Press release

Carbon Thermoplastic Composites Market Overview: Global Size, Share, Analysis, and Forecast till 2032

"The Carbon Thermoplastic Composites market is experiencing significant growth, driven by the increasing demand for lightweight, high-performance materials across various industries. Key drivers include the aerospace and automotive sectors' pursuit of fuel efficiency and reduced emissions, coupled with technological advancements in composite manufacturing processes. Carbon thermoplastic composites offer a compelling combination of strength, stiffness, and ease of recyclability, making them an attractive alternative to traditional materials like metals and thermoset composites. These materials are playing a crucial role in addressing global challenges related to sustainability and resource efficiency. Their lightweight properties contribute to lower energy consumption in transportation, while their recyclability aligns with circular economy principles. Furthermore, the enhanced performance characteristics of carbon thermoplastic composites enable the development of more durable and efficient products, leading to reduced material waste and a longer lifespan for applications in diverse fields such as energy, consumer goods, and infrastructure. As environmental regulations become stricter and consumer awareness of sustainability grows, the adoption of carbon thermoplastic composites is expected to accelerate, further solidifying their position as a critical material in shaping a more sustainable future.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/2417

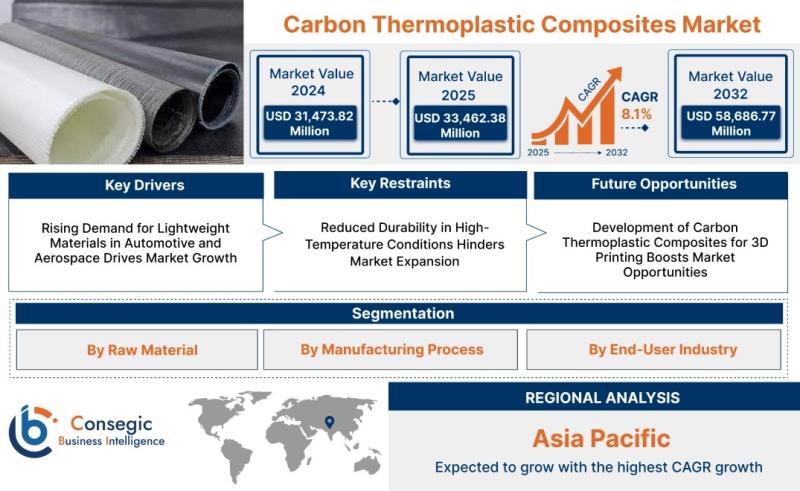

Market Size:

The carbon thermoplastic composites market size is estimated to reach over USD 58,686.77 Million by 2032 from a value of USD 31,473.82 Million in 2024 and is projected to grow by USD 33,462.38 Million in 2025, growing at a CAGR of 8.1% from 2025 to 2032.

Definition of Market:

The Carbon Thermoplastic Composites market encompasses the production, distribution, and application of materials composed of a thermoplastic polymer matrix reinforced with carbon fibers. These composites offer a unique combination of properties, including high strength-to-weight ratio, stiffness, and recyclability, making them desirable for various industries.

Key terms related to this market include:

Carbon Fibers: These are the reinforcement component, providing strength and stiffness to the composite material.

Thermoplastic Polymers: These polymers can be repeatedly softened by heating and hardened by cooling, enabling easier processing and recyclability.

Composite Materials: These are materials made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components.

Injection Molding: A manufacturing process where molten thermoplastic is injected into a mold cavity.

Compression Molding: A manufacturing process where a preheated thermoplastic is placed in an open mold cavity and then closed, forcing the material to conform to the mold's shape.

Pultrusion: A continuous molding process where reinforced fibers are pulled through a resin bath and then through a heated die to form a continuous profile.

Automated Fiber Placement (AFP): An automated process for precisely laying down fiber tows onto a mold surface to create complex composite structures.

The market also involves associated services such as design, engineering, and testing related to carbon thermoplastic composite products.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/2417

Market Scope and Overview:

The Carbon Thermoplastic Composites market spans a wide range of technologies, applications, and industries. In terms of technologies, it includes various manufacturing processes such as injection molding, compression molding, pultrusion, and automated fiber placement (AFP). These processes cater to different product geometries and production volumes. The applications of carbon thermoplastic composites are diverse, ranging from structural components in aerospace and automotive to sporting goods and consumer electronics.

The industries served by this market are equally varied. The aerospace industry utilizes these composites for aircraft fuselages, wings, and interior components to reduce weight and improve fuel efficiency. The automotive industry employs them for body panels, chassis components, and interior parts to enhance vehicle performance and reduce emissions. Other industries include energy (wind turbine blades), consumer goods (sports equipment, electronics casings), and infrastructure (bridge components, pipelines).

The importance of the carbon thermoplastic composites market is amplified by global trends towards sustainability and lightweighting. Governments worldwide are implementing stricter regulations on fuel efficiency and emissions, driving the adoption of lightweight materials in transportation. Additionally, increasing consumer awareness of environmental issues is fueling demand for recyclable and sustainable materials in various products. The market's growth is also supported by ongoing research and development efforts to improve the performance and reduce the cost of carbon thermoplastic composites, making them more competitive with traditional materials. As these trends continue to evolve, the carbon thermoplastic composites market is poised for significant expansion, playing a pivotal role in shaping a more sustainable and efficient future.

Top Key Players in this Market

Toray Industries, Inc. (Japan) Teijin Limited (Japan) Hexcel Corporation (USA) Solvay S.A. (Belgium) SGL Carbon SE (Germany) BASF SE (Germany) LANXESS AG (Germany) Celanese Corporation (USA) SABIC (Saudi Arabia) DowAksa (Turkey)

Market Segmentation:

The Carbon Thermoplastic Composites market is segmented by raw material, manufacturing process, and end-use industry.

By Raw Material: The market includes segments like Polyether Ether (PEEK), Polyamide (PA), Polypropylene (PP), Polycarbonate (PC), and Others. PEEK offers high-temperature resistance and strength, while PA provides good chemical resistance and toughness. PP is cost-effective and lightweight, and PC offers high impact resistance.

By Manufacturing Process: Segments include Injection Molding, Compression Molding, Pultrusion, Automated Fiber Placement (AFP), and Others. Injection molding is used for high-volume production of complex parts, while compression molding is suitable for large, relatively simple shapes. Pultrusion is used for creating continuous profiles, and AFP is ideal for complex, high-performance structures.

By End Use Industry: The market is segmented into Aerospace & Defense, Automotive, Energy, Consumer Goods, and Others. Aerospace & Defense benefits from lightweighting for fuel efficiency, while Automotive focuses on performance and emissions reduction. Energy utilizes composites in wind turbine blades, and Consumer Goods benefits from aesthetics and durability.

Market Drivers:

Technological Advancements: Continuous innovation in carbon fiber production and thermoplastic polymer development is improving the performance and reducing the cost of these composites.

Government Policies: Regulations aimed at improving fuel efficiency and reducing emissions in the automotive and aerospace industries are driving the adoption of lightweight materials like carbon thermoplastic composites.

Increasing Demand for Sustainability: Growing awareness of environmental issues and the desire for recyclable materials are boosting the demand for carbon thermoplastic composites.

Superior Performance Properties: The high strength-to-weight ratio, stiffness, and durability of these composites make them attractive for a wide range of applications.

Cost Reduction: As production volumes increase and manufacturing processes become more efficient, the cost of carbon thermoplastic composites is decreasing, making them more competitive with traditional materials.

Market Key Trends:

Development of bio-based thermoplastic polymers: Increased focus on sustainable materials is leading to the development of carbon composites using bio-based thermoplastic polymers, reducing reliance on fossil fuels.

Increased automation in manufacturing processes: Automation is improving production efficiency and reducing manufacturing costs, making carbon thermoplastic composites more accessible.

Growing adoption of additive manufacturing: 3D printing of carbon thermoplastic composites is enabling the creation of complex geometries and customized parts, opening up new applications.

Focus on recyclability: Development of improved recycling technologies for carbon thermoplastic composites is becoming a priority to address end-of-life concerns.

Integration of sensors and electronics: Embedding sensors and electronics into carbon thermoplastic composite structures is enabling the development of smart and multifunctional materials.

Market Opportunities:

Expansion into emerging markets: Increasing demand for lightweight and sustainable materials in developing countries presents significant growth opportunities.

Development of new applications: Continuous research and development are opening up new applications for carbon thermoplastic composites in industries such as construction, infrastructure, and healthcare.

Partnerships and collaborations: Collaboration between material suppliers, manufacturers, and end-users can accelerate the development and adoption of new carbon thermoplastic composite products.

Focus on customized solutions: Offering customized carbon thermoplastic composite solutions tailored to specific customer needs can create a competitive advantage.

Innovations in recycling technologies: Further development and commercialization of efficient recycling technologies for carbon thermoplastic composites can unlock new revenue streams and reduce environmental impact.

Market Restraints:

High Initial Costs: The cost of carbon fiber and specialized manufacturing equipment can be a barrier to entry for some potential users.

Limited Production Capacity: The availability of carbon fiber and the capacity of manufacturing facilities can constrain the growth of the market.

Technical Challenges: Joining and repairing carbon thermoplastic composite structures can be challenging.

Lack of Standardized Testing Methods: The absence of widely accepted testing methods for carbon thermoplastic composites can hinder their adoption in some industries.

Competition from Alternative Materials: Carbon thermoplastic composites face competition from other lightweight materials, such as aluminum and magnesium alloys.

Market Challenges:

The Carbon Thermoplastic Composites market, despite its promising growth trajectory, faces several significant challenges that could potentially impede its progress. One of the primary challenges is the high initial cost associated with carbon fiber production and the specialized equipment required for manufacturing. The expense of high-quality carbon fiber and the advanced machinery necessary for processes like automated fiber placement (AFP) and complex molding techniques creates a barrier to entry for smaller companies and can limit the adoption of carbon thermoplastic composites in cost-sensitive applications.

Another substantial challenge lies in the technical complexities of working with these materials. Joining carbon thermoplastic composite structures requires specialized techniques and adhesives to ensure structural integrity, and repairs can be particularly difficult and costly. Furthermore, the lack of standardized testing methods for carbon thermoplastic composites presents a challenge in ensuring consistent quality and performance across different applications. This absence of widely accepted standards can hinder their adoption in industries where rigorous testing and certification are mandatory.

Recycling poses another critical challenge. While carbon thermoplastic composites offer recyclability advantages over thermoset composites, the recycling technologies are still in their early stages of development and not yet widely implemented. Efficient and cost-effective recycling methods are needed to fully realize the environmental benefits of these materials and to address end-of-life concerns. Moreover, the limited production capacity of carbon fiber and the availability of specialized manufacturing facilities can constrain the growth of the market. Scaling up production to meet the increasing demand while maintaining quality and cost-effectiveness remains a significant hurdle.

Competition from alternative lightweight materials, such as aluminum, magnesium alloys, and advanced polymers, also presents a challenge. These materials often offer a more cost-effective solution for certain applications, and their established manufacturing processes and supply chains can provide a competitive advantage. Overcoming these challenges requires ongoing research and development efforts to reduce costs, improve manufacturing processes, develop standardized testing methods, and enhance recycling technologies. Collaboration between material suppliers, manufacturers, and end-users is also essential to accelerate innovation and adoption of carbon thermoplastic composites across various industries.

Market Regional Analysis:

The Carbon Thermoplastic Composites market exhibits varying dynamics across different regions. North America and Europe currently hold significant market shares, driven by the presence of major aerospace and automotive industries and stringent environmental regulations promoting lightweight materials. These regions benefit from advanced technological infrastructure and a strong focus on research and development.

The Asia-Pacific region is expected to witness the highest growth rate, fueled by increasing automotive production, particularly in countries like China and India, and growing investments in aerospace and renewable energy sectors. The availability of cost-competitive manufacturing and a rising demand for high-performance materials are also contributing to the region's growth.

Other regions, such as Latin America and the Middle East & Africa, are also showing increasing interest in carbon thermoplastic composites, driven by infrastructure development, growing automotive industries, and rising awareness of sustainable materials. However, these regions face challenges such as limited technological infrastructure and a lack of established supply chains, which may hinder the widespread adoption of carbon thermoplastic composites in the short term.

Frequently Asked Questions:

Q: What are the growth projections for the Carbon Thermoplastic Composites market?

A: The carbon thermoplastic composites market is projected to grow at a CAGR of 8.1% from 2025 to 2032, reaching over USD 58,686.77 Million by 2032.

Q: What are the key trends in this market?

A: Key trends include the development of bio-based thermoplastic polymers, increased automation in manufacturing processes, the growing adoption of additive manufacturing, a focus on recyclability, and the integration of sensors and electronics.

Q: What are the most popular market types for carbon thermoplastic composites?

A: Popular market types include those based on raw materials such as PEEK and PA, manufacturing processes like injection molding and AFP, and end-use industries such as aerospace and automotive.

Follow us on:

https://www.linkedin.com/company/insightverge/

https://www.linkedin.com/company/insightgrid-marketing/

https://www.linkedin.com/company/coreiq-marketing/

https://www.linkedin.com/company/tech-horizon-news/

https://www.linkedin.com/company/nextgen-updates/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Carbon Thermoplastic Composites Market Overview: Global Size, Share, Analysis, and Forecast till 2032 here

News-ID: 4062209 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Carbon

Carbon-Carbon Composite Market to Reach $3.31 Billion by 2031 | SGL Carbon, Toyo …

NEW YORK, (UNITED STATES) - QY Research latest 'Carbon-Carbon Composite Market 2025 Report' offers an unparalleled, in-depth analysis of the industry, delivering critical market insights that empower businesses to enhance their knowledge and refine their decision-making processes. This meticulously crafted report serves as a catalyst for growth, unlocking immense opportunities for companies to boost their return rates and solidify their competitive edge in an ever-evolving market. What sets this report…

Carbon Black Market Next Big Thing | Cabot, Tokai Carbon, Jiangxi Black Carbon, …

Market Research Forecast published a new research publication on "Global U.S. U.S. Carbon Black Market Insights, to 2030" with 232 pages and enriched with self-explained Tables and charts in presentable format. In the Study, you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting market-associated stakeholders. The growth of the U.S. U.S. Carbon Black Market was mainly driven by the increasing R&D spending across the world.

Get Free Exclusive…

Carbon-Carbon Composite Material Market Size, Share 2024, Impressive Industry Gr …

Report Description: -

QY Research's latest report 'Carbon-Carbon Composite Material Market 2024 Report' provides a comprehensive analysis of the industry with market insights will definitely facilitate to increase the knowledge and decision-making skills of the business, thus providing an immense opportunity for growth. Finally, this will increase the return rate and strengthen the competitive advantage within. Since it's a personalised market report, the services are catered to the particular difficulty. The…

Carbon Black Market Scenario & Industry Applications 2020-2025 | Phillips Carbon …

The global carbon black market size is projected to surpass USD 18 billion by 2025. Carbon black act as a reinforcement material for tires and rubber, and possess electrical conductive properties. Carbon black provide pigmentation, conductivity, and UV protection for a number of coating applications along with toners and printing inks for specific color requirements. Its multiple application across various end product along with rising economic outlook has significantly enhanced…

Global Carbon-Carbon Composite Market 2020-2026 SGL Carbon, Toyo Tanso, Tokai Ca …

Global Carbon-Carbon Composite Market 2020-2026 analysis Report offers a comprehensive analysis of the market. It will therefore via depth Qualitative insights, Historical standing and verifiable projections regarding market size. The projections featured inside the report square measure derived victimisation verified analysis methodologies and assumptions. Report provides a progressive summary of the Carbon-Carbon Composite business 2020 together with definitions, classifications, Carbon-Carbon Composite market research, a decent vary of applications and Carbon-Carbon…

Global Carbon Black Market to 2026| Cabot, Orion Engineered Carbons, Birla Carbo …

Albany, NY, 10th January : Recent research and the current scenario as well as future market potential of "Carbon Black Market - Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2018 - 2026" globally.

Carbon Black Market - Overview

Carbon black (CB) is manufactured through partial combustion of heavy hydrocarbons under controlled temperature and pressure to obtain fine particles and aggregates having a wide range of structure and surface properties. This…