Press release

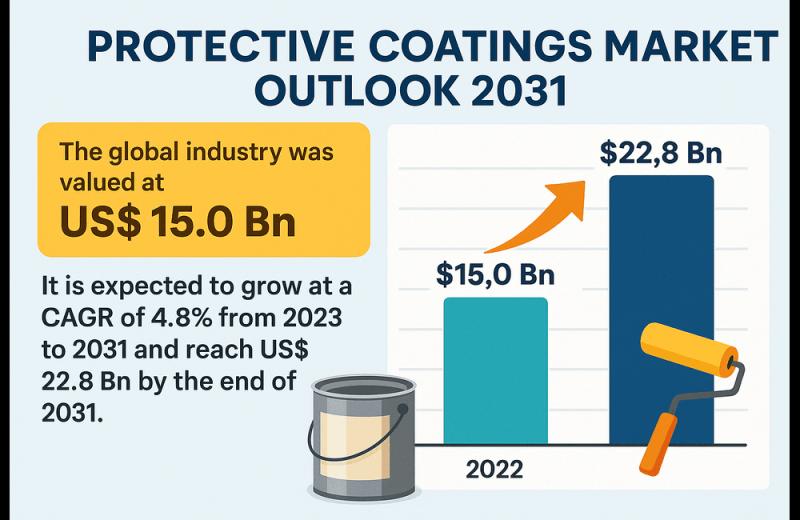

Protective Coatings Market to Reach $22.8 Billion by 2031, Driven by Infrastructure and Industrial Growth

The global protective coatings market was valued at US$ 15.0 billion in 2022 and is projected to grow at a CAGR of 4.8% from 2023 to 2031. This steady growth is expected to drive the market to reach US$ 22.8 billion by the end of 2031. The increasing demand for corrosion protection, rising infrastructure development, and growing use in industrial and automotive sectors are key factors contributing to this expansion.Growth in corrosion concerns in end-use industries and rise in adoption of protective coatings in the building & construction sector are fueling the protective coatings market size. In the building & construction sector, protective coatings are applied to concrete to increase the reflectivity of light, facilitate maintenance, and enhance the esthetics of structures. Several end-use industries such as oil & gas and aerospace employ protective coatings to safeguard surfaces from environmental damage. Thus, consistent usage of these coatings in these industries is fostering market expansion.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=40403

Market Segmentation

The protective coatings market is extensively segmented based on various factors, reflecting the diverse applications and technological advancements within the industry:

By Resin Type:

Epoxy: Dominates the market due to its excellent adhesion, durability, and resistance to chemical stresses, making it ideal for industrial facilities, marine structures, and oil and gas pipelines. Epoxy coatings are expected to maintain their leading position and exhibit the fastest growth.

Polyurethane: Known for its chemical resistance, corrosion resistance, and physical wear resistance, often used to protect metal surfaces and provide an attractive finish.

Acrylic: Widely used for its versatility and weather resistance.

Alkyd: A traditional coating type, still prevalent in certain applications.

Inorganic Zinc: Valued for its anti-corrosive properties, particularly in demanding environments.

Polyester

Others

By Technology (Product Formulation/Sourcing Type):

Solvent-borne: Historically dominant due to superior adhesion, high durability, and resistance to abrasion, moisture, and chemicals, despite environmental concerns regarding VOC emissions.

Water-borne: The fastest-growing segment, driven by increasing environmental regulations on VOC emissions, making them a more environmentally friendly choice. They are versatile and used across various industries.

Powder-based: Gaining prominence due to their eco-friendly nature and zero VOC emissions, offering excellent endurance against corrosion, chipping, and scratches, and are considered ideal for many industrial applications.

Others (e.g., High Solids Coatings, UV-cured technologies)

By Application/End-use Industry:

Building & Construction: The largest segment, where protective coatings are crucial for enhancing the durability, fire resistance, and aesthetic appeal of structures, preventing damage from corrosion, moisture, and UV exposure. This includes residential, non-residential, and infrastructure projects (roads, bridges, airports).

Oil & Gas: Critical for protecting pipelines, storage tanks, and offshore structures from harsh corrosive environments.

Industrial: Used across various manufacturing and processing industries to protect machinery, equipment, and plant facilities from wear and tear, chemical exposure, and high temperatures.

Marine: Essential for ships, offshore platforms, and other marine vessels to withstand saltwater corrosion and harsh weather conditions.

Automotive: Applied to vehicle components for protection against corrosion, scratches, and temperature changes, enhancing durability and aesthetics.

Power Generation: Important for protecting power plants, renewable energy infrastructure (e.g., solar panels), and associated equipment.

Mining: Used to protect heavy machinery and infrastructure from abrasive conditions and corrosive elements.

Aerospace: High-performance coatings are vital for aircraft to withstand extreme temperatures, UV radiation, and other environmental stresses, extending the lifespan of critical components.

Water & Wastewater Treatment

Cargo Containers

Petrochemical

Others

By Service Type: (While not explicitly detailed as a separate segmentation axis in the provided information, the demand for services such as surface preparation, application, and maintenance related to protective coatings is inherent to the market.)

Regional Analysis

The protective coatings market exhibits significant regional variations in terms of size and growth.

Asia Pacific: This region is the dominant and fastest-growing market for protective coatings, accounting for a substantial share (e.g., 44.38% in 2023, or around 49% in 2023). This growth is attributed to rapid urbanization, significant infrastructure development, and expanding industrial bases in countries like China, India, Japan, and South Korea. Government initiatives to improve connectivity and invest in infrastructure further bolster market expansion.

Europe: The second-largest market, witnessing growth driven by increased infrastructure spending, particularly in Germany, France, and the UK, alongside a focus on technical advancements and the need for maintenance of aging infrastructure. The continent's emphasis on sustainability also drives demand for advanced protection solutions.

North America: A mature market with established infrastructure and stringent regulatory frameworks. The demand for high-performance coatings and ongoing refurbishment projects contribute to steady growth.

Central & South America and Middle East & Africa (MEA): These regions represent significant potential markets due to growing infrastructure development, increasing GDP, and expanding industrial sectors. The robust oil and gas industry in MEA, coupled with rising construction activities, fuels demand.

Market Drivers and Challenges

Market Drivers:

Booming Construction Industry: Rapid urbanization and massive investments in infrastructure development (residential, commercial, industrial, and public infrastructure) globally, especially in emerging economies, are the primary drivers.

Growing Demand for Corrosion Protection: Corrosion leads to massive economic losses (estimated at US$ 2.5 trillion annually by NACE International IMPACT). Protective coatings are essential for extending the lifespan of assets and reducing maintenance costs by preventing corrosion, particularly in harsh environments.

Increasing Industrialization and Manufacturing: Expansion of various end-use industries like automotive, aerospace, oil & gas, and marine necessitates high-performance coatings to protect equipment and structures from wear, chemical exposure, and extreme conditions.

Technological Advancements: Continuous innovation in coating formulations, including eco-friendly (low-VOC, water-borne, powder-based) and advanced materials like nano and smart coatings (self-healing, antimicrobial properties, enhanced durability), is driving market growth.

Rising Concerns for Longevity and Durability: Industries are increasingly focusing on extending the service life of their assets and equipment, leading to higher adoption of protective coatings.

Government Initiatives and Regulations: Government policies promoting infrastructure development and stringent environmental regulations regarding VOC emissions are encouraging the adoption of sustainable and high-performance coatings.

Market Challenges:

Increasing Price of Raw Materials and Energy: Fluctuations in crude oil prices and other raw material costs, along with rising energy expenses and taxes, can increase manufacturing costs and impact profitability.

Stringent Environmental Regulations: While driving innovation in eco-friendly coatings, strict regulations regarding volatile organic compound (VOC) emissions can pose challenges for manufacturers, requiring significant R&D investment and compliance efforts.

Performance Limitations: Some coatings may not offer the expected longevity or fail to withstand extreme environmental conditions, raising concerns about their long-term effectiveness.

Market Trends

Shift Towards Sustainable and Eco-friendly Coatings: Growing environmental concerns and stricter regulations are driving the demand for low-VOC, water-borne, and powder-based coatings.

Development of High-Performance and Specialty Coatings: Focus on innovative coatings with enhanced properties such as self-healing, improved fire resistance, anti-corrosion, UV protection, and resistance to extreme temperatures, radiation, or specific chemicals.

Integration of Nanotechnology: The use of nanomaterials to create coatings with superior performance characteristics, including increased durability and enhanced protective qualities.

Increased Focus on Asset Lifecycle Management: Industries are increasingly valuing protective coatings as a means to extend the lifespan of their assets, reduce maintenance frequency, and lower overall operational costs.

Growth in Emerging Applications: Expansion of protective coatings into new sectors and specialized applications, such as electric vehicles and advanced infrastructure.

Digitalization and AI in Coating Formulation: Utilizing data from corrosion testing and advanced analytics to predict and design superior coating formulations.

Future Outlook

The future of the protective coatings market appears promising, characterized by continued innovation and increasing adoption across diverse industries. The ongoing global emphasis on infrastructure development, coupled with rising awareness about the importance of asset protection and sustainability, will sustain market growth. The development of advanced, eco-friendly, and multi-functional coatings will be key to meeting evolving industry demands and addressing environmental concerns.

Key Market Study Points

Market Value and CAGR: Understanding the projected market size and growth rate provides insights into the overall industry expansion.

Segmentation Analysis: Detailed analysis of resin types, technologies, and end-use industries highlights dominant segments and growth opportunities.

Regional Dynamics: Identifying the leading and fastest-growing regions helps in strategic market targeting.

Drivers and Challenges: A clear understanding of the factors propelling and hindering market growth is crucial for strategic planning.

Technological Innovations: Tracking advancements in coating materials and application methods is essential for competitive advantage.

Regulatory Landscape: Awareness of environmental regulations and their impact on product development and market trends.

Competitive Landscape: Analyzing key players, their strategies, and recent developments to understand market positioning.

Competitive Landscape

The protective coatings market is highly competitive, with several global and regional players vying for market share. Key players are investing heavily in research and development to introduce innovative and sustainable coating solutions. Strategies include product launches, capacity expansions, mergers and acquisitions, and collaborations to strengthen their market presence and expand their client base.

Key Market Players:

Akzo Nobel N.V.

PPG Industries, Inc.

The Sherwin-Williams Company

RPM International Inc.

Hempel A/S

Jotun A/S

Kansai Paint Co., Ltd.

Nippon Paint Holdings Co. Ltd.

BASF SE

Axalta Coating Systems, LLC

Wacker Chemie AG

3M Co.

The Dow Chemical Company

Arkema

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=40403<ype=S

Recent Developments

The protective coatings industry is characterized by continuous innovation and strategic initiatives:

June 2023: The Sherwin-Williams Company launched Heat-Flex CUI-mitigation coatings to address corrosion under insulation (CUI), a significant challenge in industrial settings.

June 2023: PPG Industries, Inc. introduced PPG ENVIRO-PRIME EPIC 200R coatings, electrocoat materials designed to reduce carbon dioxide emissions in manufacturing plants, emphasizing sustainable solutions.

May 2023: Akzo Nobel N.V. introduced Interpon D powder coatings, offering aluminum surfaces a natural appearance while providing protection.

February 2024: Evonik introduced Ancamine 2844, a new curing agent specifically designed for protective coating applications, highlighting advancements in material science.

Ongoing Research: Collaborations between industry leaders (e.g., AkzoNobel and the University of Manchester) are focusing on a deeper understanding of coating failure mechanisms and the AI-led development of next-generation sustainable protective coatings, including the use of nano-composite materials and computational modeling.

Acquisitions and Investments: Major players continue to acquire smaller manufacturers to expand their product portfolios and market reach, and invest in R&D for self-healing coatings and enhanced performance features.

These developments underscore the industry's commitment to innovation, sustainability, and addressing the evolving needs for enhanced asset protection and longevity across various sectors.

Explore Latest Research Reports by Transparency Market Research:

Hydrocarbon Resin Market - https://www.transparencymarketresearch.com/hydrocarbon-resins-market.html

Impregnation Sealants Market for Electronics - https://www.transparencymarketresearch.com/impregnation-sealants-market-for-electronics.html

Methyl Ester Sulfonate Market - https://www.transparencymarketresearch.com/methyl-ester-sulfonate-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Protective Coatings Market to Reach $22.8 Billion by 2031, Driven by Infrastructure and Industrial Growth here

News-ID: 4029151 • Views: …

More Releases from transparencymarketresearch

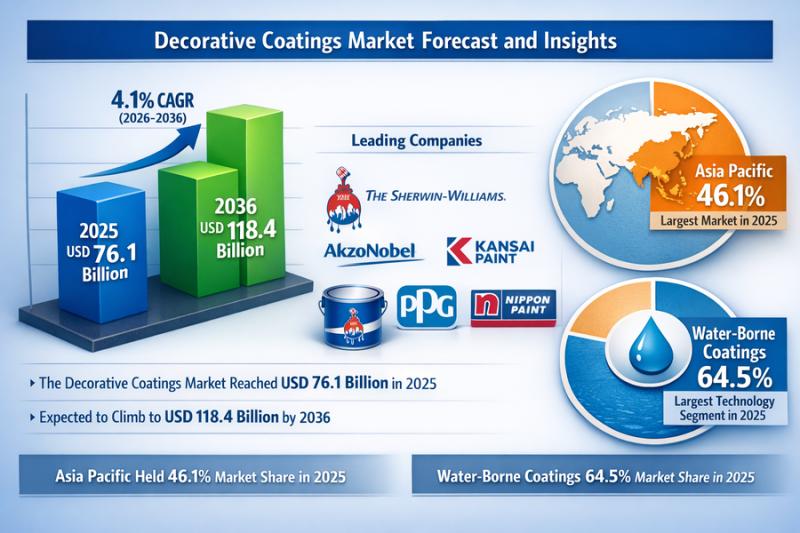

Decorative Coatings Market to Reach USD 118.4 Billion by 2036 at 4.1% CAGR

The decorative coatings market was valued at USD 76.1 billion in 2025 and is projected to reach USD 118.4 billion by 2036. The industry is expected to grow at a steady CAGR of 4.1% during the forecast period from 2026 to 2036, driven by rising construction activities, increasing demand for aesthetic building solutions, and ongoing product innovations.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1450

Market Overview

Decorative coatings are applied…

Europe and Asia Pacific Commercial Fuel Cards Market to Reach USD 1,042.2 Billio …

The Europe and Asia Pacific commercial fuel cards market was valued at USD 534.2 billion in 2025 and is projected to reach USD 1,042.2 billion by 2036, growing at a CAGR of 6.2% from 2026 to 2036. Market growth is driven by rising cross-border transportation demand across Europe and the rapid expansion of fuel retail networks in the Asia Pacific region.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85701

Market…

Air Fryer Market to Reach USD 2,343.9 Mn by 2036 Driven by Health-Focused Cookin …

The global air fryer market was valued at USD 1,103.4 Mn in 2025 and is projected to reach USD 2,343.9 Mn by 2036, expanding at a CAGR of 7.8% from 2026 to 2036. Market growth is primarily driven by rising health consciousness and increasing demand for low-oil cooking appliances among consumers. Busy urban lifestyles, compact kitchen trends, and the growing preference for convenient home-cooking solutions are further supporting adoption. Additionally,…

Global Yeast Market to Reach US$ 16.9 Bn by 2036 Driven by Bakery and Beverage D …

The global yeast market was valued at USD 9.7 Bn in 2025 and is projected to reach USD 16.9 Bn by 2036, expanding at a CAGR of 5.1% from 2026 to 2036. Market growth is primarily driven by increasing demand from the bakery and food processing industries, along with the steady expansion of alcoholic and non-alcoholic beverage production. Rising consumption of convenience foods and fermented products continues to support sustained…

More Releases for Coating

Medical Grade Coating Market: How Nanotechnology Is Advancing Coating Solutions

► Medical Grade Coating Market Poised for Significant Growth, Projected to Reach USD 22.01 Billion by 2032

The global medical grade coating market, valued at USD 13.40 billion in 2024, is anticipated to experience robust growth, reaching approximately USD 22.01 billion by 2032. This represents a compound annual growth rate (CAGR) of 6.4% during the forecast period.

Curious to peek inside? Grab your sample copy of this report now:https://www.maximizemarketresearch.com/request-sample/100541/

► Market…

Powder Coating Market - Advanced Coating Solutions for Industrial Applications | …

Powder Coating Market is expected to grow at a CAGR of 6.0% during the forecast period (2024 - 2031).

Powder Coating Market report, published by DataM Intelligence, provides in-depth insights and analysis on key market trends, growth opportunities, and emerging challenges. Committed to delivering actionable intelligence, DataM Intelligence empowers businesses to make informed decisions and stay ahead of the competition. Through a combination of qualitative and quantitative research methods, it offers…

Coating Equipment Market by Type (Powder coating equipment, Liquid coating equip …

The Coating Equipment Market research report incorporates the scope and objective of the study. Moreover, the report highlights key market segments and players covered. It also covers industry trends, focusing on market use cases and top market size by region, market trends, and global market size. Moreover, the Coating Equipment Market research report covers market growth rate and market share by region. Supply chain analysis, regional marketing analysis, opportunities, challenges,…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…

Powder Coating Market, Powder Coating Market share, global Powder Coating Market …

High application scope in consumer goods, industrial and automotive applications will drive the powder coating market. Stringent government regulation regarding VOC emissions along with product features including emit less, ecofriendly and solvent free will fuel the industry growth.

Expansion in the automotive & transportation industry particularly in the emerging nations will propel the powder coating market growth. Shifting trends towards reduction of heat requirement during the production process are the…