Press release

Aerospace Coating Market Size, Share & Growth Trends Report 2025-2033

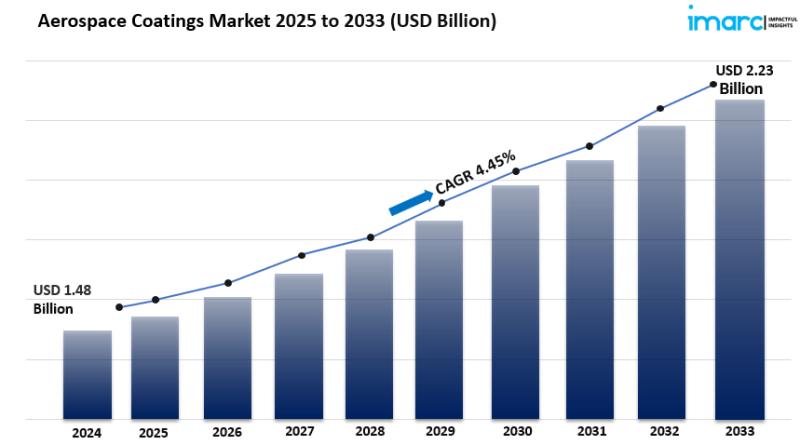

IMARC Group, a leading market research company, has recently released a report titled "Aerospace Coatings Market Size, Share, Trends and Forecast by Resin Type, Product Form, Application, Aircraft Type, End User, and Region, 2025-2033". The study provides a detailed analysis of the industry, including the Education and learning analytics market trends, share, size, and industry growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.The global aerospace coatings market size was valued at USD 1.48 Billion in 2024. Looking forward, IMARC Group estimates the market to reach USD 2.23 Billion by 2033, exhibiting a CAGR of 4.45% during 2025-2033.

Request to Get the Sample Report:

https://www.imarcgroup.com/aerospace-coatings-market/requestsample

Aerospace Coatings Market Trends

The aerospace coatings market is set to evolve significantly, influenced by various trends that reflect the changing dynamics of the aviation industry. One of the most notable trends is the increasing focus on sustainability and the development of eco-friendly coatings. By 2025, manufacturers are expected to prioritize low-VOC and water-based formulations that minimize environmental impact while maintaining high performance standards. This shift is driven by regulatory pressures and a growing awareness of environmental issues among consumers and industry stakeholders.

Additionally, the demand for advanced coatings that provide superior protection against corrosion, wear, and environmental stressors is expected to rise as airlines seek to extend the lifespan of their aircraft and reduce maintenance costs. Innovations in coating technologies, such as self-healing and anti-icing coatings, are also gaining traction, offering enhanced functionality and performance.

Furthermore, the integration of digital technologies in coating applications is anticipated to streamline processes and improve quality control, enabling manufacturers to deliver more precise and effective coatings. Overall, the aerospace coatings market is poised for growth, characterized by a blend of sustainability, innovation, and technological advancements that align with the future needs of the aviation sector.

Market Dynamics of the Aerospace Coatings Market

Rising Demand for Lightweight and Durable Coatings

The aerospace coatings market is experiencing significant growth driven by the increasing demand for lightweight and durable materials in aircraft manufacturing and maintenance. As airlines and manufacturers strive to improve fuel efficiency and reduce operational costs, the focus has shifted towards using advanced coatings that enhance the performance and longevity of aircraft components.

By 2025, the trend towards lightweight materials is expected to accelerate, with aerospace manufacturers seeking coatings that provide robust protection against environmental factors while minimizing weight. Innovations in polymer technology and nanotechnology are leading to the development of coatings that offer superior adhesion, corrosion resistance, and thermal stability without adding significant weight to the aircraft.

This demand for lightweight coatings is particularly pronounced in the commercial aviation sector, where fuel efficiency is paramount. As a result, the aerospace coatings market is poised for substantial growth, driven by the need for high-performance, lightweight solutions that meet the rigorous demands of modern aviation.

Technological Advancements in Coating Applications

Technological advancements in coating application techniques are transforming the aerospace coatings market, enhancing the efficiency and effectiveness of coatings used in aircraft manufacturing and maintenance. Innovations such as advanced spray technologies, electrostatic application, and automated coating processes are enabling manufacturers to achieve more uniform and consistent coatings, reducing waste and improving application speed. By 2025, the adoption of these advanced application methods is expected to increase, driven by the need for precision and quality in aerospace components.

Additionally, the integration of digital technologies, such as 3D printing and additive manufacturing, is allowing for the creation of complex geometries and custom coatings tailored to specific aircraft parts. These advancements not only improve the overall performance of aerospace coatings but also contribute to reduced turnaround times in manufacturing and maintenance processes. As the industry embraces these technological innovations, the aerospace coatings market is likely to see an influx of high-quality, efficient, and sustainable coating solutions that cater to the evolving needs of the aviation sector.

Sustainability and Environmental Regulations

Sustainability and environmental regulations are becoming increasingly important in shaping the aerospace coatings market. With growing concerns over environmental impact and stricter regulatory frameworks, manufacturers are under pressure to develop eco-friendly coatings that comply with environmental standards.

By 2025, the demand for low-VOC (volatile organic compounds) and water-based coatings is expected to rise as the aerospace industry seeks to reduce its carbon footprint and adhere to sustainability goals. This shift towards environmentally friendly coatings is prompting manufacturers to invest in research and development to create innovative products that offer high performance without compromising environmental standards.

Furthermore, the emphasis on sustainability is influencing supply chain decisions, with airlines and manufacturers favoring suppliers that prioritize eco-friendly practices and materials. As a result, the aerospace coatings market is evolving to meet the challenges of sustainability and regulatory compliance, positioning itself for growth in a rapidly changing industry landscape.

Buy Now: https://www.imarcgroup.com/checkout?id=3130&method=1670

Aerospace Coatings Market Report Segmentation:

Breakup By Resin Type:

· Epoxy

· Acrylic

· Polyurethane

· Others

The market is segmented by resin type into epoxy, acrylic, polyurethane, and others.

Breakup By Product Form:

· Liquid

· Powder

· Others

Based on product form, the market is segmented into liquid, powder, and others.

Breakup By Application:

· Exterior

· Interior

Based on application, the market is segmented into exterior and interior.

Breakup By Aircraft Type:

· Commercial

· Military

· Others

Based on aircraft type, the market is segmented into commercial, military, and other categories.

Breakup By End User:

· Original Equipment Manufacturers (OEMs)

· Maintenance, Repair and Overhaul Companies (MRO Companies)

Based on the end user, the market is segmented into original equipment manufacturers (OEMs) and maintenance, repair, and overhaul (MRO) companies.

Breakup By Region:

· North America

· Asia Pacific

· Europe

· Latin America

· Middle East and Africa

Region-wise, the market has been segmented into North America (United States and Canada), Asia-Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others), Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others), Latin America (Brazil, Mexico, and others), and the Middle East and Africa.

Top Aerospace Coatings Market Leaders:

The aerospace coatings market research report provides a comprehensive analysis of the competitive landscape, featuring detailed profiles of key industry players.

Some of the key players in the market are:

· Aalberts Surface Treatment GmbH

· Akzo Nobel N.V.

· Axalta Coating Systems Ltd.

· Henkel AG & Co. KGaA

· Hentzen Coatings Inc.

· IHI Ionbond AG

· Mankiewicz Gebr. & Co. (GmbH & Co. KG)

· PPG Industries Inc.

· Saint-Gobain S.A.

· The Sherwin-Williams Company

· Zircotec Ltd.

Ask Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=3130&flag=C

Key Highlights of the Report:

· Market Performance (2019-2024)

· Market Outlook (2025-2033)

· Market Trends

· Market Drivers and Success Factors

· Impact of COVID-19

· Value Chain Analysis

If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

Contact Us:

IMARC Group

134 N 4th St

Brooklyn, NY 11249, USA

Website: imarcgroup.com

Email: sales@imarcgroup.com

Americas: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aerospace Coating Market Size, Share & Growth Trends Report 2025-2033 here

News-ID: 4047947 • Views: …

More Releases from IMARC Group

China Tea Market Forecast CAGR of 8.13%, Innovation Trends, and Strategic Insigh …

Market Overview

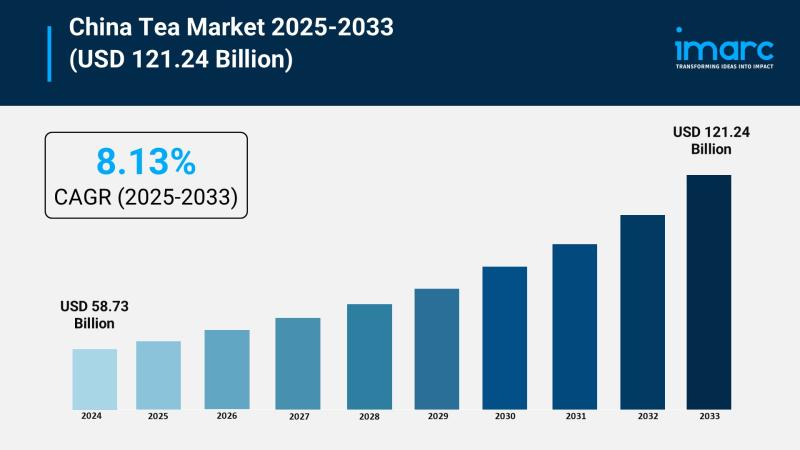

The China tea market was valued at USD 58.73 Billion in 2024 and is projected to reach USD 121.24 Billion by 2033, growing at a CAGR of 8.13% during 2025-2033. Growth is driven by rising health consciousness, premium product trends, government support, and expanding online retail. Innovation in flavors and packaging attracts younger consumers and global buyers, expanding the market.

Study Assumption Years

• Base Year: 2024

• Historical Year/Period: 2019-2024

• Forecast Year/Period: 2025-2033

China Tea…

Philippines Dairy Market 2026: Expected to Reach USD 33,997.8 Million by 2034

Market Overview

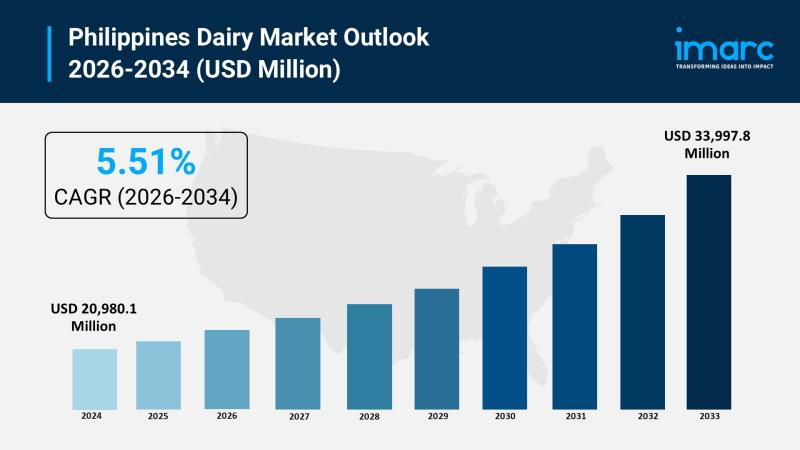

The Philippines dairy market reached a size of USD 20,980.1 Million and is anticipated to grow to USD 33,997.8 Million by 2034 with a significant growth rate of 5.51%. This expansion is driven by rising demand for nutritious and diverse dairy products, rapid urbanization, increased disposable incomes, improved retail infrastructure, and strong government initiatives promoting local dairy production. Health-conscious consumers and expanding food service sectors further fuel this growth…

Philippines Vitamins Market 2026 | Projected to Reach USD 556.0 Million by 2034

Market Overview

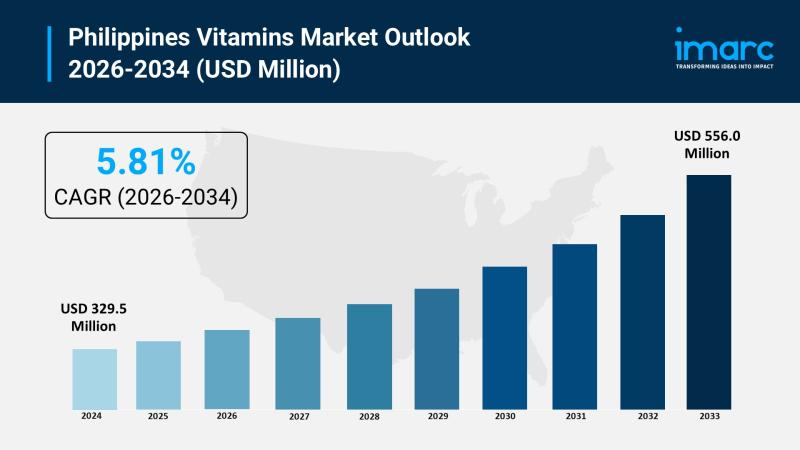

The Philippines vitamins market was valued at USD 329.5 Million in 2025 and is projected to reach USD 556.0 Million by 2034, growing steadily over the forecast period. The market's growth is driven by increasing health consciousness, a rising geriatric population, and escalating demand for supplements that support immunity, energy, and overall wellness due to proactive health measures. The forecast period for this expansion is 2026-2034, with a CAGR…

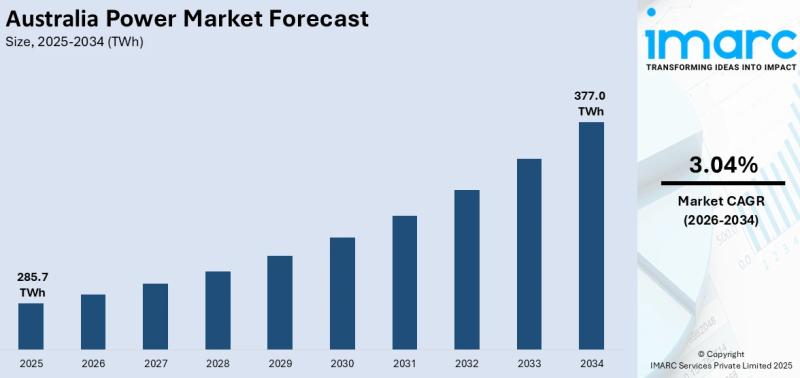

Australia Power Market Projected to Reach TWH 377 by 2034

Market Overview

The Australia power market size reached 285.7 TWh in 2025 and is projected to grow to 377.0 TWh by 2034, with a CAGR of 3.04% during the forecast period of 2026-2034. This growth is driven by rising renewable energy adoption, increased electricity demand, grid modernization, battery storage expansion, transition from coal plants, and government incentives for clean power. Key strategies such as virtual power plant integration and investments in…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…