Press release

Cost Details of PLA Pellets Manufacturing Plant Report 2025- Setup Details, Machinery Requirements and Industry Trends

Setting up a PLA pellets manufacturing facility necessitates a detailed market analysis alongside granular insights into various operational aspects, including unit processes, raw material procurement, utility provisions, infrastructure setup, machinery and technology specifications, workforce planning, logistics, and financial considerations.IMARC Group's report titled "PLA Pellets Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue" offers a comprehensive guide for establishing a PLA pellet manufacturing plant, covering everything from product overview and production processes to detailed financial insights.

Request For a Sample Report: https://www.imarcgroup.com/pla-pellets-manufacturing-plant-project-report/requestsample

Polylactic Acid (PLA) pellets are a type of biodegradable thermoplastic derived from renewable resources such as corn starch or sugarcane. These pellets serve as the raw material for manufacturing a wide range of bioplastics used in packaging, textiles, agriculture, and 3D printing. PLA pellets are favored for their compostable nature, offering an environmentally friendly alternative to conventional petroleum-based plastics. They possess similar mechanical properties to traditional plastics, such as polystyrene, making them suitable for applications that require durability, transparency, and heat resistance.

The global PLA pellets market is experiencing robust growth, driven primarily by increasing environmental awareness and regulatory support for sustainable materials. Government initiatives promoting the use of biodegradable plastics, especially in Europe and North America, are major catalysts. Additionally, the demand from the packaging and food service sectors, which are under pressure to reduce plastic waste, is significantly boosting market adoption. Technological advancements that enhance PLA performance and reduce production costs further support market expansion. The growing popularity of 3D printing also contributes to demand, as PLA is widely used in filament production due to its ease of use and eco-friendly profile.

Browse Full Report: https://www.imarcgroup.com/pla-pellets-manufacturing-plant-project-report

Key Steps Required to Set Up an PLA Pellets Plant

1. Market Analysis

The report provides insights into the landscape of the PLA pellets industry at the global level. The report also provides a segment-wise and region-wise breakup of the global PLA pellets industry. Additionally, it also provides the price analysis of feedstocks used in the manufacturing of PLA pellets, along with the industry profit margins.

• Segment Breakdown

• Regional Insights

• Pricing Analysis and Trends

• Market Forecast

2. Product Manufacturing: Detailed Process Flow

Detailed information related to the process flow and various unit operations involved in the PLA pellets manufacturing plant project is elaborated in the report. These include:

• Land, Location, and Site Development

• Plant Layout

• Plant Machinery

• Raw Material Procurement

• Packaging and Storage

• Transportation

• Quality Inspection

• Utilities

• Human Resource Requirements and Wages

• Marketing and Distribution

3. Project Requirements and Cost

The report provides a detailed location analysis covering insights into the plant location, selection criteria, location significance, environmental impact, and expenditure for PLA pellets manufacturing plant setup. Additionally, the report also provides information related to plant layout and factors influencing the same. Furthermore, other requirements and expenditures related to machinery, raw materials, packaging, transportation, utilities, and human resources have also been covered in the report.

Machinery and Equipment

• List of machinery needed for PLA pellets production

• Estimated costs and suppliers

Raw Material Costs

• Types of materials required and sourcing strategies

Utilities and Overheads

• Electricity, water, labor, and other operational expenses

4. Project Economics

A detailed analysis of the project economics for setting up an PLA pellets manufacturing plant is illustrated in the report. This includes the analysis and detailed understanding of capital expenditure (CAPEX), operating expenditure (OPEX), income projections, taxation, depreciation, liquidity analysis, profitability analysis, payback period, NPV, uncertainty analysis, and sensitivity analysis.

Capital Expenditure (CAPEX)

• Initial setup costs: land, machinery, and infrastructure

Operating Expenditure (OPEX)

• Recurring costs: raw materials, labor, maintenance

Revenue Projections

• Expected income based on production capacity, target market, and market demand

Taxation

Depreciation

Financial Analysis

• Liquidity Analysis

• Profitability Analysis

• Payback Period

• Net Present Value (NPV)

• Internal Rate of Return

• Profit and Loss Account

Uncertainty Analysis

Sensitivity Analysis

Economic Analysis

Ask an Analyst: https://www.imarcgroup.com/request?type=report&id=30811&flag=C

5. Legal and Regulatory Compliance

• Licenses and Permits

• Regulatory Procedures and Approval

• Certification Requirement

6. Hiring and Training

• Total human resource requirement

• Salary cost analysis

• Employee policies overview

The report also covers critical insights into key success and risk factors, which highlight the aspects that influence the success and potential challenges in the industry. Additionally, the report includes strategic recommendations, offering actionable advice to enhance operational efficiency, profitability, and market competitiveness. A comprehensive case study of a successful venture is also provided, showcasing best practices and real-world examples from an established business, which can serve as a valuable reference for new entrants in the market.

About Us:

IMARC is a global market research company offering comprehensive services to support businesses at every stage of growth, including market entry, competitive intelligence, procurement research, regulatory approvals, factory setup, company incorporation, and recruitment. Specializing in factory setup solutions, we provide detailed financial cost modeling to assess the feasibility and financial viability of establishing new manufacturing plants globally. Our models cover capital expenditure (CAPEX) for land acquisition, infrastructure, and equipment installation while also evaluating factory layout and design's impact on operational efficiency, energy use, and productivity. Our holistic approach offers valuable insights into industry trends, competitor strategies, and emerging technologies, enabling businesses to optimize operations, control costs, and drive long-term growth.

Contact US:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Cost Details of PLA Pellets Manufacturing Plant Report 2025- Setup Details, Machinery Requirements and Industry Trends here

News-ID: 4033483 • Views: …

More Releases from IMARC Group

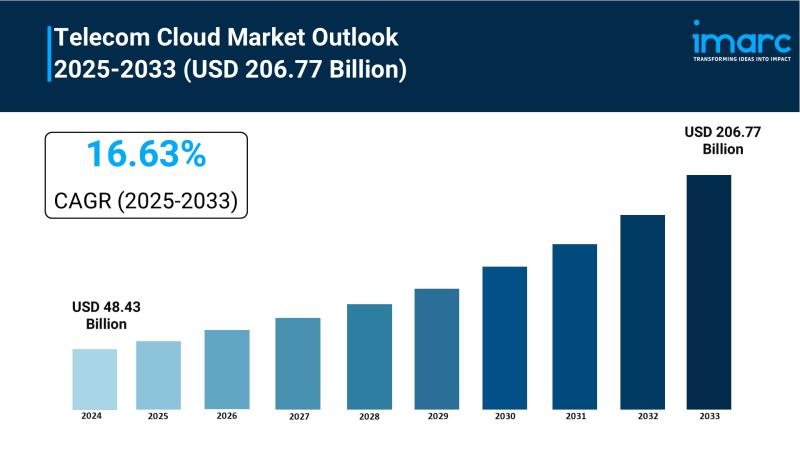

Telecom Cloud Market to Reach USD 206.77 Billion by 2033, Growing at a CAGR of 1 …

Market Overview:

The Telecom Cloud Market is experiencing significant expansion, driven by The Mass-Scale Deployment of 5G Standalone Networks, A Heightened Industry Focus on Operational and Capital Expenditure Optimization and The Surging Demand for Edge Computing in Enterprise Services. According to IMARC Group's latest research publication, "Telecom Cloud Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033", The global telecom cloud market size was valued at USD 48.43…

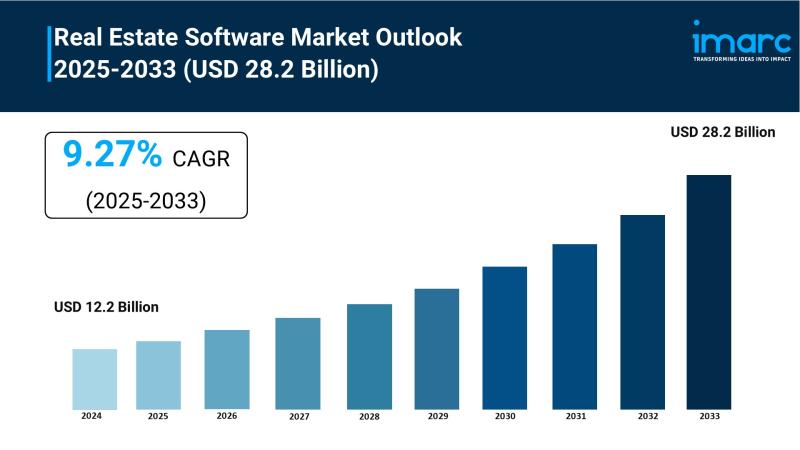

Real Estate Software Market to Reach USD 28.2 Billion by 2033, Growing at a CAGR …

Market Overview:

The Real Estate Software Market is experiencing rapid growth, driven by Integration of Artificial Intelligence and Machine Learning, Growth of Virtual and Augmented Reality in Property Viewing and Emphasis on Data Security and Regulatory Compliance. According to IMARC Group's latest research publication, "Real Estate Software Market Size, Share, Trends and Forecast by Type, Deployment, Application, End Use, and Region, 2025-2033", The global real estate software market size was valued…

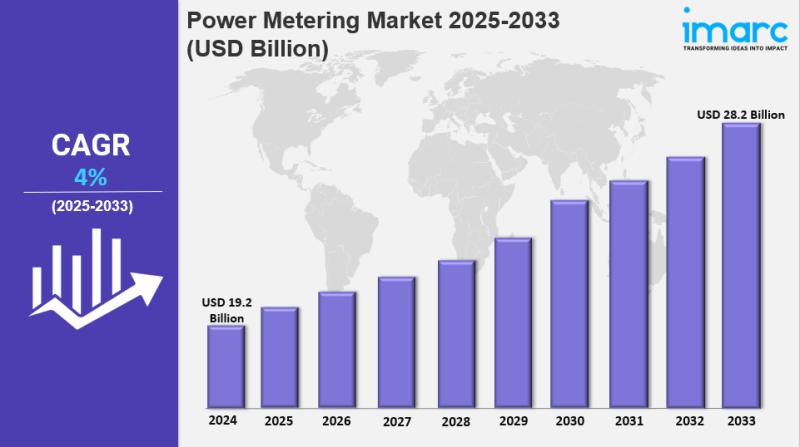

Power Metering Market Size, Growth, Latest Trends and Forecast To 2033

IMARC Group has recently released a new research study titled "Power Metering Market Report by Phase (Single Phase, Three Phase), Technology (Analog Meters, Digital Meters, Smart Meters), End Use (Residential, Commercial, Industrial), and Region 2025-2033", offers a detailed analysis of the market drivers, segmentation, growth opportunities, trends and competitive landscape to understand the current and future market scenarios.

Market Overview

The global power metering market size was valued at USD 19.2 Billion…

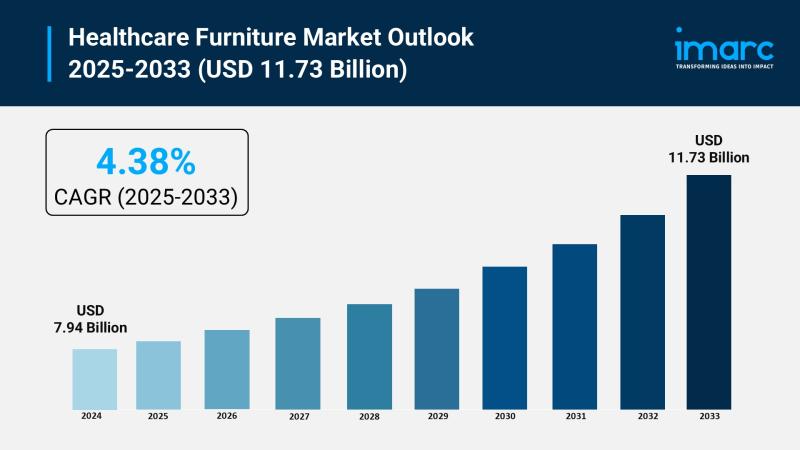

Healthcare Furniture Market Size to Hit USD 11.73 Billion in 2033 | Grow CAGR by …

Market Overview:

The healthcare furniture platform market is experiencing rapid growth, driven by global expansion of healthcare infrastructure, rising prevalence of chronic diseases and aging populations, and stringent infection control and regulatory compliance. According to IMARC Group's latest research publication, "Healthcare Furniture Market Size, Share, Trends and Forecast by Furniture Type, Sector, Application, Material, Distribution Channel, and Region, 2025-2033", The global healthcare furniture platform market size was valued at USD 7.94…

More Releases for PLA

How Compostable PLA Straws Help the Environment

Compostable PLA straw [https://www.naturecutlery.com/qh-st-5-5-x-200-mm-biodegradable-pla-drinking-straw-in-bulk-package-2-product/]s are emerging as one of the key solutions to the global plastic crisis. Made from renewable materials like corn starch, these straws are an eco-friendly alternative to traditional plastic straws. Here's a closer look at how compostable PLA straws can have a positive impact on the environment and why they're a smart choice for businesses focused on sustainability.

1. Reduce Plastic Waste Accumulation

Traditional plastic straws are single-use…

Polylactic Acid (PLA) Market Growth Opportunities and Competitive Landscape Repo …

Polylactic acid (PLA) is a biodegradable thermoplastic polymer made from renewable resources such as corn starch or sugar cane. Unlike other thermoplastics, PLA can be degraded by microorganisms over time, making it an attractive material for sustainable and biodegradable products.

Key Trends

One of the major trends in PLA technology is the development of new and improved methods for PLA production. For example, catalysis of the conversion of lactic acid to PLA…

Polylactic Acid (PLA) Market Insights by 2031 & Covid-19 Analysis | Total Corbio …

Global Polylactic Acid (PLA) Market report from Global Insight Services is the single authoritative source of intelligence on Polylactic Acid (PLA) Market. The report will provide you with analysis of impact of latest market disruptions such as Russia-Ukraine war and Covid-19 on the market. Report provides qualitative analysis of the market using various frameworks such as Porters' and PESTLE analysis. Report includes in-depth segmentation and market size data by categories,…

Bio-polylactic Acid (PLA) Films Market Size, Status and Global Outlook During 20 …

MarketInsightsReports has published a report titled global Bio-polylactic Acid (PLA) Films Market research report 2020 that is a detailed observation of several aspects, including the rate of growth, technological advances, and different methodologies implemented by the primary current market players. The report is based on a collective analysis of data, which is obtained through primary and secondary research. It provides a systematic approach to the current and prospective scenario of…

Polylactic Acid (PLA) Market May See Exponential Growth in Future | BASF SE; Dan …

This Polylactic Acid (PLA) Market research report involves six major parameters namely market analysis, market definition, market segmentation, key developments in the market, competitive analysis, and research methodology. Competitive analysis is the major aspect of any market research report and by understanding this many points are covered in the report including strategic profiling of key players in the market, analyse their core competencies, and draw a competitive landscape for the…

Growth of Bio-polylactic Acid (PLA) Films Market | Top Vendors- NatureWorks, Fut …

Global Bio-PLA Films Market was valued at $354 million in 2016, and is anticipated to reach $910 million by 2023, growing at a CAGR of 14.5% from 2017 to 2023.

The key players profiled in the report are NatureWorks LLC, Futerro, Tale & Lyle, Total Corbion PLA, Hiusan Biosciences, Toray Industries, Inc., Taghleef Industries, Amcor Ltd. Toyobo, and Avery Dennison Corporation.

The other major players (not profiled in report) in the…