Press release

Watch Out: 3D Printing Market Is Thriving Worldwide in 2025-2032 by Size, Share, Trends

"The 3D printing market, also known as additive manufacturing (AM), is experiencing a period of robust growth, transforming industries across the globe. This revolutionary technology allows for the creation of three-dimensional objects from digital designs by layering materials such as plastics, metals, ceramics, and composites. The key drivers fueling this expansion include the increasing demand for customized products, rapid prototyping, and efficient manufacturing processes. Technological advancements in materials science, printer technology, and software solutions are continuously improving the capabilities and applications of 3D printing. The market plays a crucial role in addressing global challenges by enabling decentralized manufacturing, reducing waste through optimized material usage, and facilitating the production of complex geometries previously unattainable with traditional methods. From creating intricate medical implants to building lightweight aerospace components, 3D printing is disrupting traditional manufacturing paradigms and driving innovation across various sectors. As sustainability becomes a growing concern, 3D printing offers a pathway to more environmentally friendly production by minimizing material waste and reducing the carbon footprint associated with transportation and logistics. The versatility and adaptability of 3D printing are making it an indispensable tool for companies seeking to enhance efficiency, reduce costs, and stay competitive in a rapidly evolving global marketplace. The convergence of these factors positions the 3D printing market for continued and substantial growth in the coming years, impacting industries from healthcare and aerospace to consumer goods and construction.

Get the full PDF sample copy of the report: (TOC, Tables and figures, and Graphs) https://www.consegicbusinessintelligence.com/request-sample/1563

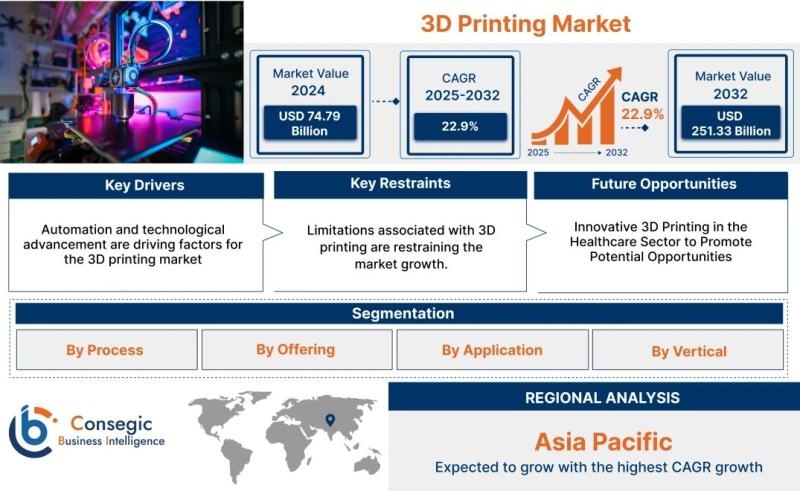

Market Size:

The 3D Printing Market size is estimated to reach over USD 134.27 Billion by 2031 from a value of USD 25.75 Billion in 2023 and is projected to grow by USD 31.20 Billion in 2024, growing at a CAGR of 22.9% from 2024 to 2031.

Definition of Market:

The 3D Printing Market, also known as the Additive Manufacturing (AM) market, encompasses the range of technologies, processes, materials, equipment, and related services involved in creating three-dimensional objects from digital designs. This is achieved by successively layering material upon material, building the object from the bottom up. The market includes various components, such as:

3D Printers: The machines that perform the additive manufacturing process. Different types of printers use different technologies and materials.

Materials: The substances used to create 3D printed objects, including plastics, metals, ceramics, composites, and biomaterials.

Software: CAD (Computer-Aided Design) software for creating and modifying 3D models, slicing software for preparing models for printing, and printer control software.

Services: Including design services, printing services (on-demand manufacturing), consulting, training, and maintenance services for 3D printing equipment.

Key terms associated with the market include:

Additive Manufacturing (AM): The general term for 3D printing processes.

Rapid Prototyping: Using 3D printing to quickly create prototypes of products.

Direct Digital Manufacturing (DDM): Using 3D printing for final part production rather than just prototyping.

Slicing: The process of dividing a 3D model into layers for printing.

Build Volume: The maximum size of an object that can be printed on a specific 3D printer.

Resolution: The level of detail that can be achieved in a 3D print.

The 3D printing market is constantly evolving with advancements in technology and materials, leading to new applications and opportunities across various industries.

Get Discount On Report @ https://www.consegicbusinessintelligence.com/request-discount/1563

Market Scope and Overview:

The scope of the 3D printing market is extensive, covering a wide array of technologies, applications, and industries. In terms of technologies, it includes various printing processes such as Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS), each suited for different materials and applications. The market caters to diverse applications ranging from prototyping and tooling to functional part manufacturing and customized medical devices. The industries served are equally broad, spanning aerospace, automotive, healthcare, consumer goods, education, and architecture, among others. This demonstrates the versatility and adaptability of 3D printing, making it a transformative force in manufacturing and design.

The 3D printing market's significance is amplified by its alignment with global trends such as mass customization, decentralized manufacturing, and sustainable production. As consumers increasingly demand personalized products, 3D printing provides a cost-effective means to deliver tailored solutions. The ability to produce goods on-demand and in close proximity to the end-user reduces the reliance on complex global supply chains, enhancing resilience and responsiveness. Furthermore, 3D printing supports sustainability by minimizing material waste through additive processes, enabling the use of recycled materials, and reducing the carbon footprint associated with transportation. In the context of Industry 4.0 and the digital transformation of manufacturing, 3D printing is a key enabler, facilitating innovation, accelerating product development cycles, and empowering businesses to create new value propositions. Its role in addressing global challenges related to healthcare, infrastructure, and environmental sustainability further underscores its importance in the broader global landscape.

Top Key Players in this Market

Stratasys (US) 3D Systems, Inc. (US) HP Development Company, L.P. (US) EOS GmbH (Germany) General Electric (US) Materialise NV (Belgium) Desktop Metal, Inc. (US) Protolabs (US) Optomec, Inc. (Mexico) Prodways Group (France)

Market Segmentation:

The 3D printing market is segmented based on various criteria, each contributing uniquely to its overall growth:

By Process: Includes Binder Jetting, Direct Energy Deposition, Material Extrusion, Material Jetting, Powder Bed Fusion, Sheet Lamination, and VAT Polymerization. Each process offers distinct advantages for different materials and applications.

By Offering: Comprises Printers (hardware), Materials (plastics, metals, ceramics), Services (design, printing, consulting), and Software (CAD, slicing). These components form the complete 3D printing ecosystem.

By Application: Encompasses Prototyping, Tooling, and Functional Part Manufacturing. These applications highlight the versatility of 3D printing across various stages of product development and production.

By Vertical: Includes Automotive, Aerospace & Defence, Healthcare, Architecture & Construction, Consumer Products, Education, and Energy. Each vertical leverages 3D printing for specific needs and applications within their respective industries.

These segments collectively drive market growth by catering to diverse customer needs and expanding the applicability of 3D printing technologies across various industries and functional areas.

Market Drivers:

Technological Advancements: Continuous improvements in printer technology, materials science, and software are enhancing the capabilities, speed, and precision of 3D printing, leading to wider adoption.

Increasing Demand for Customization: The growing consumer preference for personalized products is driving the demand for 3D printing, which enables cost-effective mass customization.

Rapid Prototyping and Product Development: 3D printing significantly reduces the time and cost associated with prototyping, accelerating product development cycles and fostering innovation.

Efficient Manufacturing Processes: 3D printing enables the production of complex geometries and intricate designs that are difficult or impossible to achieve with traditional manufacturing methods, leading to greater design freedom and efficiency.

Government Support and Policies: Government initiatives promoting advanced manufacturing, research funding, and supportive policies are fostering the growth of the 3D printing market.

Growing Awareness and Adoption: Increased awareness of the benefits and applications of 3D printing is driving adoption across various industries.

Sustainability Initiatives: The ability of 3D printing to reduce material waste, optimize energy consumption, and support localized production aligns with sustainability goals, attracting environmentally conscious businesses and consumers.

Market Key Trends:

Advancements in Materials: The development of new and improved materials, including high-performance polymers, advanced metals, and composites, is expanding the range of applications for 3D printing.

Integration of AI and Machine Learning: The use of artificial intelligence and machine learning is optimizing 3D printing processes, improving quality, and reducing errors.

Rise of Distributed Manufacturing: The trend towards decentralized production, enabled by 3D printing, is enhancing supply chain resilience and reducing transportation costs.

Focus on Sustainability: Increasing emphasis on environmentally friendly materials and processes is driving the development of sustainable 3D printing solutions.

Expansion into New Verticals: 3D printing is increasingly being adopted in emerging industries such as food, fashion, and construction.

Development of Hybrid Manufacturing: Combining 3D printing with traditional manufacturing techniques to leverage the strengths of both approaches.

Increasing Adoption of Metal 3D Printing: Metal 3D printing is gaining traction for producing high-performance parts in industries such as aerospace and automotive.

Market Opportunities:

Expanding Applications in Healthcare: Opportunities for customized medical implants, prosthetics, and surgical guides are growing rapidly.

Growth in the Aerospace and Automotive Sectors: Increasing use of 3D printing for lightweight components, tooling, and spare parts.

Development of New Materials: Opportunities for creating innovative materials with enhanced properties and functionalities.

Software and Services Market: Growth in demand for advanced software solutions and specialized services to support 3D printing operations.

Education and Training: Expanding opportunities for educational institutions and training providers to offer courses and programs in 3D printing.

Customization and Personalization: Growing demand for customized products in consumer goods and other industries.

On-Demand Manufacturing: Opportunities for providing on-demand manufacturing services to businesses of all sizes.

Market Restraints:

High Initial Costs: The upfront investment required for 3D printing equipment and materials can be a barrier for small and medium-sized enterprises.

Limited Material Availability: The range of materials that can be used in 3D printing is still limited compared to traditional manufacturing methods.

Scalability Challenges: Scaling up 3D printing production to meet mass-market demand can be challenging.

Technical Expertise: Operating and maintaining 3D printing equipment requires specialized skills and knowledge.

Intellectual Property Concerns: Protecting intellectual property in 3D printed designs can be complex.

Lack of Standardization: The absence of industry-wide standards can hinder the adoption and interoperability of 3D printing technologies.

Regulatory Hurdles: Regulatory frameworks for 3D printed products are still evolving in many industries.

Market Challenges:

The 3D printing market, despite its rapid growth and transformative potential, faces several significant challenges that could impede its progress. One of the primary challenges is the high cost associated with 3D printing technology. The initial investment in 3D printers, especially those capable of producing high-quality parts with advanced materials, can be substantial. This high cost often puts 3D printing out of reach for small and medium-sized enterprises (SMEs), limiting their ability to leverage this technology for innovation and manufacturing efficiency. Furthermore, the cost of materials, particularly specialty plastics and metals, can also be a significant barrier. Addressing this challenge requires developing more affordable printer technologies and finding ways to reduce material costs through bulk purchasing, recycling, or the development of alternative, lower-cost materials.

Another significant challenge is the limited range of materials available for 3D printing compared to traditional manufacturing processes. While the variety of printable materials has expanded in recent years, it still lags behind the diverse range of materials used in conventional manufacturing. This limitation restricts the applicability of 3D printing in certain industries and applications where specific material properties are critical. To overcome this challenge, ongoing research and development efforts are needed to expand the portfolio of printable materials, focusing on materials with enhanced mechanical, thermal, and chemical properties. Additionally, developing standardized material testing and certification processes is essential to ensure the reliability and consistency of 3D printed parts.

Scalability is another major hurdle for the 3D printing market. While 3D printing is well-suited for prototyping and small-batch production, scaling up to mass production levels can be challenging and expensive. Traditional manufacturing processes, such as injection molding, often offer superior economies of scale for large production runs. Overcoming this challenge requires improving the speed and efficiency of 3D printing processes, automating production workflows, and developing new printer technologies capable of handling larger volumes. Additionally, integrating 3D printing into existing manufacturing systems and supply chains is essential to leverage its benefits while maintaining scalability.

The lack of skilled workforce is also a significant constraint. Operating and maintaining 3D printing equipment requires specialized knowledge and expertise. However, there is a shortage of skilled professionals with the necessary training and experience in areas such as 3D printing design, materials science, and process optimization. Addressing this skills gap requires investing in education and training programs to develop a workforce capable of supporting the growth of the 3D printing market. Collaboration between industry, academia, and government is essential to create relevant training programs and ensure that the workforce is equipped with the skills needed to drive innovation and adoption of 3D printing technologies.

Finally, the lack of standardization and regulatory frameworks poses a challenge to the widespread adoption of 3D printing. The absence of industry-wide standards for materials, processes, and testing makes it difficult to ensure the quality and reliability of 3D printed parts. This can hinder the acceptance of 3D printing in regulated industries such as aerospace and healthcare, where safety and performance are paramount. Developing comprehensive standards and regulatory frameworks is essential to address these concerns and foster greater confidence in 3D printing technologies. This requires collaboration between industry stakeholders, regulatory agencies, and standards organizations to establish clear guidelines and protocols for the design, production, and testing of 3D printed products.

Market Regional Analysis:

The 3D printing market exhibits varying dynamics across different regions, influenced by factors such as economic development, technological infrastructure, and industry focus. North America has been a leading region, driven by strong adoption in aerospace, healthcare, and automotive sectors, coupled with significant R&D investments. Europe is also a key market, with a focus on industrial applications and sustainability, particularly in Germany and the UK. The Asia-Pacific region is experiencing rapid growth, fueled by increasing adoption in manufacturing, electronics, and healthcare, with China, Japan, and South Korea being key contributors.

Each region presents unique opportunities and challenges. North America benefits from a robust ecosystem of technology companies and research institutions, but faces challenges related to high labor costs and regulatory complexities. Europe's focus on sustainability drives innovation in materials and processes, but economic uncertainties can impact investment. Asia-Pacific offers cost-competitive manufacturing capabilities and a large consumer base, but faces challenges related to intellectual property protection and standardization.

Emerging markets in Latin America and the Middle East & Africa are also showing increasing interest in 3D printing, driven by infrastructure development, industrial diversification, and government support. These regions offer significant growth potential but face challenges related to infrastructure limitations and skills gaps. Understanding these regional dynamics is crucial for companies seeking to expand their presence in the 3D printing market and tailor their strategies to local conditions.

Frequently Asked Questions:

What are the growth projections for the 3D printing market?

The 3D Printing Market size is estimated to reach over USD 134.27 Billion by 2031 from a value of USD 25.75 Billion in 2023 and is projected to grow by USD 31.20 Billion in 2024, growing at a CAGR of 22.9% from 2024 to 2031.

What are the key trends in the 3D printing market?

Key trends include advancements in materials, integration of AI and machine learning, rise of distributed manufacturing, focus on sustainability, and expansion into new verticals.

What are the most popular 3D printing types?

Popular 3D printing types include Material Extrusion (FDM), Powder Bed Fusion (SLS, SLM), and VAT Polymerization (SLA, DLP), each suited for different materials and applications.

Follow Us on:

https://www.linkedin.com/company/deeptech-news/

https://www.linkedin.com/company/insights-futures/

https://www.linkedin.com/company/market-techpulse/

https://www.linkedin.com/company/market-radar-report/

https://www.linkedin.com/company/surveypulse-trends/

https://www.linkedin.com/company/market-insight-digest/

https://www.linkedin.com/company/diamonds-market-research-analytics/

https://www.linkedin.com/company/diamonds-business-intelligence-consulting/

https://www.linkedin.com/company/data-grid25/

https://www.linkedin.com/company/campaign-insight-grid/

https://www.linkedin.com/company/novaedge-market-consulting/

https://www.linkedin.com/company/data-craft-studio/

https://www.linkedin.com/company/searchsavvy-solutions/

https://www.linkedin.com/company/optisphere-seo/

https://www.linkedin.com/company/stratos-edge-consulting/

https://www.linkedin.com/company/news-insight/

https://www.linkedin.com/company/tech-disrupts-insight/

https://www.linkedin.com/company/tech-network25/"

Contact Us:

Consegic Business intelligence Pvt Ltd

Baner Road, Baner, Pune, Maharashtra - 411045

(US) (505) 715-4344

info@consegicbusinessintelligence.com

sales@consegicbusinessintelligence.com

Web - https://www.consegicbusinessintelligence.com/

About Us:

Consegic Business Intelligence is a data measurement and analytics service provider that gives the most exhaustive and reliable analysis available of global consumers and markets. Our research and competitive landscape allow organizations to record competing evolutions and apply strategies accordingly to set up a rewarding benchmark in the market. We are an intellectual team of experts working together with the winning inspirations to create and validate actionable insights that ensure business growth and profitable outcomes.

We provide an exact data interpretation and sources to help clients around the world understand current market scenarios and how to best act on these learnings. Our team provides on-the-ground data analysis, Portfolio Expansion, Quantitative and qualitative analysis, Telephone Surveys, Online Surveys, and Ethnographic studies. Moreover, our research reports provide market entry plans, market feasibility and opportunities, economic models, analysis, and an advanced plan of action with consulting solutions. Our consumerization gives all-inclusive end-to-end customer insights for agile, smarter, and better decisions to help business expansion.

Connect with us on:

LinkedIn - https://www.linkedin.com/company/consegic-business-intelligence/

YouTube - https://www.youtube.com/@ConsegicBusinessIntelligence22

Facebook - https://www.facebook.com/profile.php?id=61575657487319

X - https://x.com/Consegic_BI

Instagram - https://www.instagram.com/cbi._insights/

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Watch Out: 3D Printing Market Is Thriving Worldwide in 2025-2032 by Size, Share, Trends here

News-ID: 4052031 • Views: …

More Releases from Consegic Business Intelligence Pvt. Ltd

Europe Pharmaceutical Manufacturing Equipment Market 2025 Industry Updates, Futu …

Introduction:

The Pharmaceutical Manufacturing Equipment Market is experiencing robust growth, driven by a confluence of factors reshaping the landscape of pharmaceutical production. Increasing global demand for pharmaceuticals, fueled by an aging population and the rise of chronic diseases, necessitates advanced and efficient manufacturing processes. Technological advancements, such as continuous manufacturing, automation, and digitalization, are revolutionizing traditional methods, improving production efficiency, reducing costs, and enhancing product quality. Stringent regulatory requirements and the…

Europe Vibration Damping Materials Market Size 2025 Overview, Manufacturers, Typ …

Introduction:

The Vibration Damping Materials market is experiencing significant growth, driven by the increasing demand for noise and vibration reduction across various industries. Key drivers include stringent environmental regulations, the growing automotive industry, particularly the electric vehicle (EV) sector, and the need for enhanced comfort and safety in residential and commercial buildings. Technological advancements in materials science are also playing a pivotal role, with the development of more efficient and durable…

Europe Lightweight Aggregates Market Size 2025 Emerging Technologies, Opportunit …

Introduction:

The Lightweight Aggregates Market is experiencing substantial growth driven by several key factors. Primarily, the increasing demand for sustainable and eco-friendly construction materials is fueling the adoption of lightweight aggregates. These materials offer superior insulation properties, reduced transportation costs, and contribute to the overall reduction of the carbon footprint of construction projects. Technological advancements in the production and application of lightweight aggregates are also playing a crucial role, enhancing their…

Europe Visible Light Communication Market Share, Growth, Size, Industry Trends, …

Introduction:

The Visible Light Communication (VLC) market is experiencing significant growth, driven by the increasing demand for faster, more secure, and energy-efficient communication technologies. VLC leverages light waves for data transmission, offering a complementary solution to traditional radio frequency (RF) based wireless communication. Key drivers include the proliferation of LED lighting, growing concerns about RF spectrum congestion, and the need for secure communication in sensitive environments. Technological advancements, such as improved…

More Releases for Material

Firestop Material Market

LOS ANGELES, United States: The global Firestop Material market is carefully researched in the report while largely concentrating on top players and their business tactics, geographical expansion, market segments, competitive landscape, manufacturing, and pricing and cost structures. Each section of the research study is specially prepared to explore key aspects of the global Firestop Material market. For instance, the market dynamics section digs deep into the drivers, restraints, trends, and…

New Material Direction for Electric Toothbrushes - Si-TPV Soft Over Molded Mater …

When it comes to factors such as consumer experience or ergonomics, Si-TPV Soft Over Molded Material has had a huge impact on the improvement of various products such as electric toothbrushes, etc. Si-TPV is a Silicone Combine TPU developed and produced by SILIKE, a Thermoplastic Elastomer Manufacturer (Thermoplastic Elastomer Suppliers). Si-TPV material adopts Innovative Soft Slip Technology and Sustainable Overmolding Techniques, which can be used to make Stain Resistance Soft…

A new light on a misjudged material - Plastic waste: material for art

Used plastic bottles are not waste, but a valuable resource. They can be reprocessed in a variety of ways and transformed into new products or fresh energy. And into art. This is exactly what Ve-ronika Richterová does. The Czech artist creates fascinating sculp-tures made out of old PET bottles.

Plastic has inspired artists from the very beginning. The reason: plas-tic meets almost all technical and aesthetic requirements. It is a uni-versal…

Global Thermal Transfer Material Market, Global Thermal Transfer Material Indust …

Thermal conductivity refers as an important characteristic for several manufacturing operations. Thermal transfer properties of a variety of materials are effective in certain applications owing to natural molecular structure that allows for direct heat-transfer. Thermal transfer materials are extensively used to manufacture the heat conductive adhesive tapes, printable products and polymer sheets. These polymer sheets are utilized for barcodes, labeling, and QR code labels for retailing, logistics, and consumer goods.…

The Future of Smart Material Market Runs Through the Material Industry

Smart Materials Market is expected to garner $72.63 billion by 2022, registering a CAGR of 14.9% during the forecast period 2016-2022. Smart materials are adaptive or intelligent materials which pose intrinsic and extrinsic capabilities. These can be altered by external stimuli, such as moisture, temperature, electromagnetic field, and pressure to obtain the desired functional effects. In addition, these materials are dynamic in nature and respond to their immediate interaction environments…

Global Regenerative Artificial Skin Sales Market Research Report 2017 (Temporary …

The report "Global Regenerative Artificial Skin Sales Market Report 2017", has been prepared based on an in-depth market analysis with inputs from industry experts.

This report studies sales (consumption) of Regenerative Artificial Skin in Global market, especially in United States, China, Europe and Japan, focuses on top players in these regions/countries, with sales, price, revenue and market share for each player in these regions, covering

Integra Life Sciences Corporation

Mylan N.V

Johnson & Johnson…