Press release

Colloidal Silica in Precision Casting: The Hidden Backbone of High-Performance Industrial Components

In the expanding landscape of advanced materials and industrial chemicals, colloidal silica rarely receives the spotlight it deserves. Most reports tend to emphasize its utility in electronics polishing, coatings, and paints. However, a significantly underappreciated yet critical application lies in its role as a binder in precision casting, especially in industries where perfection is non-negotiable. From jet turbine blades to orthopedic implants, colloidal silica forms the silent foundation that ensures dimensional accuracy and surface integrity. This article explores this niche yet impactful corner of the colloidal silica market and explains how its importance is only growing with evolving manufacturing demands.Make Informed Decisions - Access Your Sample Report Instantly! https://www.futuremarketinsights.com/reports/sample/REP-GB-6499

Understanding the Chemistry and Functionality of Colloidal Silica in Casting Binders

Colloidal silica, a suspension of fine amorphous silica particles in water, behaves uniquely when used as a binder in investment casting or precision mold making. Its particle size, typically in the range of 10 to 100 nanometers, offers a large surface area which enhances the adhesive strength of ceramic shell molds used in investment casting. When used as a binder, colloidal silica enables the mold to develop excellent green and fired strength, meaning the mold maintains its shape both during the drying stage and under extreme casting temperatures.

Unlike organic binders, colloidal silica is inorganic and leaves no carbon residue during burnout, thus supporting a cleaner and more controlled casting environment. Its low volatility and chemical stability are instrumental in producing parts with near-net-shape dimensions, reducing the need for extensive machining or surface finishing. This makes colloidal silica indispensable in industries where tolerances are tight, and performance requirements are rigorous.

Precision Casting Applications: Where Performance Demands Perfection

In investment casting-a subset of precision casting-colloidal silica binders are used to form ceramic shells around wax patterns. These shells, after dewaxing and firing, are filled with molten metals like titanium, nickel alloys, or cobalt-chromium, creating components with complex geometries and fine features. The critical role of colloidal silica here is to ensure mold integrity and thermal shock resistance, both of which are necessary to prevent cracking or deformation during metal pouring.

Unlock Comprehensive Market Insights - Explore the Full Report Now: https://www.futuremarketinsights.com/reports/colloidal-silica-market

Aerospace is a sector that exemplifies the demanding nature of such applications. Turbine blades, for instance, must maintain aerodynamic performance at extremely high temperatures. These components are cast with molds bonded by high-purity colloidal silica slurry, which delivers the thermal stability and detail reproduction essential to ensure optimal performance. Similarly, in the medical device sector, orthopedic implants require a flawless finish and accurate dimensions to integrate with the human body effectively. Colloidal silica's contribution to achieving that level of precision in mold formation is foundational.

Case Studies: Aerospace and Medical Innovations Driven by Silica-Based Binders

A real-world example is evident in the manufacturing practices of GE Aviation and Rolls-Royce, both of which use investment casting techniques to produce turbine blades. These components undergo multiple shell-dipping and drying cycles, each facilitated by colloidal silica to build a robust ceramic mold. High-purity colloidal silica ensures that even the tiniest cooling channels and aerodynamic profiles are faithfully reproduced.

In the medical field, companies like Zimmer Biomet and Stryker have integrated investment casting methods that rely on silica-bonded ceramic shells for producing joint replacement components. These parts not only require exceptional dimensional fidelity but also a biocompatible surface finish, which can be achieved by casting into molds formed using colloidal silica slurry.

Market Growth Factors and Regional Trends Supporting This Niche Demand

Although not as widely discussed in market summaries, the demand for colloidal silica in investment casting is quietly rising, supported by the increasing complexity of industrial parts and the trend toward lightweight metal components. According to Future Market Insights, high-performance materials will drive end-use sector growth which will expand the market from USD 282.6 million in 2025 to USD 398.7 million by 2035 at a rate of 3.5% CAGR throughout the forecast period.

Asia-Pacific countries, particularly China and India, are emerging as hotspots for precision casting using colloidal silica due to the growth of domestic aerospace manufacturing and automotive component export. European foundries are also pivoting toward silica-based binders to meet increasingly stringent environmental and quality regulations. While polishing and coatings still command the majority share in colloidal silica applications, the precision casting sector exhibits a strong compound annual growth rate (CAGR), particularly in high-purity grades.

General & Advanced Materials Industry Analysis: https://www.futuremarketinsights.com/industry-analysis/general-and-advanced-materials

Future Pathways and Untapped Opportunities in Precision Casting

Colloidal silica is more than just an industrial chemical-it is a precision enabler. In the high-stakes environments of aerospace, medical, and defense manufacturing, its role as a binder in ceramic mold formation is indispensable. As industries continue to chase tighter tolerances, lighter materials, and cleaner processes, the importance of colloidal silica in precision casting will only grow.

Emerging technologies such as additive manufacturing combined with investment casting are also likely to increase the demand for colloidal silica-based slurries. With its ability to deliver exceptional performance in challenging conditions, colloidal silica has moved from the periphery to the core of precision manufacturing strategies. For stakeholders in the market, recognizing and investing in this underexplored application could offer a significant competitive advantage.

Colloidal Silica Market by Category

By Product Type:

- Alkaline Colloidal Silica

- Acidic Colloidal Silica

- Modified Colloidal Silica

- Ordinary Colloidal Silica

By Application:

- Pulp & Paper

- Metals & Metallurgy

- Electronics & Semiconductors

- Chemicals

- Paints & Coatings

- Building & Construction

- Textiles & Fabrics

By Region:

- North America

- Latin America

- Europe

- South Asia

- East Asia

- Oceania

- MEA

Related Reports:

Bromine Market: https://www.futuremarketinsights.com/reports/bromine-market

Bonded Magnets Market: https://www.futuremarketinsights.com/reports/bonded-magnets-market

Sailcloth Market: https://www.futuremarketinsights.com/reports/sailcloth-market

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

About Future Market Insights (FMI)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Colloidal Silica in Precision Casting: The Hidden Backbone of High-Performance Industrial Components here

News-ID: 4047398 • Views: …

More Releases from Future Market Insights

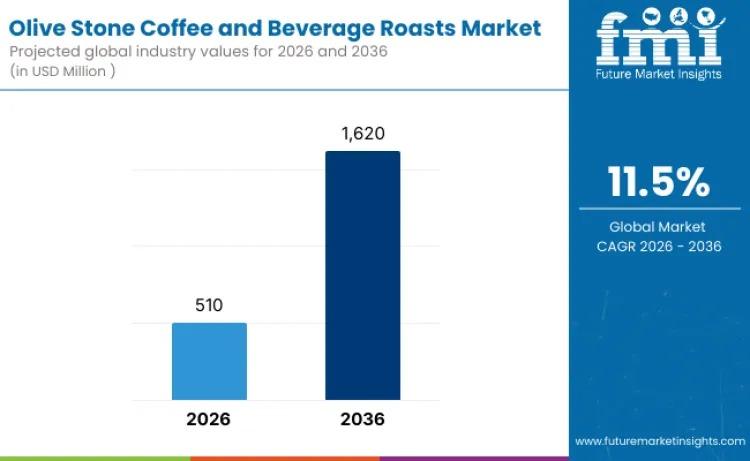

Global Olive Stone Coffee and Beverage Roasts Market to Reach USD 1,620 Million …

The global olive stone coffee and beverage roasts market is entering a high-growth decade, fueled by sustainability innovation and evolving specialty coffee culture. Valued at USD 510 million in 2026, the market is projected to reach USD 1,620 million by 2036, expanding at a compelling CAGR of 11.5%.

As consumers increasingly seek beverages that combine sustainability, functionality, and distinctive taste, olive stone-based roasting solutions are transitioning from niche experimentation to structured…

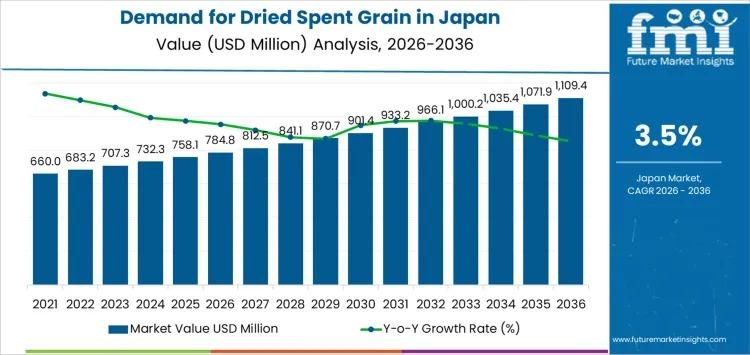

Japan Dried Spent Grain Market to Surpass USD 1.1 Billion by 2036 as Feed Optimi …

Japan's dried spent grain market is entering a decade of steady, value-driven expansion, supported by structured feed demand, brewery byproduct utilization, and rising integration of fiber-rich ingredients into food manufacturing. Industry estimates place the market at USD 784.8 million in 2026, with projections indicating growth to USD 1,109.4 million by 2036, reflecting a CAGR of 3.5%.

Between 2020 and 2026, demand increased from USD 637.5 million to USD 784.8 million, shaped…

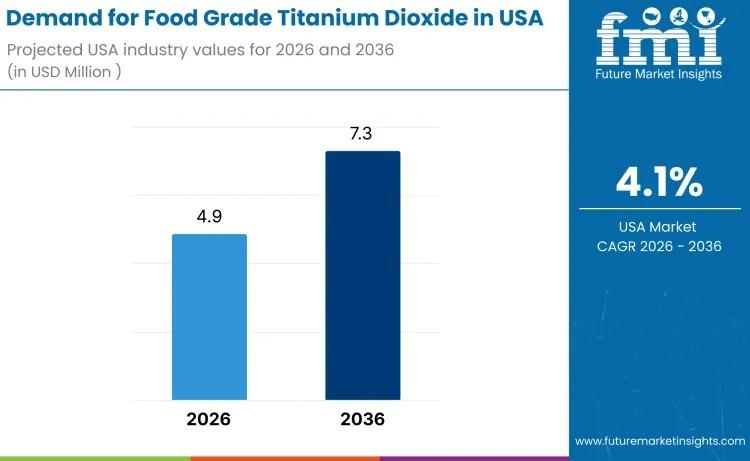

USA Food Grade Titanium Dioxide Market to Reach USD 7.3 Million by 2036 Amid Ste …

The demand for food grade titanium dioxide in the USA is valued at USD 4.9 million in 2026 and is projected to reach USD 7.3 million by 2036, expanding at a CAGR of 4.1%. Growth remains moderate yet stable, supported by continued use of titanium dioxide as a whitening and opacifying agent across confectionery coatings, bakery decorations, sauces, dairy analogues, and processed food matrices.

Despite heightened regulatory scrutiny and evolving clean-label…

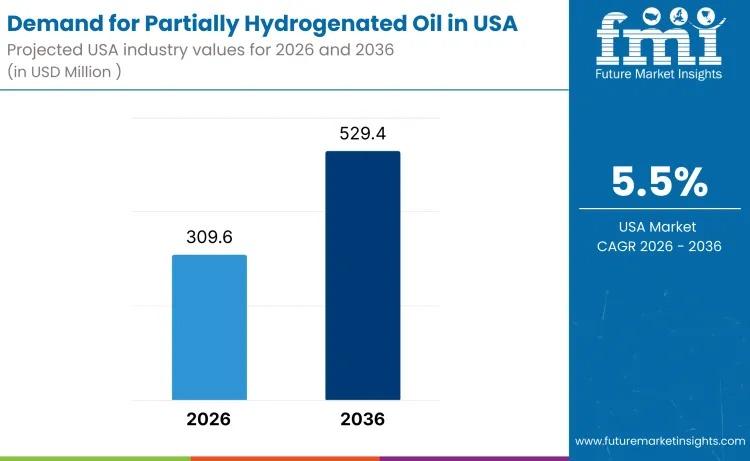

USA Partially Hydrogenated Oil Market to Reach USD 529.4 Million by 2036 Amid Me …

The demand for partially hydrogenated oil in the USA is projected to rise from USD 309.6 million in 2026 to USD 529.4 million by 2036, expanding at a steady CAGR of 5.5%. While edible applications remain tightly regulated, demand persists across specialty industrial and permitted food-related segments where oxidative stability, viscosity control, and texture performance remain critical.

Despite regulatory constraints on trans fats in conventional food manufacturing, PHOs continue to serve…

More Releases for Colloidal

Colloidal Silica Market Demand Analysis Report 2026

On Dec 11, the latest report "Global Colloidal Silica Market 2026 by Manufacturers, Regions, Types and Applications, Forecast to 2032" from Global Info Research provides a detailed and comprehensive analysis of the global Colloidal Silica market. The report provides both quantitative and qualitative analysis by manufacturers, regions and countries, types and applications. As the market is constantly changing, this report explores market competition, supply and demand trends, and key factors…

Track Colloidal Silicon Dioxide Price Report Historical and Forecast

Colloidal Silicon Dioxide Price Trend and Forecast Report | Global Market Insights Across North America, APAC, and Europe

Executive Summary

The global Colloidal Silicon Dioxide market demonstrated mixed yet predominantly upward pricing momentum across major regions in 2024 and 2025, supported by strong downstream demand from pharmaceuticals, nutraceuticals, food additives, and specialty chemicals. For the quarter ending September 2025, North America, APAC, and Europe all reported notable increases in their respective Colloidal…

Colloidal Silica For CMP Slurry Market

Colloidal Silica For CMP Slurry Market analysis report has recently added which helps to make informed business decisions. This research report further identifies the market segmentation along with their sub-types. The Global Colloidal Silica For CMP Slurry Market is expected to reach at a huge CAGR during the forecast period. Various factors are responsible for the market's growth, which are studied in detail in this research report.

The report envelops a…

Colloidal Silica Market Size, Share, Development by 2024

LP INFORMATION offers a latest published report on Colloidal Silica Market Analysis and Forecast 2019-2025 delivering key insights and providing a competitive advantage to clients through a detailed report.

Colloidal silica is silica particles that are suspended in a liquid. The liquid is denser than water and has been stabilized electrostatically to allow the particles to stay suspended in the solution.

The industry is mainly affected by the economic environment…

Colloidal Silver Market to Garner Brimming Revenues by 2028

Colloidal Silver Market Outlook:

Colloidal Silver is a natural substance consisting of sub-microscopic clusters of silver, held in a suspension of pure ionized water by a microscopic electric charge placed on each particle. Colloidal silver is considered as a natural antibiotic and used in several industries ranging from dietary supplement to water treatment. Colloidal silver has been utilized all through history to treat various diseases. Although colloidal silver based over the…

Colloidal Bismuth Pecti Market Outlook till 2018-2023

Future Market Reports on Global Colloidal Bismuth Pecti 2018 Research Report presents a professional and complete analysis of on the current Industry situation. The Global report includes Colloidal Bismuth Pecti Revenue, market Share, industry volume, Trends, Growth aspects. It analyses the important factors of the based on present industry situations, demands, business strategies utilized by Colloidal Bismuth Pecti market players and the future prospects from various angles in detail. Industry…