Press release

Aerospace Coatings Market Set to Grow at 5.8% CAGR Through 2031

The global aerospace coatings market was valued at USD 1.9 billion in 2022 and is projected to reach USD 3.1 billion by the end of 2031. This growth reflects a robust CAGR of 5.8% from 2023 to 2031, driven by rising demand for fuel-efficient aircraft, increasing air travel, and advancements in coating technologies that enhance durability, corrosion resistance, and aesthetic appeal of aircraft surfaces. The market is also benefiting from increasing fleet modernization and maintenance, repair, and overhaul (MRO) activities globally.Surge in air traffic, led by globalization, and rise in adoption of advanced technologies in aircraft are primary factors that are boosting the aerospace coatings market size. Aerospace coatings safeguard mechanical components used in aircraft from extreme temperatures, UV radiations, moisture, and other environmental factors. Growth in demand for lightweight aircraft - they help improve fuel efficiency and enhance cost-effectiveness - is fueling market progress.

Unlock Full Market Insights: Get a Sample Report Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=38471

Market Segmentation

The aerospace coatings market can be segmented across various dimensions, providing a granular understanding of its dynamics:

By Resin Type:

Polyurethane: Dominates the market, accounting for a significant share (e.g., 55% in 2022, and over 61.2% in 2023 by some reports) due to its superior durability, chemical resistance, weight-saving properties, and environmental sustainability.

It is often used as a top-coat.

Epoxy: A fast-growing segment, commonly used as a primer due to its excellent adhesion and corrosion protection.

Acrylic: Another significant resin type.

Others (e.g., fluoropolymers, polyesters).

By Technology:

Liquid Coating: Holds the largest market share (over 65.4% in 2023) due to its application versatility and ease of use, with solvent-based liquid coatings historically dominating.

Powder Coating: Gaining rapid traction due to its environmental friendliness and ease of application, anticipated to be the fastest-growing category.

Water-based Coatings: Witnessing increasing demand due to stringent regulations on VOC emissions.

Other Technologies.

By Product Type:

Top-coat: Provides a seal, protection from climate, moisture, and chemicals, and ensures durability and exterior abrasion resistance.

Primer: Essential for adhesion and corrosion protection.

Others (e.g., sealants, adhesives, surface preparations, specialty coatings).

By Application:

Exterior: Holds the largest market share (over 68.5% in 2023) due to the critical need for protective coatings against extreme environmental conditions.

Interior: Important for aesthetics, cabin hygiene, and passenger comfort.

By Industry Vertical/End-User:

Original Equipment Manufacturer (OEM): Involves coatings applied to new aircraft during manufacturing.

Maintenance, Repair, and Overhaul (MRO): Accounts for a substantial market share (e.g., 72% in 2022) due to the ongoing need for aircraft maintenance, refurbishment, and repainting. This segment is driven by increasing passenger traffic and the necessity for regular upkeep of aging aircraft fleets.

Commercial Aviation: The largest end-user segment, propelled by increasing air passenger traffic and fleet expansion.

Military Aviation: Driven by defense spending and the demand for advanced military aircraft.

General Aviation: Includes private jets and smaller aircraft.

Space: Growing due to increased investment in space missions.

Regional Analysis

North America: Dominates the aerospace coatings market, largely due to the strong presence of leading OEMs and Tier-1 suppliers, particularly in the United States, which is a hub for aircraft manufacturing and exports. Government incentives and robust defense and space programs further contribute to its leading position.

Asia Pacific: Expected to be the fastest-growing region, driven by the rapid expansion of the aviation industry in countries like China and India. Increased air travel, rising disposable incomes, and significant investments in airport infrastructure and MRO centers are fueling demand in this region.

Europe: Holds the second-largest market share, characterized by technological advancements and a consolidated aviation sector. Stringent environmental regulations also drive the adoption of innovative and sustainable coating solutions.

Middle East & Africa and Latin America: These regions are also exhibiting growth, influenced by increasing air passenger numbers, tourism, and investments in aviation infrastructure.

Market Drivers and Challenges

Market Drivers:

Surge in Air Traffic and Aircraft Fleet Expansion: Globalization, rising disposable incomes, and increased accessibility of air travel are driving a consistent rise in passenger numbers, leading to airlines expanding and upgrading their fleets.

Growing Demand for Lightweight Aircraft: Lightweight coatings contribute to improved fuel efficiency and cost-effectiveness, a critical factor for airlines facing rising fuel costs.

Rising Focus on Aircraft Safety and Performance: Aerospace coatings safeguard mechanical components from extreme conditions, enhancing durability, corrosion resistance, and overall aircraft performance.

Technological Advancements in Coatings: Continuous innovation in coating materials, including nanotechnology, smart coatings, and self-healing coatings, offers enhanced protective capabilities and improved aircraft performance.

Increasing MRO Activities: The aging global aircraft fleet necessitates regular maintenance, repair, and overhaul, driving the demand for aerospace coatings.

Government Investments in Space Missions: Increased government spending on space exploration and related aerospace activities contributes to market growth.

Market Challenges:

Stringent Regulatory Compliance: The aerospace sector is heavily regulated by bodies like the FAA and EASA. Compliance with complex and evolving regulations regarding safety, environmental impact (e.g., VOC emissions, chrome-free coatings), and certification processes can be time-consuming and costly for manufacturers.

High Cost of Advanced Coatings: The use of high-performance materials and intricate manufacturing procedures makes aerospace coatings expensive, particularly for smaller aircraft manufacturers.

Fluctuating Raw Material Prices: Volatility in the prices of key ingredients like resins, pigments, and specialty additives can impact production costs and market stability.

Scarcity of Skilled Labor: The specialized nature of the aerospace industry can lead to a shortage of skilled labor, impacting production efficiency.

Market Trends

Sustainability and Eco-friendly Coatings: A significant shift towards low-VOC (Volatile Organic Compounds), chrome-free, and water-based coatings to reduce environmental impact and comply with stringent regulations.

Nanotechnology in Coatings: The integration of nanomaterials to enhance coating properties like durability, strength, corrosion resistance, and lightweighting.

Digitalization and Smart Coatings: Development of intelligent coatings with functionalities such as self-sensing, self-healing, and real-time monitoring capabilities.

Demand for Fuel Efficiency: Ongoing focus on developing coatings that reduce drag, increase engine efficiency, and minimize aircraft weight to improve fuel economy.

Anti-icing and De-icing Coatings: Research and development in coatings that prevent ice formation or facilitate its removal, enhancing flight safety.

Customization and Specialization: Growing demand for tailored coating solutions to meet specific aircraft requirements and operational conditions.

Future Outlook

The aerospace coatings market is poised for continued growth, fueled by the long-term upward trajectory of the aviation industry. The increasing demand for new-generation aircraft, coupled with the imperative for regular maintenance and refurbishment of existing fleets, will ensure sustained demand.

Furthermore, the relentless pursuit of fuel efficiency, the drive for sustainable aviation practices, and ongoing technological advancements in coating formulations will shape the future landscape of this market. Emerging economies, particularly in Asia Pacific, are expected to be key growth engines.

Key Market Study Points

Market Dynamics: Understanding the interplay of drivers, challenges, and opportunities.

Technological Evolution: Monitoring advancements in coating materials, application methods, and smart functionalities.

Regulatory Impact: Analyzing the influence of environmental and safety regulations on product development and market adoption.

Regional Growth Pockets: Identifying high-potential geographic areas driven by aviation sector expansion.

Value Chain Analysis: Understanding the flow from raw material suppliers to end-users.

Competitive Strategies: Examining the approaches of key players in terms of product innovation, R&D, strategic partnerships, and market expansion.

Emerging Application Areas: Exploring new uses for aerospace coatings beyond traditional aircraft, such as in drones or advanced air mobility.

Competitive Landscape

The aerospace coatings market is characterized by the presence of several global and regional players, with intense competition driven by product differentiation, technological innovation, and strategic collaborations. Key market players are investing significantly in research and development to introduce innovative and cost-effective solutions, expand their product portfolios, and enhance production capacities.

Key Companies in the Aerospace Coatings Market include:

PPG Industries, Inc. (US)

AkzoNobel N.V. (The Netherlands)

The Sherwin-Williams Company (US)

Mankiewicz Gebr. & Co. (Germany)

Axalta Coating Systems Ltd. (US)

Henkel AG & Co. KGaA (Germany)

Saint-Gobain S.A. (France)

Hentzen Coatings, Inc. (US)

Zircotec Ltd (UK)

LORD Corporation (US)

Mapaero (France)

3Chem (US)

Creative Coatings (US)

Qioptiq (UK)

BASF Coatings

These companies engage in various strategies, including new product launches, mergers and acquisitions, and expanding their global footprint to strengthen their market positions.

Recent Developments

April 2023: PPG Industries, Inc. launched a portable aerospace sealant removal, mixing, and application kit to simplify sealant processes.

December 2023: DuPont introduced new Tedlar® PVF solutions and PVF coatings specifically for interior aircraft applications.

January 2022: Sherwin-Williams Aerospace Coatings launched the Aircraft Color Visualizer platform, an online 3D tool for designing aircraft color schemes.

March 2024: Embraer collaborated with AkzoNobel to develop advanced aerospace coatings tailored for Brazil's tropical climate.

May 2025: The Federal Aviation Administration (FAA) partnered with several companies to advance leading-edge protective coatings for turbofan blades, focusing on enhancing durability and improving fuel efficiency.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=38471<ype=S

These developments highlight the industry's continuous evolution towards more sustainable, efficient, and technologically advanced coating solutions for the demanding aerospace sector.

Explore Latest Research Reports by Transparency Market Research:

Monochloroacetic Acid Market - https://www.transparencymarketresearch.com/monochloroacetic-acid-market.html

Boranophosphates Market - https://www.transparencymarketresearch.com/boranophosphates-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Want to know more? Get in touch now. -https://www.transparencymarketresearch.com/contact-us.html

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aerospace Coatings Market Set to Grow at 5.8% CAGR Through 2031 here

News-ID: 4061910 • Views: …

More Releases from transparencymarketresearch

Microgreens Market to Surge at 10.9% CAGR, Set to Reach USD 8.56 Billion by 2036

The global microgreens market was valued at USD 2,780.5 million in 2025 and is projected to reach USD 8,563.5 million by 2036. Driven by rising demand for nutrient-dense foods and growing adoption across foodservice and retail channels, the industry is expected to expand at a robust CAGR of 10.9% from 2026 to 2036.

The global microgreens market represents a specialized, high-value segment within the broader fresh produce and specialty horticulture industry,…

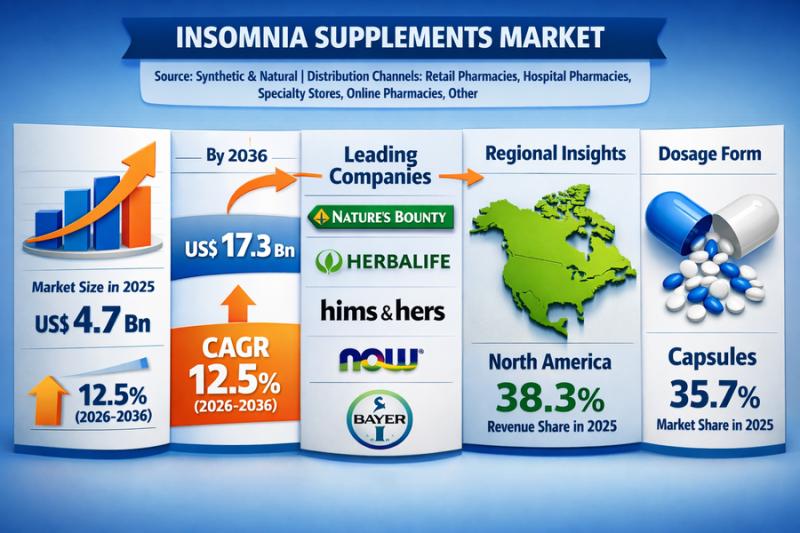

Insomnia Supplements Market Set to Reach US$ 17.3 Bn by 2036, Growing at a Robus …

The global insomnia supplements market was valued at USD 4.7 billion in 2025 and is projected to reach USD 17.3 billion by 2036, reflecting strong growth potential. The market is anticipated to expand at a CAGR of 12.5% from 2026 to 2036, driven by rising sleep disorder prevalence, increasing consumer focus on mental wellness, and growing demand for natural and non-prescription sleep aids.

The insomnia supplements market is expected to witness…

Fiber-Based Blister Pack Market Set to Surge at 21.5% CAGR Through 2036

The global fiber-based blister pack market was valued at US$ 1,633.8 million in 2025 and is projected to surge to US$ 13,591.8 million by 2036. Driven by rising demand for sustainable and eco-friendly packaging solutions, the market is expected to grow at a robust CAGR of 21.5% from 2026 to 2036.

Fiber-based blister packaging is a type of packaging that substitutes the usual plastic blister with paperboard or molded fiber components…

Psychotropic Drugs Market to Reach US$ 41.2 Bn by 2036, Growing at 5.4% CAGR

The global psychotropic drugs market was valued at USD 23.1 Bn in 2025 and is projected to reach USD 41.2 Bn by 2036. Driven by rising awareness of mental health disorders, increasing diagnosis rates, and ongoing pharmaceutical innovations, the industry is expected to grow at a CAGR of 5.4% from 2026 to 2036.

The primary drivers of the expanding psychotropic drugs market include the rising prevalence of mental disorders such as…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…