Press release

Electrical Appliance Coatings Market to Reach $11.2 Billion by 2031, Growing at 5.7% CAGR

The global electrical appliance coatings market was valued at US$ 6.8 billion in 2022 and is projected to reach US$ 11.2 billion by the end of 2031, growing at a CAGR of 5.7% from 2023 to 2031. This growth is driven by increasing demand for durable, aesthetic, and energy-efficient coatings across a wide range of home and industrial electrical appliances. Technological advancements and rising consumer preference for stylish, corrosion-resistant finishes are also fueling market expansion.Electrical appliance coatings provide thermal protection and ensure effective insulation to enhance the operational performance of electronic devices, thereby being extensively used in consumer electronics. Surge in demand for sustainable coating solutions in electronic industry is fostering market expansion.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=44628

Electrical appliance coatings are applied to various electrical components and appliances to provide insulation, protection, aesthetics, and functionality. These coatings enhance the performance, safety, and durability of electrical appliances.

Market Segmentation

The electrical appliance coatings market can be segmented in various ways to provide a detailed analysis:

By Product Type/Chemistry:

Epoxies: Widely used for their excellent adhesion, chemical resistance, and protective properties.

Acrylics: Known for their good weatherability, color retention, and aesthetic appeal.

Alkyds: Cost-effective and offer good adhesion, often used in less demanding applications.

Polyurethanes: Valued for their superior abrasion resistance, flexibility, and chemical resistance, often holding the highest market revenue share.

Polycarbonates: Used for their strength and heat resistance.

Others (e.g., Phenolics and Polyesters): Include specialized coatings for specific performance requirements.

Powder Coatings: Gaining traction due to their eco-friendly, low-VOC (Volatile Organic Compound) nature and excellent durability.

Liquid Coatings: Traditional coatings, including water-based and solvent-based options.

UV Curable Coatings: Offer fast curing times and excellent durability.

By Application/End-Use Industry:

Refrigeration Appliances: Including single-door and double-door models, demanding high corrosion resistance and aesthetic finishes.

Laundry Appliances: Requiring chemical resistance against detergents.

Dishwashers: Needing finishes to withstand high humidity and thermal cycling.

Air Treatment Appliances (e.g., Air Conditioners):

Cooking Appliances (e.g., Microwaves, Ovens): Require specialized finishes for high-temperature resistance.

Personal Care Appliances:

Entertainment Appliances (e.g., Televisions, Gaming Consoles, Audio Equipment): Driving demand for high-quality finishes and protective coatings that enhance aesthetics and durability.

Industrial Appliances: Such as heavy machinery and electrical equipment.

Automotive (EV components): Growing demand for protective coatings for battery systems and electrical components in electric vehicles.

By Sourcing Type: (While not explicitly detailed as "sourcing type" in the search results, this can refer to the origin of raw materials or manufacturing processes.)

Domestic Production: Focusing on reducing exposure to import duties and enhancing quality control.

International Sourcing: Leveraging global supply networks and trade agreements.

By Service Type: (This segmentation is not explicitly detailed in the provided search results for "Electrical Appliance Coatings Market." However, in a broader coatings context, services could include coating application, technical support, R&D, and maintenance.)

By Region:

Regional Analysis

The electrical appliance coatings market exhibits significant regional variations, driven by industrial capacity, regulatory frameworks, and consumer preferences.

Asia Pacific: Dominates the global market, accounting for a substantial share (e.g., 53.31% in 2021, and 35% in 2024). This is attributed to rapid industrialization, a thriving manufacturing sector, and growing consumer electronics demand in countries like China, Japan, India, and South Korea. Low-cost labor and raw materials also make the region an attractive manufacturing hub.

North America: Holds a significant market share (e.g., 30% in 2024), driven by demand for eco-friendly and high-performance coatings, along with a focus on product innovation and the rising popularity of smart appliances.

Europe: Follows closely with a substantial share (e.g., 25% in 2024), fueled by stringent sustainability initiatives and environmental regulations.

Latin America and Middle East & Africa: Collectively hold a smaller but steadily growing share (e.g., 10%), influenced by rising demand for appliances in developing economies.

Market Drivers and Challenges

Market Drivers:

Growing Demand for Durable and High-Performance Coatings: Manufacturers seek coatings that enhance appliance efficiency and longevity, particularly in consumer electronics.

Technological Advancements in Coating Materials: Innovations in areas like UV-cured coatings, nanocoatings, and eco-friendly formulations are expanding the range of protective solutions.

Rising Adoption of Smart Appliances: The increasing complexity of smart home appliances necessitates specialized coatings for insulation, corrosion resistance, and protection against electrical hazards.

Focus on Sustainability and Environmental Regulations: Stringent environmental regulations, especially in developed economies, are driving the adoption of waterborne, low-VOC, and powder coatings.

Increasing Disposable Incomes and Urbanization: Particularly in emerging economies, this fuels the demand for modern electrical appliances and, consequently, high-quality coatings.

Emphasis on Energy Efficiency: Coatings that improve thermal insulation and overall energy performance are in high demand.

Market Challenges:

High Cost of Advanced Coating Materials and Production Processes: Significant investment in specialized equipment and infrastructure can be a barrier for smaller manufacturers.

Stringent Regulatory Compliance: Concerns regarding the environmental impact of certain coating materials and regulations around harmful chemicals or heavy metals pose challenges.

Competition from Alternative Coating Technologies: The market faces competition from alternative solutions that may offer similar performance at lower costs.

Volatility in Raw Material Prices: Fluctuations in raw material costs can disrupt supply chains and impact profitability.

Supply Chain Issues and Geopolitical Shifts: Global events can affect the availability and pricing of raw materials.

Market Trends

Shift Towards Eco-friendly Coatings: A strong emphasis on water-based, powder, and low-VOC coatings to meet environmental regulations and consumer preferences for sustainable products.

Integration of Nanotechnology: Nanocoatings are offering enhanced performance characteristics, including superior protection against corrosion, abrasion, and UV degradation.

Development of Smart Coatings: Coatings with advanced functionalities such as self-healing, sensing, and antimicrobial properties are emerging.

Antimicrobial Coatings: Gaining momentum, particularly for kitchen and healthcare-related appliances, to enhance hygiene and safety.

Customized Formulations: Manufacturers are developing specialized coating formulations to cater to different types of appliances, usage conditions, and aesthetic preferences.

Increasing R&D Investments: Focus on developing advanced products with improved dielectric qualities, aesthetics, and regulatory compliance.

Future Outlook

The electrical appliance coatings market is poised for continued growth, driven by the increasing global demand for electrical appliances, particularly in developing countries. The ongoing focus on energy efficiency, sustainability, and technological advancements will be key to market expansion. The integration of cutting-edge coating technologies to improve appliance durability, safety, and aesthetic appeal will remain a primary objective for manufacturers. The shift towards electric vehicles will also be a significant driver for specialized coatings in their electrical components.

Key Market Study Points

Analysis of market value and volume (Kilo Tons).

Detailed segmentation by product type, application, and region.

Examination of market dynamics, including drivers, restraints, and opportunities.

Competitive landscape analysis, profiling key market players.

Assessment of raw material trends, pricing analysis, and regulatory frameworks.

Impact of macroeconomic factors and geopolitical scenarios on the market.

Forecasts for market growth across different segments and regions.

Competitive Landscape

The electrical appliance coatings market is characterized by the presence of both large multinational corporations and specialized regional players. Key companies operating in this market include:

DSM

Rust-Oleum

Henkel Adhesives Technologies India Private Limited

Altana

Evonik Industries

Nippon Electric Glass Co., Ltd.

Erie Powder Coatings

GMMDL

Axalta Coating Systems, LLC.

AGC Chemicals Europe, Ltd.

CEKO, Inc.

Daikin Industries, Ltd.

PPG Industries

AkzoNobel

Sherwin-Williams

These players are actively engaged in strategic investments, partnerships, and new product development to expand their market share and address evolving consumer demands and regulatory requirements.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=44628<ype=S

Recent Developments

PPG: Launched its PPG STEELGUARD 951 epoxy intumescent fire protection coating in the Americas (September 2024).

AkzoNobel: Introduced a new line of Resicoat EV powder coatings to preserve battery systems and electrical components in electric vehicles (July 2024).

Focus on Antiviral Technology: Key players are increasingly developing coatings with antiviral properties for enhanced hygiene and safety in appliances.

Capacity Expansion and Research: Firms are expanding their research and production capacities to meet increasing global demand and drive innovation.

The electrical appliance coatings market is a vital component of the modern manufacturing landscape, continuously evolving to meet the demands for more durable, efficient, and aesthetically pleasing electrical appliances. Its future success hinges on continued innovation and adaptation to sustainability trends and technological advancements.

Explore Latest Research Reports by Transparency Market Research:

High Purity Quartz Sand Market for UVC Lighting - https://www.transparencymarketresearch.com/uvc-lighting-high-purity-quartz-sand-market.html

Zinc-air Batteries Market - https://www.transparencymarketresearch.com/zin-cair-batteries-market.html

Fire Resistant Hydraulic Fluid Market - https://www.transparencymarketresearch.com/fire-resistant-hydraulic-fluid-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Electrical Appliance Coatings Market to Reach $11.2 Billion by 2031, Growing at 5.7% CAGR here

News-ID: 4045351 • Views: …

More Releases from transparencymarketresearch

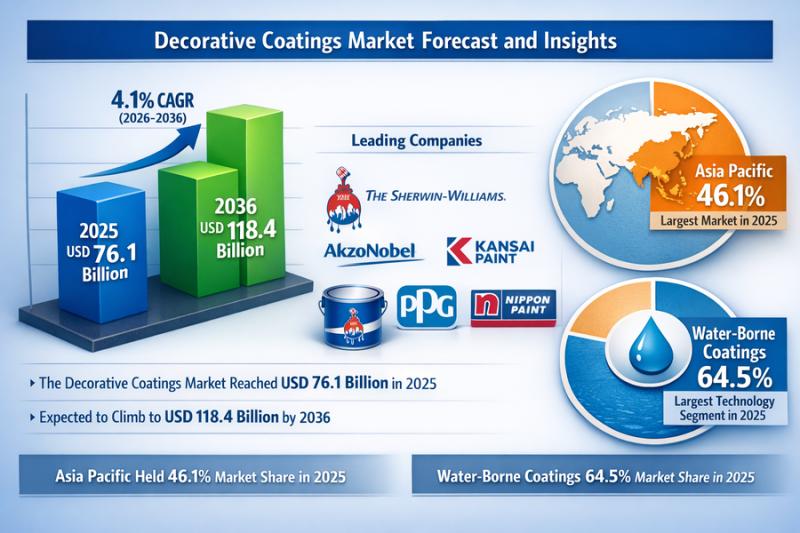

Decorative Coatings Market to Reach USD 118.4 Billion by 2036 at 4.1% CAGR

The decorative coatings market was valued at USD 76.1 billion in 2025 and is projected to reach USD 118.4 billion by 2036. The industry is expected to grow at a steady CAGR of 4.1% during the forecast period from 2026 to 2036, driven by rising construction activities, increasing demand for aesthetic building solutions, and ongoing product innovations.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1450

Market Overview

Decorative coatings are applied…

Europe and Asia Pacific Commercial Fuel Cards Market to Reach USD 1,042.2 Billio …

The Europe and Asia Pacific commercial fuel cards market was valued at USD 534.2 billion in 2025 and is projected to reach USD 1,042.2 billion by 2036, growing at a CAGR of 6.2% from 2026 to 2036. Market growth is driven by rising cross-border transportation demand across Europe and the rapid expansion of fuel retail networks in the Asia Pacific region.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85701

Market…

Air Fryer Market to Reach USD 2,343.9 Mn by 2036 Driven by Health-Focused Cookin …

The global air fryer market was valued at USD 1,103.4 Mn in 2025 and is projected to reach USD 2,343.9 Mn by 2036, expanding at a CAGR of 7.8% from 2026 to 2036. Market growth is primarily driven by rising health consciousness and increasing demand for low-oil cooking appliances among consumers. Busy urban lifestyles, compact kitchen trends, and the growing preference for convenient home-cooking solutions are further supporting adoption. Additionally,…

Global Yeast Market to Reach US$ 16.9 Bn by 2036 Driven by Bakery and Beverage D …

The global yeast market was valued at USD 9.7 Bn in 2025 and is projected to reach USD 16.9 Bn by 2036, expanding at a CAGR of 5.1% from 2026 to 2036. Market growth is primarily driven by increasing demand from the bakery and food processing industries, along with the steady expansion of alcoholic and non-alcoholic beverage production. Rising consumption of convenience foods and fermented products continues to support sustained…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…