Press release

Metal Stamping Market Size, Share, Analysis Trends & Forecast 2033

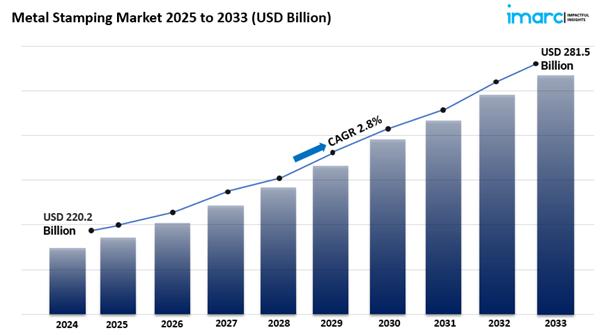

IMARC Group, a leading market research company, has recently released a report titled "Metal Stamping Market Size, Share, Trends and Forecast Report by Material, Press Type, Process, Application, and Region, 2025-2033". The study provides a detailed analysis of the industry, including the global metal stamping market share, trends, size, and industry trends forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.The global metal stamping market size was valued at USD 220.2 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 281.5 Billion by 2033, exhibiting a CAGR of 2.8% during 2025-2033.

Request to Get the Sample Report:

https://www.imarcgroup.com/metal-stamping-market/requestsample

Global Metal Stamping Market Trends:

The growth of the metal stamping market is also driven by the increasing adoption of renewable energy technologies. The production of solar panels, wind turbines, and other renewable energy equipment requires precise metal components, fueling demand for metal stamping processes to meet the rising global emphasis on sustainable energy solutions.

Furthermore, the market is further propelled by the expansion of the aerospace industry, which demands high-quality, durable metal components for aircraft manufacturing. Apart from this, the growing infrastructure and construction activities worldwide require robust metal parts, boosting the demand for stamped metal products in these sectors.

Factors Affecting the Growth of the Metal Stamping Industry:

· Technological advancements:

Advanced techniques such as progressive die stamping, four-slide stamping, and fine blanking have improved the efficiency, precision, and versatility of metal stamping processes. Progressive die stamping, for instance, allows for multiple operations like punching, bending, and piercing to be carried out simultaneously on a single piece of metal, significantly reducing production time and costs.

Furthermore, the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems has enhanced the accuracy and repeatability of stamped metal parts. These advancements enable manufacturers to produce complex and intricate designs with high precision, meeting the stringent quality standards of various industries.

Additionally, the adoption of automation and robotics in metal stamping has led to higher production rates, lower labor costs, and minimized human error, further driving the market forward.

· Rise of the automotive industry:

Stamped metal components are integral to vehicle manufacturing, used in body panels, chassis, engine parts, and other critical components. The increasing production of vehicles globally, driven by rising consumer demand and the expansion of automotive manufacturing in emerging economies, has boosted the demand for metal stamping.

Furthermore, the shift towards electric vehicles (EVs) and the need for lightweight, fuel-efficient vehicles have spurred innovations in metal stamping. Lightweight materials such as aluminum and high-strength steel are increasingly used in automotive stamping to reduce vehicle weight and improve fuel efficiency, aligning with stringent environmental regulations. The automotive industry's emphasis on high-volume production and cost-efficiency also complements the scalability and economic advantages of metal stamping, making it an indispensable process in automotive manufacturing.

· Increasing demand for consumer electronics:

Consumer electronics, including smartphones, laptops, tablets, and wearables, require precision-engineered metal components for their housings, connectors, and various internal parts. The miniaturization trend in electronics has heightened the need for highly accurate and intricate metal-stamped parts. Metal stamping provides the necessary precision and repeatability for producing small, complex components essential for modern electronic devices.

Moreover, the rapid pace of technological advancements in consumer electronics leads to frequent product launches and updates, necessitating efficient and flexible manufacturing processes. Metal stamping meets these requirements by offering fast turnaround times and the ability to adapt to design changes quickly.

Additionally, the growing trend of smart homes and the Internet of Things (IoT) further propels the demand for stamped metal parts used in a wide array of connected devices, reinforcing the importance of metal stamping in the consumer electronics sector.

Buy Now: https://www.imarcgroup.com/checkout?id=2152&method=1670

Metal Stamping Market Report Segmentation:

By Material:

· Steel

· Aluminum

· Copper

· Others

Steel represents the largest segment due to its high strength, durability, and cost-effectiveness making it the preferred material for a wide range of metal stamping applications.

By Press Type:

· Mechanical Press

· Hydraulic Press

· Servo Press

Mechanical press dominates the market because it offers high-speed operation and precision, making them ideal for large-scale production in the metal stamping industry.

By Process:

· Blanking

· Embossing

· Bending

· Coining

· Deep Drawing

· Flanging

· Others

Blanking accounts for the majority of the market share as it is a fundamental process in metal stamping, enabling the efficient production of precise and uniform parts.

By Application:

· Automotive

· Industrial Machinery

· Consumer Electronics

· Aerospace

· Electrical and Electronics

· Healthcare

· Defense

· Telecommunications

· Others

Automotive stores represent the largest market segment as they require extensive use of metal-stamped components for vehicle manufacturing.

Regional Insights:

· North America

· Europe

· Asia Pacific

· Latin America

· Middle East and Africa

Asia Pacific leads the market, with its robust manufacturing base, growing industrialization, and expanding automotive and electronics sectors driving the high demand for metal stamping in the region.

Competitive Landscape with Key Players:

The competitive landscape of the metal stamping market size has been studied in the report with the detailed profiles of the key players operating in the market.

Some of These Key Players Include:

· Acro Metal Stamping

· American Axle & Manufacturing Inc.

· American Industrial Company

· Arconic Corporation

· Aro Metal Stamping Company Inc.

· Caparo Engineering India Limited

· CIE Automotive

· Clow Stamping Company Inc.

· D&H Industries (Vista Equity Partners)

· Goshen Stamping LLC

· Interplex Industries Inc. (Amtek Engineering)

· Kenmode Precision Metal Stamping

· Klesk Metal Stamping Inc.

· Tempco Manufacturing Company Inc.

Ask Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=2152&flag=C

Key Highlights of the Report:

· Market Performance (2019-2024)

· Market Outlook (2025-2033)

· Market Trends

· Market Drivers and Success Factors

· Impact of COVID-19

· Value Chain Analysis

If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

Contact Us:

IMARC Group

134 N 4th St

Brooklyn, NY 11249, USA

Website: imarcgroup.com

Email: sales@imarcgroup.com

Americas: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Metal Stamping Market Size, Share, Analysis Trends & Forecast 2033 here

News-ID: 4051383 • Views: …

More Releases from IMARC Group

LED Ceiling Light Manufacturing Plant DPR 2026: Machinery, CapEx/OpEx, ROI and R …

Setting up an LED ceiling light manufacturing plant positions investors in one of the most dynamic and rapidly expanding segments of the global lighting and energy efficiency value chain, driven by increasing demand for energy-efficient lighting solutions, growing awareness of sustainability, rapid urbanization and infrastructure development, and advancements in smart lighting technologies across residential, commercial, industrial, and public sector applications worldwide.

Market Overview and Growth Potential:

The global LED ceiling light market…

Aluminium Recycling Plant DPR & Unit Setup - 2026: Demand Analysis and Project C …

Setting up an aluminium recycling plant positions investors in one of the most stable and essential segments of the circular economy and sustainable materials value chain, backed by sustained global growth driven by increasing sustainability initiatives, rising demand from automotive and construction sectors, stringent carbon emission regulations, and the growing adoption of circular economy practices across industrial value chains. As industries seek to reduce carbon footprints, automotive manufacturers adopt lightweight…

Cassava Starch Manufacturing Plant DPR 2026: Raw Materials, Machinery Cost and R …

Setting up a cassava starch manufacturing plant positions investors in one of the most versatile and rapidly expanding segments of the global agri-processing and industrial starch value chain, driven by rising demand from the food processing, paper, textile, pharmaceutical, and biodegradable packaging industries, along with increasing consumer and industry preference for gluten-free, clean-label, and plant-based ingredients.

Market Overview and Growth Potential:

The global cassava starch market demonstrates a robust growth trajectory, valued…

G-Salt Manufacturing Plant DPR 2026: Investment Cost, Market Growth & ROI

Setting up a g-salt manufacturing plant positions investors in one of the most stable and essential segments of the industrial specialty chemicals value chain, backed by sustained global growth driven by rising demand from industrial water treatment, increasing use in chemical processing, and growing applications in pharmaceuticals and food preservation. The g-salt market production and use are widely concentrated in Asia-Pacific and Europe regions, presenting compelling opportunities for manufacturers and…

More Releases for Metal

Metal Roofing Companies Revolutionizing the Industry: Classic Metal Roofs Leads …

Classic Metal Roofs has established itself as a leading provider of durable and energy-efficient roofing systems in Southern New England. With over 20 years of experience, the company is known for high-quality installations, customer satisfaction, and sustainable metal roofing solutions.

As homeowners increasingly seek durable and energy-efficient solutions, metal roofing companies continue to provide top-tier roofing systems. Among the industry leaders, Classic Metal Roofs [http://business.bigspringherald.com/bigspringherald/markets/article/abnewswire-2025-2-15-classic-metal-roofs-expert-aluminum-shingle-metal-roof-installation-and-services/] stands out for its commitment to…

Rare Metal Raw Materials - Boron(B) Metal

Boron Powder [https://www.urbanmines.com/boron-powder-product/]

Short Description:

Boron [,%20a%20chemical%20element%20with%20the%20symbol%20B%20and%20atomic%20number%205,%20is%20a%20black/brown%20hard%20solid%20amorphous%20powder.%20It%20], a chemical element with the symbol B and atomic number 5, is a black/brown hard solid amorphous powder. It is highly reactiveand soluble in concentrated nitric and sulfuric acids but insoluble in water, alcohol and ether. It has a high neutro absorption capacity. UrbanMines specializes in producing high purity Boron Powder with the smallest possible average grain sizes. Our standard powderparticle sizes average in the…

Metal Polishing Services Market Trends and Leading Players 2023-2030 | Metal Pol …

With a CAGR of 6.1%, the Metal Polishing Services Market is expected to grow from USD 1.5 billion in 2023 to USD 2.3 billion by 2030, offering a gleaming finish to metal surfaces for aesthetic and functional purposes.

Market Overview:

The Metal Polishing Services market is poised for rapid growth, driven by several pivotal drivers. There is a continuous demand for metal finishing and polishing services that improve the appearance and…

Metal-to-metal Seal Market 2021 | Detailed Report

Metal-to-metal Seal Market Forecasts report provided to identify significant trends, drivers, influence factors in global and regions, agreements, new product launches and acquisitions, Analysis, market drivers, opportunities and challenges, risks in the market, cost and forecasts to 2027.

Get Free Sample PDF (including full TOC, Tables and Figures) of Metal-to-metal Seal Market @ https://www.reportsnreports.com/contacts/requestsample.aspx?name=5089735

The report provides a comprehensive analysis of company profiles listed below:

- Parker

- CPI

- HTMS

- American Seal &…

Metal Polishing Services Market Research Report 2020 Analysis: Enhanced Growth a …

Metal Polishing Services Market

Global Metal Polishing Services Market is providing the summarized study of several factors encouraging the growth of the market such as manufacturers, market size, type, regions and numerous applications. By using the report consumer can recognize the several dynamics that impact and govern the market. For any product, there are several companies playing their role in the market, some new, some established and some are planning to…

Worldwide Recycled Metal Market By Metal 2024 | Nucor, Steel Dynamics, Schnitzer …

The 2018-2024 report on global Recycled Metal market explores the essential factors of Recycled Metal industry covering current scenario, market demand information, coverage of active companies and segmentation forecasts.

North America recycled metal market was estimated close to USD 8.5 billion in 2017. This is mainly attributed to strong presence of transportation, electrical & electronics and defense industry which majorly constitute to the overall product demand. Moreover, strict laws formulated…