Press release

Automated Optical Inspection System Market Outlook 2026: Industry Share, Trends, and Future Forecast - 2035

"The Automated Optical Inspection (AOI) System market is experiencing significant growth driven by the increasing complexity of electronic devices, the rising demand for high-quality manufacturing, and the growing adoption of automation across various industries. These systems play a crucial role in ensuring product quality and reducing manufacturing defects, leading to improved efficiency and cost savings. Technological advancements, such as the integration of artificial intelligence (AI) and machine learning (ML), are further enhancing the capabilities of AOI systems, enabling more accurate and efficient defect detection. The market is also being propelled by stringent quality control regulations and the increasing focus on minimizing waste and maximizing resource utilization in manufacturing processes. AOI systems are integral in addressing global challenges related to product reliability, supply chain optimization, and the need for sustainable manufacturing practices, by minimizing rework and , the AOI systems contribute to a more environmentally responsible production ecosystem.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/1684

Market Size:

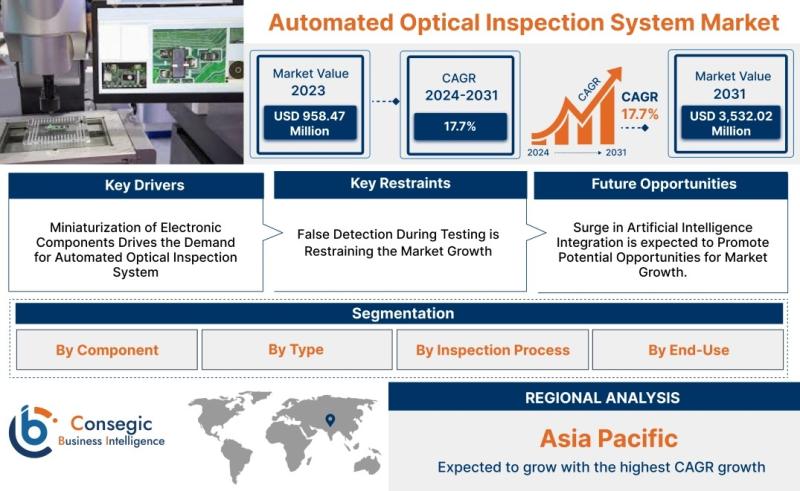

The Automated Optical Inspection System Market size is estimated to reach over USD 3,532.02 Million by 2031 from a value of USD 958.47 Million in 2023 and is projected to grow by USD 1,111.12 Million in 2024, growing at a CAGR of 17.7% from 2024 to 2031.

Definition of Market:

The Automated Optical Inspection (AOI) System market encompasses the technologies, equipment, and services used to automatically inspect manufactured products for defects, inconsistencies, and quality deviations. This market centers around systems designed to visually scan a product, such as a printed circuit board (PCB), a semiconductor wafer, or an assembled electronic device, using cameras and other optical sensors. These systems then analyze the captured images to identify anomalies based on predefined parameters and acceptance criteria.

Key components of the AOI system market include:

AOI Equipment: The core hardware, encompassing cameras, lighting systems, motion control mechanisms, and processing units.

AOI Software: Algorithms and software platforms that drive the inspection process, perform image analysis, and report detected defects.

AOI Services: Support, maintenance, training, and consultation services related to the implementation and operation of AOI systems.

Key terms associated with the market include:

Defect Detection: The process of identifying flaws or deviations from established quality standards.

False Calls: Instances where the AOI system incorrectly identifies a defect.

Throughput: The number of products that can be inspected within a given time frame.

Inspection Coverage: The percentage of the product's surface or features that are inspected by the AOI system.

Resolution: The level of detail captured by the imaging system, influencing the ability to detect smaller defects.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/1684

Market Scope and Overview:

The Automated Optical Inspection (AOI) System market has a broad scope, encompassing various technologies, applications, and industries. The market includes 2D and 3D AOI systems, inline and offline configurations, and systems tailored for specific inspection processes. The core technologies involved are optics, image processing, automation, and increasingly, artificial intelligence (AI) and machine learning (ML). AI-powered AOI systems can learn from past inspections to improve accuracy and reduce false calls, offering significant advantages in complex manufacturing environments.

Applications of AOI systems span across a wide range of industries, including electronics manufacturing, semiconductor fabrication, automotive manufacturing, pharmaceuticals, aerospace and defense, and energy and power. In electronics, AOI is critical for inspecting PCBs, components, and assemblies to ensure functionality and reliability. In the automotive industry, AOI is used to inspect critical components and assemblies, ensuring safety and performance standards are met. The importance of the AOI system market is amplified by the increasing demand for high-quality, reliable products across all sectors, along with the growing need for efficient and automated manufacturing processes. AOI directly addresses the global trend towards Industry 4.0, where automation, data analytics, and connectivity are paramount for achieving operational excellence and maintaining a competitive edge. In the larger context of global trends, the AOI market plays a key role in supporting sustainable manufacturing by minimizing waste and maximizing resource utilization. Furthermore, as global supply chains become more intricate and interconnected, AOI systems are essential for maintaining product quality and minimizing risks associated with defective products, reinforcing the market's integral role in ensuring a robust and reliable global economy.

Top Key Players in this Market

Nordson Corporation (U.S) ITEC (The Netherlands) Omron Corporation (Japan) GÃ-PEL electronic GmbH (Germany) Chroma ATE Inc. (U.S) ZhenHuaXing (China) AOI Systems Ltd (UK) Orbotech (Israel) SAKI (Japan) Viscom (Germany)

Market Segmentation:

The Automated Optical Inspection (AOI) System market can be segmented based on several factors:

By Component:

Hardware: Includes cameras, lighting systems, motion control systems, and processors that capture and process images.

Software: Encompasses algorithms and programs that analyze images, identify defects, and provide feedback for process improvement.

Service: Involves maintenance, support, training, and consulting services to ensure optimal AOI system performance.

By Type:

Inline: Integrated into the production line for real-time inspection, offering continuous monitoring and immediate feedback.

Standalone: Separate inspection stations used for batch or sample testing, providing flexibility and detailed analysis.

By Inspection Process:

2D AOI System: Utilizes two-dimensional imaging for basic defect detection, suitable for simpler applications.

3D AOI System: Employs three-dimensional imaging for more accurate and comprehensive inspection, especially for complex geometries and hidden defects.

By End-User:

Electronics: Used for inspecting PCBs, components, and assemblies in electronic devices.

Semiconductor Manufacturing: Essential for ensuring the quality and reliability of semiconductor wafers and devices.

Automotive: Applied for inspecting critical components and assemblies in vehicles, ensuring safety and performance.

Pharmaceuticals: Used for inspecting drug packaging, labeling, and product integrity.

Aerospace & Defence: Critical for inspecting components and assemblies in aircraft and defense systems, ensuring reliability and safety.

Energy & Power: Applied for inspecting components in energy generation and distribution systems.

Others: Includes industries such as medical devices, food and beverage, and consumer goods.

Market Drivers:

The growth of the Automated Optical Inspection (AOI) System market is driven by several key factors:

Technological Advancements: Continuous innovations in imaging technology, AI, and machine learning are enhancing the capabilities of AOI systems, enabling more accurate and efficient defect detection.

Increasing Demand for High-Quality Products: Growing consumer expectations and stringent quality control regulations are driving the need for effective inspection solutions.

Rising Complexity of Electronic Devices: The increasing density and miniaturization of electronic components necessitate advanced inspection systems to ensure reliability.

Growing Adoption of Automation: The increasing automation of manufacturing processes across industries is driving the demand for integrated AOI solutions.

Stringent Quality Control Regulations: Compliance with industry standards and regulations, especially in sectors like aerospace, defense, and pharmaceuticals, is driving the adoption of AOI systems.

Market Key Trends:

Significant market trends in the Automated Optical Inspection (AOI) System market include:

Integration of AI and Machine Learning: The increasing use of AI and ML algorithms to improve defect detection accuracy and reduce false calls.

Adoption of 3D AOI Systems: Growing demand for 3D AOI systems to inspect complex geometries and hidden defects.

Development of High-Resolution Imaging Systems: Continuous advancements in camera and lens technology to capture finer details and smaller defects.

Integration with Smart Manufacturing Platforms: Increasing integration of AOI systems with Manufacturing Execution Systems (MES) and other smart manufacturing platforms for real-time data analysis and process optimization.

Cloud-Based AOI Solutions: Growing adoption of cloud-based AOI solutions for remote monitoring, data storage, and collaborative analysis.

Market Opportunities:

The Automated Optical Inspection (AOI) System market presents several growth opportunities:

Expansion into New Industries: Extending the application of AOI systems to emerging sectors, such as electric vehicles and renewable energy.

Development of Advanced AI-Powered Solutions: Creating more sophisticated AI algorithms for automated defect detection and process optimization.

Enhancement of 3D Inspection Capabilities: Improving 3D AOI systems to handle more complex geometries and materials.

Integration with Predictive Maintenance Systems: Combining AOI data with predictive maintenance systems to proactively identify and address potential issues.

Development of Customized AOI Solutions: Offering tailored AOI systems to meet the specific needs of different industries and applications.

Market Restraints:

The Automated Optical Inspection (AOI) System market faces several challenges and restraints:

High Initial Costs: The initial investment in AOI systems can be substantial, especially for advanced 3D systems.

Complexity of Implementation: Integrating AOI systems into existing production lines can be complex and require specialized expertise.

Data Management and Analysis: Managing and analyzing the large volumes of data generated by AOI systems can be challenging.

False Call Rates: High false call rates can reduce the efficiency of AOI systems and require manual verification.

Lack of Skilled Personnel: Operating and maintaining AOI systems requires skilled personnel, which can be a limiting factor for some organizations.

Market Challenges:

The Automated Optical Inspection (AOI) System market encounters several critical challenges that impact its growth and adoption. One of the foremost challenges is the high initial investment required for implementing advanced AOI systems. The sophisticated equipment, including high-resolution cameras, precision optics, and powerful processing units, often necessitates a significant capital outlay, which can be a barrier for smaller manufacturers and organizations with limited budgets. Overcoming this challenge requires manufacturers to demonstrate a clear return on investment through improved product quality, reduced defect rates, and enhanced production efficiency.

Another significant challenge lies in the complexity of integrating AOI systems into existing manufacturing processes. The integration process can be intricate, requiring careful planning and execution to ensure seamless compatibility with existing machinery, software, and data systems. This often involves customizing AOI systems to meet the specific requirements of the manufacturing environment, which adds to the complexity and cost. Furthermore, the management and analysis of the vast amounts of data generated by AOI systems pose a considerable challenge. The data needs to be processed efficiently to identify trends, patterns, and anomalies that can inform process improvements and prevent future defects. The effective utilization of data analytics tools and machine learning algorithms is crucial for extracting valuable insights from the data and maximizing the benefits of AOI systems.

False call rates, which refer to the instances where the AOI system incorrectly identifies a defect, represent another significant challenge. High false call rates can lead to unnecessary rework, reduced throughput, and increased costs. Minimizing false calls requires fine-tuning the AOI system's algorithms, improving image quality, and optimizing lighting conditions. Advanced techniques, such as AI-powered defect detection, can help to reduce false call rates and improve the overall accuracy of AOI systems. Additionally, the lack of skilled personnel capable of operating and maintaining AOI systems is a notable challenge. Operating these systems requires a strong understanding of optics, image processing, and automation technologies. Providing adequate training and development opportunities for personnel is essential to ensure the effective utilization and maintenance of AOI systems.

As manufacturing processes become more complex and product designs evolve, the ability of AOI systems to keep pace with these changes presents an ongoing challenge. The systems need to be adaptable and scalable to handle new materials, geometries, and inspection requirements. This requires continuous innovation in AOI technology, including the development of more flexible and versatile inspection systems. Addressing these challenges is crucial for the continued growth and adoption of AOI systems across various industries, enabling manufacturers to improve product quality, reduce costs, and enhance overall operational efficiency.

Market Regional Analysis:

The Automated Optical Inspection (AOI) System market exhibits distinct regional dynamics influenced by factors such as industrial development, technological infrastructure, and regulatory landscapes. In North America, the market is driven by the presence of advanced manufacturing industries, particularly in electronics, aerospace, and automotive. The region's strong focus on quality control and automation, combined with the availability of advanced technological infrastructure, fosters the adoption of AOI systems. Europe, with its stringent quality standards and emphasis on sustainable manufacturing, also presents a significant market for AOI systems. The region's automotive, aerospace, and pharmaceutical industries are key consumers of AOI solutions.

The Asia-Pacific region is experiencing rapid growth in the AOI system market, driven by the burgeoning electronics and semiconductor industries in countries like China, Japan, and South Korea. The region's cost-competitive manufacturing environment and increasing investments in automation are fueling the demand for AOI systems. Additionally, supportive government policies aimed at promoting industrial development and technological advancements are contributing to the market's expansion. Latin America and the Middle East are emerging markets for AOI systems, with growing investments in manufacturing and infrastructure development. These regions are witnessing increasing adoption of AOI systems in sectors such as automotive, electronics, and energy, driven by the need to improve product quality and enhance operational efficiency. Each region's unique industrial landscape, regulatory environment, and technological advancements shape the adoption and application of AOI systems, driving the global market's growth and evolution.

Frequently Asked Questions:

What is the projected growth rate of the Automated Optical Inspection (AOI) System market?

The Automated Optical Inspection System Market is growing at a CAGR of 17.7% from 2024 to 2031.

What are the key trends in the AOI System market?

Key trends include the integration of AI and machine learning, the adoption of 3D AOI systems, and the integration with smart manufacturing platforms.

What are the most popular types of AOI Systems?

Both inline and standalone AOI systems are popular, depending on the specific application and production environment. 3D AOI systems are gaining traction due to their ability to detect complex defects.

Follow us on:

https://www.linkedin.com/company/trendloom-analytics46/

https://www.linkedin.com/company/coggrow-insights/

https://www.linkedin.com/company/insightsphere-pro41/

https://www.linkedin.com/company/futuredge-reports/

https://www.linkedin.com/company/marketscope-central/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Automated Optical Inspection System Market Outlook 2026: Industry Share, Trends, and Future Forecast - 2035 here

News-ID: 4057668 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for AOI

AstoCare joins hands with AOI- India

In partnership with Academy of Oral Implantology - India, AstoCare intends to speak at the prestigious

SPRING SUMMIT 2020 (of implantology)

August 22nd and 23rd, 2020.

All stakeholders are invited, with much gusto, to grace the event with their benevolent presence.

See you there!

To register yourself for the event, please click the below link and fill the form: https://docs.google.com/forms/d/e/1FAIpQLSeqx-vtLS0SHEWCTWILGpak0avcSJCP6q4fidZpMuNpYxp26A/viewform

For more, LIVE CHAT with us at www.astocare.com or write to us at hello@astocare.com.

Industrial area

Phase…

Current Market Scenario of Global 3D AOI Equipment Market

GLOBAL INFO RESEARCH�indicates that the global3D AOI Equipment�market�is expected to surge at a steady rate in the coming years, as economies flourish. The�COVID-19�research report, titled [Global and Japan 3D AOI Equipment Market 2020 by Manufacturers, Type and Application, Forecast to 2025], provides a comprehensive review of the global market. Analysts have identified the key drivers and restraints in the overall market. They have studied the historical milestones achieved by the…

3D AOI systems to hold the largest size of the automated optical inspection (AOI …

Automated optical inspection (AOI) systems are used for the inspection of printed circuit boards (PCBs). The system is superior and less time consuming compared to manual inspection. AOI systems are preliminarily used for the detection of defects such as soldering defects, component defects, and ball grid arrays (BGA), and chip-scale packaging (CSP) defects.

https://www.marketsandmarkets.com/Market-Reports/automated-optical-inspection-system-market-179056156.html

The global automated optical inspection (AOI) system market size is expected to reach USD 1,583 million by…

Automated Optical Inspection Market Report 2018: Segmentation by Type (2D AOI Sy …

Global Automated Optical Inspection market research report provides company profile for Nordson Corporation, Camtek Ltd, AOI Systems Ltd, Mirtec, Viscom AG, Daiichi Jitsugyo, Omron Corporation, Test Research Inc, VI Technology, Cyberoptics Corporation and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR…

Inline AOI Systems Market - Growth of Inline Aoi System Market Is Boosted By Inc …

Automated optical inspection (AOI) is a process of visual inspection which is operated automatically to detect different manufacturing defect such as catastrophic failure and quality defect. This technology is adopting by different types of manufacturer such as printed circuit board manufacturing, liquid - crystal display (LCD) manufacturing, transistor manufacturing, others. Moreover, AOI systems has been segmented in two types such as desktop AOI and Inline AOI systems. Inline AOI…

Fast Generation of production-oriented AOI Programs

The newest version of GOEPEL electronic’s AOI system software features a special highlight. An integrated debug statistics captures AOI relevant variations in the production process and provides them for statistical evaluations. Hence, OptiCon series AOI systems enable a highly effective and convenient optimisation of generated test programs. Increased false call rates, originated in process tolerances or component variations, can be directly counter measured.

The software package OptiCon PILOT 5.1…