Press release

Iron and Steel Casting Market to Reach $218.6 Billion by 2031 Amid Steady 4.3% CAGR Growth

The global iron and steel casting market was valued at US$ 149.4 billion in 2022 and is projected to reach US$ 218.6 billion by 2031, expanding at a CAGR of 4.3% from 2023 to 2031. This growth is driven by increasing demand across industries such as automotive, construction, and heavy machinery, where durable and cost-effective metal components are essential. Rising infrastructure development and technological advancements in casting techniques also contribute to the market's positive outlook.Iron and steel cast products are gaining traction in the automotive & transport sector such as they offer abrasion resistance and high tensile strength. Prominent players in the iron and steel casting industry are focusing on sustainable production to cater to environmentally conscious customers. They are also investing in the R&D of new products to expand their product portfolio.

Dive Deeper into Data: Get Your In-Depth Sample Now! https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=20456

Market Segmentation

The iron and steel casting market can be segmented across various parameters:

By Service Type: While specific "service types" are not always explicitly detailed in market reports, the casting process itself encompasses various methods. These include:

Sand Casting: Dominates the market due to its versatility, simplicity, and cost-effectiveness, suitable for various sizes, shapes, and complexities.

Investment Casting: Known for producing high-precision, intricate components with excellent surface finish.

Die Casting: Ideal for high-volume production of accurate components with smooth surfaces, particularly for lightweight, high-performance parts.

Centrifugal Casting: Used for producing cylindrical components with fine grain structure and high density.

Others: Including plaster casting, lost-foam casting, vacuum casting, etc.

By Sourcing Type: This segmentation often refers to the origin of the raw materials (virgin vs. recycled) or the type of casting being produced (e.g., large, medium, or small casting).

By Product Size:

Large Casting: Pertains to objects weighing over 500 kilograms or exceeding one meter, used in heavy machinery, shipbuilding, and industrial equipment.

Medium Casting: Includes automotive parts, construction components, etc.

Small Casting: Often precision components for various applications.

By Material Type:

Iron Castings:

Gray Iron: Largest share in the iron casting market, known for its good machinability and damping properties.

Ductile Iron: Fastest-growing segment, widely used for lightweight iron castings.

Malleable Iron

White Iron

Steel Castings:

Carbon Steel: Dominates the steel casting market due to affordability and ease of manufacturing.

Low-Alloy Steel: Growing demand for its balanced strength, toughness, and corrosion resistance.

High-Alloy Steel: Offers enhanced properties like wear, corrosion, and heat resistance.

Stainless Steel

By Application: The diverse applications of iron and steel castings highlight their critical role across industries.

Automotive and Transportation: A major consumer, utilizing castings for engine components, transmissions, braking systems, suspension systems, flywheels, cylinder heads, and railway parts. The trend towards lightweight vehicles is increasing demand for aluminum and magnesium castings, but steel and iron remain crucial for structural integrity.

Construction and Infrastructure: Essential for structural components in buildings, bridges, tunnels, roads, and other infrastructure projects (e.g., expansion joints, columns, beams, trusses).

Industrial Machinery: Used in bearing housings, machine tool components, machinery frames and bases, and other industrial equipment.

Power Generation: Critical for turbines, pumps, and generators in both traditional and renewable energy systems.

Oil & Gas: Applied in pipes, fittings, pumps, and valves for exploration, production, and transportation.

Mining: Components for heavy-duty mining equipment requiring high durability and wear resistance.

Aerospace & Defense: For manufacturing turbine engines and aircraft components where high strength and precision are paramount.

Others: Including households, electrical, and shipbuilding.

By Industry Vertical: This broadly aligns with the application segments:

Automotive & Transportation

Building & Construction

Industrial Machinery & Equipment

Energy & Power (including Oil & Gas)

Mining

Aerospace & Defense

By Region:

Asia Pacific: Holds the largest market share (around 52% in 2023 for metal casting market), driven by rapid industrialization, robust automotive production, and significant infrastructure development in countries like China and India.

North America: A significant market, fueled by demand from the automotive and industrial sectors, and ongoing infrastructure modernization.

Europe: Expected to record significant growth due to the presence of key players and strong automotive and industrial bases in countries like Germany and the UK.

Middle East & Africa: Growth supported by investments in oil & gas and infrastructure.

Latin America: Showing consistent growth in demand for cast products.

Regional Analysis

Asia Pacific is expected to maintain its dominance throughout the forecast period, owing to burgeoning automotive and construction sectors, coupled with increasing investments in manufacturing across countries like China, India, Japan, and South Korea. The region's focus on economic growth and infrastructure development will continue to spur demand for iron and steel castings.

North America and Europe represent mature markets with strong demand from their well-established automotive, industrial machinery, and construction industries. These regions are also seeing a push towards adopting green technologies and sustainable casting practices.

Market Drivers and Challenges

Market Drivers:

Growth in End-Use Industries: The flourishing automotive, construction, industrial machinery, and power generation sectors are primary drivers.

Increasing vehicle production, infrastructure development projects, and industrial expansion directly translate to higher demand for cast components.

Technological Advancements in Casting Processes: Innovations such as 3D printing for mold creation, automation, and digitization in manufacturing processes are improving efficiency, precision, and cost-effectiveness.

Rising Demand for Lightweight Materials: While iron and steel are traditional, the push for lighter components in automotive and aerospace is leading to advancements in their alloys and manufacturing to reduce weight without compromising strength.

Increasing Focus on Recycling and Sustainability: Growing environmental concerns are promoting the adoption of recycled iron and steel casting, leading to "green steel" initiatives and energy conservation.

Government Investments in Infrastructure: Substantial government spending on roads, bridges, energy systems, and other infrastructure projects globally creates a sustained demand for cast iron and steel components.

Market Challenges:

Environmental Concerns and Regulations: The casting industry faces scrutiny regarding emissions, energy consumption, and waste generation, leading to stricter environmental regulations.

High Initial Costs: Setting up and operating foundries requires significant capital investment in equipment and infrastructure.

Fluctuating Raw Material Prices: The volatility in prices of raw materials like iron ore, and energy can impact profit margins.

Shortage of Skilled Labor: The industry requires a skilled workforce with expertise in metallurgy, mold making, and casting processes, and a shortage can hinder growth.

Competition from Alternative Materials: Materials like aluminum, composites, and polymers are increasingly being adopted in industries prioritizing weight reduction and cost efficiency, posing a challenge to traditional iron and steel castings in certain applications.

Market Trends

Sustainable Casting Practices: Increasing adoption of eco-friendly practices, including the use of recycled materials, energy-efficient processes, and reduction of emissions.

Product Innovations: Focus on developing advanced casting products with enhanced features, such as improved strength-to-weight ratio and greater durability.

Automation and Digitization: Implementation of automation and advanced digital technologies, including Industry 4.0 concepts, to improve efficiency, quality control, and production flexibility.

Hybrid Production and 3D Printing: Growing use of additive manufacturing (3D printing) for creating complex molds and patterns, complementing traditional casting methods.

Strategic Partnerships and Collaborations: Companies are forming alliances to leverage expertise, expand market reach, and develop new technologies.

Future Outlook

The iron and steel casting market is set for continued growth, driven by ongoing global industrialization and infrastructure development. The emphasis on sustainable manufacturing practices, technological advancements, and the development of high-performance, lightweight cast products will shape the future landscape. While challenges related to environmental concerns and raw material prices persist, the fundamental demand from key industries ensures a stable trajectory for the market. Emerging economies, particularly in Asia Pacific, will play a crucial role in driving this growth.

Key Market Study Points

Market Value and Growth Rate: Understanding the current and projected market size and CAGR from 2023 to 2031.

Dominant Regions: Identifying the leading geographical contributors to market revenue.

Key Application Areas: Recognizing the industries driving the demand for iron and steel castings.

Technological Advancements: Analyzing the impact of new casting processes and innovations.

Sustainability Initiatives: Assessing the role of green manufacturing practices and recycled materials.

Competitive Dynamics: Understanding the strategies and market positions of key players.

Competitive Landscape

The global iron and steel casting market is characterized by the presence of both large multinational corporations and numerous regional players. Key market participants are continually investing in research and development to enhance product quality, develop advanced alloys, and adopt sustainable manufacturing processes. Notable companies in this space include:

ArcelorMittal S.A.

AMSTED Industries Incorporated

Tata Steel Ltd.

Evraz PLC

Hitachi Metals Ltd.

Steel Authority of India Limited (SAIL)

ThyssenKrupp AG

Georg Fischer

Buhler Industries

These companies are focused on strategic initiatives such as product innovation, mergers and acquisitions, and geographical expansion to strengthen their market presence.

Recent Developments

Recent developments in the iron and steel casting market highlight a strong emphasis on sustainability and technological advancement:

Green Steel Initiatives: Numerous major players like ArcelorMittal, Nippon Steel, POSCO, and Tata Steel have announced significant investments and partnerships in "green steel" technologies, focusing on reducing carbon emissions, utilizing hydrogen-based steel production, and enhancing sustainability in their production processes. This includes the introduction of the first-ever Green Iron Castings by Brakes India in collaboration with Volvo Group in June 2022, aimed at reducing CO2 emissions.

Capacity Expansions: Companies like Nucor and JSW Steel are undertaking expansions of their manufacturing facilities to boost production capacity and meet growing demand.

Acquisitions and Partnerships: Strategic acquisitions, such as Endurance Technologies Limited acquiring Grimeca Srl (an automotive manufacturer) and Tata Steel's recycling plant, are aimed at expanding capabilities and reinforcing market positions.

Focus on Advanced Materials: Development of advanced high-strength steel and eco-friendly steel products are becoming key differentiators.

Increased Adoption of 3D Printing: The American Foundry Society's initiative to promote the usage of 3D printing in metal casting processes signifies a move towards more efficient and complex part creation.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=20456

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

This release was published on openPR.

Permanent link to this press release:

Copy

Please set a link in the press area of your homepage to this press release on openPR. openPR disclaims liability for any content contained in this release.

You can edit or delete your press release Iron and Steel Casting Market to Reach $218.6 Billion by 2031 Amid Steady 4.3% CAGR Growth here

News-ID: 4026469 • Views: …

More Releases from transparencymarketresearch

Microgreens Market to Surge at 10.9% CAGR, Set to Reach USD 8.56 Billion by 2036

The global microgreens market was valued at USD 2,780.5 million in 2025 and is projected to reach USD 8,563.5 million by 2036. Driven by rising demand for nutrient-dense foods and growing adoption across foodservice and retail channels, the industry is expected to expand at a robust CAGR of 10.9% from 2026 to 2036.

The global microgreens market represents a specialized, high-value segment within the broader fresh produce and specialty horticulture industry,…

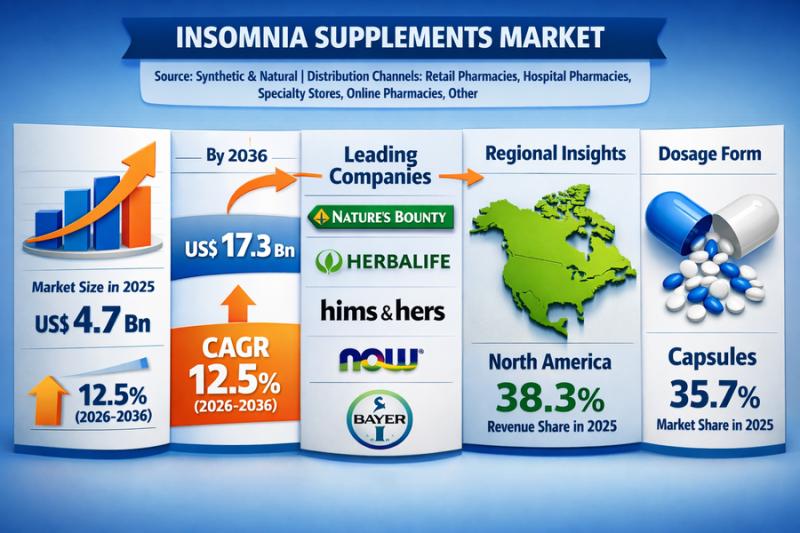

Insomnia Supplements Market Set to Reach US$ 17.3 Bn by 2036, Growing at a Robus …

The global insomnia supplements market was valued at USD 4.7 billion in 2025 and is projected to reach USD 17.3 billion by 2036, reflecting strong growth potential. The market is anticipated to expand at a CAGR of 12.5% from 2026 to 2036, driven by rising sleep disorder prevalence, increasing consumer focus on mental wellness, and growing demand for natural and non-prescription sleep aids.

The insomnia supplements market is expected to witness…

Fiber-Based Blister Pack Market Set to Surge at 21.5% CAGR Through 2036

The global fiber-based blister pack market was valued at US$ 1,633.8 million in 2025 and is projected to surge to US$ 13,591.8 million by 2036. Driven by rising demand for sustainable and eco-friendly packaging solutions, the market is expected to grow at a robust CAGR of 21.5% from 2026 to 2036.

Fiber-based blister packaging is a type of packaging that substitutes the usual plastic blister with paperboard or molded fiber components…

Psychotropic Drugs Market to Reach US$ 41.2 Bn by 2036, Growing at 5.4% CAGR

The global psychotropic drugs market was valued at USD 23.1 Bn in 2025 and is projected to reach USD 41.2 Bn by 2036. Driven by rising awareness of mental health disorders, increasing diagnosis rates, and ongoing pharmaceutical innovations, the industry is expected to grow at a CAGR of 5.4% from 2026 to 2036.

The primary drivers of the expanding psychotropic drugs market include the rising prevalence of mental disorders such as…

More Releases for Steel

Steel Beams Market is Booming Worldwide with Steel Dynamics, JSW Steel, JFE Stee …

HTF MI just released the Global Steel Beams Market Study, a comprehensive analysis of the market that spans more than 143+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

Major Giants in Steel Beams Market are:

ArcelorMittal (Luxembourg), Nippon Steel (Japan),…

Special Ball Bearing Steel Market : Eminent Players - Nippon Steel, Suzhou Steel …

Market Description -

Los Angeles, (United States) - The information made available in the Special Ball Bearing Steel report will definitely facilitate to increase the knowledge and decision-making skills of the business, thus providing an immense opportunity for growth. This will at last increase the return rate and drive the competitive edge within. Being a custom market report, it provides services tailored to the exact challenge. Whether it is survey work,…

Miscellaneous Steel Detailing | Steel Detailer | Steel Detailing Services

We provide the highest quality of finished projects in the industry. Boasting unmatched turnaround times, and superb accuracy. WorldSteel Detailings has onboard team of experienced steel detailers and engineers with a wide range of experience from industrial and commercial projects to high rise buildings. By using innovative technologies and latest softwares, our structural steel detailing team provides accurate services as per your requirements based on country standards.Our steel detailing professionals…

What's driving the Structural Steel Market trends? ArcelorMittal, Tata Steel, Ni …

A detailed study on ‘Structural Steel market’ formulated by Market Study Report, LLC, puts together a concise analysis of the growth factors impacting the current business scenario across assorted regions. Significant information pertaining to the industry’s size, share, application, and statistics are also summed in the report in order to present an ensemble prediction. In addition, this report undertakes an accurate competitive analysis illustrating the status of market majors in…

What's driving the Structural Steel Market trends? ArcelorMittal, Tata Steel, Ni …

A detailed study on ‘Structural Steel market’ formulated by Market Study Report, LLC, puts together a concise analysis of the growth factors impacting the current business scenario across assorted regions. Significant information pertaining to the industry’s size, share, application, and statistics are also summed in the report in order to present an ensemble prediction. In addition, this report undertakes an accurate competitive analysis illustrating the status of market majors in…

What's driving the Structural Steel Market trends? ArcelorMittal, Tata Steel, Ni …

A detailed study on ‘Structural Steel market’ formulated by Market Study Report, LLC, puts together a concise analysis of the growth factors impacting the current business scenario across assorted regions. Significant information pertaining to the industry’s size, share, application, and statistics are also summed in the report in order to present an ensemble prediction. In addition, this report undertakes an accurate competitive analysis illustrating the status of market majors in…