Press release

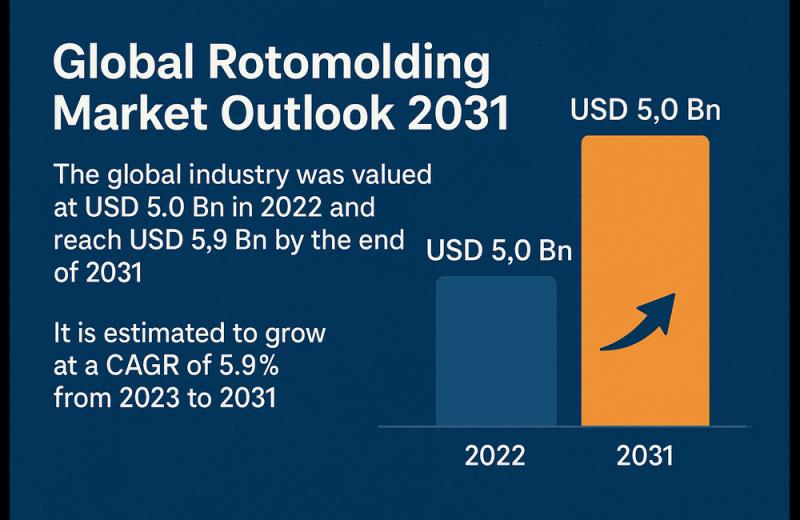

Rotomolding Market to Reach USD 5.9 Billion by 2031 Amid Steady 5.9% CAGR Growth

The global rotomolding market was valued at USD 5.0 billion in 2022 and is projected to grow at a CAGR of 5.9% between 2023 and 2031. This steady growth is expected to drive the market to reach approximately USD 5.9 billion by the end of 2031. The increasing demand for lightweight, durable plastic products across industries such as automotive, agriculture, and packaging is fueling this expansion.Surge in demand for polyethylene in building & construction and automotive & transportation sectors is expected to drive the rotomolding market size during the forecast period. Rotational molding or rotomolding is a plastic molding technique that is used in the production of hollow articles. Rise in usage of water tanks and pipes is also projected to augment market expansion in the near future.

Unlock Full Market Insights: Get a Sample Report Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=69095

Rotomolded plastic is primarily used in the manufacture of electric vehicles. Governments and construction companies are promoting the usage of rotomolding plastics for the manufacture of rotomolded furniture, outdoor playground equipment, industrial hoppers, and tanks & containers. Vendors in the global rotomolding industry are investing significantly in R&D of new products to broaden their revenue streams.

Market Segmentation

The rotomolding market can be segmented based on various criteria, offering a detailed understanding of its dynamics:

By Material Type:

Polyethylene (PE)

Polypropylene (PP)

Polyvinyl Chloride (PVC) Plastisols

Nylon

Polycarbonate

Elastomers

Ethylene Vinyl Acetate

Polyurethane

Others

By Sourcing Type (Form):

Powder

Granules

By Application:

Storage Tanks

Automotive Components

Containers

Toys and Leisure Equipment

Materials Handling

Industrial

Furniture & Home Decor

Building & Construction

pipes

Marine

Others

By Industry Vertical (End-use Industry):

Construction

Automotive & Transportation

Agriculture

Consumer Goods

Chemicals

Food & Beverage

Pharmaceuticals

Aerospace & Defense

Material Handling

Packaging

Others

By Region:

North America: A key market with a substantial share (U.S. holds around 40% of the rotomolding compounds market in 2023), driven by technological advancements and high industrial applications, and significant investments in capacity expansion.

Europe: Focus on sustainable materials and adherence to strict environmental regulations.

Asia-Pacific: Anticipated to dominate the market with the largest revenue share (projected 50% by 2037), fueled by rapid industrialization, urbanization, infrastructure development, and the presence of numerous resin makers offering competitive prices. China is expected to remain the world's largest market for rotomolding compounds.

Latin America: Increasing investment in industrial and transportation sectors.

Middle East & Africa: Growing industrial and transportation sectors.

Regional Analysis

Asia-Pacific is poised to be the leading region in the rotomolding market, primarily due to robust industrialization, rapid urbanization, and significant investments in infrastructure. Countries like China and India are major contributors, driven by their large populations, expanding manufacturing sectors, and competitive pricing for raw materials. The burgeoning automotive industry in China, in particular, is a key demand driver for rotomolding compounds for lightweight vehicle production.

North America remains a strong market, characterized by technological advancements in leisure, material handling, and construction equipment. Manufacturers in the U.S. are focusing on capacity expansion, acquisitions, and mergers to meet growing demand for innovative and customized products.

Europe is a mature market with a strong emphasis on sustainability and the adoption of eco-friendly materials and processes, influenced by stringent environmental regulations.

Market Drivers and Challenges

Market Drivers:

Increasing Demand for Lightweight and Durable Products: Industries like automotive, packaging, and construction are seeking materials that can reduce weight while maintaining high strength and impact resistance, which rotomolding excels at.

Cost-Effectiveness and Design Flexibility: Rotomolding allows for the production of complex, hollow, and large-sized parts with relatively low tooling costs compared to other molding techniques, offering significant design freedom.

Growth in Key End-Use Industries: Expanding sectors such as automotive, construction, agriculture, and consumer goods are consistently driving the demand for rotomolded products.

Technological Advancements and Automation: Innovations in mold design, process automation (e.g., robotic arms for precision), and control systems are enhancing efficiency, reducing costs, and improving product quality and consistency.

Rising Demand for Customized Solutions: The ability of rotomolding to create bespoke products tailored to specific industry or consumer needs is a significant growth factor.

Sustainability Initiatives: The growing emphasis on recycling and the development of bio-based and recyclable rotomolding compounds are attracting environmentally conscious businesses and consumers.

Market Challenges:

Fluctuations in Raw Material Prices: The primary materials used in rotomolding, such as polyethylene and polypropylene, are dependent on oil prices, leading to price volatility that can impact manufacturers' profit margins.

Competition from Alternative Molding Technologies: Processes like injection molding and blow molding offer lower production costs for mass-produced, smaller items, posing competition for certain applications.

Environmental Concerns and Strict Regulations: The disposal of plastic materials and the hazardous fumes/chemicals released during manufacturing raise environmental concerns, potentially leading to stricter regulations on resin usage and waste management.

Long Cycle Times: Rotomolding generally has longer cycle times compared to other molding processes, which can affect production efficiency for high-volume, small-part manufacturing.

High Initial Investment Costs: While molds are relatively inexpensive, the machinery for rotomolding can involve a significant initial investment.

Recycling Complexity: Recycling polyethylene and polypropylene can be operationally complex and expensive.

Market Trends

Shift Towards Sustainable Materials: Increasing adoption of recycled plastics, bio-based polymers, and biodegradable compounds to reduce environmental impact and align with circular economy principles.

Automation and Industry 4.0 Integration: Greater incorporation of advanced robotics, artificial intelligence, and digital tools (e.g., predictive maintenance systems, digital twins) to streamline processes, improve productivity, and enhance product quality.

Customization and Personalization: Growing demand for tailor-made rotomolded products with unique designs, colors, and features to meet specific customer requirements across various industries.

Development of High-Performance Polymers: Research and development efforts are focused on creating new rotomolding compounds with enhanced properties like UV resistance, fire resistance, and superior strength-to-weight ratios.

Expansion into New Application Areas: Exploration of rotomolding's potential in niche markets such as medical devices, aerospace components, and specialized packaging solutions.

Focus on Smart Manufacturing: Companies are investing in technologies that enable real-time monitoring and control of the rotomolding process for optimal efficiency and quality.

Future Outlook

The future of the rotomolding market appears promising, characterized by continuous innovation and increasing adoption across a broader spectrum of industries. The persistent demand for durable, lightweight, and customizable plastic products will continue to fuel its growth. Strategic partnerships, investments in R&D for advanced materials and processes, and a proactive approach to sustainability will be crucial for companies to maintain a competitive edge. The market is expected to evolve with a greater emphasis on green technologies, smart manufacturing, and personalized solutions, particularly in emerging economies. The ability to produce complex, hollow, and seamless parts efficiently will ensure rotomolding remains a vital manufacturing process.

Key Market Study Points

Market Size Analysis and Projected Growth: Understanding the historical growth and forecasting future expansion from 2023 to 2031.

Regional Trends and Market Dynamics: Analyzing the performance and growth drivers in key geographical regions.

Key Drivers and Challenges: Identifying the factors propelling market growth and the obstacles hindering it.

Competitive Landscape and Recent Developments: Assessing the strategies of key players and recent innovations in the industry.

Emerging Trends and Future Growth Opportunities: Pinpointing new technologies, materials, and applications that will shape the market's future.

Segmentation Analysis: In-depth breakdown by material type, application, industry vertical, and form to understand specific market segments.

Competitive Landscape

The global rotomolding market is fragmented, with a mix of large global players and numerous regional manufacturers. Key players are focusing on maximizing production efficiency, investing in research and development for new products and sustainable solutions, and establishing long-term contracts with end-users. Consolidation and capacity expansion through mergers and acquisitions are also notable strategies.

Key Companies Profiled: (While specific company names are mentioned in search results, a general overview of key players in the rotomolding compounds and products market includes leading chemical companies and specialized rotomolders).

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=69095<ype=S

Recent Developments

Sustainable Material Innovation: Increased focus on developing and utilizing recycled and bio-based polyethylene compounds. For instance, manufacturers are increasingly adopting biodegradable and recyclable plastics driven by environmental concerns and regulations.

Capacity Expansion: Companies like Trilogy Plastics and Stern have recently doubled their processing and production capacities through facility expansions and acquisitions to meet rising demand for complex and innovative rotomolded products.

Technological Advancements: Continuous improvements in mold design, process automation, and control systems, including the integration of robotics for more precise shaping and reduced manufacturing defects.

New Application Development: Rotomolding is gaining significant traction in sectors like civil construction for manufacturing essential components like sinks, bathtubs, and thermal insulation blocks.

Product Innovation for Specific Industries: Development of specialized rotomolded products such as lightweight plastic engine hoods for premium domestic NEV brands (e.g., LyondellBasell's collaboration with Hunan Huda Aisheng Group) and improved buoy designs for marine environments (e.g., Almarin's EVO buoy using rotomolded polyethylene).

Focus on Customization: Manufacturers are increasingly emphasizing the ability to offer high levels of customization and flexibility in product design, allowing for the creation of tailored solutions for various industries.

Explore Latest Research Reports by Transparency Market Research:

Silicon Metal Market - https://www.transparencymarketresearch.com/silicon-metal-market.html

Aluminum Slugs Market - https://www.transparencymarketresearch.com/aluminum-slugs-market.html

Coal Market - https://www.transparencymarketresearch.com/coal-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Rotomolding Market to Reach USD 5.9 Billion by 2031 Amid Steady 5.9% CAGR Growth here

News-ID: 4038494 • Views: …

More Releases from transparencymarketresearch

Microgreens Market to Surge at 10.9% CAGR, Set to Reach USD 8.56 Billion by 2036

The global microgreens market was valued at USD 2,780.5 million in 2025 and is projected to reach USD 8,563.5 million by 2036. Driven by rising demand for nutrient-dense foods and growing adoption across foodservice and retail channels, the industry is expected to expand at a robust CAGR of 10.9% from 2026 to 2036.

The global microgreens market represents a specialized, high-value segment within the broader fresh produce and specialty horticulture industry,…

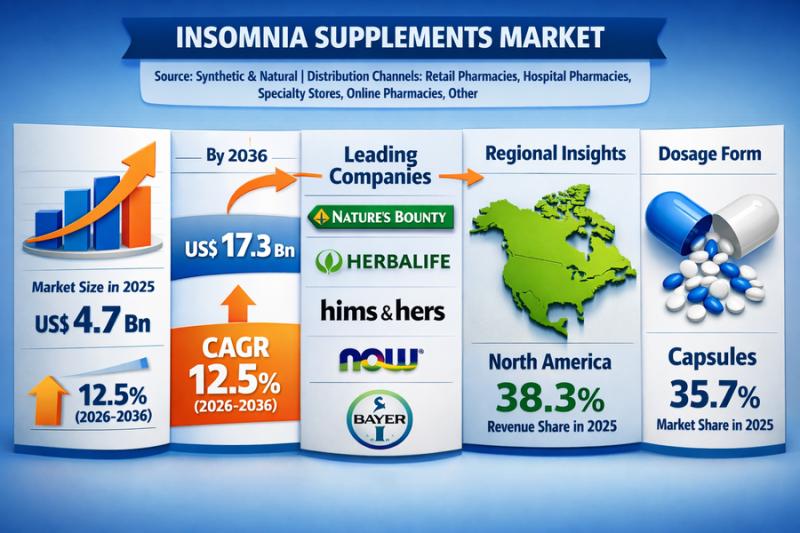

Insomnia Supplements Market Set to Reach US$ 17.3 Bn by 2036, Growing at a Robus …

The global insomnia supplements market was valued at USD 4.7 billion in 2025 and is projected to reach USD 17.3 billion by 2036, reflecting strong growth potential. The market is anticipated to expand at a CAGR of 12.5% from 2026 to 2036, driven by rising sleep disorder prevalence, increasing consumer focus on mental wellness, and growing demand for natural and non-prescription sleep aids.

The insomnia supplements market is expected to witness…

Fiber-Based Blister Pack Market Set to Surge at 21.5% CAGR Through 2036

The global fiber-based blister pack market was valued at US$ 1,633.8 million in 2025 and is projected to surge to US$ 13,591.8 million by 2036. Driven by rising demand for sustainable and eco-friendly packaging solutions, the market is expected to grow at a robust CAGR of 21.5% from 2026 to 2036.

Fiber-based blister packaging is a type of packaging that substitutes the usual plastic blister with paperboard or molded fiber components…

Psychotropic Drugs Market to Reach US$ 41.2 Bn by 2036, Growing at 5.4% CAGR

The global psychotropic drugs market was valued at USD 23.1 Bn in 2025 and is projected to reach USD 41.2 Bn by 2036. Driven by rising awareness of mental health disorders, increasing diagnosis rates, and ongoing pharmaceutical innovations, the industry is expected to grow at a CAGR of 5.4% from 2026 to 2036.

The primary drivers of the expanding psychotropic drugs market include the rising prevalence of mental disorders such as…

More Releases for Rotomolding

Rotomolding Market Share, Innovation, and Sustainability Trends 2035

Market Outlook and Forecast

The rotomolding market continues to evolve as a crucial manufacturing segment within the global plastics and composites industry. Valued at USD 2.31 billion in 2025, the market is expected to reach USD 4.18 billion by 2035, expanding at a steady 6.1% CAGR over the forecast period (2026-2035). (2026-2035). The process-also known as rotational molding-has become indispensable for producing hollow, seamless plastic components with excellent durability, design flexibility,…

Global Rotomolding Market Imapct of AI and Automation

Rotomolding Market Impact of AI and Automation

The global rotomolding market was valued at approximately $8.3 billion in 2022, with a compound annual growth rate (CAGR) of 4.5% projected from 2022 to 2030. This growth is driven by increased demand across various industries, including automotive, aerospace, and consumer goods, where rotomolded products offer superior durability and design flexibility. The market's expansion is further supported by the rising adoption of advanced manufacturing…

Rotomolding Products Market Size, Share And Growth Analysis For 2024-2031 - Roto …

DataM Intelligence has published a new research report on "Rotomolding Products Market Size 2024". The report explores comprehensive and insightful Information about various key factors like Regional Growth, Segmentation, CAGR, Business Revenue Status of Top Key Players and Drivers. The purpose of this report is to provide a telescopic view of the current market size by value and volume, opportunities, and development status.

Get a Free Sample Research PDF - https://datamintelligence.com/download-sample/rotomolding-products-market

The…

Rotomolding Market 2023-2031: Revolutionizing Plastic Manufacturing

Rotomolding, also known as rotational molding, is a versatile manufacturing process widely used for producing hollow plastic products. This method offers advantages such as design flexibility, cost-effectiveness, and durability, making it popular across various industries. The period from 2023 to 2031 is poised to witness significant growth in the global rotomolding market, driven by several factors including technological advancements, increasing demand for lightweight and durable plastic products, and expanding applications…

Rotomolding Will Generate Booming Growth Opportunities to 2031

The global Rotomolding market is estimated to attain a valuation of US$ 8.28 Bn by the end of 2031, states a study by Transparency Market Research (TMR). Besides, the report notes that the market is prognosticated to expand at a CAGR of 5.9% during the forecast period, 2020-2031.

The key objective of the TMR report is to offer a complete assessment of the global market including major leading stakeholders of the…

Global Rotomolding Market Analysis by 2020-2025

Scope of the Report:

The global Rotomolding market size is expected to gain market growth in the forecast period of 2020 to 2025, with a CAGR of xx%% in the forecast period of 2020 to 2025 and will expected to reach USD xx million by 2025, from USD xx million in 2019.

Market segmentation

Rotomolding market is split by Type and by Application. For the period 2015-2025, the growth among segments provide accurate…