Press release

Aluminium Anodizing Manufacturing Plant Cost: Business Plan and Detailed Project Report

Report Scope and Overview:Syndicated Analytics' latest report, titled "Aluminium Anodizing Manufacturing Plant Project Report 2025," serves as a comprehensive resource for entering the aluminium anodizing industry. It outlines key success drivers, risks, and performance indicators while offering an in-depth look at the manufacturing process, including flow diagrams and unit operations. The study also presents a location analysis covering site selection, environmental concerns, strategic importance, and cost implications. Financial aspects, such as startup capital and industry economics, are thoroughly addressed. This report is essential for entrepreneurs, investors, consultants, and researchers seeking actionable insights and data to support decision-making in aluminium anodizing plant development. It combines technical, strategic, and financial guidance in one comprehensive document.

Plant Setup Requirements:

Establishing an aluminium anodizing production plant requires comprehensive market research, coupled with in-depth understanding of multiple operational components. These include individual process stages, sourcing of raw materials, utility arrangements, infrastructure development, selection of machinery and technological systems, labor force organization, transportation logistics, and financial planning.

Request For a Sample Report:

https://www.syndicatedanalytics.com/aluminium-anodizing-manufacturing-plant-project-report/enquiryBeforeBuying

Aluminium Anodizing Manufacturing Plant Project Report Summary:

• A thorough study on establishing a aluminium anodizing production facility

• Insights into expected market developments and industry forecasts for 2025

• Step-by-step breakdown of plant setup, highlighting core processes and operational stages

• Specifications for raw materials and utility consumption

• Detailed requirements for machinery and structural facilities

• Staffing plans, including labor force composition and hiring needs

• Information on packaging standards and transport logistics

• Financial overview encompassing capital investment, cost breakdown, and income estimates

What is aluminium anodizing?

Aluminum anodizing is an electrochemical process that transforms the metal's surface. It creates a decorative, durable, and corrosion-resistant oxide finish. Unlike painting or plating, anodizing bonds the oxide layer to the aluminum. This makes it tough against chipping and peeling. The process involves dipping the aluminum part into an electrolytic solution, usually sulfuric acid. Then, an electric current runs through it. This reaction causes aluminum ions on the surface to combine with oxygen. This forms a uniform, porous oxide layer. We can control the thickness and porosity of this layer by changing the process parameters. Afterward, this porous layer can be dyed in various colors before sealing it. Sealing locks in the color and boosts corrosion resistance.

Market Drivers and Trends

The aluminium anodizing industry is growing rapidly, and this growth comes from the rising demand for lightweight, durable, and attractive materials in many sectors. The automotive industry drives much of this demand. Car makers want lighter vehicles to boost fuel efficiency and cut emissions. This need leads to more anodized aluminum parts in cars. The construction sector also plays a role, especially in architecture. Anodized aluminum is favored for its resistance to corrosion, low maintenance, and variety of colors. These features make it popular for facades, windows, and decorative elements. Additionally, the consumer electronics market significantly contributes. Anodized finishes are common on smartphones, laptops, and other devices because they look premium and resist scratches. Moreover, smart technologies are making their way into anodizing. For example, sensors can be embedded in anodized layers for monitoring. Ongoing research is exploring new electrolytes and additives to boost the performance of anodized coatings. Overall, the combination of sustainability efforts, technological progress, and diverse applications promises strong growth for the aluminium anodizing industry.

Buy Now: https://www.syndicatedanalytics.com/checkout?id=1273&method=48

Report Coverage:

The aluminium anodizing project report covers the following information:

Market Overview:

• Market Performance

• Regional Insights

• Key Market Segmentation

• Price Trend Analysis

• Market Outlook

• Market Key Players Analysis

The report offers an in-depth analysis of the aluminium anodizing market, highlighting recent performance metrics, key regional trends, and major segmentation categories. It includes a detailed review of pricing patterns, evaluates the competitive landscape featuring leading players, and presents forward-looking projections to assess future market direction and opportunities.

Manufacturing Operations:

• Product Description and Insights

• Detailed Process Flow

• Identification of Unit Operations Involved

• Mass Balance Analysis and Raw Material Requirements

• Quality Control

The report outlines the aluminium anodizing manufacturing process, offering a clear product overview and operational insights. It maps the complete process flow, identifies each unit operation, and presents a mass balance analysis with raw material needs. Quality control measures are also detailed to ensure consistent product standards.

Project Requirements, Details, and Costs:

• Site Development, Location, and Land Requirements

• Plant Layout

• Machinery Requirements and Associated Costs

• Raw Material Requirements and Associated Costs

• Packaging Requirements and Associated Costs

• Transportation Requirements and Associated Costs

• Utility Requirements and Associated Costs

• Manpower Requirements and Associated Costs

The report provides a thorough breakdown of project essentials, including land and site development needs, ideal plant layout, and detailed machinery specifications with costs. It also covers raw material, packaging, transportation, utility, and manpower requirements, offering a complete cost assessment for each to guide efficient plant setup and budgeting.

Project Financial Analysis:

• Capital Investments Analysis

• Operating Costs Analysis

• Expenditure Projections Analysis

• Revenue Projections Analysis

• Taxation and Depreciation Analysis

• Profit Projections Analysis

• Comprehensive Financial Analysis

The report delivers a detailed financial evaluation, covering capital investment needs, operating expenses, and projected outlays. It outlines expected revenue streams, assesses tax and depreciation impacts, and estimates profit margins. A complete financial analysis supports investment decisions and helps determine the long-term viability of the aluminium anodizing manufacturing project.

Ask an Analyst: https://www.syndicatedanalytics.com/request?type=report&id=1273&flag=C

Need a Customized Project Report?

You can share any particular business requirements that you have, and we will adjust the scope of the report to your needs. The following are some typical customizations that our clients ask for:

• The report may be customized based on the region/country in which you intend to locate your business.

• The production capacity of the facility can be customized in accordance with your needs.

• Suppliers of machinery and prices can be tailored to your requirements.

• Depending on your needs, we may also modify the current scope.

Key Questions Addressed in the Report on Aluminium Anodising Manufacturing Project:

1. What is the current performance of the global aluminium anodizing market, and what growth trends are expected in the coming years?

2. How is the global aluminium anodizing market segmented, and what are the key regional trends?

3. What are the prevailing price trends of major feedstocks used in aluminium anodizing production?

4. Who are the leading players in the aluminium anodizing industry, and what is the industry structure like?

5. What are the essential unit operations and process flow involved in aluminium anodizing manufacturing?

6. What are the land, infrastructure, and layout requirements for setting up a aluminium anodizing plant?

7. What machinery, raw materials, and utilities are required to establish the plant, and what are their associated costs?

8. What are the manpower and staffing needs for operating a aluminium anodizing manufacturing unit?

9. What transportation and logistical arrangements are needed for raw materials and finished products?

10. What are the total capital and operating costs involved in setting up and running the plant?

11. What is the recommended pricing strategy for aluminium anodizing, and how does it impact profitability?

12. What are the projected revenues, profit margins, and break-even timeline for the plant?

13. What are the regulatory approvals and certifications required for starting operations?

14. What risks should investors be aware of, and what are the key factors that influence project success?

About Us:

Syndicated Analytics, a subsidiary of IMARC Group, offers consulting services and provides comprehensive market intelligence in the form of research reports, production cost reports, and feasibility studies. Our team, consisting of experienced researchers and analysts from diverse industries, is deeply committed to the quality of the information and insights delivered to the clients, which range from small and medium enterprises to Fortune 1000 companies. These firms are able to achieve this by studying the qualitative and quantitative aspects of the market as well as staying up to date with the current and evolving trends of the industry.

Contact Info:

Katherine Shields

Senior Sales & Marketing Manager

134 N 4th St., Brooklyn,

NY 11249, USA

Phone No: +1-213-316-7435

Website: https://www.syndicatedanalytics.com/

Email Address: sales@syndicatedanalytics.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Aluminium Anodizing Manufacturing Plant Cost: Business Plan and Detailed Project Report here

News-ID: 4040568 • Views: …

More Releases from IMARC Group

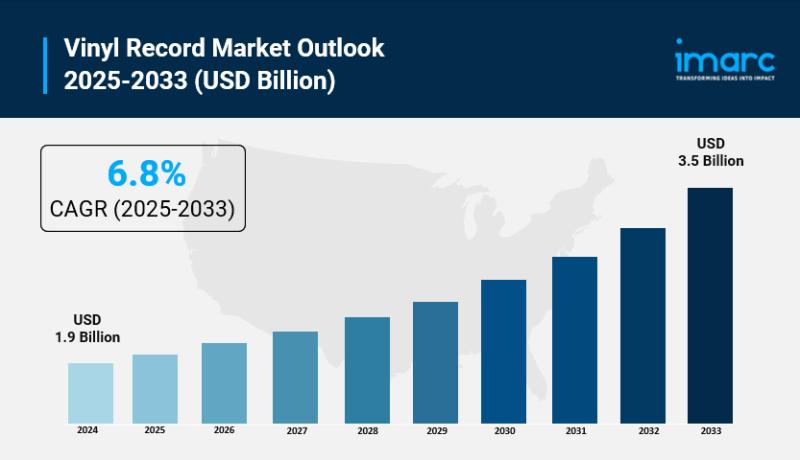

Vinyl Record Market Size to Reach USD 3.5 Billion by 2033 | With a 6.8% CAGR

Market Overview:

According to IMARC Group's latest research publication, "Vinyl Record Market Report by Product (LP/EP Vinyl Records, Single Vinyl Records), Feature (Colored, Gatefold, Picture), Gender (Men, Women), Age Group (13-17, 18-25, 26-35, 36-50, Above 50), Application (Private, Commercial), Distribution Channel (Supermarkets and Hypermarkets, Independent Retailers, Online Stores, and Others), and Region 2025-2033", The global vinyl record market size reached USD 1.9 Billion in 2024. Looking forward, IMARC Group expects the…

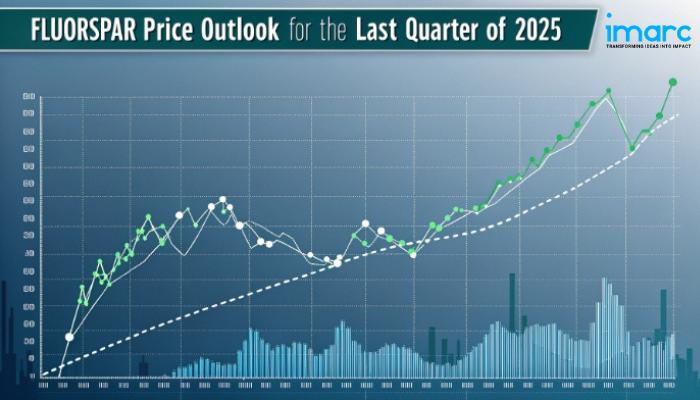

North America Fluorspar Prices Rise in Q4 2025: USA at USD 484/MT, Canada Peaks …

North America Fluorspar Prices Movement Q4 2025:

Fluorspar Prices in USA:

In Q4 2025, fluorspar prices in the USA averaged USD 484 per metric ton. Stable demand from aluminum production and chemical manufacturing supported price levels. Domestic mining operations maintained consistent output, while transportation and energy costs influenced overall supply. Moderate industrial activity and inventory management helped prevent significant price fluctuations across the regional market.

Get the Real-Time Prices Analysis: https://www.imarcgroup.com/fluorspar-pricing-report/requestsample

Note: The analysis…

Brazil Hybrid Electric Vehicle Market: Growth Dynamics, Consumer Shifts, and Com …

The Brazil hybrid electric vehicle market size was 348.75 Thousand Units in 2025 and is forecasted to reach 2,551.74 Thousand Units by 2034, reflecting a CAGR of 24.75% during 2026-2034. This robust expansion is fueled by increasing environmental awareness, rising fuel costs, and government policies aimed at emission reduction. Advances in battery technology and flex-fuel hybrid variants leveraging Brazil's ethanol resources also contribute to market growth.

Sample Request Link: https://www.imarcgroup.com/brazil-hybrid-electric-vehicle-market/requestsample

Study Assumption…

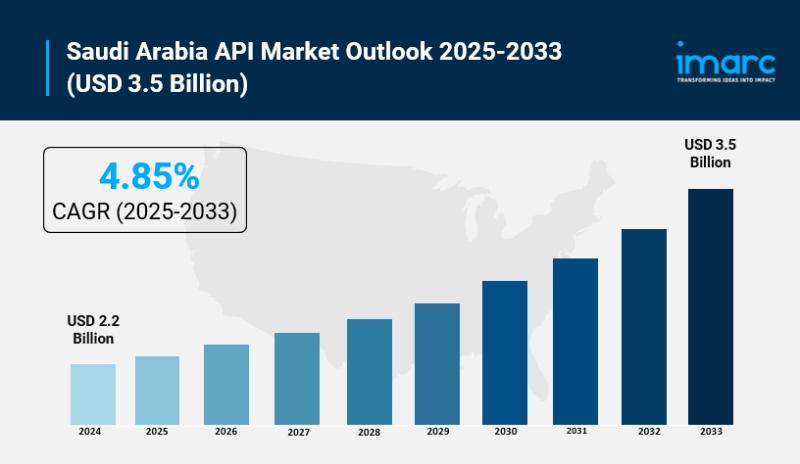

Saudi Arabia API Market Size to Expand USD 3.5 Billion by 2033 at a CAGR of 4.85 …

Saudi Arabia API Market Overview

Market Size in 2024: USD 2.2 Billion

Market Forecast in 2033: USD 3.5 Billion

Market Growth Rate 2025-2033: 4.85%

According to IMARC Group's latest research publication, "Saudi Arabia API Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The Saudi Arabia API market size reached USD 2.2 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 3.5 Billion by 2033, exhibiting a growth rate…

More Releases for Requirements

Maintenance requirements for Instandhaltungssoftware

Holistic digitalization is necessary for greater productivity in maintenance

Manufacturing companies face a number of challenges when it comes to reducing costs and maximizing machine availability while establishing a sustainable maintenance strategy.

It is important to use powerful tools to increase efficiency, significantly improve data quality and thus make more accurate statements.

Standard software such as the Instandhaltungssoftware Wartungsplaner https://www.Wartungsplaner.de/details/Instandhaltungssoftware-Software-zur-Instandhaltung.htm plays a central role in implementation, as this type of software guarantees a…

PVC Wires and Cables Manufacturing Plant Project Report: Unit Operations, Raw Ma …

IMARC Group's "PVC Wires and Cables Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" report provides a comprehensive guide on how to successfully set up a PVC wires and cables manufacturing plant. The report offers clarifications on various aspects, such as unit operations, raw material requirements, utility supply, infrastructural needs, machinery models, labour necessities, transportation timelines, packaging costs, etc.

In addition to…

Frozen Shrimp Manufacturing Plant Project Report 2024, Machinery Requirements, P …

IMARC Group's report titled "Frozen Shrimp Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" provides a comprehensive guide for establishing a frozen shrimp manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging and transportation requirements, and more.

In addition to…

One-Stop Solution for Scaffold Requirements

Founded in the year 2012, Scaffolding Solutions operates with the objective of delivering excellent quality services. The company takes pride to claim that it is the one-stop solution for all the scaffolding needs of the client. The company can easily manage a scaffold project from its very first stage to the last. This includes delivery, erection as well as dismantling services for clients.

Scaffolding Solutions offer several services which include the…

Global Requirements Management Software Market Size, Key Player (Software, Requi …

A newly compiled business intelligent report, titled “Global Requirements Management Software Market Size, Status and Forecast 2018-2025” has been publicized to the vast archive of Market Research Hub (MRH) online repository. The study revolves around the analysis of (Requirements Management Software) market, covering key industry developments and market opportunity map during the mentioned forecast period. This report further conveys quantitative & qualitative analysis on the concerned market, providing a 360…

California Updates Prop 65 Labeling Requirements

On August 30, 2016, the Office of Administrative Law approved the adoption of a new set of rules regarding the language requirements for clear and reasonable warnings under California Proposition 65 (Prop 65). The changes, originally proposed in January 2016 by the Office of Health Hazard assessment (OEHHA), will come into effect on August 30, 2018. Until that time, both the old and new warning language will be acceptable for…