Press release

Injection Molded Plastics Market to Reach $511.7 Billion by 2031

The global injection molded plastics market was valued at US$ 337.8 billion in 2022 and is projected to grow at a CAGR of 4.7% from 2023 to 2031. This steady growth is expected to drive the market to reach US$ 511.7 billion by the end of 2031. The expansion is fueled by increasing demand across industries such as automotive, packaging, electronics, and healthcare, driven by the material's versatility, cost-effectiveness, and suitability for mass production.Injection molding is used to produce various plastic products. The molten material is injected into a mold. The material is allowed to set and take the shape of the mold. Injection molding uses a ram or screw-type plunger to force molten plastic into a mold cavity. The process is rapid compared to other methods and offers a high production output, making it an efficient and cost-effective method of producing various plastic products. Injection molded plastic is widely employed in various end-use industries such as home appliances, electrical & electronics, packaging, automotive, and medical devices.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=634

Market Segmentation

The injection molded plastics market can be segmented based on various factors:

By Raw Material:

Polypropylene (PP): Expected to hold a significant market share and continue its growth due to its versatility, cost-effectiveness, electrical insulating properties, and heat resistance. It is widely used in packaging, automotive components, and household goods.

Acrylonitrile Butadiene Styrene (ABS): Anticipated to be one of the fastest-growing segments, owing to its unique properties such as high impact resistance, rigidity, excellent surface finish, and ease of processing. ABS finds extensive use in automotive, electronics, and consumer appliances.

Polyethylene (PE) (including HDPE and LDPE): Increasingly used due to its versatility, performance, and sustainability, particularly in packaging (e.g., bottles, caps) and automotive applications.

Polystyrene (PS): Used for various applications, including general-purpose, high-impact, and expanded polystyrene (EPS).

Others: This category includes materials like Polyvinyl Chloride (PVC), Polycarbonate (PC), Polyethylene Terephthalate (PET), Nylon (PA), Polyoxymethylene (POM), Polyether, Polyetherimide (PEI), Polybutylene Terephthalate (PBT), and Thermoplastic Elastomers (TPE).

By Application:

Packaging: The largest and fastest-growing application segment, driven by the increasing demand for lightweight, durable, and cost-efficient packaging solutions, especially for food and beverages, pharmaceuticals, and cosmetics. The booming e-commerce sector further fuels this demand.

Automotive & Transportation: A significant consumer of injection molded plastics, with increasing adoption for lightweight components (interior, exterior, and design components) to improve fuel efficiency and overall vehicle performance, especially with the surge in electric vehicle (EV) sales.

Consumer Goods & Electronics: Wide usage in housings for electronic devices, connectors, switches, toys, and various household appliances due to properties like insulation, lightweight, and design flexibility.

Building & Construction: Employed for piping systems, insulation, wall boards, and roofing, benefiting from the strength, durability, and appearance of injection molded plastic parts.

Medical & Healthcare: The fastest-growing application segment, driven by the demand for highly sophisticated and precise medical devices and components such such as syringes, surgical instruments, diagnostic equipment parts, and drug delivery systems, owing to their lightweight, cost-effectiveness, and easy sterilizability.

Others: Includes applications in agriculture, industrial, and other niche sectors.

By Service Type / Sourcing Type: (While not explicitly detailed in the provided data, common service types include custom injection molding, standard parts manufacturing, prototyping, mold design and manufacturing, and assembly services. Sourcing types might differentiate between in-house production and outsourcing to contract manufacturers.)

By Industry Vertical: (Corresponds largely with the "By Application" segmentation, but can be further refined to specific industries like food & beverage, pharmaceuticals, automotive, aerospace, electronics, construction, etc.)

Regional Analysis

The injection molded plastics market exhibits significant regional variations:

Asia Pacific: Dominates the global market and is expected to remain the largest and fastest-growing region during the forecast period. This is attributed to rapid industrialization, urbanization, increasing disposable income, growing consumer expenditure, easy availability of raw materials, and comparatively lower labor costs in countries like China, India, Indonesia, and Malaysia. The booming automotive and packaging sectors are key drivers.

North America: Holds a substantial share, driven by technological advancements in precision molding, increasing adoption of high-performance polymers in automotive and healthcare sectors, and growing investments in sustainable material innovation. The U.S. is a major contributor, particularly due to the growing construction industry and increasing demand for efficient food packaging.

Europe: A significant market with an emphasis on innovation and high-quality injection molding technology. The region sees strong demand from non-food & beverage packaging (pharmaceuticals, cosmetics), and a growing automotive sector with established automakers.

Latin America and Middle East & Africa (LAMEA): Expected to exhibit notable growth, fueled by rising industrialization and infrastructure development.

Market Drivers and Challenges

Market Drivers:

Growing Demand from End-Use Industries: The expanding automotive, packaging, consumer goods, electronics, and healthcare sectors are continuously driving the demand for injection molded plastic components.

Cost-Effectiveness and High-Volume Production: Injection molding offers efficient and economical manufacturing of complex parts at scale, making it highly attractive for mass production.

Lightweighting Trends: The increasing focus on reducing vehicle weight for fuel efficiency and enhancing product portability in various industries (e.g., automotive, aerospace) fuels the demand for lightweight injection molded plastics.

Technological Advancements: Continuous evolution in injection molding machinery, automation (Industry 4.0), precision controls, and robotic integration enhances production efficiency and product quality.

Design Flexibility and Customization: The ability of injection molding to create intricate designs and customize parts with high precision is a significant advantage.

Increasing Urbanization and Disposable Income: Rising urbanization and increasing disposable incomes in emerging economies lead to higher consumption of packaged goods and consumer electronics, boosting market demand.

Market Challenges:

Competition from Alternative Materials: The market faces competition from alternative materials like metal, glass, and composites, especially where specific properties or environmental considerations favor them.

Fluctuating Raw Material Prices: The volatility of crude oil prices directly impacts the cost of plastic resins, posing a challenge for manufacturers.

Environmental Concerns and Regulations: Growing concerns about plastic pollution and increasing stringent environmental regulations regarding plastic waste and disposal can hinder market growth, pushing for more sustainable solutions.

High Capital Investment: Setting up an injection molding facility requires significant upfront capital investment.

Skilled Labor Shortage: The need for skilled operators and technicians to manage complex machinery can be a limiting factor.

Expensive Mold Redesigning: Changes to mold designs can be costly and time-consuming.

Market Trends

Sustainability and Circular Economy: A strong emphasis on developing and adopting biodegradable plastics, bio-based plastics, and advanced recycling technologies to reduce the environmental impact of plastics.

Adoption of High-Performance Polymers: Increasing use of engineered plastics and thermoplastic elastomers (TPEs) with superior properties (e.g., higher strength-to-weight ratio, heat resistance) in demanding applications.

Miniaturization and Micro Injection Molding: Growing demand for smaller and more intricate plastic components, particularly in medical devices and electronics, driving the development of micro injection molding technologies.

Automation and Industry 4.0 Integration: Increasing integration of automation, robotics, IoT, and data analytics in injection molding processes to enhance efficiency, quality control, and production optimization.

Focus on Post-Consumer Recycled (PCR) Content: Growing demand for products incorporating recycled plastics to meet sustainability goals.

Customization and Niche Applications: Expansion into specialized and customized injection molding solutions for specific industry needs.

Future Outlook

The injection molded plastics market is poised for continued growth, driven by innovation and increasing demand across diverse sectors. The industry's future will be shaped by its ability to address environmental concerns through sustainable practices, embrace advanced materials, and leverage automation and digital technologies. The shift towards electric vehicles, miniaturization of medical devices, and the ever-growing packaging industry will continue to be significant drivers.

Key Market Study Points

Material Innovation: Focus on the development and adoption of new, sustainable, and high-performance polymer resins.

Process Optimization: Continuous improvement in injection molding techniques for higher precision, faster cycle times, and reduced waste.

Regional Growth Dynamics: Understanding the unique growth drivers and challenges in key geographical markets.

End-Use Industry Analysis: Detailed examination of demand patterns and specific requirements from various application sectors.

Regulatory Landscape: Monitoring evolving environmental regulations and their impact on material choices and manufacturing processes.

Competitive Strategies: Analyzing the strategies adopted by key market players, including mergers & acquisitions, collaborations, and product innovations.

Competitive Landscape

The injection molded plastics market is characterized by a fragmented competitive landscape with a mix of large global players and numerous regional and local manufacturers. Key players are actively engaged in strategic initiatives such as:

Mergers & Acquisitions: To expand product portfolios, technological capabilities, and market reach.

Collaborations and Partnerships: To foster innovation and enhance market position.

Capacity Expansion: Investing in new production facilities and machinery to meet growing demand.

Product Development: Focusing on developing new materials and solutions, especially those with sustainable properties.

Some of the prominent companies in the injection molded plastics market include:

BASF SE

LyondellBasell Industries Holdings B.V.

SABIC

INEOS

DuPont

ExxonMobil

Dow Inc.

Eastman Chemical Company

Chevron Corporation

Formosa Plastics Corporation

Solvay

CNPC (China National Petroleum Corporation)

LG Chem Ltd.

Lotte Chemical

Proto Labs

PSI Molded Plastics

Reliance Industries Limited

Sibur

Takween Advanced Industries

Versalis S.P.A.

Westlake Corporation

Recent Developments

April 2024: MILACRON, a leading plastic molding company, unveiled its latest injection molding platform integrated with progressive co-injection technology, signaling advancements in machinery for custom solders.

July 2023: Arburg showcased its 150-ton Allrounder 520 H hybrid press at Fakuma, emphasizing sustainability and energy efficiency in injection molding machinery.

October 2022: Evco Plastics proposed an $11 million production capacity expansion in Wisconsin, U.S., highlighting investment in growth.

July 2022: ALPLA invested in a new mold shop in India, demonstrating expansion into emerging markets and local solution provision.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=634

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Injection Molded Plastics Market to Reach $511.7 Billion by 2031 here

News-ID: 4026619 • Views: …

More Releases from transparencymarketresearch

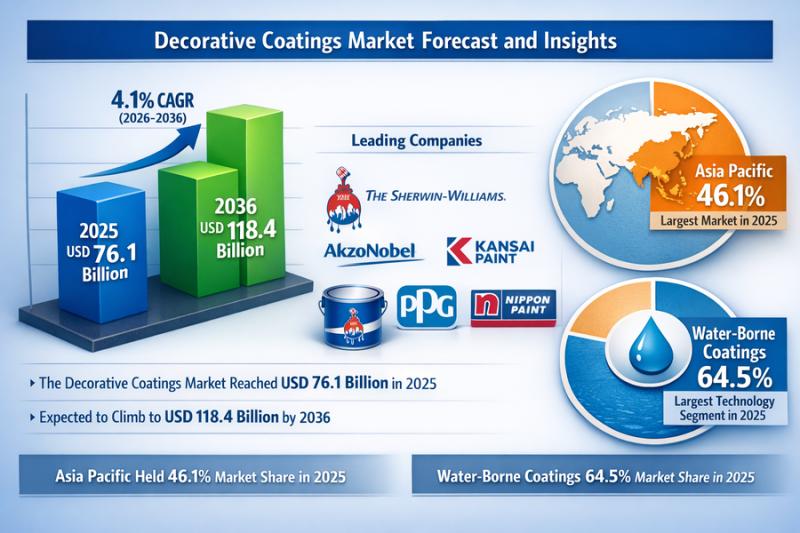

Decorative Coatings Market to Reach USD 118.4 Billion by 2036 at 4.1% CAGR

The decorative coatings market was valued at USD 76.1 billion in 2025 and is projected to reach USD 118.4 billion by 2036. The industry is expected to grow at a steady CAGR of 4.1% during the forecast period from 2026 to 2036, driven by rising construction activities, increasing demand for aesthetic building solutions, and ongoing product innovations.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=1450

Market Overview

Decorative coatings are applied…

Europe and Asia Pacific Commercial Fuel Cards Market to Reach USD 1,042.2 Billio …

The Europe and Asia Pacific commercial fuel cards market was valued at USD 534.2 billion in 2025 and is projected to reach USD 1,042.2 billion by 2036, growing at a CAGR of 6.2% from 2026 to 2036. Market growth is driven by rising cross-border transportation demand across Europe and the rapid expansion of fuel retail networks in the Asia Pacific region.

👉 Get sample market research report copy today@ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85701

Market…

Air Fryer Market to Reach USD 2,343.9 Mn by 2036 Driven by Health-Focused Cookin …

The global air fryer market was valued at USD 1,103.4 Mn in 2025 and is projected to reach USD 2,343.9 Mn by 2036, expanding at a CAGR of 7.8% from 2026 to 2036. Market growth is primarily driven by rising health consciousness and increasing demand for low-oil cooking appliances among consumers. Busy urban lifestyles, compact kitchen trends, and the growing preference for convenient home-cooking solutions are further supporting adoption. Additionally,…

Global Yeast Market to Reach US$ 16.9 Bn by 2036 Driven by Bakery and Beverage D …

The global yeast market was valued at USD 9.7 Bn in 2025 and is projected to reach USD 16.9 Bn by 2036, expanding at a CAGR of 5.1% from 2026 to 2036. Market growth is primarily driven by increasing demand from the bakery and food processing industries, along with the steady expansion of alcoholic and non-alcoholic beverage production. Rising consumption of convenience foods and fermented products continues to support sustained…

More Releases for Injection

Chinese Injection Molding: Ezra Made Emerges as a Global Strategic Partner for I …

Image: https://www.globalnewslines.com/uploads/2025/11/1762824589.jpg

Ezra Made offers integrated engineering and project management for global clients seeking transparent and quality-focused Chinese injection molding services.

Global manufacturers navigating complex supply chains are increasingly turning to China for precision components, yet challenges persist in quality control and project management. Ezra Made, a Chinese injection molding [https://ezramade.com/] facility based in Dongguan, is addressing this gap by positioning itself not just as a supplier, but as an integrated engineering…

China injection mold company and What is injection mold

Nowadays plastic goods' application fully our life,whatever in household or industrial. But do you really know how to make a plastic product? Keep reading, this article will tell you.

What is injection mold

Injection molding usually defined as a thermoplastic polymer is heated above its melting point, resulting in the conversion of the solid polymer to a molten fluid with a reasonably low viscosity. This melt is mechanically forced, that is,…

Diabetes Injection Pens Market - Innovative Tools for Diabetes Control: Injectio …

Newark, New Castle, USA: The "Diabetes Injection Pens Market" provides a value chain analysis of revenue for the anticipated period from 2023 to 2031. The report will include a full and comprehensive analysis of the business operations of all market leaders in this industry, as well as their in-depth market research, historical market development, and information about their market competitors

Diabetes Injection Pens Market: https://www.growthplusreports.com/report/diabetes-injection-pens-market/7639

This latest report researches the industry…

Global Light Vehicle Fuel Injection Market Size, Share and Trends Analysis Repor …

The global light vehicle fuel injection market is anticipated to grow at a CAGR of 3.4% during the forecast period (2022-2028). The major factor is the increasing sales of private vehicles across the globe. After COVID-19, people realize they need their personal vehicles to commute from one place to another. The majority of the sales of cars and bikes are happening in emerging economies, and generally, cars having 1200-1500 cc…

Injection Molding Materials Market Report 2018: Segmentation by Material (Plasti …

Global Injection Molding Materials market research report provides company profile for ExxonMobil, BASF, Dow, Huntsman, Eastman, INEOS, SABIC, Magna International, Newell Rubbermaid, Beckton Dickinson, IAC group and Others.

This market study includes data about consumer perspective, comprehensive analysis, statistics, market share, company performances (Stocks), historical analysis 2012 to 2017, market forecast 2018 to 2025 in terms of volume, revenue, YOY growth rate, and CAGR for the year 2018 to 2025,…

Tags---- Gasoline Direct Injection GDI Market, Market Research Report, Industry …

Market Research Reports Search Engine (MRRSE) has recently updated its massive report catalogue by adding a fresh study titled “Global Gasoline Direct Injection (GDI) Market – Analysis, Trends, Growth opportunity and Forecasted during (2018 – 2023)”. This business intelligence study encapsulates vital details about the market current as well as future status during the mentioned forecast period of 2026.The report also targets important facets such as market drivers, challenges, latest…