive for greater efficiency and durability, braze alloys are becoming essential components, addressing global challenges related to material performance and resource optimization. The continuous development of new alloy compositions tailored to specific applications also contributes to the market's expansion. This market is also supporting the adoption of new manufacturing techniques like 3D printing which needs specific brazing solutions.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2288

Market Size:

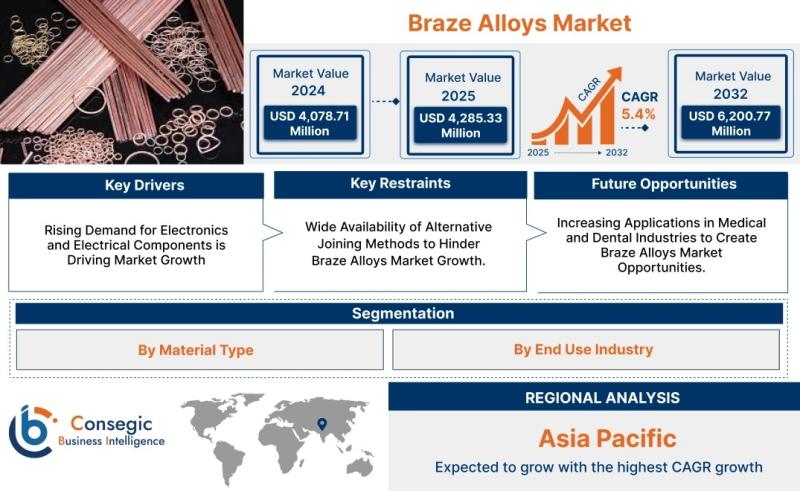

The Braze Alloys Market is projected to grow at a CAGR of 5.4% during the forecast period (2025-2032), reaching a value of USD 6,200.77 Million by 2032 from USD 4,078.71 Million in 2024. The market value for 2025 is estimated at USD 4,285.33 Million.

Definition of Market:

The Braze Alloys Market encompasses the production, distribution, and application of metallic alloys used in the brazing process. Brazing is a joining technique where a filler metal, the braze alloy, is heated to its melting temperature and distributed between two or more close-fitting parts by capillary action. Upon cooling, the braze alloy solidifies, creating a strong metallurgical bond. Key components within this market include:

* Braze Alloys: The core product, available in various compositions (e.g., copper-based, silver-based, nickel-based, aluminum-based) tailored for specific applications and base metals.

* Fluxes: Chemical compounds used to clean the base metals and promote wetting of the braze alloy.

* Brazing Equipment: Includes torches, furnaces, induction heaters, and automated brazing systems.

* Services: Encompasses technical support, custom alloy development, and brazing process optimization.

Key terms related to the market include ""brazability,"" which refers to the ease with which a metal can be brazed; ""wetting,"" describing the ability of the molten alloy to spread evenly on the base metal; and ""joint strength,"" the measure of the mechanical resistance of the brazed joint.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2288

Market Scope and Overview:

The Braze Alloys Market spans a broad range of applications across diverse industries. It includes the development, manufacturing, and sales of various braze alloy compositions designed for specific performance requirements. These alloys are integral to industries such as automotive, aerospace, electronics, construction, healthcare, and more. Technologies within the market encompass advanced alloy formulations, innovative brazing techniques (e.g., vacuum brazing, controlled atmosphere brazing), and sophisticated quality control methods. The scope also extends to customized alloy solutions, meeting the precise needs of specialized applications and addressing evolving industry standards.

The braze alloys market is crucial in the context of global trends towards enhanced material efficiency, lightweighting, and increased reliability of engineered components. As industries pursue sustainable practices, the demand for braze alloys that enable the joining of dissimilar materials without compromising structural integrity is growing. Additionally, the market supports the advancement of new technologies, such as electric vehicles, renewable energy systems, and advanced medical devices, where reliable and high-performance brazed joints are essential. The demand for higher performance, more reliable and environmentally friendly joining solutions is also driving innovation in alloy formulations and brazing processes.

Top Key Players in this Market

Wall Colmonoy Corporation (U.S.) Johnson Matthey PLC (UK) Hobart Brothers (U.S.) Indian Solder and Braze Alloys Pvt. Ltd. (India) Harris Product Groups (U.S.) Lucas Milhaupt (U.S.) Morgan Advanced Materials plc. (UK) Oerlikon Metco (Switzerland) Bellman-Melcor LLC (U.S.)

Market Segmentation:

The Braze Alloys Market can be segmented as follows:

* By Material Type:

* Copper-based: Widely used due to their excellent thermal and electrical conductivity.

* Silver-based: Offer superior corrosion resistance and are often used in electronics and medical applications.

* Nickel-based: Provide high-temperature strength and are suitable for aerospace and automotive components.

* Aluminum-based: Ideal for joining aluminum alloys in lightweight structures.

* Gold-based: Used in critical, high-reliability applications such as aerospace and electronics, where extreme corrosion resistance and high-temperature performance are required.

* Others: Includes alloys based on materials like cobalt, titanium, and magnesium, serving niche applications.

* By End Use Industry:

* Automotive: Used in heat exchangers, fuel systems, and powertrain components.

* Aerospace: Essential for joining aircraft engines, airframes, and hydraulic systems.

* Electronics and Electrical: Used in connecting electronic components, heat sinks, and electrical conductors.

* Construction: Used in joining pipes, HVAC systems, and structural components.

* Healthcare: Utilized in medical devices, implants, and surgical instruments.

* Others: Includes industries like power generation, oil & gas, and chemical processing.

Market Drivers:

Several factors are driving growth in the Braze Alloys Market:

* Technological Advancements: Innovations in brazing techniques, such as vacuum brazing and controlled atmosphere brazing, enhance the quality and efficiency of brazed joints.

* Increasing Demand for Lightweight Materials: The need to reduce weight in automotive and aerospace industries drives the use of braze alloys for joining dissimilar lightweight materials like aluminum and magnesium.

* Stringent Quality Standards: Growing demands for high-reliability joints in critical applications necessitate the use of advanced braze alloys.

* Government Policies and Regulations: Regulations promoting energy efficiency and environmental sustainability encourage the adoption of eco-friendly braze alloys.

* Growing Industrialization: Increased manufacturing activities in developing economies boost the demand for brazing solutions.

Market Key Trends:

Key trends in the Braze Alloys Market include:

* Development of Eco-Friendly Braze Alloys: A focus on developing alloys with reduced or no hazardous elements, such as cadmium and lead, to meet environmental regulations.

* Adoption of Advanced Brazing Techniques: Increased use of vacuum brazing and controlled atmosphere brazing to improve joint quality and reduce oxidation.

* Customized Alloy Solutions: Growing demand for braze alloys tailored to specific applications and base materials.

* Integration of Automation: Increased automation in brazing processes to enhance productivity and reduce labor costs.

* Rising Adoption of 3D Printing: As 3D printing gains traction, there is a growing need for brazing solutions to join 3D-printed parts.

Market Opportunities:

The Braze Alloys Market presents several growth opportunities:

* Expansion in Emerging Markets: Increasing industrialization and infrastructure development in developing countries create significant market opportunities.

* Growing Aerospace and Defense Sector: Rising demand for aircraft and defense equipment drives the need for high-performance braze alloys.

* Electric Vehicle Market: The growth of the electric vehicle market presents opportunities for braze alloys in battery cooling systems and electric motor components.

* Medical Device Industry: The increasing demand for advanced medical devices and implants drives the need for biocompatible braze alloys.

* Innovations in Alloy Development: Research and development efforts focused on creating alloys with enhanced properties, such as high-temperature strength, corrosion resistance, and biocompatibility, offer significant growth prospects.

Market Restraints:

The Braze Alloys Market faces certain restraints:

* High Initial Costs: The cost of advanced brazing equipment and specialized braze alloys can be a barrier for small and medium-sized enterprises.

* Technical Expertise: Skilled labor is required to operate brazing equipment and ensure proper joint quality.

* Environmental Regulations: Stringent environmental regulations on the use of certain hazardous materials in braze alloys can limit their application.

* Material Costs: Fluctuations in the prices of raw materials used in braze alloy production can impact the profitability of manufacturers.

* Supply Chain Disruptions: Global events can disrupt the supply chain of raw materials and finished products, affecting market growth.

Market Challenges:

The Braze Alloys Market faces several significant challenges that could impact its growth trajectory. One key challenge is the increasing pressure to comply with stringent environmental regulations. Many traditional braze alloys contain hazardous substances like cadmium and lead, which pose environmental and health risks. The phase-out of these substances requires significant investment in research and development to create viable, eco-friendly alternatives that offer comparable performance. This involves not only identifying new alloy compositions but also optimizing brazing processes to ensure that these alternatives can be effectively implemented across various applications.

Another major challenge is the need for continuous innovation to meet the evolving demands of various industries. As industries such as aerospace, automotive, and electronics advance, they require braze alloys with improved properties, such as higher strength, better corrosion resistance, and enhanced high-temperature performance. Meeting these demands necessitates ongoing research and development efforts to create customized alloy solutions tailored to specific application needs. Furthermore, the increasing complexity of modern manufacturing processes, including the use of dissimilar materials and advanced joining techniques, requires a deeper understanding of the interactions between braze alloys and base materials. This includes addressing issues such as intermetallic compound formation, diffusion, and residual stress, which can affect the long-term reliability of brazed joints.

The market also faces challenges related to cost competitiveness and supply chain management. The cost of raw materials, particularly precious metals like silver and gold, can significantly impact the overall cost of braze alloys. Fluctuations in these material prices can create uncertainty and affect the profitability of manufacturers. Moreover, ensuring a stable and reliable supply chain is crucial to meet the growing demand for braze alloys. This involves managing risks related to sourcing, logistics, and geopolitical factors that could disrupt the supply of critical materials.

The scarcity of skilled labor is another significant challenge. Brazing is a highly specialized process that requires trained technicians to operate equipment, control process parameters, and ensure joint quality. The shortage of skilled labor can limit the capacity of manufacturers to meet demand and maintain consistent quality. Addressing this challenge requires investment in training programs and education initiatives to develop a skilled workforce capable of supporting the growth of the braze alloys market. Finally, the market faces competition from alternative joining technologies, such as welding and adhesive bonding. While brazing offers unique advantages in certain applications, these alternative technologies may be more suitable for others. Therefore, braze alloy manufacturers must continuously demonstrate the value proposition of brazing, highlighting its advantages in terms of joint strength, precision, and material compatibility.

Market Regional Analysis:

The Braze Alloys Market exhibits varying dynamics across different regions. North America and Europe have historically been major markets, driven by strong automotive, aerospace, and electronics industries. These regions emphasize technological advancements and stringent quality standards. Asia-Pacific is expected to be the fastest-growing market, fueled by rapid industrialization in countries like China and India, and increasing investments in manufacturing and infrastructure development. Latin America and the Middle East & Africa present emerging opportunities, particularly in construction, oil & gas, and power generation sectors.

Each region is influenced by unique factors. North America focuses on high-performance alloys for aerospace and defense applications. Europe is driven by environmental regulations and the adoption of eco-friendly braze alloys. Asia-Pacific benefits from lower manufacturing costs and increasing demand from domestic industries. Latin America is characterized by growing infrastructure development and demand for cost-effective brazing solutions. The Middle East & Africa are driven by investments in oil & gas and construction sectors, with a focus on corrosion-resistant alloys.

Understanding these regional differences is crucial for companies to tailor their products and strategies to meet the specific needs of each market.

Frequently Asked Questions:

Q: What is the projected growth rate of the Braze Alloys Market?

A: The Braze Alloys Market is projected to grow at a CAGR of 5.4% during the forecast period (2025-2032).

Q: What are the key trends in the Braze Alloys Market?

A: Key trends include the development of eco-friendly braze alloys, the adoption of advanced brazing techniques, and the growing demand for customized alloy solutions.

Q: Which material type is most popular in the Braze Alloys Market?

A: Copper-based and Silver-based braze alloys are among the most popular due to their excellent thermal/electrical conductivity and corrosion resistance, respectively, depending on the application requirements.

Follow us on:

https://www.linkedin.com/company/growthh360/

https://www.linkedin.com/company/stuttgart-business-review/

https://www.linkedin.com/company/digitals-pioneers/

https://www.linkedin.com/company/future-tech-digest/

https://www.linkedin.com/company/techs-trends-unplugged/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Emerging Trends in Braze Alloys Market 2032: New Study Forecasts Key Trend to Drive Growth here

News-ID: 4062269 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Alloy

Alloy Steel Market Report 2024 - Alloy Steel Market Trends And Forecast

"The Business Research Company recently released a comprehensive report on the Global Alloy Steel Market Size and Trends Analysis with Forecast 2024-2033. This latest market research report offers a wealth of valuable insights and data, including global market size, regional shares, and competitor market share. Additionally, it covers current trends, future opportunities, and essential data for success in the industry.

Ready to Dive into Something Exciting? Get Your Free Exclusive Sample…

Nickel-Copper Alloy Wire Market 2023 - 2028 Worldwide Major Industry | Alloy Wir …

Nickel-Copper Alloy Wire Market 2023 Forecast: Unveiling Opportunities and Growth

Nickel-Copper Alloy Wire Market research report helps to recognize the market challenges and opportunities. Global Nickel-Copper Alloy Wire Market report contains the recent forecast research for the predicted period. The report extensively offers the latest information about the technological developments and market growth prospect on the basis of the regional landscape. This Report offers a complete evaluation of every area including…

Biodegradable Mg-Alloy Implant market: Technological Advancements in 2022 | Biod …

"The global Biodegradable Mg-Alloy Implant Market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Biodegradable Mg-Alloy Implant Market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and opportunities of…

Vermiculizer Market global outlook and forecast 2021 -2027| QINLI Alloy ,ZHUFENG …

The Global Vermiculizer Market research report is a careful examination of the worldwide industry which has been a region of enthusiasm for a Vermiculizer makers, organizations, authorities, chiefs, and likely speculators, and analysts. The report profoundly lights up noteworthy features in the business, including a contention situation, condition, portions, showcase size, share, gainfulness, development potential, and advancements.

The report likewise spins around the most powerful factors of…

Automotive Alloy Wheel Market Participants Superior Industries International, FU …

Automotive Alloy Wheel Market: Introduction

The automotive alloy wheel market is in a growth phase due to increasing demand for light weight wheels that have the same strength as steel wheels alongside having high thermal stability & ductility. Automotive alloy wheels are made from either an alloy of magnesium or aluminum or a mixture of both. Automotive alloy wheels are light weight wheels which improve the steering and speed of a…

Automotive Magnesium Alloy Market Report 2018: Segmentation by Product (Wrought …

Global Automotive Magnesium Alloy market research report provides company profile for Nanjing Yunhai Special Metals, DongGuan Eontec, Faw Foundry, DY Group, Shanghai Meridian Magnesium, Qingoo Technology, STOLFIG, TAKATA, Autoliv, GF and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the…